Introduction: Navigating the Global Market for shacman Dump Truck 6×4 8×4

In the fast-evolving landscape of heavy machinery, sourcing the right Shacman Dump Truck 6×4 and 8×4 models presents unique challenges for international B2B buyers. With increasing demands for efficiency, reliability, and cost-effectiveness in construction and mining operations, understanding the nuances of these trucks is crucial. This comprehensive guide delves into the diverse types of Shacman dump trucks, their specific applications, and critical factors to consider when evaluating suppliers.

We will explore the engineering specifications, performance capabilities, and unique features that set Shacman trucks apart in competitive markets across Africa, South America, the Middle East, and Europe, including countries like Vietnam and Brazil. Additionally, this guide will address essential aspects such as supplier vetting processes, pricing strategies, and maintenance considerations, enabling buyers to make informed purchasing decisions.

By leveraging the insights provided in this guide, B2B buyers can confidently navigate the complexities of sourcing Shacman dump trucks, ensuring they select the right vehicles that align with their operational needs and financial goals. Whether you’re looking to enhance your fleet or invest in a reliable solution for demanding projects, this guide is designed to empower your decision-making process in the global market.

Understanding shacman Dump Truck 6×4 8×4 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 6×4 Standard Dump Truck | High loading capacity, low fuel consumption, and Euro II to VI compliance. | Construction, logistics, and mining. | Pros: Cost-effective, versatile. Cons: Limited off-road capabilities compared to 8×4. |

| 8×4 Heavy-Duty Dump Truck | Reinforced chassis, larger cargo box, and advanced hydraulic lifting. | Heavy construction, mining, and infrastructure projects. | Pros: Superior load capacity, robust performance. Cons: Higher initial investment. |

| 6×4 Off-Road Dump Truck | Enhanced suspension and traction features for rugged terrains. | Mining and off-road construction projects. | Pros: Excellent off-road capability. Cons: May have lower fuel efficiency. |

| 8×4 Tipper Dump Truck | Designed for quick unloading, equipped with a large cargo capacity. | Bulk material transport and waste management. | Pros: Efficient unloading, high volume. Cons: Requires more maintenance. |

| 6×4 Container Truck | Adaptable for transporting containers, featuring a flatbed design. | Intermodal transport and logistics. | Pros: Flexible use, ideal for various cargo types. Cons: Less specialized for heavy loads. |

What Are the Characteristics of the 6×4 Standard Dump Truck?

The 6×4 Standard Dump Truck is characterized by its balanced design, offering a strong load capacity while maintaining fuel efficiency. It complies with Euro II to VI emissions standards, making it suitable for diverse international markets. This type of truck is ideal for construction and logistics, where versatility is key. Buyers should consider its cost-effectiveness and suitability for urban applications, although it may not perform as well in off-road conditions compared to its 8×4 counterpart.

How Does the 8×4 Heavy-Duty Dump Truck Stand Out?

The 8×4 Heavy-Duty Dump Truck is specifically designed for demanding applications, featuring a reinforced chassis and a larger cargo box. It excels in heavy construction and mining operations, where durability and high load capacity are crucial. The truck’s advanced hydraulic lifting system allows for quick unloading, enhancing operational efficiency. While the upfront investment is higher, its robust performance and lower operational costs can yield significant long-term savings for businesses.

Why Choose the 6×4 Off-Road Dump Truck?

The 6×4 Off-Road Dump Truck is engineered for rugged terrains, equipped with enhanced suspension and traction features. This makes it a reliable choice for mining and off-road construction projects where traditional trucks may struggle. Its ability to navigate challenging landscapes provides a competitive edge in specialized applications. However, buyers should be aware of its potentially lower fuel efficiency, which could impact operational costs.

What Advantages Does the 8×4 Tipper Dump Truck Offer?

The 8×4 Tipper Dump Truck is designed for efficient unloading, making it an ideal choice for bulk material transport and waste management. Its large cargo capacity allows for the transportation of significant volumes, while the hydraulic tipping mechanism simplifies unloading processes. Although it may require more maintenance due to its advanced features, the efficiency gains in high-volume operations can justify the investment for many businesses.

How Does the 6×4 Container Truck Fit into B2B Logistics?

The 6×4 Container Truck is versatile, designed to transport standard shipping containers with ease. Its flatbed design allows for a range of cargo types, making it suitable for intermodal transport and logistics. This adaptability is a significant advantage for businesses looking to optimize their supply chains. However, while it offers flexibility, it may not be as specialized for heavy loads as other dump truck variants, which is an important consideration for buyers focused on specific applications.

Key Industrial Applications of shacman Dump Truck 6×4 8×4

| Industry/Sector | Specific Application of shacman Dump Truck 6×4 8×4 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Transporting aggregates, soil, and construction materials | Enhances efficiency and reduces operational delays | Reliability, payload capacity, and compatibility with local regulations |

| Mining | Hauling ore and waste materials from extraction sites | Increases productivity and minimizes downtime | Durability under extreme conditions and availability of spare parts |

| Infrastructure Development | Moving materials for road and bridge construction | Streamlines logistics, improving project timelines | Fuel efficiency, engine power, and after-sales service support |

| Agriculture | Transporting fertilizers and bulk agricultural products | Supports timely deliveries, boosting crop yields | Versatility in loading and unloading mechanisms |

| Waste Management | Collecting and transporting construction debris and landfill waste | Promotes efficient waste disposal and recycling efforts | Compliance with environmental standards and payload management |

How is the shacman Dump Truck 6×4 8×4 Used in Construction?

In the construction industry, the shacman Dump Truck 6×4 8×4 is vital for transporting aggregates, soil, and other essential materials to and from job sites. Its high payload capacity and robust design allow it to handle heavy loads, reducing the number of trips required and thereby enhancing overall project efficiency. Buyers in this sector should prioritize trucks with reliability and compliance with local regulations to ensure smooth operations.

What Role Does the shacman Dump Truck 6×4 8×4 Play in Mining?

Mining operations frequently utilize the shacman Dump Truck 6×4 8×4 for hauling ore and waste materials. The truck’s powerful engine and durable construction enable it to navigate rough terrains, increasing productivity while minimizing downtime. For international buyers, especially in regions like Africa and South America, it’s crucial to consider the truck’s performance under extreme conditions and the availability of spare parts for maintenance.

How Does the shacman Dump Truck 6×4 8×4 Support Infrastructure Development?

In infrastructure development, the shacman Dump Truck 6×4 8×4 is essential for moving materials required for road and bridge construction. Its efficient logistics capabilities help streamline project timelines and reduce costs. Buyers should focus on features such as fuel efficiency and engine power, as well as the availability of after-sales service support, to ensure reliable operations in large-scale projects.

In What Ways is the shacman Dump Truck 6×4 8×4 Beneficial for Agriculture?

The agricultural sector benefits from the shacman Dump Truck 6×4 8×4 for transporting fertilizers and bulk agricultural products. Its versatility in loading and unloading mechanisms supports timely deliveries, which is crucial for maximizing crop yields. Buyers must assess the truck’s adaptability to different terrains and loading requirements, ensuring it meets specific agricultural needs.

How is the shacman Dump Truck 6×4 8×4 Used in Waste Management?

In waste management, the shacman Dump Truck 6×4 8×4 is employed to collect and transport construction debris and landfill waste. Its design promotes efficient waste disposal and recycling efforts, contributing to environmental sustainability. Buyers should consider the truck’s compliance with environmental standards and its ability to manage payloads effectively to ensure operational success in waste management operations.

3 Common User Pain Points for ‘shacman Dump Truck 6×4 8×4’ & Their Solutions

Scenario 1: Navigating High Fuel Costs in Dump Truck Operations

The Problem: In regions with fluctuating fuel prices, such as parts of Africa and South America, B2B buyers of Shacman Dump Trucks face the challenge of managing operating costs effectively. High fuel consumption can significantly impact profit margins, particularly for businesses engaged in construction or mining where these trucks are essential for transporting heavy loads. Buyers often find that while the initial purchase price of the truck may be competitive, ongoing fuel expenses can erode profitability, leading to frustration and financial strain.

The Solution: To mitigate high fuel costs, buyers should consider the fuel efficiency features of the Shacman Dump Truck 6×4 and 8×4 models. These trucks are equipped with advanced engine technology, such as the Weichai WP12 engine, which offers optimal power while maintaining fuel efficiency. Buyers can further enhance fuel savings by implementing a regular maintenance schedule that includes timely oil changes, air filter replacements, and tire pressure checks. Additionally, utilizing telematics systems can provide real-time data on fuel consumption, allowing businesses to adjust driving behaviors for more efficient operation. Educating drivers on eco-driving techniques can also lead to significant savings, ensuring that the trucks operate within their most efficient performance range.

Scenario 2: Ensuring Reliability in Harsh Operating Conditions

The Problem: Many international buyers, especially those in the Middle East and Southeast Asia, often operate in challenging environments such as extreme heat, rough terrain, and heavy loads. Under these conditions, the reliability of equipment is paramount. B2B buyers may experience downtime due to mechanical failures, which not only disrupts operations but can also lead to substantial financial losses and damage to client relationships.

The Solution: To enhance reliability, B2B buyers should prioritize the selection of Shacman Dump Trucks that feature heavy-duty components designed for harsh conditions. The F3000 series, for example, includes a reinforced chassis and a robust suspension system that can withstand heavy usage. Buyers should also consider investing in additional training for operators to ensure they understand the specific needs of the vehicle in extreme conditions. Establishing a preventative maintenance program that includes regular inspections and prompt repairs can further minimize the risk of breakdowns. Partnering with local service providers or establishing a relationship with Shacman’s after-sales support can ensure quick access to parts and service, thereby reducing downtime and maintaining operational continuity.

Scenario 3: Managing Compliance with Emission Standards

The Problem: As environmental regulations become more stringent globally, B2B buyers in Europe and other regions may struggle with ensuring their fleet meets the latest emission standards. Non-compliance can result in hefty fines and damage to a company’s reputation. Buyers of Shacman Dump Trucks must navigate the complexities of these regulations, which can vary significantly by region and impact their ability to operate effectively.

The Solution: To address compliance challenges, buyers should opt for the Shacman Dump Truck models equipped with engines that adhere to Euro II to Euro VI emission standards. This not only helps in meeting regulatory requirements but also enhances the company’s sustainability profile. Buyers should stay informed about the local environmental regulations and consider working with consultants who specialize in compliance to ensure they are meeting all necessary guidelines. Additionally, implementing a comprehensive fleet management system can assist in tracking emissions and ensuring that all vehicles within the fleet are compliant. Engaging with Shacman’s customer support for updates on emissions technology can also help buyers remain ahead of regulatory changes, ensuring ongoing compliance and reducing the risk of penalties.

Strategic Material Selection Guide for shacman Dump Truck 6×4 8×4

When selecting materials for the Shacman Dump Truck 6×4 and 8×4 models, it is essential to consider the properties, advantages, and limitations of each material in relation to performance, durability, and cost-effectiveness. The following analysis focuses on four common materials used in the construction of these trucks: high-strength steel, aluminum, rubber, and composite materials.

What Are the Key Properties of High-Strength Steel in Dump Trucks?

High-strength steel is widely used in the chassis and cargo box of Shacman dump trucks due to its excellent strength-to-weight ratio and durability. This material can withstand high stress and impact, making it suitable for heavy-duty applications in construction and mining. It typically has a temperature rating up to 500°C and good corrosion resistance when treated.

Pros: High-strength steel offers exceptional durability and load-bearing capacity, which is crucial for transporting heavy materials. It is also relatively cost-effective compared to other materials.

Cons: The manufacturing complexity can be higher due to the need for advanced welding techniques. Additionally, untreated high-strength steel may be prone to corrosion in harsh environments, necessitating protective coatings.

Impact on Application: High-strength steel is compatible with various media, including aggregates and construction materials, ensuring longevity and reliability in demanding conditions.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential for ensuring quality. Buyers in regions like Africa and South America should consider the availability of local suppliers for maintenance and repair.

How Does Aluminum Compare as a Material for Dump Trucks?

Aluminum is increasingly being used in dump truck applications, especially for components like the cargo box and body panels. It is lightweight, with a density approximately one-third that of steel, which can enhance fuel efficiency.

Pros: The primary advantage of aluminum is its resistance to corrosion, which is particularly beneficial in humid or coastal environments. Its lightweight nature contributes to better fuel economy and payload capacity.

Cons: Aluminum can be more expensive than high-strength steel, and its lower tensile strength may limit its use in heavy-load applications without reinforcement.

Impact on Application: Aluminum is suitable for transporting lighter materials and can significantly reduce the overall weight of the truck, improving efficiency.

Considerations for International Buyers: Buyers should ensure that aluminum components meet local and international standards, such as JIS and ASTM. The higher initial cost may be offset by long-term savings in fuel and maintenance.

What Role Does Rubber Play in Shacman Dump Trucks?

Rubber is primarily used in tires and suspension systems of dump trucks. Its elasticity and shock-absorbing properties are crucial for providing a smooth ride and maintaining traction on various terrains.

Pros: Rubber tires offer excellent grip, durability, and resistance to wear, which is essential for off-road conditions. The shock-absorbing qualities enhance driver comfort and vehicle stability.

Cons: Rubber can degrade over time due to exposure to UV light and extreme temperatures, necessitating regular replacements. Additionally, high-quality rubber tires can be costly.

Impact on Application: The choice of rubber affects the truck’s performance in different environments, making it vital for operations in rugged terrains common in construction and mining.

Considerations for International Buyers: Buyers should focus on sourcing tires that comply with local regulations and standards for safety and performance. Availability of replacement tires in local markets is also important for minimizing downtime.

How Do Composite Materials Enhance Dump Truck Performance?

Composite materials, such as fiberglass-reinforced plastics, are becoming popular in various truck components due to their lightweight and high strength.

Pros: Composites are resistant to corrosion and can be molded into complex shapes, allowing for innovative designs. They also contribute to weight reduction, improving fuel efficiency.

Cons: The manufacturing process for composites can be complex and expensive, which may not be justifiable for all applications. Additionally, the repair of composite materials can be more challenging than traditional materials.

Impact on Application: Composites are suitable for non-structural components where weight savings are critical, such as body panels and interior fittings.

Considerations for International Buyers: Compliance with international standards is essential, and buyers should consider the availability of skilled labor for repairs and maintenance in their regions.

Summary Table of Material Selection for Shacman Dump Truck 6×4 8×4

| Material | Typical Use Case for shacman Dump Truck 6×4 8×4 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High-Strength Steel | Chassis, cargo box | Exceptional durability and load-bearing capacity | Prone to corrosion without treatment | Medium |

| Aluminum | Cargo box, body panels | Lightweight, corrosion-resistant | Higher cost, lower tensile strength | High |

| Rubber | Tires, suspension systems | Excellent grip and shock absorption | Degrades over time, can be expensive | Medium |

| Composite Materials | Body panels, interior fittings | Lightweight, corrosion-resistant | Complex manufacturing, challenging repairs | High |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions when sourcing Shacman Dump Trucks 6×4 and 8×4. Understanding the material properties and their implications on performance will help in selecting the right configurations for specific applications in diverse environments.

In-depth Look: Manufacturing Processes and Quality Assurance for shacman Dump Truck 6×4 8×4

What Are the Key Stages in the Manufacturing Process of Shacman Dump Trucks 6×4 and 8×4?

The manufacturing process of Shacman Dump Trucks, specifically the 6×4 and 8×4 models, is a meticulous endeavor that encompasses several critical stages: material preparation, forming, assembly, and finishing.

-

Material Preparation

The first stage involves sourcing high-quality raw materials, including high-strength steel for the chassis and body, and components such as engines and axles. Shacman employs advanced procurement strategies to ensure that materials meet international quality standards. Rigorous testing is conducted on incoming materials to verify compliance with specifications, setting the foundation for durable construction. -

Forming

The forming stage utilizes modern techniques like stamping, bending, and welding. Advanced CNC (Computer Numerical Control) machines are employed to achieve precision in cutting and shaping components. The chassis is formed using high-strength steel, which is crucial for the truck’s durability and load-bearing capabilities. Additionally, robotic welding technology is integrated to enhance consistency and reduce human error, ensuring that each truck adheres to the same quality benchmarks. -

Assembly

During the assembly phase, components are brought together in a systematic manner. This includes installing the engine, transmission, axles, and suspension systems. Shacman utilizes an assembly line process that emphasizes efficiency without compromising quality. Each unit undergoes initial checks to ensure that parts fit correctly and function as intended. Workers are trained extensively in assembly procedures to maintain high standards throughout the production line. -

Finishing

The final stage involves finishing touches, which include painting, quality checks, and installation of additional features such as the cabin and hydraulic systems. The painting process is carried out in a controlled environment to ensure optimal adhesion and durability of the finish. After painting, trucks are subjected to a series of inspections to confirm that they meet both aesthetic and functional standards.

How Is Quality Assurance Implemented During Manufacturing?

Quality assurance (QA) is a cornerstone of Shacman’s manufacturing philosophy, ensuring that each dump truck meets international standards and customer expectations.

-

What International Standards Are Followed?

Shacman adheres to several international standards, including ISO 9001 for quality management systems and CE certification for compliance with European safety and health requirements. These certifications demonstrate Shacman’s commitment to quality and customer satisfaction, which is crucial for B2B buyers who prioritize reliability in their procurement decisions. -

What Are the Key Quality Control Checkpoints?

Quality control is integrated at various stages of production:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specifications before being used in manufacturing.

- In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing process. This includes checking welds, assembly accuracy, and component functionality.

- Final Quality Control (FQC): Completed trucks undergo rigorous testing, including performance evaluations and safety checks, before they are released for shipment.

- What Testing Methods Are Commonly Used?

Shacman employs a range of testing methods to ensure the reliability and performance of its dump trucks. Common tests include:

- Dynamic Testing: Evaluating the truck’s performance under various load conditions.

- Durability Testing: Simulating real-world conditions to assess the truck’s longevity and resilience.

- Safety Testing: Ensuring that all safety features, such as braking systems and lights, function correctly.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential. Here are actionable steps to ensure that Shacman meets your quality expectations:

-

Conducting Supplier Audits

Buyers should perform regular audits of Shacman’s manufacturing facilities. These audits help to assess compliance with quality standards and provide insights into the production processes. During audits, buyers can evaluate the effectiveness of quality control checkpoints and the overall manufacturing environment. -

Requesting Quality Control Reports

B2B buyers can request documentation regarding quality control processes, including IQC, IPQC, and FQC reports. These documents offer transparency and assurance that Shacman maintains rigorous quality standards throughout production. -

Engaging Third-Party Inspection Services

Utilizing third-party inspection services can provide an unbiased assessment of the manufacturing processes and final products. Independent inspectors can evaluate the quality of raw materials, manufacturing practices, and finished trucks, offering additional peace of mind.

What Are the Quality Certification Nuances for International Buyers?

International buyers must be aware of specific certification nuances when procuring dump trucks from Shacman. For example, compliance with local regulations in their respective countries is critical. Different regions may have varying emission standards and safety requirements that need to be adhered to.

-

Understanding Regional Compliance: Buyers should familiarize themselves with the required certifications for their region, such as Euro VI emissions standards for European countries or specific safety certifications required in South America and Africa.

-

Customization and Adaptability: Shacman is known for its ability to customize vehicles according to the buyer’s specifications, which may include adjustments to meet local regulations. Clear communication regarding these requirements at the outset of the procurement process is essential.

By understanding the manufacturing processes, quality assurance measures, and certification nuances, B2B buyers can make informed decisions when considering Shacman Dump Trucks 6×4 and 8×4 for their operations. This knowledge not only enhances procurement strategies but also contributes to building long-term partnerships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘shacman Dump Truck 6×4 8×4’

The following is a practical sourcing checklist designed to assist B2B buyers in procuring Shacman Dump Trucks (6×4 and 8×4 models). This guide will streamline your purchasing process, ensuring you cover all necessary aspects for a successful acquisition.

Step 1: Define Your Technical Specifications

Start by establishing clear technical specifications for the Shacman Dump Truck you require. Consider factors such as load capacity, engine power, axle configuration, and any specific requirements based on your operational needs. Knowing these details upfront helps in narrowing down options and ensures that the chosen model aligns with your operational requirements.

- Engine Type: Look for options like the Weichai WP12 series, known for its fuel efficiency and power.

- Payload Requirements: Determine the maximum load you intend to transport to select the appropriate model.

Step 2: Identify Potential Suppliers

Research potential suppliers who specialize in Shacman Dump Trucks. A thorough market analysis can reveal reputable manufacturers and distributors with a track record of reliability and customer satisfaction.

- Online Directories: Utilize platforms such as Alibaba or industry-specific directories to find verified suppliers.

- Trade Shows: Attend construction and transportation expos to meet suppliers and see their offerings firsthand.

Step 3: Verify Supplier Certifications

Before proceeding, ensure that the supplier holds necessary certifications such as ISO 9001 and any regional compliance certificates. Certifications indicate a commitment to quality and adherence to international standards.

- Quality Control: Check if the supplier has a robust quality management system in place.

- Warranty Information: Inquire about warranty terms to understand the support you can expect post-purchase.

Step 4: Request Detailed Quotations

Request comprehensive quotations from shortlisted suppliers. A detailed quote will not only include pricing but also shipping costs, delivery timelines, and payment terms, allowing for better budget planning.

- Compare Offers: Look for value beyond just the price, such as additional services or better payment terms.

- Clarification: Don’t hesitate to ask for clarifications on any ambiguous terms in the quotation.

Step 5: Evaluate After-Sales Support

Assess the after-sales support offered by the supplier, as this can significantly impact your operations. Reliable after-sales service ensures quick resolution of any issues that may arise post-purchase.

- Spare Parts Availability: Confirm that spare parts are readily available to minimize downtime.

- Maintenance Services: Inquire whether the supplier offers maintenance services or training for your team.

Step 6: Conduct Reference Checks

Before finalizing your purchase, conduct reference checks with existing customers of the supplier. This step provides insights into the supplier’s reliability, product performance, and customer service.

- Industry Relevance: Focus on references from companies in similar industries or regions to gauge relevant experiences.

- Feedback: Ask about the supplier’s responsiveness and how they handle issues.

Step 7: Finalize the Purchase Agreement

Once you are satisfied with your supplier, finalize the purchase agreement. Ensure that all terms, including delivery timelines, payment terms, and warranty conditions, are clearly outlined in the contract.

- Legal Review: Consider having a legal professional review the agreement to protect your interests.

- Clear Communication: Maintain open lines of communication with the supplier throughout the purchase process to address any last-minute concerns.

By following this checklist, you can navigate the procurement process with confidence, ensuring that you select the right Shacman Dump Truck to meet your business needs.

Comprehensive Cost and Pricing Analysis for shacman Dump Truck 6×4 8×4 Sourcing

What Are the Key Cost Components in Sourcing SHACMAN Dump Trucks 6×4 and 8×4?

When analyzing the cost structure for SHACMAN Dump Trucks, several critical components come into play:

-

Materials: The primary materials include high-strength steel for the chassis, components for the engine and transmission systems, and the hydraulic systems used for dumping. Quality of materials directly influences both durability and performance, which can affect pricing.

-

Labor: Labor costs encompass the wages for skilled workers involved in the assembly, welding, and quality control processes. Given the technical nature of truck manufacturing, a skilled workforce is essential for maintaining high production standards.

-

Manufacturing Overhead: This includes utilities, depreciation of manufacturing equipment, and factory maintenance costs. Efficient operations can help reduce overhead, impacting overall pricing.

-

Tooling: Investment in specialized tools and machinery to manufacture various components is significant. Customization or unique design specifications may necessitate additional tooling costs.

-

Quality Control (QC): Implementing rigorous QC processes ensures compliance with international standards such as Euro II to VI emissions. This is critical for international buyers, particularly in regions with strict regulatory environments.

-

Logistics: Transportation costs to deliver trucks to international markets vary based on distance, mode of transport, and local tariffs. Efficient logistics planning can mitigate these costs.

-

Margin: Manufacturers typically include a profit margin in the final pricing, which can vary based on market demand, competition, and the strategic positioning of the brand.

How Do Price Influencers Affect the Cost of SHACMAN Dump Trucks?

Several factors can influence the pricing of SHACMAN Dump Trucks, particularly for international buyers:

-

Volume/MOQ: Bulk purchases often lead to better pricing. Suppliers may offer discounts for larger orders, making it advantageous for companies looking to fleet purchase.

-

Specifications and Customization: Custom features, such as enhanced engine specifications or tailored body configurations, can increase costs. Buyers should clearly define their needs to avoid unexpected expenses.

-

Materials and Quality Certifications: Higher quality materials and certifications (e.g., ISO 9001) may lead to increased upfront costs but can provide long-term savings through reduced maintenance and increased reliability.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established brands like SHACMAN may command a premium, but they often provide better after-sales support and warranty options.

-

Incoterms: Understanding shipping terms is crucial. Options like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly impact the total landed cost of the trucks.

What Buyer Tips Should Be Considered for Cost Efficiency?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

-

Negotiate Effectively: Engage in discussions about pricing, especially if purchasing in bulk. Suppliers may offer flexible terms based on the buyer’s commitment.

-

Consider Total Cost of Ownership (TCO): Look beyond the purchase price. Assess fuel consumption, maintenance costs, and potential downtime. A slightly higher initial investment can lead to significant savings over the truck’s lifespan.

-

Understand Pricing Nuances: Be aware of regional pricing variations due to local demand, competition, and economic factors. This understanding can aid in negotiating better terms.

-

Explore Financing Options: Some suppliers offer financing or leasing options that can alleviate upfront costs while providing immediate access to the vehicles.

-

Research and Compare Suppliers: Take the time to compare various suppliers, focusing on their reliability, service offerings, and past customer feedback. This due diligence can lead to better pricing and service agreements.

Disclaimer

The prices mentioned herein are indicative and subject to fluctuations based on market conditions, exchange rates, and supplier negotiations. Always consult with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing shacman Dump Truck 6×4 8×4 With Other Solutions

When considering heavy-duty transportation solutions, it’s essential for B2B buyers to evaluate not only the products available but also the alternatives that can meet their operational needs. The Shacman Dump Truck 6×4 and 8×4 series offers robust capabilities, but other options exist in the marketplace. This analysis will provide a comparison of the Shacman Dump Trucks against two viable alternatives: the Volvo FMX 8×4 and the MAN TGS 6×4.

Comparison Table

| Comparison Aspect | Shacman Dump Truck 6X4 8X4 | Volvo FMX 8×4 | MAN TGS 6×4 |

|---|---|---|---|

| Performance | 430 HP engine, Euro II/III emission standards | 500 HP engine, excellent off-road capabilities | 480 HP engine, strong torque for heavy loads |

| Cost | Competitive pricing, cost-effective maintenance | Higher initial cost, but strong resale value | Mid-range pricing, moderate maintenance costs |

| Ease of Implementation | Simple setup, widely available parts | More complex due to advanced tech | Generally straightforward, but tech-dependent |

| Maintenance | Low maintenance requirements, robust design | Higher maintenance due to advanced features | Balanced maintenance needs, good parts availability |

| Best Use Case | Ideal for construction and mining operations | Best for rugged off-road conditions | Versatile for construction and logistics |

Detailed Breakdown of Alternatives

What are the Key Benefits and Drawbacks of the Volvo FMX 8×4?

The Volvo FMX 8×4 is engineered for demanding off-road environments, making it an excellent choice for construction and mining operations. It boasts a powerful 500 HP engine that ensures high performance under heavy loads. While its advanced features contribute to safety and efficiency, they also lead to a higher initial investment and potentially increased maintenance costs. This truck excels in challenging terrains but may be more costly in terms of both acquisition and upkeep, which could be a limiting factor for budget-conscious buyers.

How Does the MAN TGS 6×4 Compare in Terms of Versatility?

The MAN TGS 6×4 is known for its versatility, making it suitable for a range of applications from construction to logistics. With a 480 HP engine, it offers impressive torque and load-carrying capabilities. Its pricing is positioned in the mid-range, providing a balance between performance and cost. The MAN TGS is relatively easy to maintain, with good parts availability, but its reliance on technology can complicate repairs. Buyers seeking a truck that can adapt to various tasks without breaking the bank may find this option appealing.

How Should B2B Buyers Choose the Right Solution?

In conclusion, when selecting between the Shacman Dump Truck 6×4 and 8×4 and its alternatives, buyers should carefully consider their specific operational requirements, budget constraints, and the environments in which they will be operating. Each option presents distinct advantages and potential drawbacks. For those focused on cost-effectiveness and reliability, the Shacman Dump Trucks offer significant value. However, if advanced features and off-road performance are paramount, the Volvo FMX may be the better choice. Conversely, for buyers needing versatility without excessive costs, the MAN TGS stands out as a solid option. Ultimately, understanding the unique demands of your projects will guide you in making the best purchasing decision.

Essential Technical Properties and Trade Terminology for shacman Dump Truck 6×4 8×4

What Are the Key Technical Properties of Shacman Dump Trucks 6×4 and 8×4?

When considering the procurement of Shacman Dump Trucks, understanding their technical specifications is crucial for making informed purchasing decisions. Here are some critical properties that B2B buyers should prioritize:

-

Engine Specifications

The Shacman 6×4 and 8×4 Dump Trucks typically feature powerful Weichai engines, such as the WP12.430E50, with outputs around 430 HP. This high power enables efficient hauling capabilities essential for heavy-duty operations in construction and mining. Buyers should assess engine performance in relation to their operational requirements, including load capacity and terrain challenges. -

Chassis Construction

The chassis of Shacman Dump Trucks is often made from high-strength steel, providing durability and resistance to wear and tear. A robust chassis is vital for maintaining structural integrity under heavy loads, which is particularly important in rugged environments. Understanding the material grade and design can help buyers ensure that the trucks meet their operational demands without excessive maintenance. -

Load Capacity and Dimensions

The payload capacity for these trucks can vary, with the 8×4 model accommodating up to 20 tons. Additionally, the cargo box dimensions, typically around 7500 x 2300 x 1500 mm, are designed to optimize load volume. Knowing these specifications is essential for buyers to match the trucks with their specific transportation needs, ensuring they can efficiently handle expected loads. -

Transmission Type

Shacman Dump Trucks often utilize a 12-speed FAST transmission system, which allows for smooth gear shifting and adaptability to different driving conditions. This feature enhances fuel efficiency and overall performance, making it a critical specification to consider for buyers who operate in varied terrains. -

Suspension System

The suspension system, which commonly consists of multi-layered leaf springs, plays a significant role in driving comfort and load stability. A well-engineered suspension system helps minimize wear on both the truck and its cargo, reducing maintenance costs over time. Buyers should evaluate the suspension design to ensure it aligns with their operational conditions. -

Braking System

Advanced braking systems, including drum brakes and auxiliary engine exhaust brakes, enhance vehicle safety and performance. Understanding the braking capabilities is crucial for ensuring compliance with safety standards and operational efficiency, particularly in challenging environments.

What Are Common Trade Terminology and Concepts in the B2B Truck Industry?

Navigating the procurement process requires familiarity with industry jargon. Here are some essential terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. Buyers should consider whether they are sourcing trucks directly from an OEM or through a distributor, as this can affect pricing and warranty options. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to ensure they meet supplier requirements without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for specified goods. This process allows buyers to compare offers and negotiate better deals, making it a vital step in procurement. -

Incoterms (International Commercial Terms)

These are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping arrangements. Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities associated with their purchases. -

Lead Time

Lead time refers to the period from placing an order to receiving the goods. Understanding lead times is crucial for planning operations and ensuring that projects remain on schedule. -

After-Sales Service

This term encompasses the support provided after a purchase, including maintenance, repairs, and spare parts availability. A strong after-sales service network can significantly influence a buyer’s decision, as it impacts the long-term reliability of the equipment.

By grasping these essential technical properties and trade terminology, B2B buyers can make well-informed decisions when sourcing Shacman Dump Trucks, ultimately enhancing operational efficiency and cost-effectiveness in their projects.

Navigating Market Dynamics and Sourcing Trends in the shacman Dump Truck 6×4 8×4 Sector

What Are the Current Market Dynamics and Key Trends Affecting the Shacman Dump Truck 6×4 and 8×4 Sector?

The global demand for heavy-duty vehicles, particularly dump trucks, is driven by rapid urbanization, infrastructure development, and mining activities across emerging markets in Africa, South America, and the Middle East. These regions are experiencing significant growth in construction projects, necessitating reliable transport solutions. For international B2B buyers, understanding these dynamics is crucial. The Shacman 6×4 and 8×4 dump trucks stand out due to their high load capacities, fuel efficiency, and adherence to stringent emission standards, making them ideal for projects that require heavy lifting and sustainability.

Emerging technologies are also shaping the sourcing landscape. The integration of telematics in dump trucks allows for real-time tracking and performance analysis, enhancing operational efficiency. Additionally, buyers are increasingly looking for suppliers that offer comprehensive after-sales support and spare parts accessibility, ensuring minimal downtime. The rise of e-commerce platforms is facilitating easier sourcing processes, allowing buyers to compare specifications and prices more efficiently.

How Can Sustainability and Ethical Sourcing Influence Your Procurement of Shacman Dump Trucks?

Sustainability is becoming a focal point in the procurement process for heavy machinery, including dump trucks. B2B buyers are increasingly aware of the environmental impact of their purchases. The Shacman Dump Truck 6×4 and 8×4 models are designed to meet Euro emission standards, demonstrating a commitment to reducing carbon footprints. Furthermore, the use of low-fuel consumption engines not only cuts operational costs but also aligns with global sustainability goals.

Ethical sourcing is another critical consideration. Buyers are encouraged to engage with manufacturers that prioritize transparent supply chains and responsible sourcing of materials. Certifications such as ISO 14001 for environmental management can be pivotal in assessing a supplier’s commitment to sustainability. By choosing Shacman trucks that meet these standards, buyers can ensure that their investments contribute positively to the environment and society.

What is the Historical Context Behind the Development of Shacman Dump Trucks?

The Shacman brand has a rich history that dates back to its inception in 1968, with a focus on producing heavy-duty vehicles tailored for rugged conditions. Over the years, Shacman has evolved to incorporate advanced technologies and manufacturing practices, establishing itself as a leader in the dump truck segment. The introduction of the F3000 series marked a significant milestone, combining superior engineering with modern design principles to meet the growing demands of international markets. This evolution has positioned Shacman as a reliable choice for B2B buyers looking for durable and efficient dump trucks for their projects.

Conclusion

Navigating the market dynamics of the Shacman Dump Truck 6×4 and 8×4 sector requires a keen understanding of current trends and a commitment to sustainability. By prioritizing ethical sourcing and leveraging technology, international B2B buyers can make informed decisions that not only enhance operational efficiency but also contribute to a more sustainable future. Engaging with a brand that has a proven track record, such as Shacman, ensures that buyers are investing in quality and reliability, essential components for the success of their projects.

Frequently Asked Questions (FAQs) for B2B Buyers of shacman Dump Truck 6×4 8×4

-

How do I determine the right Shacman Dump Truck model for my needs?

To select the appropriate Shacman Dump Truck model, consider your operational requirements, such as load capacity, terrain type, and fuel efficiency. The 6×4 model is ideal for moderate loads and urban environments, while the 8×4 model excels in heavy-duty applications like mining and large construction projects. Evaluate the engine specifications, cargo dimensions, and intended usage to ensure the truck aligns with your business objectives. -

What are the key features of the Shacman Dump Truck 6×4 and 8×4?

Both the 6×4 and 8×4 Shacman Dump Trucks boast high loading capacities, efficient fuel consumption, and robust build quality. The 8×4 variant offers a larger cargo box and enhanced stability for heavy loads, while the 6×4 provides a balance of power and maneuverability. Features like advanced hydraulic lifting systems, reinforced chassis, and comfortable driver cabins further enhance their usability across various industries. -

What should I consider when vetting suppliers for Shacman Dump Trucks?

When vetting suppliers, prioritize their reputation, experience in the industry, and customer feedback. Ensure they have a solid track record of delivering quality vehicles and prompt after-sales support. Verify their compliance with international standards, such as ISO certifications, and assess their capabilities in terms of production capacity and spare parts availability to ensure reliability in your supply chain. -

What are the minimum order quantities (MOQ) for Shacman Dump Trucks?

Minimum order quantities can vary depending on the supplier and specific model. Generally, for Shacman Dump Trucks, the MOQ is often set at one unit, allowing buyers to test the market without significant upfront investment. However, larger orders may qualify for discounts or favorable payment terms, so it’s advisable to discuss your needs directly with the supplier to find a suitable arrangement. -

What payment terms are typically available for international buyers?

International buyers can expect a range of payment options, including T/T (Telegraphic Transfer), L/C (Letter of Credit), and D/P (Documents Against Payment). Terms may vary based on order size and the buyer-supplier relationship. It’s crucial to establish clear payment conditions upfront to avoid disputes and ensure a smooth transaction process. -

How can I ensure the quality of Shacman Dump Trucks before purchase?

To ensure quality, request a pre-production sample or detailed specifications before mass production. Additionally, ask for third-party inspection reports or certifications that validate the truck’s adherence to international standards. Establishing a quality assurance agreement with the supplier can also help maintain standards throughout the manufacturing and delivery processes. -

What logistics considerations should I keep in mind when importing Shacman Dump Trucks?

Logistics planning is vital for timely delivery and cost management. Consider shipping methods (e.g., container shipping or roll-on/roll-off) and associated costs, including customs duties and taxes. Collaborate with a reliable freight forwarder familiar with heavy equipment to navigate regulations and ensure all necessary documentation is prepared for smooth customs clearance. -

Can Shacman Dump Trucks be customized to meet specific requirements?

Yes, Shacman Dump Trucks can be customized to suit specific operational needs. Options may include modifications in engine specifications, cargo box dimensions, and additional features such as enhanced safety systems or specialized hydraulic setups. Discuss your customization requirements with the supplier early in the negotiation process to ensure feasibility and alignment with production timelines.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 10 Shacman Dump Truck 6X4 8X4 Manufacturers & Suppliers List

1. SHACMAN – 8×4 Standard Dump Truck

Domain: global.shacman.com

Registered: 2014 (11 years)

Introduction: {“Product Name”: “8×4 Standard Dump Truck”, “Manufacturer”: “SHACMAN”, “Key Features”: [“High loading capacity”, “High dependability”, “Low fuel consumption”, “Comfortable and easy to drive”, “Matching engines: 10L, 11L, 12L”, “Euro II to VI emission standards”, “Four-point airbag shock absorption”], “Material”: “High-strength steel plate”, “Applications”: [“Standard transportation of toll roads”,…

2. SHACMAN – F3000 8X4 DUMP Truck

Domain: shacman-truck.com

Registered: 2021 (4 years)

Introduction: {“model”:”SHACMAN F3000 8X4 DUMP Truck”,”driving_type”:”8*4″,”wheelbase_mm”:”1800+3975+1400″,”max_speed_km_h”:”75 km/h”,”engine_brand”:”WEICHAI”,”engine_model”:”WP12.430E201″,”emission_standard”:”EURO II/III”,”rated_output_power”:”430 HP (294 KW)”,”displacement_L”:”11.596 L”,”transmission_brand”:”FAST”,”transmission_model”:”12-speed transmission”,”front_axle_brand”:”HANDE”,”front_axle_model”:”MAN …

3. Shacman – X3000 6X4 Dump Truck

Domain: trucks-shacman.com

Registered: 2021 (4 years)

Introduction: {“Model”:”Shacman X3000 6X4 Dump Truck”,”Loading Capacity”:”31-40 tons”,”Chassis Brand”:”Shacman”,”Horsepower”:”351 – 450hp”,”Cabin”:”X3000, Mid Lengthened Flat Roof”,”Transport Type”:”Ore/sand/gravel/coal”,”Driving Type”:”6×4″,”Engine Model”:”WP12.380, WP12.420, ISM 385″,”Engine Power”:”351 – 450hp”,”Engine Emission”:”Euro II”,”Gross Vehicle Weight”:”13400 kg”,”Transmission”:”10JSD160+QH50, 12JSD…

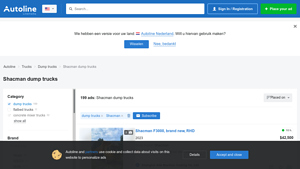

4. Shacman – Key Truck Models

Domain: autoline.com

Registered: 1997 (28 years)

Introduction: Brand: Shacman

Models: F2000, F3000, H3000, L3000, M3000, X3000

Engine Power: Ranges from 336 HP to 430 HP

Fuel Type: Diesel, Biodiesel

Axle Configuration: 6×2, 6×4, 8×4

Load Capacity: Up to 110,200 lb

Suspension: Spring/Spring

Way of Unloading: Rear

Euro Standards: Euro 2, Euro 4, Euro 5

Body Brand: Shacman

Location: China (various cities)

Price Range: $9,400 to $44,500

Volume: Up to 3,218 ft³

Co…

5. Shacman – F3000 Dump Truck

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: {“Model”:”Shacman F3000″,”Capacity”:”25 Cubic Meters”,”Drive Wheel”:”6×4 / 8×4″,”Load Capacity”:”21 – 30T”,”Horsepower”:”351 – 450hp”,”Condition”:”New”,”Transmission Type”:””}

6. Shacman – Heavy Duty Dump Trucks

Domain: heavytrucks-parts.com

Registered: 2024 (1 years)

Introduction: Shacman F2000 F3000 X3000 Dump Truck, 6X4 and 8X4 configurations, Heavy Duty Tipper Truck, designed for Mining Transport.

7. Ownace – 380 HP Shacman F3000 Tipper Lorry

Domain: ownacechina.com

Registered: 2021 (4 years)

Introduction: 380 HP Shacman F3000 6×4 8×4 Tipper Lorry Dump Truck

8. Shacman – Tipper Truck 6X4 8X4 30tons

Domain: truckcnhtc.com

Registered: 2019 (6 years)

Introduction: Model: Shacman Tipper Truck 6X4 8X4 30tons

Cabin: Four point suspension HOWO Cabin with spring and air shock absorber, VDO panel, Adjustable steering, sun cover

Engine Type: Diesel 4-stroke Direct injection, 6-cylinder in line, Turbo-charging, Inner cooling

Engine Model: WD615.69 STEYR technology (CNHTC)

Max Horse Power: 336HP / 247kw

Displacement: 9.726 liters

Max Torque: 1350NM @ 1100-1600rpm

Bo…

9. Shacman – Dump Truck

Domain: autoline.info

Introduction: Shacman dump truck, manual, used; Power: 336-430 HP; Fuel: diesel; Axle configuration: 6×4 or 8×4; Load capacity: 13,000 – 50,000 kg; Euro standards: Euro 2, Euro 3, Euro 5, Euro 6; Suspension: spring/spring or spring/air; Way of unloading: rear; Body brand: Shacman; Volume: 23.97 – 91.11 m³; Year of manufacture: 2021 – 2023; Price range: $14,500 – $40,000.

10. Shacman – Dump Truck

Domain: truckman-vehicle.com

Registered: 2023 (2 years)

Introduction: Shacman Dump Truck is a heavy-duty truck designed for construction, mining, logistics, and infrastructure projects. It features German MAN technology for stability and durability, a driver-focused German MAN TGS cab for comfort and visibility, and heavy-duty versatility for transporting various materials. Customizable configurations are available to meet specific industry needs. Key specifications…

Strategic Sourcing Conclusion and Outlook for shacman Dump Truck 6×4 8×4

In the competitive landscape of heavy-duty transportation, the Shacman Dump Truck 6×4 and 8×4 models stand out for their robust performance and operational efficiency. With features such as high loading capacities, advanced engine technology, and low fuel consumption, these trucks are designed to meet the rigorous demands of construction, mining, and infrastructure projects across diverse regions, including Africa, South America, the Middle East, and Europe.

Strategic sourcing of these vehicles not only ensures access to reliable and durable equipment but also fosters long-term partnerships with reputable manufacturers. This approach can significantly reduce operational costs, enhance supply chain efficiency, and improve project timelines.

As international B2B buyers, it is crucial to leverage the advantages offered by Shacman trucks, including their extensive after-sales support and quality assurance standards. The commitment to Euro emission standards further underscores their adaptability to varying regulatory environments, making them a smart investment for sustainable operations.

Looking ahead, now is the time to engage with Shacman as a strategic partner. By prioritizing these reliable dump trucks in your procurement strategy, you position your business for success in the evolving global marketplace. Reach out today to explore how Shacman can elevate your operational capabilities.