Introduction: Navigating the Global Market for electric vehicle parts

In an era where electric vehicles (EVs) are rapidly gaining traction globally, the challenge of sourcing reliable electric vehicle parts is more pressing than ever for international B2B buyers. With diverse markets spanning Africa, South America, the Middle East, and Europe—regions like Nigeria and Saudi Arabia—companies face the daunting task of navigating a complex supply chain. This guide serves as a comprehensive resource, addressing key aspects such as types of EV components, their applications, effective supplier vetting processes, and cost considerations.

Understanding the intricacies of the electric vehicle parts market is crucial for making informed purchasing decisions. Buyers will benefit from detailed insights into various categories of components, including batteries, motors, and charging systems, as well as best practices for selecting dependable suppliers. By providing actionable strategies and expert recommendations, this guide empowers B2B buyers to optimize their procurement processes, ensuring they acquire quality parts that meet their specific needs. As the demand for sustainable transport solutions grows, having a reliable roadmap for sourcing EV parts will position businesses for success in this dynamic market landscape.

Understanding electric vehicle parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Lithium-ion Batteries | High energy density, lightweight, rechargeable | Electric vehicles, energy storage | Pros: Long lifespan, high efficiency. Cons: Higher initial cost. |

| Electric Motors | Converts electrical energy to mechanical energy | EV propulsion, industrial applications | Pros: High torque, low maintenance. Cons: Requires precise control systems. |

| Battery Management Systems (BMS) | Monitors battery health, optimizes performance | Battery packs in EVs | Pros: Enhances safety, extends battery life. Cons: Complexity in integration. |

| Charging Infrastructure | Includes chargers, connectors, and stations | EV charging networks | Pros: Essential for EV adoption, diverse options. Cons: High setup costs. |

| Inverters | Converts DC to AC power for motor operation | EV systems, renewable energy systems | Pros: Improves energy efficiency. Cons: Requires proper sizing for applications. |

What Are the Characteristics of Lithium-ion Batteries in Electric Vehicles?

Lithium-ion batteries are the cornerstone of electric vehicle technology, known for their high energy density and lightweight nature. They are rechargeable and can be configured in various voltages, making them suitable for a wide range of applications, including electric vehicles and energy storage systems. When purchasing, B2B buyers should consider factors such as battery capacity, cycle life, and warranty terms, as these elements significantly impact long-term operational costs and performance.

How Do Electric Motors Function and What Are Their Applications?

Electric motors are critical components that convert electrical energy into mechanical energy, providing the necessary propulsion for electric vehicles. These motors typically deliver high torque and require minimal maintenance compared to traditional internal combustion engines. For B2B buyers, understanding the specific motor type (AC or DC), power ratings, and cooling requirements is essential for ensuring compatibility with vehicle designs and operational efficiency.

Why Are Battery Management Systems (BMS) Important for Electric Vehicle Performance?

Battery Management Systems (BMS) play a vital role in monitoring and managing the health of lithium-ion batteries. They optimize performance by balancing charge across cells, ensuring safety, and extending battery life. B2B buyers should evaluate the BMS capabilities, such as communication protocols and integration with existing systems, to ensure they meet specific application requirements and enhance overall battery performance.

What Should B2B Buyers Know About Charging Infrastructure for Electric Vehicles?

Charging infrastructure is essential for the widespread adoption of electric vehicles, encompassing chargers, connectors, and charging stations. Various charging options, including fast and standard chargers, cater to different market needs. B2B buyers must consider the installation costs, compatibility with existing vehicle models, and potential partnerships with local utility providers when investing in charging infrastructure to maximize their return on investment.

How Do Inverters Impact Electric Vehicle Efficiency?

Inverters are crucial for converting direct current (DC) from batteries to alternating current (AC) needed for electric motors. They significantly enhance energy efficiency and can improve overall vehicle performance. B2B buyers should focus on inverter specifications, such as power ratings and efficiency levels, to ensure they align with the power demands of their electric vehicle systems while also considering integration challenges with other components.

Key Industrial Applications of electric vehicle parts

| Industry/Sector | Specific Application of Electric Vehicle Parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Public Transportation | Electric Buses and Trams | Reduced operational costs and lower emissions | Compliance with local regulations, availability of parts, and warranty options. |

| Logistics and Delivery | Electric Delivery Vans | Enhanced efficiency and lower fuel costs | Battery capacity, range specifications, and charging infrastructure compatibility. |

| Renewable Energy | EV Battery Energy Storage Systems | Improved energy management and grid stability | Battery technology, scalability, and integration with existing systems. |

| Automotive Manufacturing | EV Conversion Kits | Access to new markets and innovative vehicle designs | Quality assurance, compatibility with existing vehicles, and after-sales support. |

| Agriculture | Electric Tractors and Farm Equipment | Increased productivity and reduced emissions | Durability, power requirements, and serviceability in remote locations. |

How Are Electric Vehicle Parts Utilized in Public Transportation?

In the public transportation sector, electric buses and trams are increasingly being adopted to meet environmental regulations and reduce operational costs. Key components such as electric motors, battery packs, and charging systems are essential for these vehicles. By sourcing high-quality electric vehicle parts, operators can ensure reliability and performance, while also benefiting from lower maintenance costs. International buyers must consider local regulations, the availability of replacement parts, and the warranty terms provided by suppliers, particularly in regions like Africa and the Middle East, where infrastructure may still be developing.

What Role Do Electric Vehicle Parts Play in Logistics and Delivery?

Electric delivery vans are revolutionizing the logistics industry by providing an eco-friendly alternative to traditional fuel-powered vehicles. Electric vehicle parts, including advanced battery systems and efficient electric drivetrains, allow for longer ranges and faster charging times. This results in reduced fuel costs and enhanced delivery efficiency. Buyers in South America and Africa should prioritize battery capacity and range specifications, as well as compatibility with local charging infrastructure, to maximize operational effectiveness.

How Do Electric Vehicle Parts Enhance Renewable Energy Solutions?

Electric vehicle parts are critical in renewable energy applications, particularly in battery energy storage systems. These systems utilize high-capacity lithium-ion batteries to store energy generated from renewable sources, such as solar and wind. This capability not only provides grid stability but also enables businesses to manage energy costs effectively. When sourcing these parts, international buyers should focus on battery technology advancements, scalability options, and how well these systems integrate with existing energy setups, especially in regions with fluctuating energy demands.

What Advantages Do Electric Vehicle Conversion Kits Offer to Automotive Manufacturers?

For automotive manufacturers, electric vehicle conversion kits present an opportunity to innovate and enter new markets. These kits typically include electric motors, controllers, and battery management systems designed for retrofitting existing vehicles. This approach not only extends the life of older models but also aligns with increasing consumer demand for sustainable options. Buyers need to assess the quality of components, compatibility with specific vehicle models, and the level of after-sales support when selecting conversion kits, particularly in Europe, where regulatory standards are stringent.

How Are Electric Vehicle Parts Transforming Agriculture?

In agriculture, electric tractors and farm equipment are becoming more prevalent, driven by the need for sustainable practices. Electric vehicle parts such as high-torque motors and robust battery systems enable these machines to operate efficiently while reducing greenhouse gas emissions. Farmers looking to invest in electric equipment must consider the durability of components, power requirements for various tasks, and the availability of service support in remote areas, particularly in regions like Africa where agricultural operations may be spread out.

3 Common User Pain Points for ‘electric vehicle parts’ & Their Solutions

Scenario 1: Navigating Supply Chain Delays in EV Parts Procurement

The Problem: B2B buyers in regions like Africa and South America often face significant delays in the supply chain for electric vehicle (EV) parts. Factors such as limited local suppliers, long shipping times, and customs clearance issues can lead to frustrating interruptions in production schedules. This situation is particularly challenging for businesses relying on timely deliveries to meet customer demands and maintain operational efficiency.

The Solution: To mitigate supply chain delays, buyers should diversify their sourcing strategies by establishing relationships with multiple suppliers across different regions. This not only spreads risk but also creates competitive pricing opportunities. When selecting suppliers, prioritize those with a proven track record of reliability and efficient logistics. Additionally, consider implementing an inventory management system that allows for real-time tracking of parts and forecasting future needs based on historical sales data. This proactive approach enables businesses to make informed purchasing decisions and maintain adequate stock levels, reducing the impact of unforeseen delays.

Scenario 2: Ensuring Compatibility of EV Components

The Problem: As the EV market grows, B2B buyers often encounter compatibility issues between different components, such as batteries, controllers, and chargers. This is especially prevalent when sourcing parts from various manufacturers, leading to potential performance inefficiencies and increased costs associated with returns or replacements. Such challenges can hinder project timelines and affect customer satisfaction.

The Solution: To ensure compatibility, buyers should conduct thorough research on the specifications of the parts they intend to purchase. Create a detailed compatibility matrix that includes voltage ratings, connector types, and communication protocols of the components. Collaborating with manufacturers that offer comprehensive documentation and customer support can also be beneficial. It’s advisable to engage in direct communication with suppliers to confirm compatibility before placing bulk orders. Additionally, consider investing in modular components that allow for easier integration and flexibility in future upgrades.

Scenario 3: Managing Quality Assurance for EV Parts

The Problem: Quality assurance is a critical concern for B2B buyers of EV parts, especially in emerging markets where standards may vary significantly. Buyers may face challenges with subpar components that lead to safety issues or operational failures, ultimately affecting their reputation and bottom line. This risk is compounded by the need for rigorous compliance with international standards.

The Solution: To manage quality assurance effectively, buyers should implement a stringent vendor evaluation process that includes assessing certifications, quality control practices, and product testing procedures. Establishing partnerships with suppliers who adhere to recognized quality standards, such as ISO certifications, can help mitigate risks. Additionally, consider conducting periodic audits of suppliers to ensure compliance with quality benchmarks. Setting up a feedback loop with end-users can also provide insights into component performance, allowing for continuous improvement in procurement strategies. By prioritizing quality, businesses can enhance their product reliability, reduce warranty claims, and build stronger customer trust.

Strategic Material Selection Guide for electric vehicle parts

What Are the Key Materials Used in Electric Vehicle Parts?

The selection of materials for electric vehicle (EV) parts is crucial for ensuring performance, safety, and cost-effectiveness. Here, we analyze four common materials used in the manufacturing of EV components, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

How Does Aluminum Benefit Electric Vehicle Components?

Aluminum is widely used in EV manufacturing due to its excellent strength-to-weight ratio and corrosion resistance. It can withstand high temperatures, making it suitable for various applications, including battery enclosures and structural components.

Pros: Aluminum is lightweight, which contributes to improved vehicle efficiency and range. It is also recyclable, aligning with sustainability goals.

Cons: The primary drawback is its cost, which is generally higher than steel. Additionally, aluminum can be more challenging to weld, potentially complicating manufacturing processes.

Impact on Application: Aluminum is compatible with various media, including coolant systems, due to its corrosion resistance.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and DIN. In regions like Africa and South America, where local sourcing might be preferred, understanding the availability of aluminum alloys is essential.

What Role Does Steel Play in Electric Vehicle Manufacturing?

Steel, particularly high-strength low-alloy (HSLA) steel, is another common material in EV construction. It is known for its durability and ability to withstand high pressure and impact.

Pros: Steel is cost-effective and offers excellent tensile strength, making it ideal for structural components that require high durability.

Cons: Steel is heavier than aluminum, which may negatively impact the overall efficiency of the vehicle. It is also prone to corrosion unless treated or coated.

Impact on Application: Steel’s strength makes it suitable for chassis and safety components, but its weight can affect performance metrics like range and acceleration.

Considerations for International Buyers: Buyers in the Middle East and Europe should be aware of local regulations regarding steel grades and corrosion resistance standards, such as JIS and ASTM specifications.

How Do Composites Enhance Electric Vehicle Performance?

Composite materials, including carbon fiber and fiberglass, are increasingly being used in EVs for their lightweight and high-strength properties.

Pros: Composites offer excellent strength-to-weight ratios and can be molded into complex shapes, allowing for innovative designs. They also provide good thermal and electrical insulation.

Cons: The primary limitation is cost; composites can be significantly more expensive than metals. Additionally, manufacturing processes for composites can be complex and time-consuming.

Impact on Application: Composites are ideal for body panels and interior components, where weight savings can lead to improved efficiency.

Considerations for International Buyers: Buyers should consider the availability of composite manufacturing capabilities in their regions. Compliance with international standards for safety and performance is also crucial.

What Advantages Do Plastics Offer in Electric Vehicle Parts?

Plastics, particularly engineering plastics like polycarbonate and nylon, are used in various applications, including connectors, housings, and interior components.

Pros: Plastics are lightweight, cost-effective, and can be easily molded into complex shapes. They also offer good resistance to chemicals and moisture.

Cons: Plastics may have lower heat resistance compared to metals and can degrade under UV exposure unless treated.

Impact on Application: Plastics are suitable for non-structural components and can help reduce overall vehicle weight, enhancing efficiency.

Considerations for International Buyers: Buyers should ensure that the plastics used comply with relevant environmental regulations and standards, particularly in Europe, where regulations are stringent.

Summary Table of Material Selection for Electric Vehicle Parts

| Material | Typical Use Case for Electric Vehicle Parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Battery enclosures, structural components | Lightweight and corrosion-resistant | Higher cost and welding complexity | High |

| Steel | Chassis, safety components | Cost-effective and durable | Heavier, prone to corrosion | Medium |

| Composites | Body panels, interior components | Excellent strength-to-weight ratio | High cost and complex manufacturing | High |

| Plastics | Connectors, housings, interior components | Lightweight and cost-effective | Lower heat resistance, UV degradation | Low |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, facilitating informed decisions in sourcing electric vehicle parts tailored to their specific regional needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for electric vehicle parts

What Are the Main Stages in the Manufacturing Process of Electric Vehicle Parts?

The manufacturing process of electric vehicle (EV) parts is intricate and requires precision to ensure high-quality output. The main stages include:

-

Material Preparation: The first step involves sourcing high-grade materials, such as aluminum, steel, and advanced composites. For battery components, lithium-ion or LiFePO4 (Lithium Iron Phosphate) materials are commonly used. Material testing is essential to verify that they meet specific criteria, such as conductivity, weight, and thermal resistance.

-

Forming: This stage encompasses various techniques, including stamping, extrusion, and molding. For instance, battery casings might be formed through die-casting, while electric motor components could use precision machining. The choice of technique depends on the part’s complexity, volume requirements, and material properties.

-

Assembly: After forming, parts are assembled into larger units. This could involve soldering electronic components onto circuit boards or integrating battery cells into packs. Automation plays a significant role here, enhancing efficiency and reducing human error. For example, robotic arms may be employed to handle repetitive tasks, ensuring consistent quality.

-

Finishing: The final stage involves surface treatments, coatings, and quality checks. Processes like anodizing for aluminum parts or applying protective coatings for battery packs are crucial to enhancing durability and performance. Finishing also includes final inspections to ensure parts meet design specifications.

How Is Quality Assurance Ensured in the Manufacturing of Electric Vehicle Parts?

Quality assurance (QA) is critical in the EV parts manufacturing sector, ensuring that products are reliable and safe. Key components of QA include adherence to international standards and rigorous testing protocols.

-

International Standards: Compliance with standards such as ISO 9001 for quality management systems is essential. This certification demonstrates a commitment to quality and continuous improvement. Additionally, industry-specific certifications like CE mark for European markets and API standards for battery components may be necessary.

-

Quality Control Checkpoints: Implementing various quality control checkpoints throughout the manufacturing process is vital. These typically include:

– Incoming Quality Control (IQC): Verification of raw materials and components upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process to identify and rectify defects early.

– Final Quality Control (FQC): Comprehensive testing of finished products to ensure they meet all specifications before shipment. -

Common Testing Methods: Various testing methodologies are used to assess the performance and reliability of EV parts. These include:

– Electrical Testing: Ensuring that battery packs meet voltage and capacity specifications.

– Thermal Testing: Assessing heat dissipation capabilities of motors and battery systems.

– Mechanical Testing: Evaluating the strength and durability of components under stress.

What Strategies Can B2B Buyers Use to Verify Supplier Quality Control?

B2B buyers must implement effective strategies to verify the quality control practices of their suppliers, especially in international contexts where standards may vary.

-

Supplier Audits: Conducting on-site audits can provide insights into a supplier’s manufacturing processes and quality control measures. This helps buyers understand the level of compliance with international standards and the effectiveness of their QA systems.

-

Quality Reports: Requesting detailed quality reports from suppliers is another effective strategy. These documents should outline the results of various tests conducted on their products, including failure rates and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These firms can conduct random inspections and testing, ensuring that the products meet the required specifications before shipment.

What Are the Specific Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate several nuances related to quality control and certification.

-

Regional Standards: Understanding regional compliance requirements is crucial. For instance, products sold in Europe must comply with EU regulations, including CE certification, while those entering the Middle East may need to meet Gulf Cooperation Council (GCC) standards.

-

Cultural Considerations: Different regions may have varying expectations regarding quality and reliability. Buyers should consider local practices and preferences when assessing suppliers. For example, suppliers in Europe may focus more on sustainability, while those in Africa might prioritize affordability and accessibility.

-

Documentation and Traceability: Maintaining thorough documentation is vital for international transactions. Buyers should ensure that suppliers can provide complete traceability for their products, including material certifications, manufacturing processes, and quality checks.

-

Communication: Establishing clear communication channels with suppliers is essential. This enables buyers to raise concerns, request updates on quality control processes, and ensure that their specifications are understood and met.

In conclusion, the manufacturing processes and quality assurance protocols for electric vehicle parts are vital components in ensuring product reliability and performance. B2B buyers must employ strategic measures to verify supplier quality, considering international standards and regional nuances. By doing so, they can build strong partnerships and ensure successful procurement of high-quality EV components.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric vehicle parts’

Introduction

Sourcing electric vehicle (EV) parts requires a strategic approach to ensure quality, reliability, and cost-effectiveness. This checklist is designed to guide B2B buyers through the essential steps to procure EV components, catering specifically to the needs of international markets such as Africa, South America, the Middle East, and Europe. By following these steps, you can make informed decisions that align with your business objectives and operational requirements.

Step 1: Define Your Technical Specifications

Clearly outline the technical specifications for the EV parts you need. This includes voltage requirements, compatibility with existing systems, and performance standards. Precise specifications help in streamlining the sourcing process and ensuring that the parts meet your operational needs.

- Considerations:

- Voltage and capacity requirements (e.g., battery size, inverter specifications).

- Environmental conditions (e.g., temperature, humidity) that the parts will be exposed to.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers specializing in EV parts. Look for companies that have a strong reputation in the industry, especially those with experience in your target market.

- Where to Look:

- Industry trade shows and expos.

- Online marketplaces and directories focused on EV components.

- Recommendations from industry peers.

Step 3: Evaluate Supplier Credentials

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, certifications, and references from buyers in similar industries or regions. Don’t just rely on their website; investigate their track record.

- Key Aspects to Verify:

- ISO certifications or other relevant industry standards.

- Customer testimonials and case studies demonstrating successful partnerships.

Step 4: Request Samples and Technical Support

Before finalizing any order, request samples of the parts you intend to purchase. This allows you to assess quality and compatibility firsthand. Additionally, inquire about the technical support offered by the supplier.

- What to Assess:

- Build quality and material specifications of the samples.

- Availability of technical assistance for installation and maintenance.

Step 5: Compare Pricing and Payment Terms

Gather quotes from multiple suppliers to compare pricing structures and payment terms. Keep an eye out for hidden costs such as shipping fees, customs duties, or taxes that may affect the total cost.

- Considerations:

- Payment flexibility (e.g., upfront payment, credit terms).

- Bulk purchase discounts or loyalty programs.

Step 6: Understand Warranty and Return Policies

Review the warranty and return policies of the suppliers you are considering. A robust warranty indicates the supplier’s confidence in their products and provides peace of mind for your investment.

- Key Questions to Ask:

- What does the warranty cover, and for how long?

- What is the process for returns or exchanges in case of defects?

Step 7: Establish Communication Channels

Finally, ensure you establish clear communication channels with your chosen supplier. Effective communication is vital for resolving issues, coordinating shipments, and addressing any concerns that may arise during the sourcing process.

- Best Practices:

- Designate a point of contact for all communications.

- Utilize project management tools to track progress and maintain transparency.

By following this checklist, B2B buyers can streamline the procurement process for electric vehicle parts, ensuring they select the best suppliers and products for their operational needs.

Comprehensive Cost and Pricing Analysis for electric vehicle parts Sourcing

What Are the Key Cost Components in Electric Vehicle Parts Sourcing?

When sourcing electric vehicle (EV) parts, understanding the cost structure is crucial for effective budgeting and pricing strategy. The primary cost components include:

-

Materials: The choice of raw materials significantly impacts the overall cost. High-performance components often utilize advanced materials, such as lithium for batteries or specialized alloys for motors, which can increase costs.

-

Labor: Labor costs vary by region and can affect manufacturing prices. In regions with higher labor costs, such as Europe, the final pricing may reflect this, whereas manufacturers in regions with lower labor costs may offer more competitive pricing.

-

Manufacturing Overhead: This encompasses costs related to facilities, utilities, and administrative expenses. Efficient manufacturing processes can reduce overhead, benefiting buyers through lower prices.

-

Tooling: The initial investment in tooling for custom parts can be substantial. Buyers should consider whether they require standard components, which often have lower costs due to existing tooling, or custom solutions that may require additional investment.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but adds to the cost structure. Buyers should evaluate whether the additional expense is justified by the quality and performance requirements of their applications.

-

Logistics: Shipping costs, including international freight and customs duties, can substantially affect the total cost. Buyers should factor in logistics when calculating overall expenses, especially when importing from distant suppliers.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding industry standards for margins can help buyers assess whether they are receiving competitive pricing.

How Do Price Influencers Affect Electric Vehicle Parts Costs?

Several factors influence the pricing of electric vehicle parts, which buyers must consider:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for bulk pricing, reducing the per-unit cost. Establishing a strong relationship with suppliers can help negotiate lower MOQs.

-

Specifications and Customization: Custom parts tailored to specific requirements tend to be more expensive due to the additional design and manufacturing processes involved.

-

Materials: The choice of materials not only influences performance but also cost. Buyers should balance the need for high-quality materials with budget constraints.

-

Quality Certifications: Parts that meet international quality standards or have certifications may carry higher prices. However, these certifications can also provide assurance of reliability and performance.

-

Supplier Factors: The reputation, reliability, and location of suppliers can impact pricing. Established suppliers may charge a premium for their proven track record, while newer entrants may offer lower prices to gain market share.

-

Incoterms: The shipping terms agreed upon can affect total costs. Understanding Incoterms (International Commercial Terms) can help buyers manage logistics expenses more effectively.

What Are the Best Negotiation Strategies for B2B Buyers in Electric Vehicle Parts Sourcing?

When engaging with suppliers, especially in international contexts like Africa, South America, the Middle East, and Europe, several negotiation strategies can yield favorable outcomes:

-

Understand Total Cost of Ownership (TCO): Beyond initial pricing, consider long-term costs associated with maintenance, efficiency, and potential downtime. Presenting a TCO analysis can provide leverage in negotiations.

-

Be Informed About Pricing Nuances: Market conditions, such as demand fluctuations or geopolitical issues, can affect prices. Staying informed can help buyers negotiate better terms.

-

Explore Alternative Suppliers: Don’t hesitate to consider multiple suppliers. Having alternatives can strengthen your negotiating position, allowing you to leverage competitive quotes.

-

Build Long-term Relationships: Establishing a solid relationship with suppliers can lead to better pricing, priority access to new products, and enhanced service levels.

-

Leverage Local Knowledge: Understanding regional market dynamics can provide insights into pricing strategies and help identify opportunities for cost savings.

Disclaimer on Indicative Prices

Please note that prices for electric vehicle parts can vary widely based on numerous factors, including supplier, specifications, and market conditions. The pricing information provided should be considered indicative and subject to change. Always consult directly with suppliers for the most accurate and current pricing information.

Alternatives Analysis: Comparing electric vehicle parts With Other Solutions

Understanding Alternatives in Electric Vehicle Parts

As the electric vehicle (EV) market continues to evolve, so does the landscape of available solutions for various components. B2B buyers must consider a range of options when sourcing parts, as alternatives can vary significantly in terms of performance, cost, and suitability for specific applications. This analysis compares electric vehicle parts to two viable alternatives: hybrid vehicle components and traditional internal combustion engine (ICE) parts. Each option presents distinct advantages and challenges that can influence purchasing decisions.

| Comparison Aspect | Electric Vehicle Parts | Hybrid Vehicle Components | Traditional Internal Combustion Engine Parts |

|---|---|---|---|

| Performance | High efficiency, lower emissions | Moderate efficiency, dual power sources | Established performance but higher emissions |

| Cost | Generally higher upfront costs | Mid-range costs, depending on components | Typically lower upfront costs |

| Ease of Implementation | Requires specialized knowledge | Familiarity with both systems needed | Well understood, easier integration |

| Maintenance | Lower maintenance, fewer moving parts | Moderate, dual system complexity | Higher maintenance, more frequent repairs |

| Best Use Case | Fully electric applications | Short-range travel and fuel efficiency | Long-range travel, existing infrastructure |

What Are the Pros and Cons of Hybrid Vehicle Components?

Hybrid vehicle components represent a blend of electric and traditional technology, making them a compelling alternative. One significant advantage is their ability to leverage both electric and gasoline power, providing flexibility in various driving conditions. However, the complexity of hybrid systems can lead to higher maintenance costs and the need for specialized service knowledge. For B2B buyers focused on reducing emissions while maintaining range, hybrid components can serve as a transitional solution, especially in markets where charging infrastructure is still developing.

How Do Traditional Internal Combustion Engine Parts Compare?

Traditional ICE parts are the most established option, benefiting from widespread availability and lower initial costs. They are suitable for applications where electric infrastructure is lacking and can be easily integrated into existing vehicle designs. However, with rising fuel costs and stricter emissions regulations, the long-term operational costs can be higher. Additionally, as global trends shift towards sustainability, reliance on ICE parts may become less favorable. B2B buyers in regions with robust fuel supply chains may still find ICE parts appealing, but they should be mindful of the evolving regulatory landscape.

Choosing the Right Solution for Your Needs

When evaluating electric vehicle parts versus alternatives, B2B buyers must consider their specific operational needs, budget constraints, and long-term goals. Electric vehicle parts offer cutting-edge efficiency and sustainability but may come with higher upfront costs and require specialized knowledge for implementation. Hybrid solutions can bridge the gap for those transitioning towards full electrification, while traditional ICE components remain a viable option in regions where electric infrastructure is limited. Ultimately, the decision should align with the buyer’s strategic objectives, market conditions, and commitment to sustainability.

Essential Technical Properties and Trade Terminology for electric vehicle parts

What Are the Key Technical Properties of Electric Vehicle Parts?

Understanding the essential technical properties of electric vehicle (EV) parts is crucial for B2B buyers, especially when sourcing components for production or assembly. Here are some critical specifications to consider:

-

Material Grade

The material grade of components, such as aluminum or lithium for batteries, is vital. It determines the strength, weight, and corrosion resistance of the parts. High-grade materials enhance performance and longevity, which are essential for maintaining vehicle efficiency and safety. -

Tolerance

Tolerance refers to the permissible limits of variation in a physical dimension. In EV parts, precise tolerances are essential for ensuring compatibility and performance. For example, a battery pack must fit perfectly within the designated space in a vehicle to avoid overheating or mechanical failure. -

Voltage Rating

Each electrical component, such as battery management systems (BMS) and inverters, has a specific voltage rating that indicates its operational capability. Understanding voltage ratings is crucial for preventing electrical faults and ensuring the safe operation of EV systems. -

Capacity

For batteries, capacity is measured in ampere-hours (Ah) or kilowatt-hours (kWh) and indicates how much energy can be stored and used. Higher capacity batteries provide longer ranges, making them more desirable in the competitive EV market. -

Charging Speed

This property indicates how quickly a battery can be charged, usually measured in kilowatts (kW). Fast-charging capabilities are increasingly essential for consumer satisfaction, influencing purchasing decisions. -

Cycle Life

Cycle life refers to the number of charge and discharge cycles a battery can undergo before its capacity significantly diminishes. A longer cycle life means lower replacement costs and greater reliability, making it a key consideration for B2B buyers.

Which Trade Terminology Should B2B Buyers Know in the EV Parts Market?

Familiarity with industry jargon is essential for effective communication and negotiation in the EV parts market. Here are some common terms that buyers should understand:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are then sold under another company’s brand name. Understanding OEM specifications is critical for ensuring compatibility and quality, as OEM parts typically meet the original standards set by the vehicle manufacturer. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for budgeting and inventory management, as it influences how much stock a buyer needs to commit to initially. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price bids from suppliers for specific products or services. Understanding how to draft and interpret RFQs can streamline the purchasing process and help in securing competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping costs, risk transfer, and delivery points. Familiarity with these terms helps buyers understand their obligations and rights during the shipping process. -

Lead Time

Lead time is the time it takes from placing an order to receiving the goods. Knowing the lead time is essential for planning production schedules and ensuring timely delivery to customers. -

Aftermarket Parts

These are parts not made by the OEM but are designed to fit and function in the original vehicle. Understanding the aftermarket landscape can provide buyers with cost-effective alternatives while maintaining quality.

By comprehending these technical properties and trade terminologies, B2B buyers can make informed decisions, ensuring they source high-quality EV parts that meet their operational needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the electric vehicle parts Sector

What Are the Current Market Dynamics and Key Trends in the Electric Vehicle Parts Sector?

The electric vehicle (EV) parts sector is experiencing significant growth driven by the global shift towards sustainable transportation. Governments worldwide are implementing stricter emissions regulations and providing incentives for EV adoption, fostering a robust market for electric vehicle parts. The rise of electric mobility is particularly evident in regions such as Africa, South America, the Middle East, and Europe, where local manufacturers are increasingly sourcing components to meet rising demand.

Emerging technologies, such as advanced battery management systems (BMS) and smart charging solutions, are reshaping the sourcing landscape. B2B buyers must stay abreast of these innovations to ensure they are procuring state-of-the-art components that enhance vehicle performance and safety. Moreover, the digitalization of supply chains through platforms that offer real-time data on inventory levels and logistics is becoming more prevalent. This transformation allows international buyers to optimize their procurement strategies, leading to cost efficiencies and better alignment with market demands.

Sourcing trends also reflect a shift towards local suppliers, particularly in regions like Nigeria and Saudi Arabia, where establishing regional supply chains can mitigate risks associated with global logistics disruptions. Buyers are increasingly prioritizing suppliers who can demonstrate agility and responsiveness to market changes, as well as those who can provide a diverse range of components—from batteries and motors to charging infrastructure.

How Is Sustainability Influencing Sourcing Decisions in the Electric Vehicle Parts Market?

Sustainability has become a cornerstone of sourcing strategies in the electric vehicle parts sector. As the environmental impact of traditional fossil fuels becomes more apparent, B2B buyers are increasingly concerned with the sustainability of the products they source. This has led to a growing emphasis on ethical supply chains that prioritize environmentally friendly practices, such as the use of recyclable materials and reduced carbon footprints in manufacturing processes.

Buyers are also seeking suppliers that possess ‘green’ certifications, which validate their commitment to sustainable practices. Certifications such as ISO 14001 for environmental management and compliance with REACH regulations for chemical safety are becoming essential for building trust and credibility in the marketplace. Furthermore, as consumers become more eco-conscious, the demand for electric vehicle parts that meet sustainability criteria is likely to increase, making it a crucial consideration for B2B buyers in their procurement strategies.

In addition to regulatory compliance, focusing on sustainability can enhance brand reputation and open up new market opportunities. Buyers who prioritize ethical sourcing are not only contributing to a healthier planet but also aligning themselves with the values of an increasingly environmentally aware customer base.

How Has the Electric Vehicle Parts Sector Evolved Over Time?

The evolution of the electric vehicle parts sector can be traced back to the early days of electric mobility, where components were limited and often bespoke. As technology progressed and consumer demand surged, the industry saw a rapid expansion of component offerings, including advanced batteries, motors, and charging systems. This evolution was significantly accelerated by the advent of large-scale manufacturers and the development of standardized parts, which allowed for mass production and reduced costs.

The past decade has witnessed a paradigm shift, with a growing focus on innovation and sustainability. New players have entered the market, bringing fresh ideas and technologies that have transformed traditional manufacturing processes. Today, the sector is characterized by a collaborative ecosystem where established manufacturers and startups work together to push the boundaries of what is possible in electric vehicle technology. This ongoing evolution presents B2B buyers with a wealth of opportunities to source cutting-edge components that can enhance their product offerings and meet the demands of a rapidly changing market.

By understanding these dynamics, international B2B buyers can navigate the complexities of the electric vehicle parts sector more effectively, ensuring they remain competitive in a landscape that is continually evolving.

Frequently Asked Questions (FAQs) for B2B Buyers of electric vehicle parts

1. How do I solve supply chain delays when sourcing electric vehicle parts?

To mitigate supply chain delays, establish strong relationships with multiple suppliers to diversify your sourcing options. Implement a robust inventory management system that tracks stock levels and lead times. Regularly communicate with suppliers about their production schedules and potential disruptions. Additionally, consider sourcing from local suppliers when possible, as this can significantly reduce shipping times and costs. Lastly, maintain a buffer stock of critical components to ensure continuity in your operations.

2. What is the best battery type for electric vehicles?

Lithium Iron Phosphate (LiFePO4) batteries are often regarded as the best option for electric vehicles due to their safety, thermal stability, and long cycle life. They offer a good balance between performance and cost, making them suitable for various applications. When choosing a battery, consider factors such as energy density, weight, charging speed, and longevity. It’s also crucial to assess compatibility with your vehicle’s existing systems to ensure optimal performance.

3. How can I vet suppliers of electric vehicle parts effectively?

To vet suppliers, conduct comprehensive research that includes reviewing their online presence, customer testimonials, and industry certifications. Request references from previous clients and inquire about their experience with product quality and service reliability. Additionally, assess their production capabilities and compliance with international standards. A visit to their manufacturing facility can provide valuable insights into their operations and quality control processes. Establishing a trial order can also help evaluate their service before committing to larger purchases.

4. What are typical minimum order quantities (MOQs) for electric vehicle parts?

Minimum order quantities (MOQs) for electric vehicle parts can vary significantly based on the supplier and the specific component. Generally, MOQs range from 10 to 100 units for standard parts, while specialized or custom components may require higher MOQs. It’s essential to communicate your needs with suppliers upfront to negotiate favorable terms. If you anticipate regular orders, consider discussing a long-term partnership that may allow for lower MOQs.

5. What payment terms should I expect when buying electric vehicle parts internationally?

Payment terms for international purchases typically include options like upfront payment, letters of credit, or payment on delivery. Common practices involve partial payment (e.g., 30-50%) upfront, with the remainder due upon shipment or delivery. Always clarify payment terms before finalizing orders to avoid misunderstandings. Additionally, consider using secure payment methods that protect both parties, such as escrow services, especially for large transactions.

6. How do I ensure quality assurance for electric vehicle parts?

To ensure quality assurance, establish clear specifications and standards for the parts you require. Request samples before placing bulk orders to evaluate quality firsthand. Additionally, ask suppliers about their quality control processes, including testing and certification procedures. Implementing a third-party inspection service can provide an extra layer of assurance, particularly for large shipments or critical components. Regular audits of suppliers can also help maintain quality standards over time.

7. What logistics considerations should I keep in mind when importing electric vehicle parts?

When importing electric vehicle parts, consider factors such as shipping methods, customs regulations, and import duties. Choose a reliable logistics provider that understands the specific requirements of transporting EV components. It’s crucial to factor in lead times for shipping and customs clearance to avoid delays in your supply chain. Additionally, ensure that all documentation is accurate and complete to facilitate smooth customs processing and reduce the risk of additional charges.

8. How can I customize electric vehicle parts to meet my specific needs?

Customization of electric vehicle parts can often be achieved by collaborating directly with manufacturers. Clearly communicate your requirements, including dimensions, materials, and performance specifications. Many suppliers offer customization options for bulk orders, allowing you to tailor products to your application. Be prepared for potential lead times associated with custom orders and ensure that you validate prototypes before proceeding with larger quantities to confirm they meet your expectations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Electric Vehicle Parts Manufacturers & Suppliers List

1. Electric Car Parts Company – Lithium Batteries & Chargers

Domain: electriccarpartscompany.com

Registered: 2012 (13 years)

Introduction: Affordable EV & Solar Batteries | Electric Car Parts Company specializes in Lithium Batteries, Chargers, and Solar Storage. Key products include: 12V, 24V, 48V Battery Packs, Complete Lithium Battery Packs, Rack Mounted Systems, Lithium LiFePo4 Batteries (Prismatic – CALB, Fortune), Battery Management Systems (BMS), Orion Chargers for Lithium Batteries (24V & 48V Fan-Cooled), Off-Grid Pure Sine Wa…

2. myigetit – Key Electric Vehicle Components

Domain: myigetit.com

Registered: 2000 (25 years)

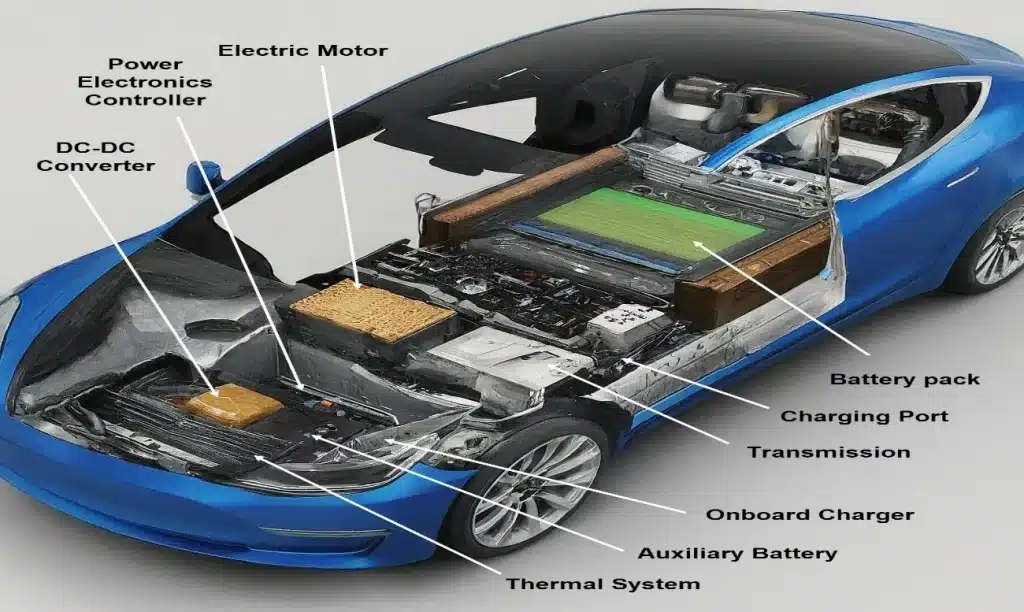

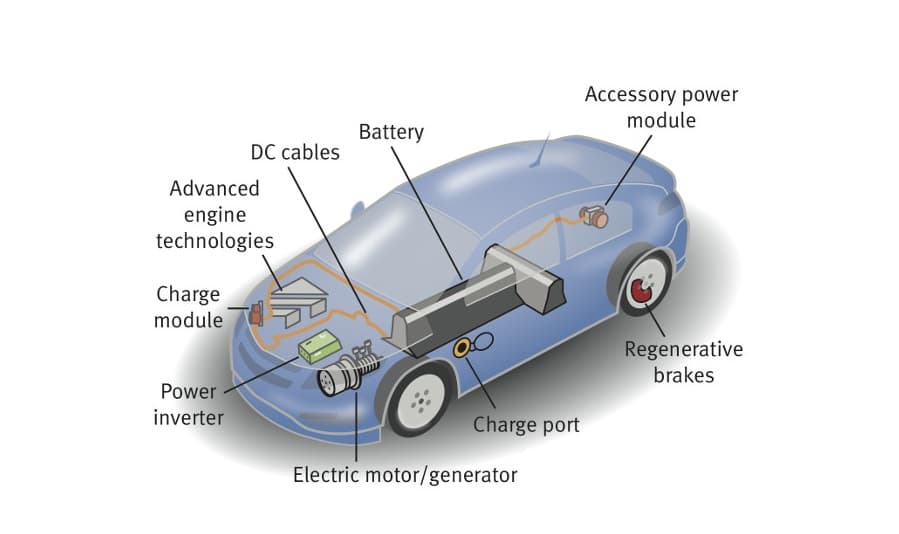

Introduction: Key Electric Vehicle Components: 1. Battery Pack: Stores electrical energy, typically using lithium-ion batteries. Consists of individual cells (cylindrical, prismatic, pouch), grouped into modules, and assembled into a pack with cooling systems and battery management systems (BMS). Capacity measured in kWh determines energy storage and driving range. Charging options include AC charging (slower, …

3. EV Resource – Key Components of BEVs

Domain: ev-resource.com

Registered: 2019 (6 years)

Introduction: Full battery electric vehicles (BEVs) do not require gasoline or an internal combustion engine. Key components of BEVs include: 1. Battery Pack: Energy reservoir for driving and operating accessories. 2. Power Inverter: Converts DC from the battery to AC for the motor and manages regenerative braking. 3. Electric Motor: Transforms electrical energy into rotational energy for vehicle movement. 4. O…

4. Moto Electric Vehicles – Electric Golf Cart Parts

Domain: motoelectricvehicles.com

Registered: 2010 (15 years)

Introduction: Electric Golf Cart Parts | Electric Vehicle Parts & Components | Moto Electric Vehicles stocks the largest inventory of electric cart parts for the brands MotoEV, Bintelli, citEcar, Zone Golf Cart, StarEV Golf Cart, and EVE Golf Cart. Moto Electric Vehicles maintains two separate warehouses which are fully stocked with replacement electric golf cart parts for immediate purchase. If not in stock, o…

5. Lectron – EV Charging Station and Accessories

Domain: transend.us

Registered: 2018 (7 years)

Introduction: [{“name”:”Lectron Charging Station”,”part_number”:”EV-CHARGER48A-J1772″,”price”:”$523.74″,”description”:”V-BOX 240V 48A with NEMA 14-50 Plug – Compatible With All J1772 Electric Vehicles”},{“name”:”Lectron Electric Vehicle Charger Nozzle Holster Dock”,”part_number”:”J1772DHCOMBOBKNUSA”,”price”:”$24.65″,”description”:”EV Charger Nozzle Holster Dock and J-Hook Combination for J1772 Connector Electri…

6. YoCharge – Key Components of Electric Vehicles

Domain: yocharge.com

Registered: 2021 (4 years)

Introduction: The main components of electric vehicles include: 1. Traction Battery Pack: Powers the electric motors, stores energy in DC current, estimated lifetime of 200,000 miles. 2. DC-DC Converter: Distributes output power from the battery to different components and charges the auxiliary battery. 3. Electric Motor: Converts electrical energy into kinetic energy, features regenerative braking. 4. Power In…

Strategic Sourcing Conclusion and Outlook for electric vehicle parts

In conclusion, strategic sourcing in the electric vehicle (EV) parts sector is crucial for international B2B buyers looking to enhance their supply chains and operational efficiencies. By prioritizing partnerships with reliable suppliers, such as those offering advanced battery management systems, efficient charging solutions, and high-performance components, businesses can significantly reduce costs and improve product quality. The global demand for EV parts is on the rise, driven by an increasing emphasis on sustainability and technological innovation.

For buyers in regions like Africa, South America, the Middle East, and Europe, leveraging strategic sourcing not only ensures access to high-quality components but also fosters collaboration with manufacturers who understand local market dynamics. As the electric vehicle market continues to evolve, staying ahead of trends and technological advancements will be vital.

We encourage B2B buyers to actively engage with suppliers and explore diverse sourcing options to meet their unique needs. By doing so, they can position themselves favorably in a competitive landscape, ensuring they are well-equipped for the future of mobility. Embrace the opportunity to innovate and thrive in the expanding electric vehicle market today.