Introduction: Navigating the Global Market for electric car not built in battery

In the rapidly evolving landscape of electric vehicles, the emergence of electric cars not built with traditional batteries presents a unique opportunity and challenge for international B2B buyers. As companies look to source innovative transportation solutions that align with sustainability goals, understanding the nuances of battery-free electric vehicles becomes essential. This guide delves deep into the diverse types and applications of electric cars that operate without conventional batteries, such as the groundbreaking nanoFlowcell technology, which utilizes bi-ION solutions for energy storage and delivery.

By exploring the various models, their operational efficiencies, and the implications for different markets, this comprehensive resource equips buyers from Africa, South America, the Middle East, and Europe—like Brazil and Germany—with the insights needed to make informed purchasing decisions. The guide will cover critical aspects such as supplier vetting processes, cost considerations, and the regulatory landscape affecting these innovative vehicles.

Empowering businesses to navigate the complexities of sourcing battery-free electric cars, this guide aims to facilitate strategic investments that not only enhance operational capabilities but also contribute to a more sustainable future. By embracing these advanced technologies, companies can position themselves at the forefront of the green mobility revolution, aligning their fleets with emerging global standards and consumer expectations.

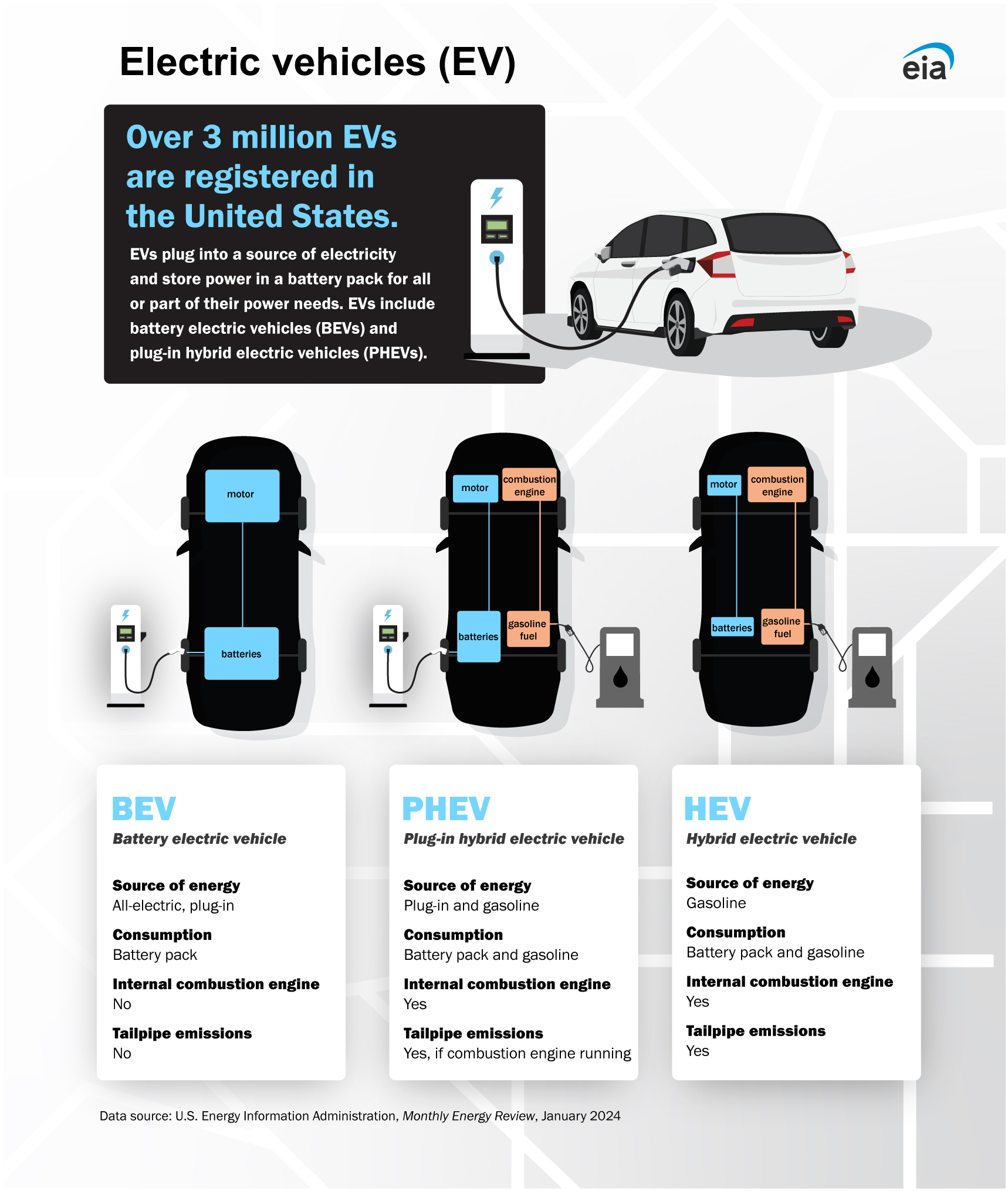

Understanding electric car not built in battery Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flow Cell Electric Vehicles | Uses liquid electrolytes instead of traditional batteries | Public transport, logistics, and fleet operations | Pros: Long range, quick refueling; Cons: Limited infrastructure and availability. |

| Supercapacitor Electric Cars | Employs supercapacitors for energy storage, offering rapid charging | Urban mobility solutions, short-distance transport | Pros: Fast charging, high power output; Cons: Limited range compared to batteries. |

| Hydrogen Fuel Cell Vehicles | Converts hydrogen into electricity using fuel cells | Heavy-duty transport, public transport, and emergency services | Pros: High efficiency and long range; Cons: Hydrogen production and refueling infrastructure challenges. |

| Electric Vehicles with Alternative Energy Sources | Integrates solar panels or wind turbines for energy generation | Sustainable transport solutions, eco-friendly fleets | Pros: Renewable energy use, reduced operational costs; Cons: Dependent on weather conditions. |

| Battery-Free Electric Vehicles | Utilizes alternative methods like kinetic energy recovery systems | Innovative urban transport, personal mobility solutions | Pros: No battery disposal concerns, lighter weight; Cons: Limited power and range capabilities. |

What Are Flow Cell Electric Vehicles and Their B2B Suitability?

Flow cell electric vehicles utilize liquid electrolytes to store and convert energy, providing a sustainable alternative to traditional battery-powered cars. They are particularly suited for public transport and logistics applications due to their impressive range and quick refueling capabilities, which can reach up to 2,000 kilometers. B2B buyers should consider the current infrastructure for flow cell technology, as it may not be as developed as conventional electric vehicle charging stations.

How Do Supercapacitor Electric Cars Function in Urban Mobility?

Supercapacitor electric cars store energy in supercapacitors, allowing for rapid charging and high power output. This technology is ideal for urban mobility solutions, such as short-distance transport and public transit systems where quick turnaround times are essential. B2B buyers should evaluate the trade-off between the limited range of these vehicles and their fast charging capabilities, particularly in high-demand urban environments.

What Are the Advantages of Hydrogen Fuel Cell Vehicles for Heavy-Duty Transport?

Hydrogen fuel cell vehicles generate electricity through the chemical reaction of hydrogen and oxygen, making them highly efficient and suitable for heavy-duty transport and public service applications. Their long range and quick refueling times are significant advantages for fleets. However, B2B buyers must address the challenges of hydrogen production and refueling infrastructure, which can limit the feasibility of adopting this technology in certain regions.

How Can Electric Vehicles with Alternative Energy Sources Benefit Sustainable Transport?

Electric vehicles that incorporate alternative energy sources, such as solar panels or wind turbines, offer a unique solution for sustainable transport. These vehicles can significantly reduce operational costs and reliance on fossil fuels. B2B buyers should consider the variability of energy generation based on environmental conditions, which can affect the vehicle’s efficiency and reliability in diverse climates.

What Are the Key Features of Battery-Free Electric Vehicles in Personal Mobility?

Battery-free electric vehicles leverage alternative energy storage methods, like kinetic energy recovery systems, to operate without traditional batteries. This innovation is particularly beneficial for personal mobility solutions, where weight and disposal concerns are critical. While they offer a lighter design and reduced environmental impact, B2B buyers should assess the limitations in power and range, which may restrict their application in more demanding transport scenarios.

Key Industrial Applications of electric car not built in battery

| Industry/Sector | Specific Application of electric car not built in battery | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Public Transportation | Electric taxis and ride-sharing services | Reduced operational costs and increased sustainability | Infrastructure compatibility and regulatory compliance |

| Tourism and Hospitality | Shuttle services for hotels and resorts | Enhanced guest experience and eco-friendly branding | Local refueling stations and service support |

| Logistics and Delivery | Last-mile delivery vehicles | Lower fuel costs and improved delivery efficiency | Vehicle range and refueling logistics |

| Municipal Services | Waste collection and public service vehicles | Lower emissions and operational cost savings | Maintenance support and local infrastructure |

| Agriculture | Electric utility vehicles for farming operations | Reduced fuel expenses and sustainable farming practices | Terrain adaptability and power requirements |

How Can Electric Cars Not Built in Battery Transform Public Transportation?

In the public transportation sector, electric taxis and ride-sharing services can greatly benefit from battery-free electric vehicles. These vehicles, utilizing innovative technologies like nanoFlowcell, offer reduced operational costs through lower fuel expenses and less maintenance. Additionally, they contribute to sustainability goals, appealing to environmentally conscious consumers. Buyers in this sector must ensure compatibility with existing infrastructure and adhere to local regulatory standards, particularly in regions where electric vehicle adoption is growing, such as Europe and Brazil.

What Advantages Do Battery-Free Electric Vehicles Offer in Tourism and Hospitality?

In the tourism and hospitality industry, electric vehicles serve as shuttles for hotels and resorts, enhancing the guest experience while promoting eco-friendly practices. Battery-free models provide rapid refueling capabilities, allowing for continuous service without long downtimes. This not only improves operational efficiency but also aligns with the increasing demand for sustainable tourism options. B2B buyers should consider local refueling infrastructure and the availability of service support to ensure seamless operations.

How Can Logistics and Delivery Benefit from Battery-Free Electric Vehicles?

Logistics and delivery companies can leverage battery-free electric vehicles for last-mile delivery solutions. These vehicles offer significant cost savings on fuel and maintenance, improving overall delivery efficiency. With the ability to travel long distances without the need for frequent charging, they are ideal for urban environments where quick service is essential. Buyers in this industry should focus on the vehicle’s range and the logistics of refueling to optimize their delivery operations, particularly in regions with developing infrastructure.

What Role Do Battery-Free Electric Vehicles Play in Municipal Services?

Municipal services, including waste collection and maintenance operations, can greatly benefit from the adoption of electric vehicles that do not rely on batteries. These vehicles contribute to lower emissions and operational costs, aligning with city sustainability initiatives. Additionally, their ability to refuel quickly makes them suitable for intensive daily operations. Buyers in this sector must ensure that the vehicles meet local maintenance and operational requirements, as well as evaluate the infrastructure necessary for effective refueling.

How Can Agriculture Utilize Battery-Free Electric Vehicles for Sustainable Practices?

In agriculture, battery-free electric utility vehicles can facilitate various operations such as crop management and transportation of goods. These vehicles help reduce fuel expenses, supporting sustainable farming practices that are increasingly demanded by consumers. Buyers should consider the adaptability of these vehicles to different terrains and their power requirements to ensure they meet the specific needs of agricultural operations, particularly in diverse environments found in Africa and South America.

3 Common User Pain Points for ‘electric car not built in battery’ & Their Solutions

Scenario 1: The Challenge of Limited Charging Infrastructure

The Problem: For B2B buyers looking to adopt electric vehicles (EVs) without traditional batteries, one of the most pressing concerns is the availability of charging infrastructure. In regions like Africa and South America, where the electric grid may not be robust or widespread, the challenge is exacerbated. Companies may struggle to find reliable and accessible refueling stations that can accommodate innovative systems like the nanoFlowcell’s bi-ION technology. This can lead to operational inefficiencies, delayed deliveries, and increased costs as businesses may need to invest heavily in their own refueling solutions.

The Solution: To effectively address this challenge, B2B buyers should engage with local governments and energy providers to explore partnerships that can expand the refueling infrastructure. Additionally, businesses can conduct feasibility studies to identify optimal locations for establishing their own refueling stations, especially in high-traffic areas. Investing in a mobile refueling unit that can transport bi-ION electrolyte solutions to various locations can also enhance operational flexibility. Companies should prioritize collaboration with technology partners specializing in renewable energy solutions to develop a sustainable and accessible refueling network tailored to their specific needs.

Scenario 2: Navigating Regulatory and Compliance Hurdles

The Problem: As the market for battery-free electric vehicles evolves, navigating the regulatory landscape can be daunting for B2B buyers. Different regions, such as Europe and the Middle East, have varying regulations regarding vehicle safety, emissions, and operational standards. Buyers may find themselves grappling with compliance issues, which can delay project timelines and increase costs. This uncertainty can hinder the decision-making process when considering the adoption of cutting-edge technologies like nanoFlowcell systems.

The Solution: To mitigate these challenges, B2B buyers should invest time in understanding the regulatory frameworks specific to each market they operate in. Consulting with legal experts who specialize in automotive regulations can provide clarity on compliance requirements. Additionally, buyers should engage with manufacturers that have already obtained necessary certifications, such as TÜV approval for safety and quality standards. This not only streamlines the compliance process but also offers a competitive edge, ensuring that businesses remain aligned with both local and international regulations.

Scenario 3: Addressing Concerns Over Range and Performance

The Problem: One of the primary concerns for B2B buyers considering electric vehicles not built on traditional battery systems is the perceived limitations regarding range and overall performance. Potential users may be skeptical about whether vehicles powered by nanoFlowcell technology can meet their operational demands, particularly in industries requiring high mobility and long-distance travel, such as logistics and transportation. This skepticism can hinder purchasing decisions and slow down the adoption of innovative solutions.

The Solution: To build confidence among stakeholders, B2B buyers should prioritize comprehensive testing and demonstration of the technology. Collaborating with manufacturers to organize trial runs can provide firsthand experience of the vehicles’ performance, showcasing their capabilities in real-world scenarios. Buyers should also gather data on the range and efficiency of vehicles powered by nanoFlowcell technology, comparing them against traditional electric vehicles to highlight advantages. Additionally, offering testimonials from early adopters can serve to alleviate concerns and demonstrate the reliability and effectiveness of battery-free electric vehicles in meeting diverse operational needs.

Strategic Material Selection Guide for electric car not built in battery

What Materials Are Commonly Used in Electric Cars Not Built with Traditional Batteries?

In the evolving landscape of electric vehicles (EVs) that do not rely on conventional batteries, material selection plays a crucial role in ensuring performance, safety, and sustainability. Here, we analyze several materials commonly used in battery-free electric cars, focusing on their properties, advantages, limitations, and considerations for international B2B buyers.

Which Lightweight Composites Are Suitable for Electric Cars Without Batteries?

Carbon Fiber Reinforced Polymer (CFRP)

CFRP is known for its high strength-to-weight ratio, making it an ideal choice for electric vehicles aiming for enhanced performance and efficiency. It exhibits excellent corrosion resistance and can withstand high temperatures, which is critical for components exposed to heat during operation. However, CFRP is relatively expensive and requires specialized manufacturing processes, which can complicate production.

From a B2B perspective, buyers should consider the cost implications of CFRP, especially in regions like Africa and South America, where budget constraints may limit its use. Compliance with international standards such as ASTM and DIN is essential to ensure quality and safety.

How Does Aluminum Fit into the Design of Battery-Free Electric Vehicles?

Aluminum

Aluminum is a widely used material in the automotive industry due to its lightweight nature and good corrosion resistance. It is relatively easy to manufacture and can be extruded or molded into complex shapes, making it versatile for various applications in electric cars. However, while aluminum is more affordable than CFRP, it may not offer the same level of strength, especially in high-stress applications.

International buyers should be aware of the varying standards for aluminum alloys used in automotive applications. Compliance with specific regional regulations, such as those in Europe and the Middle East, is crucial for market acceptance.

What Role Does Steel Play in Battery-Free Electric Vehicles?

High-Strength Steel (HSS)

High-strength steel is often utilized in structural components due to its durability and cost-effectiveness. It has excellent tensile strength and can withstand significant stress, making it suitable for safety-critical parts. However, HSS is heavier than aluminum and CFRP, which could affect the overall efficiency of electric vehicles.

For B2B buyers in regions like Brazil and Germany, understanding the local manufacturing capabilities and standards for HSS is important. Compliance with safety standards, such as those outlined by JIS in Japan or DIN in Germany, can influence procurement decisions.

How Do Advanced Polymers Contribute to Electric Vehicle Design?

Polycarbonate (PC)

Polycarbonate is a durable and lightweight thermoplastic that is often used for windows and other transparent components in electric vehicles. It offers excellent impact resistance and can withstand a range of temperatures, making it suitable for various environmental conditions. However, its UV sensitivity can lead to degradation over time if not properly treated.

International buyers should consider the specific applications of polycarbonate in their vehicles, particularly in regions with extreme weather conditions. Compliance with environmental regulations regarding plastic use is also a consideration for buyers in Europe and the Middle East.

Summary Table of Material Selection for Battery-Free Electric Cars

| Material | Typical Use Case for electric car not built in battery | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Fiber Reinforced Polymer | Structural components, body panels | High strength-to-weight ratio | High cost, complex manufacturing | High |

| Aluminum | Chassis, body panels | Lightweight, corrosion resistant | Lower strength compared to CFRP | Medium |

| High-Strength Steel | Safety-critical structural parts | Excellent tensile strength | Heavier, may affect efficiency | Low |

| Polycarbonate | Windows, transparent components | Impact resistance, lightweight | UV sensitivity, potential degradation | Medium |

By understanding the properties and implications of these materials, international B2B buyers can make informed decisions that align with their operational needs and market standards.

In-depth Look: Manufacturing Processes and Quality Assurance for electric car not built in battery

What Are the Main Stages in the Manufacturing Process of Electric Cars Not Built in Battery?

The manufacturing process of electric cars, particularly those designed without traditional batteries, involves several critical stages. Understanding these stages is essential for B2B buyers to assess the capabilities of potential suppliers.

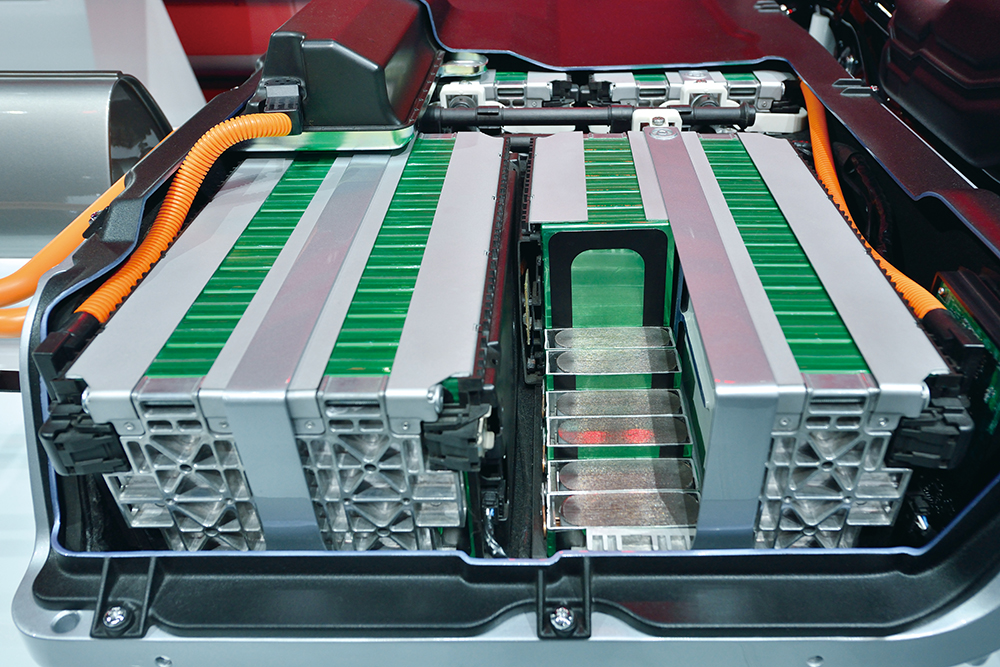

Material Preparation

The first step is material preparation, where various components are sourced and processed. In the case of battery-free electric vehicles, materials such as lightweight metals, composites, and specialized polymers are often prioritized to enhance efficiency and performance. Suppliers must ensure that materials meet international safety and environmental standards, which can significantly impact the vehicle’s overall quality.

Forming Techniques

Once materials are prepared, forming techniques come into play. This stage typically involves advanced manufacturing methods such as:

- CNC Machining: Used for precision parts that require exact specifications.

- Injection Molding: Common for producing complex plastic components, ensuring uniformity and reducing waste.

- Metal Stamping: Utilized for creating car body panels, ensuring structural integrity while minimizing weight.

Employing these techniques helps in achieving high precision and consistency, essential for the performance and safety of electric vehicles.

Assembly Processes

The assembly process is where the vehicle’s various components are integrated. For electric cars without batteries, this includes:

- Integration of Power Systems: Incorporating alternative energy systems, such as nanoFlowcell technology, which utilizes liquid electrolytes instead of conventional batteries.

- Installation of Electronic Systems: Ensuring that all electronic components function seamlessly together is critical. This includes the vehicle’s control systems, safety features, and infotainment systems.

Efficient assembly lines often use lean manufacturing principles to minimize waste and improve throughput, which is crucial for meeting international demand.

Finishing Touches

The final stage, finishing, involves painting, coating, and quality checks. Aesthetics are important in automotive design, and advanced techniques such as robotic painting ensure a high-quality finish. Additionally, surface treatments are applied to enhance durability and resistance to corrosion, which is particularly important for vehicles expected to operate in diverse climates, such as those found in Africa or South America.

How Is Quality Assurance Implemented in Battery-Free Electric Vehicles?

Quality assurance (QA) is a vital aspect of manufacturing electric vehicles, ensuring that every unit produced meets stringent quality standards and safety regulations. This process involves several checkpoints and international standards.

What International Standards Should B2B Buyers Look For?

B2B buyers should be familiar with various international standards that govern quality assurance in automotive manufacturing:

- ISO 9001: This standard focuses on quality management systems and ensures that organizations consistently provide products that meet customer and regulatory requirements.

- ISO 26262: Specifically for automotive safety, this standard addresses the functional safety of electrical and electronic systems in vehicles.

- CE Marking: Particularly relevant for the European market, CE marking indicates compliance with safety, health, and environmental protection standards.

Understanding these standards helps B2B buyers assess the credibility of their suppliers and the quality of the vehicles they produce.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is implemented at various stages of the manufacturing process, typically classified into three main checkpoints:

- Incoming Quality Control (IQC): This initial checkpoint ensures that all raw materials and components meet specified quality standards before production begins.

- In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC involves regular inspections and tests to identify defects early, ensuring that corrective actions can be taken promptly.

- Final Quality Control (FQC): This final checkpoint includes comprehensive testing of the completed vehicle. It assesses safety features, performance metrics, and compliance with all relevant standards.

Each checkpoint is essential for ensuring that the final product is not only functional but also safe for consumers.

What Common Testing Methods Are Used for Quality Assurance?

Various testing methods are employed throughout the manufacturing process to ensure quality assurance:

- Performance Testing: Evaluates the vehicle’s efficiency, range, and handling characteristics.

- Safety Testing: Involves crash tests and assessments of electronic safety systems to ensure compliance with safety regulations.

- Environmental Testing: Simulates various environmental conditions to assess how the vehicle performs in different climates.

These testing methods are crucial for validating the integrity and reliability of electric cars, particularly those utilizing innovative technologies.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying a supplier’s quality control measures is essential for ensuring the reliability of the products. Here are some actionable strategies:

- Supplier Audits: Conducting regular audits of suppliers allows buyers to assess compliance with quality standards and manufacturing processes. This can include on-site inspections and reviews of quality management systems.

- Quality Assurance Reports: Requesting detailed QA reports from suppliers can provide insights into their manufacturing processes, including results from IQC, IPQC, and FQC stages.

- Third-Party Inspections: Engaging independent third-party inspectors can provide an unbiased assessment of a supplier’s quality control measures and product quality.

By implementing these strategies, buyers can mitigate risks associated with quality and ensure they receive high-quality products.

What Are the Specific QC and Certification Nuances for International B2B Buyers?

International B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification:

- Regional Compliance Requirements: Different regions may have unique compliance standards that must be met. For example, vehicles sold in Europe must adhere to strict EU regulations, while those in the Middle East may have different criteria.

- Certification Recognition: Ensure that certifications held by suppliers are recognized in the target markets. For example, TÜV certifications are highly regarded in Germany, and their presence can enhance supplier credibility.

- Cultural and Market Variability: Understanding cultural differences in quality expectations can help in negotiating terms and ensuring that products meet local standards.

Being aware of these nuances can empower B2B buyers to make informed decisions when selecting suppliers in the competitive electric vehicle market.

Conclusion

Understanding the manufacturing processes and quality assurance protocols for electric cars not built in batteries is crucial for B2B buyers. By familiarizing themselves with the stages of production, relevant international standards, QC checkpoints, testing methods, and verification strategies, buyers can ensure they partner with reliable suppliers capable of meeting their quality expectations. This knowledge not only enhances procurement strategies but also aligns with the evolving landscape of sustainable automotive solutions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric car not built in battery’

Introduction

This guide is designed to assist B2B buyers in sourcing electric cars that operate without traditional battery systems. As the automotive industry shifts towards sustainable solutions, understanding the nuances of battery-free electric vehicles, such as those powered by innovative technologies like nanoFlowcell, is essential for making informed procurement decisions. This checklist will ensure that you evaluate all critical factors before finalizing your purchase.

Step 1: Define Your Technical Specifications

Establish clear technical specifications for the electric vehicle you intend to procure. This includes aspects such as range, power output, and charging/refueling technology. Understanding your operational requirements will help you identify models that align with your business needs and environmental goals.

- Range Requirements: Determine how far the vehicle needs to travel on a single refueling.

- Power Output: Identify the power specifications necessary for your operations, considering factors like load capacity and terrain.

Step 2: Research Available Technologies

Investigate the various technologies available in battery-free electric vehicles. Options like nanoFlowcell and other innovative systems have unique advantages and limitations. Understanding these technologies will aid in assessing which vehicle aligns best with your operational needs.

- Technology Types: Explore the differences between flow cell technology and other alternatives.

- Efficiency Metrics: Look into the efficiency and environmental impact of each technology.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, it is crucial to vet potential suppliers thoroughly. Request comprehensive company profiles, product specifications, and references from other businesses that have procured similar vehicles. This step ensures you are engaging with reputable manufacturers.

- Supplier Background: Assess the supplier’s history and expertise in battery-free electric vehicles.

- Client Testimonials: Seek feedback from existing clients to gauge reliability and performance.

Step 4: Verify Regulatory Compliance

Ensure that the vehicle complies with all relevant safety and quality standards, particularly for international markets. Certifications such as TÜV and WMI are indicators of a manufacturer’s commitment to meeting global regulations.

- Documentation Review: Request copies of certifications and compliance documents.

- Market-Specific Regulations: Be aware of specific regulations in your target markets, especially in regions like Africa and Europe.

Step 5: Conduct a Cost-Benefit Analysis

Perform a thorough cost-benefit analysis comparing the initial investment against long-term operational savings and environmental benefits. Battery-free electric cars may offer lower maintenance costs and reduced environmental impact, which can be crucial for your business model.

- Total Cost of Ownership: Include maintenance, refueling, and operational costs in your analysis.

- Environmental Impact: Consider the sustainability benefits and how they align with your corporate responsibility goals.

Step 6: Arrange Test Drives and Demonstrations

Where possible, arrange for test drives or demonstrations of the vehicles you are considering. This step allows you to assess the vehicle’s performance, comfort, and usability firsthand, ensuring it meets your expectations.

- Performance Assessment: Evaluate how the vehicle handles under conditions similar to those it will face in your operations.

- User Experience: Gather feedback from potential drivers to ensure the vehicle meets ergonomic and functional needs.

Step 7: Finalize Contracts and Terms

Once you have chosen a supplier and vehicle, ensure that all contractual terms are clear and favorable. Pay attention to warranties, service agreements, and any clauses related to technology updates or support.

- Warranties and Support: Ensure you understand the support structure and what is covered under warranty.

- Payment Terms: Clarify payment schedules and any financing options available.

By following this checklist, you will be well-equipped to make informed decisions when sourcing electric cars that do not rely on traditional battery systems, ultimately leading to successful procurement outcomes.

Comprehensive Cost and Pricing Analysis for electric car not built in battery Sourcing

Understanding the cost structure and pricing dynamics of electric cars not built on traditional battery systems is crucial for international B2B buyers. This analysis will break down the cost components, price influencers, and provide actionable buyer tips to navigate the complexities of sourcing in this innovative sector.

What Are the Key Cost Components in Sourcing Battery-Free Electric Cars?

-

Materials: The primary materials for battery-free electric cars include advanced composite materials for lightweight construction, nanoFlowcell technology components, and bi-ION electrolyte solutions. The cost of these materials can vary significantly based on market demand, supplier contracts, and the availability of eco-friendly alternatives.

-

Labor: Labor costs encompass skilled workers for assembly and engineers for design and development. The geographical location of manufacturing facilities can influence labor expenses, with regions in Europe and North America generally having higher labor costs compared to parts of Africa and South America.

-

Manufacturing Overhead: This includes utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can help mitigate these costs, particularly in plants that utilize automation and advanced production techniques.

-

Tooling: Tooling costs are associated with the creation of molds and machines required for production. These costs are typically amortized over the volume of units produced, meaning larger orders can reduce the per-unit tooling expense.

-

Quality Control (QC): Implementing stringent QC measures is essential to ensure the safety and reliability of electric vehicles. The costs associated with QC processes, including testing and certification, can impact overall pricing but are critical for maintaining quality standards, particularly for international markets.

-

Logistics: Transportation costs must be factored into the overall price, influenced by the distance from manufacturing sites to buyer locations, shipping methods, and customs duties. Efficient logistics management can lead to cost savings.

-

Margin: Manufacturers will typically add a profit margin to cover their costs and ensure sustainability. This margin can vary widely based on competition, brand reputation, and market positioning.

What Influences Pricing for Battery-Free Electric Cars?

Several factors can significantly affect pricing structures:

-

Volume/MOQ: Minimum order quantities (MOQs) can lead to price breaks. Buyers seeking larger volumes may negotiate better rates, making it essential to understand the manufacturer’s pricing strategy.

-

Specifications and Customization: Custom features or specifications can increase production costs, leading to higher prices. Buyers should clarify their needs upfront to avoid unexpected costs.

-

Materials: The choice of materials directly influences both the manufacturing cost and final price. Eco-friendly materials may carry a premium but can appeal to environmentally conscious consumers.

-

Quality Certifications: Vehicles meeting international safety and environmental standards may incur additional costs during production, reflecting in the final pricing.

-

Supplier Factors: Supplier reliability, reputation, and production capabilities can affect pricing. Conducting thorough due diligence on suppliers can yield better pricing and quality assurances.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) can impact the total landed cost of the vehicle. Buyers should understand the implications of terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) to assess total costs accurately.

What Tips Can Help B2B Buyers Negotiate Better Prices?

-

Leverage Negotiation: Use volume commitments and long-term contracts to negotiate better pricing. Suppliers may offer discounts for guaranteed orders.

-

Focus on Total Cost of Ownership (TCO): Beyond upfront costs, consider maintenance, energy efficiency, and resale value when evaluating the overall cost. This approach can yield significant savings in the long run.

-

Understand Pricing Nuances for International Markets: Currency fluctuations, tariffs, and local regulations can impact pricing. Buyers should factor these into their financial assessments, especially in regions like Africa and South America.

-

Stay Informed on Market Trends: Keeping abreast of technological advancements and shifts in supply chains can provide leverage in negotiations and sourcing strategies.

-

Request Indicative Pricing: While prices can vary based on multiple factors, requesting indicative pricing from multiple suppliers can help establish a baseline for negotiations.

In conclusion, navigating the cost and pricing landscape of battery-free electric cars requires a comprehensive understanding of various components and market dynamics. By employing strategic negotiation techniques and a focus on total cost considerations, B2B buyers can effectively source innovative electric vehicles that meet their operational needs while optimizing costs.

Alternatives Analysis: Comparing electric car not built in battery With Other Solutions

Introduction: Exploring Alternatives to Battery-Free Electric Cars

As the automotive industry pivots towards sustainable mobility solutions, the emergence of electric cars that operate without traditional batteries presents a compelling alternative. This innovation, such as the QUANTiNO twentyfive utilizing nanoFlowcell technology, prompts B2B buyers to evaluate various transportation methods that align with environmental goals, operational efficiency, and cost-effectiveness. In this analysis, we will compare battery-free electric vehicles with hydrogen fuel cell vehicles and traditional electric vehicles powered by lithium-ion batteries.

| Comparison Aspect | Electric Car Not Built In Battery | Hydrogen Fuel Cell Vehicle | Traditional Electric Vehicle (Battery-Powered) |

|---|---|---|---|

| Performance | Up to 2,000 km range; quick refueling | Similar range; refueling takes minutes | Range varies (150-500 km); charging time varies |

| Cost | Premium pricing; low operational cost | Higher initial cost; moderate operational cost | Moderate to high upfront cost; lower long-term operational costs |

| Ease of Implementation | Requires specialized refueling stations | Limited refueling infrastructure; growing network | Established charging infrastructure; requires charging stations |

| Maintenance | Lower maintenance due to fewer moving parts | Moderate maintenance; fuel cells require regular checks | Higher maintenance due to battery degradation over time |

| Best Use Case | Ideal for long-distance travel with rapid refueling needs | Suitable for commercial fleets and long-haul transport | Best for urban commuting and short to mid-range travel |

Detailed Breakdown of Alternatives

Hydrogen Fuel Cell Vehicles: Advantages and Disadvantages

Hydrogen fuel cell vehicles (FCVs) convert hydrogen gas into electricity, producing only water as a byproduct. They offer a similar range to battery-free electric cars and can be refueled in a matter of minutes, making them ideal for long-haul transport and commercial applications. However, the infrastructure for hydrogen refueling is still developing, which may limit their practicality in certain regions. Additionally, the production of hydrogen can be energy-intensive, impacting the overall sustainability of this solution.

Traditional Electric Vehicles (Battery-Powered): Advantages and Disadvantages

Traditional electric vehicles rely on lithium-ion batteries, providing a well-established technology with a growing charging infrastructure. These vehicles are excellent for urban environments where charging stations are readily available. However, they face challenges such as longer charging times, range anxiety, and battery degradation over time, which can lead to higher maintenance costs. Furthermore, the initial purchase price can be a barrier for some businesses, although incentives may be available in various markets.

Conclusion: How to Choose the Right Solution for Your Needs

When evaluating alternatives to battery-free electric cars, B2B buyers should consider their specific operational needs, geographical context, and long-term sustainability goals. Hydrogen fuel cell vehicles may offer quick refueling and are suitable for commercial applications but depend on developing infrastructure. In contrast, traditional electric vehicles are more established but come with limitations in range and charging times. Ultimately, the best choice will align with the buyer’s operational requirements, budget constraints, and commitment to sustainable practices. By thoroughly analyzing these options, businesses can make informed decisions that benefit both their bottom line and the environment.

Essential Technical Properties and Trade Terminology for electric car not built in battery

What Are the Key Technical Properties of Electric Cars Not Built in Battery?

Understanding the technical specifications of electric cars that do not utilize traditional battery systems is crucial for B2B buyers. Here are some essential properties that should be considered:

-

Powertrain Configuration

– Definition: This refers to the arrangement of the electric drive system, including the type of electric motors and their configuration.

– B2B Importance: Buyers need to understand how the powertrain affects performance, efficiency, and maintenance. Different configurations can lead to variations in torque, acceleration, and overall vehicle responsiveness, impacting customer satisfaction and marketability. -

Energy Source Type

– Definition: This specifies the type of energy used to power the vehicle, such as liquid electrolytes in nanoFlowcell technology.

– B2B Importance: Identifying the energy source is essential for understanding operational costs and refueling infrastructure requirements. For markets in regions like Africa and South America, where charging infrastructure may be limited, alternative energy sources can provide a competitive advantage. -

Range Capability

– Definition: This refers to the maximum distance the vehicle can travel on a single refueling or energy source replenishment.

– B2B Importance: Range is a critical factor for consumers. Understanding the range capabilities allows B2B buyers to position their offerings effectively, addressing concerns about range anxiety in target markets. -

Charging/Refueling Time

– Definition: The duration required to fully refuel the vehicle’s energy source.

– B2B Importance: Faster refueling times enhance user convenience and are a significant selling point. Buyers should assess how this affects operational efficiency, especially in commercial applications where downtime can impact profitability. -

Vehicle Weight and Material Composition

– Definition: This includes the overall weight of the vehicle and the materials used in its construction.

– B2B Importance: Lighter vehicles typically offer better efficiency and performance. Understanding material grades and their respective tolerances can inform purchasing decisions related to durability, safety, and compliance with international standards.

Which Trade Terminology Should B2B Buyers Understand?

Familiarity with industry jargon can facilitate smoother negotiations and partnerships. Here are key terms relevant to electric cars not built in battery:

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces components or vehicles that are used in another company’s end product.

– Importance: Understanding OEM relationships is crucial for buyers looking to source components or vehicles. It can influence the quality and reliability of the products they offer. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers assess inventory requirements and manage cash flow effectively, especially when entering new markets. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing information for specific products or services.

– Importance: Issuing an RFQ allows buyers to compare prices and terms from different suppliers, helping them make informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of rules that define the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms is essential for understanding shipping costs, risk management, and logistics, particularly for international buyers from diverse regions. -

TÜV Certification

– Definition: A certification mark that indicates compliance with specific safety and quality standards, often required for vehicles in Europe.

– Importance: TÜV certification can enhance product credibility and market acceptance, making it vital for buyers targeting European markets.

By grasping these technical properties and trade terms, B2B buyers can better navigate the evolving landscape of electric vehicles, enabling informed decisions that align with their strategic objectives.

Navigating Market Dynamics and Sourcing Trends in the electric car not built in battery Sector

What Are the Current Market Dynamics and Key Trends in the Electric Car Not Built in Battery Sector?

The electric vehicle market is undergoing a significant transformation, particularly with the emergence of battery-free technologies, like the nanoFlowcell system. This shift is driven by the need for sustainable alternatives to traditional battery-operated vehicles, which face limitations such as long charging times and environmental concerns surrounding lithium extraction. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should note that innovations in electric mobility are fostering new sourcing opportunities. For instance, the QUANTiNO twentyfive showcases a fully electric vehicle that operates without conventional batteries, leveraging a bi-ION electrolyte solution for energy storage.

As governments worldwide push for greener transportation solutions, regulatory frameworks are becoming more supportive of battery-free electric vehicles. Countries like Germany are investing heavily in R&D for these technologies, while nations in Africa and South America are exploring electric mobility to leapfrog traditional fuel-based transportation systems. Furthermore, there is a growing trend towards modular and scalable production processes, enabling manufacturers to respond quickly to varying demands across international markets.

How Can Sustainability and Ethical Sourcing Impact B2B Decisions in the Electric Car Sector?

Sustainability is becoming a non-negotiable aspect of B2B purchasing decisions in the electric vehicle sector. The environmental impact of sourcing materials for traditional batteries has raised concerns about ethical supply chains, particularly regarding lithium and cobalt mining. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices and transparent sourcing.

In the context of battery-free electric cars, the use of eco-friendly materials and processes, such as the bi-ION solution utilized by the QUANTiNO twentyfive, presents a compelling case for ethical sourcing. Companies that obtain certifications such as ISO 14001 for environmental management or are compliant with green supply chain standards are more likely to attract B2B partnerships. Furthermore, companies that proactively engage in carbon offset initiatives and promote circular economy principles will resonate better with environmentally conscious buyers, paving the way for long-term business relationships.

What Is the Brief Evolution and History of Battery-Free Electric Vehicles?

The evolution of electric vehicles has seen a resurgence in interest, particularly as technology has advanced to address the limitations of traditional battery systems. Early electric vehicles, dating back to the 19th century, were hampered by the inefficiency of non-rechargeable batteries. The breakthrough came with the development of rechargeable batteries, but the sector has continued to seek improvements in efficiency and sustainability.

Recent innovations, such as flow cell technology, represent a significant leap forward. The QUANTiNO twentyfive, which operates without conventional batteries, exemplifies this shift. By utilizing a bi-ION electrolyte solution, this vehicle can achieve remarkable ranges—up to 2,000 kilometers—without the need for traditional refueling infrastructure. As the market for electric vehicles evolves, B2B buyers are presented with new opportunities to engage with innovative technologies that promise to redefine the future of sustainable mobility.

Frequently Asked Questions (FAQs) for B2B Buyers of electric car not built in battery

-

How do I evaluate suppliers of electric cars not built in battery?

To effectively evaluate suppliers, begin by researching their industry reputation and certifications, such as TÜV or ISO standards. Assess their production capabilities and technology, ensuring they align with your quality requirements. Request references or case studies from previous clients, especially those in your region. Additionally, consider their ability to provide after-sales support and spare parts, as these factors are crucial for long-term partnerships. Engaging in a preliminary trial order can also help gauge their reliability and product performance. -

What is the best way to negotiate payment terms for electric cars not built in battery?

Negotiating payment terms involves understanding your cash flow and the supplier’s payment expectations. Aim for terms that allow you to maintain liquidity while ensuring the supplier feels secure. Common arrangements include upfront deposits with the balance due upon delivery or after a specified trial period. Be transparent about your financial capabilities and explore options like letters of credit for international transactions, which can offer both parties security. Always document agreed terms clearly in the contract to avoid disputes. -

What are the minimum order quantities (MOQ) for electric cars without batteries?

Minimum order quantities can vary significantly by supplier and the specific model of the vehicle. It’s crucial to discuss your needs with potential suppliers upfront. Some manufacturers may have flexible MOQs, especially for new clients or during promotional periods. However, larger orders often result in better pricing and lead times, so consider planning your purchases accordingly. Always confirm any MOQ requirements in the supplier’s contract to prevent misunderstandings. -

How can I ensure the quality of electric cars not built in battery?

To ensure quality, request detailed specifications and compliance documents from the supplier. Conduct thorough quality assurance inspections during production and prior to shipment. You might also consider third-party inspections to verify product standards meet your requirements. Establish clear communication channels with the supplier to address any concerns promptly. Additionally, you can request samples or prototypes for testing before placing a bulk order, allowing you to assess performance and quality firsthand. -

What customization options are available for electric cars not built in battery?

Customization options often include design modifications, specific features, and technology integrations based on your business needs. Discuss your requirements with the supplier early in the negotiation process to understand their capabilities. Some manufacturers may offer bespoke solutions, such as tailored interiors or specialized performance features. Be sure to inquire about lead times and any additional costs associated with customization, as these can affect your overall budget and timeline. -

How do logistics and shipping work for electric cars not built in battery?

Logistics for shipping electric cars typically involve collaboration with freight forwarders experienced in handling automotive transport. Ensure your supplier has a well-defined logistics plan, including packaging, insurance, and customs documentation. Discuss the shipping terms, such as Incoterms, to clarify responsibilities regarding transport costs and risks. Additionally, factor in potential tariffs and regulations in your destination country, as these can impact delivery timelines and overall costs. -

What are the key regulatory considerations for importing electric cars not built in battery?

Importing electric cars requires compliance with local regulations, including safety standards, emissions regulations, and import tariffs. Research the specific requirements in your target market, such as certification processes and documentation needed for customs clearance. Engage with local authorities or customs brokers to ensure you meet all legal obligations. Additionally, staying updated on changing regulations can help mitigate risks and ensure smooth importation. -

What are the advantages of sourcing electric cars not built in battery compared to traditional electric vehicles?

Sourcing electric cars that do not rely on traditional batteries can offer several advantages, such as reduced weight and potentially lower production costs. These vehicles may feature longer ranges and quicker refueling times due to innovative technologies like flow cell systems. Additionally, they can provide a unique selling proposition in your market, appealing to environmentally conscious consumers. Understanding these benefits can help you strategically position your offerings and meet the evolving demands of the automotive market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Electric Car Not Built In Battery Manufacturers & Suppliers List

1. Reddit – Swappable Batteries for EVs

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The discussion revolves around the concept of swappable batteries for electric vehicles (EVs). Key points include: 1. Current EVs typically have one large battery, while the proposed idea suggests using multiple smaller batteries. 2. A battery-swapping station would use a mechanical arm to replace depleted batteries with charged ones in under a minute. 3. Challenges include the high cost of buildi…

2. Chongqing Changan – Battery-Electric Compact Vehicles

Domain: bloomberg.com

Registered: 1993 (32 years)

Introduction: China’s abandoned electric cars, primarily battery-electric compact vehicles manufactured by Chongqing Changan Automobile Co., have been left in graveyards across cities like Hangzhou. These vehicles were mostly operated by ride-hailing companies such as Didi Chuxing Technology Co. and Faststep Automobile Management. The cars were registered before December 2017, indicated by blue plates, and some…

3. Iberdrola – Electric Vehicle Innovation

Domain: iberdrola.com

Registered: 1998 (27 years)

Introduction: The first electric car, the Flocken Elektrowagen, was invented in 1888 in Germany by Andreas Flocken. It had a design similar to a buggy, featured four wheels, a 0.7 kW motor, a 100 kg battery, and could reach speeds of 15 km/h. The first electric motor was created by Ányos Jedlik around 1828, and the first prototype of an electric car was developed by Robert Anderson between 1832 and 1839. The br…

4. NanoFlowcell – QUANTiNO Twentyfive

Domain: nanoflowcell.com

Registered: 2013 (12 years)

Introduction: QUANTiNO twentyfive is a fully electric roadster powered by nanoFlowcell® and bi-ION® technology, operating without traditional batteries. It features a revolutionary nanoFlowcell® 48VOLT electric drive system, achieving a range of up to 2,000 kilometers. The vehicle is designed with a compact electrolytic capacitor that initiates the e-drive, supplying power to four low-voltage e-motors. It has t…

5. The Guardian – Electric Vehicles

Domain: theguardian.com

Registered: 1994 (31 years)

Introduction: Electric vehicles (EVs) are fast, quiet, and until recently, cheap to run. However, their environmental benefits are questioned due to high greenhouse gas emissions during production, particularly from lithium-ion batteries, which are heavy and energy-intensive to manufacture. Solid-state batteries are being developed as a lighter alternative but are years away from market availability. Hydrogen f…

6. The Conversation – Swappable EV Batteries

Domain: theconversation.com

Registered: 2003 (22 years)

Introduction: Swappable batteries for electric vehicles (EVs) could help revive declining sales. Key details include: 1. Adoption of EVs in western countries is slowing, with UK market share for new EVs projected at 20% in 2024, below the 22% government goal. 2. Hybrid vehicles are gaining market share, with a rise from 25% to 30% in Europe. 3. Swappable battery technology is thriving in India, particularly for…

7. Energy Saving Trust – Electric Vehicles

Domain: energysavingtrust.org.uk

Registered: 2000 (25 years)

Introduction: Electric vehicles (EVs) are crucial for reducing transport emissions and achieving net zero targets in the UK. They produce zero tailpipe emissions and are gaining popularity, especially with the upcoming ban on new petrol and diesel car sales by 2035. The history of electric cars dates back to the early 19th century, with significant milestones including: 1832 – First crude electric vehicle by Ro…

8. Pod Point – Solo 3S Charger

Domain: pod-point.com

Registered: 2009 (16 years)

Introduction: Pod Point offers home charging solutions for electric vehicles (EVs), including the Solo 3S Charger with next day and weekend installations available. The product includes a 5-year warranty for added peace of mind. The Pod Point App provides a complete guide on EV charging costs and management. The company also offers business solutions for workplace EV charging and has a focus on efficient instal…

Strategic Sourcing Conclusion and Outlook for electric car not built in battery

As the electric vehicle (EV) market evolves, the emergence of battery-free electric cars, such as the QUANTiNO twentyfive, signifies a pivotal shift in sustainable mobility. By leveraging innovative technologies like nanoFlowcell, these vehicles promise extended ranges and faster refueling times, making them appealing options for international B2B buyers looking to invest in environmentally-friendly transportation solutions.

Strategic sourcing in this domain is crucial. Buyers must prioritize partnerships with manufacturers that adhere to global safety and quality standards while also being adaptable to the unique needs of different markets, particularly in regions like Africa, South America, the Middle East, and Europe. The integration of battery-free technologies not only reduces dependency on traditional batteries but also aligns with growing regulatory frameworks aimed at enhancing sustainability.

Looking ahead, international buyers are encouraged to explore and engage with emerging technologies that can reshape the future of electric mobility. By investing in battery-free electric vehicles, businesses can not only enhance their operational efficiencies but also contribute to a greener planet. Embrace this opportunity to lead in the transition toward sustainable transportation.