Introduction: Navigating the Global Market for tractor Truck Assembly

In a rapidly evolving global market, sourcing reliable tractor truck assembly solutions presents a significant challenge for international B2B buyers. The complexity of assembling heavy-duty vehicles, combined with the need for customization and adherence to various regulatory standards, can make the selection process daunting. This guide aims to demystify the intricacies of tractor truck assembly by providing a comprehensive overview of the types of trucks available, their applications across industries, and the critical factors to consider when vetting suppliers.

From understanding the assembly line processes to evaluating cost implications, this resource empowers decision-makers from Africa, South America, the Middle East, and Europe, including key markets like Germany and Saudi Arabia, to make informed purchasing decisions. By delving into the nuances of tractor truck assembly, buyers will gain insights into quality standards, technological advancements, and supply chain efficiencies that can significantly impact their operational success.

With actionable strategies and expert guidance, this guide not only facilitates better supplier selection but also enhances the overall procurement strategy, ensuring that businesses can navigate the complexities of the global market with confidence and precision.

Understanding tractor Truck Assembly Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Conventional Tractor | Standard design with a separate cab and trailer coupling | Long-haul freight transport | Pros: Versatile, widely available; Cons: Less maneuverable in tight spaces. |

| Articulated Tractor | Flexible joint between cab and trailer | Heavy-duty logistics and construction | Pros: Excellent maneuverability; Cons: More complex maintenance. |

| Heavy-Duty Tractor | Built for extreme loads, often with reinforced chassis | Mining, logging, and construction | Pros: High durability and load capacity; Cons: Higher initial cost. |

| Electric Tractor | Powered by electric motors, often with zero emissions | Urban logistics and short-haul transport | Pros: Eco-friendly, lower operating costs; Cons: Limited range and charging infrastructure. |

| Specialty Tractor | Customized for specific industries (e.g., refrigerated) | Agriculture, food transport, and waste management | Pros: Tailored solutions for niche markets; Cons: Potentially higher costs and longer lead times. |

What are the Characteristics of Conventional Tractors?

Conventional tractors are the most common type in the industry, featuring a distinct separation between the cab and the trailer. They are designed for long-haul freight transport and are widely recognized for their versatility. Buyers should consider the availability of parts and service networks, as well as fuel efficiency, when opting for this type. They are suitable for various cargo types, making them a reliable choice for companies looking to transport goods over long distances.

How Do Articulated Tractors Stand Out?

Articulated tractors are characterized by their flexible joint, allowing for greater maneuverability around tight corners and challenging terrains. This design is particularly advantageous in heavy-duty logistics and construction applications, where space can be limited. When purchasing, B2B buyers should evaluate the complexity of maintenance and the potential need for specialized training for operators. Their enhanced maneuverability makes them ideal for construction sites and urban deliveries.

What Makes Heavy-Duty Tractors Suitable for Tough Jobs?

Heavy-duty tractors are engineered to handle extreme loads, often featuring reinforced chassis and powerful engines. They are essential in industries like mining, logging, and construction, where durability and load capacity are critical. Buyers should assess the initial investment against long-term operational costs, considering factors like fuel efficiency and maintenance. Their robust design ensures reliability in demanding environments, making them a preferred choice for heavy-duty applications.

Why Consider Electric Tractors for Urban Logistics?

Electric tractors are increasingly popular due to their eco-friendly design, operating with electric motors that produce zero emissions. They are particularly suited for urban logistics and short-haul transport, where environmental regulations are stringent. Buyers should weigh the initial cost against potential savings in fuel and maintenance, as well as the availability of charging infrastructure. Although they have limited range, their lower operating costs make them an attractive option for businesses looking to reduce their carbon footprint.

What Advantages Do Specialty Tractors Offer?

Specialty tractors are customized to meet specific industry needs, such as refrigerated transport for perishable goods or waste management applications. These tractors provide tailored solutions that enhance operational efficiency in niche markets. B2B buyers should consider the potential for higher costs and longer lead times associated with custom builds. However, the ability to meet unique requirements can significantly improve service delivery and competitiveness in specialized sectors.

Key Industrial Applications of tractor Truck Assembly

| Industry/Sector | Specific Application of Tractor Truck Assembly | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics and Transportation | Assembly of long-haul tractor trucks for freight transport | Enhanced efficiency in transporting goods over long distances, reducing operational costs | Compliance with local regulations, quality assurance, and timely delivery of components |

| Agriculture | Manufacturing of agricultural tractors and trailers | Increased productivity in farming operations, enabling efficient transport of goods | Customization options for specific agricultural needs, durability in harsh environments |

| Construction | Production of heavy-duty trucks for construction sites | Improved capability to transport heavy materials, enhancing project timelines | Robustness and reliability of components, adherence to safety standards |

| Mining | Assembly of specialized trucks for mining operations | Enhanced load capacity and durability for challenging terrains, optimizing resource extraction | Sourcing of high-strength materials, compliance with environmental regulations |

| Oil and Gas | Creation of tankers and transport trucks for oil and gas | Efficient transport of fuel and equipment, ensuring smooth supply chain operations | Specialized design for hazardous materials, compliance with international safety standards |

How is Tractor Truck Assembly Used in Logistics and Transportation?

In the logistics and transportation sector, tractor truck assembly is crucial for producing long-haul trucks that facilitate freight movement across vast distances. These trucks are engineered for efficiency, allowing businesses to reduce fuel consumption and operational costs while maximizing cargo capacity. International buyers, particularly from Africa and South America, must consider local regulations and quality assurance when sourcing components to ensure compliance and reliability in their fleets.

What Role Does Tractor Truck Assembly Play in Agriculture?

The agricultural industry relies heavily on tractor truck assembly for manufacturing robust tractors and trailers designed to transport goods efficiently. These vehicles enhance productivity by enabling farmers to move supplies and harvests quickly, which is vital in time-sensitive agricultural operations. Buyers must seek customization options to meet specific farming needs and ensure the durability of vehicles to withstand harsh field conditions, especially in regions like the Middle East and parts of Europe.

How is Tractor Truck Assembly Beneficial for Construction?

In construction, the assembly of heavy-duty trucks is essential for transporting materials and equipment to job sites. These trucks are built to handle heavy loads, improving project timelines and enhancing the efficiency of construction operations. Buyers in Europe and the Middle East should prioritize sourcing robust and reliable components that adhere to safety standards to minimize downtime and ensure compliance with industry regulations.

Why is Tractor Truck Assembly Important in Mining?

Tractor truck assembly plays a vital role in the mining industry by producing specialized trucks that can navigate challenging terrains while carrying heavy loads. These vehicles are engineered for durability and load capacity, which are critical for optimizing resource extraction processes. When sourcing these trucks, international buyers must focus on obtaining high-strength materials and ensuring compliance with environmental regulations to mitigate operational risks.

How Does Tractor Truck Assembly Support the Oil and Gas Sector?

In the oil and gas industry, tractor truck assembly is pivotal for creating tankers and transport trucks that facilitate the movement of fuel and equipment. These vehicles are designed for safety and efficiency, ensuring that the supply chain operates smoothly. Buyers should prioritize sourcing trucks with specialized designs for hazardous materials and adherence to international safety standards, particularly in regions where stringent regulations are enforced.

3 Common User Pain Points for ‘tractor Truck Assembly’ & Their Solutions

Scenario 1: Ensuring Quality and Compliance in Truck Assembly

The Problem: For international B2B buyers, particularly those in regions with stringent regulatory standards, ensuring that tractor trucks meet quality and compliance requirements can be a daunting task. Buyers often face challenges in verifying that assembly processes adhere to local and international standards, which can lead to potential liabilities and costly recalls. Additionally, the lack of consistent quality across different suppliers can create uncertainty regarding product reliability and safety.

The Solution: To overcome this challenge, buyers should prioritize partnerships with assembly service providers who are certified in international quality standards such as ISO 9001 and ISO/TS 16949. It’s crucial to conduct thorough due diligence by requesting documentation and proof of compliance during the vendor selection process. Establishing a quality assurance protocol that includes regular audits and inspections throughout the assembly process will help maintain oversight. Furthermore, leveraging technology solutions such as real-time monitoring systems can provide continuous feedback on assembly quality, enabling quick adjustments to prevent compliance issues before they escalate.

Scenario 2: Customization Challenges for Diverse Market Needs

The Problem: Many B2B buyers encounter difficulties when seeking customized tractor trucks tailored to specific industry requirements or regional conditions. The challenge lies in finding assembly services that can accommodate unique specifications, such as different axle configurations or specialized cargo options. Buyers may also struggle with long lead times and increased costs associated with customization, leading to frustration and potential loss of competitive advantage in their markets.

The Solution: To address customization challenges, buyers should engage with assembly partners who specialize in flexible manufacturing processes that prioritize customization. It’s essential to communicate specific needs early in the design phase to ensure that the assembly line can accommodate these requirements without significant delays. Establishing a collaborative approach with the assembly provider can lead to innovative solutions, such as modular designs that allow for easier adjustments in the assembly process. Additionally, buyers should evaluate the provider’s capability for rapid prototyping, enabling quicker turnaround times for customized solutions.

Scenario 3: Supply Chain Disruptions Impacting Production Timelines

The Problem: Supply chain disruptions, especially in the wake of global events, have become a significant pain point for B2B buyers in the tractor truck assembly sector. Delays in the availability of critical components can halt production, leading to missed deadlines and financial losses. Buyers often find themselves in a precarious position, balancing the need for timely delivery against the risk of sourcing from unreliable suppliers.

The Solution: To mitigate supply chain risks, buyers should develop strategic partnerships with multiple suppliers to diversify their sourcing options. Implementing a robust supply chain management system that incorporates real-time tracking and analytics can enhance visibility and allow for proactive adjustments to production schedules. Additionally, buyers should consider establishing local assembly facilities or partnerships in key markets to reduce dependency on international supply chains. Engaging in long-term contracts with suppliers who demonstrate reliability can also provide security against price fluctuations and shortages, ensuring a more stable production environment.

Strategic Material Selection Guide for tractor Truck Assembly

What Are the Key Materials Used in Tractor Truck Assembly?

In the assembly of tractor trucks, material selection is critical for ensuring performance, safety, and longevity. The choice of materials affects everything from structural integrity to operational efficiency. Here, we analyze four common materials used in tractor truck assembly: steel, aluminum, composites, and plastics.

How Does Steel Contribute to Tractor Truck Assembly?

Steel is a primary material used in the chassis, frame, and various structural components of tractor trucks. Its key properties include high tensile strength, excellent durability, and good weldability, making it suitable for heavy-duty applications. Steel can withstand high temperatures and pressures, which is essential for components exposed to engine heat and road stress.

Pros: Steel offers exceptional strength and durability, making it ideal for heavy loads. It is also cost-effective compared to other materials, which is a crucial consideration for manufacturers focused on budget constraints.

Cons: The main drawback of steel is its susceptibility to corrosion, particularly in harsh environments, which can lead to increased maintenance costs. Additionally, its weight can negatively impact fuel efficiency.

Impact on Application: Steel’s robustness makes it suitable for high-stress applications, but its weight can affect the overall vehicle performance, especially in regions with varying terrain.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider the local climate and road conditions when choosing steel grades. Compliance with international standards such as ASTM and DIN is essential for ensuring quality and safety.

What Role Does Aluminum Play in Tractor Truck Assembly?

Aluminum is increasingly used in tractor truck assembly due to its lightweight nature and resistance to corrosion. Key properties include a lower density than steel, good thermal conductivity, and excellent fatigue resistance.

Pros: The primary advantage of aluminum is its weight reduction, which enhances fuel efficiency and payload capacity. Its corrosion resistance also minimizes maintenance needs over time.

Cons: Aluminum is generally more expensive than steel, and its manufacturing processes can be more complex, requiring specialized techniques such as welding and riveting.

Impact on Application: Aluminum is particularly beneficial for components that require weight savings without sacrificing strength, such as body panels and certain structural elements.

Considerations for International Buyers: Buyers in Europe, particularly Germany, often prefer aluminum for its environmental benefits. Compliance with JIS and other international standards is crucial for ensuring the quality of aluminum components.

How Do Composites Enhance Tractor Truck Assembly?

Composite materials, often made from a combination of fibers and resins, are used in specific applications like body panels and interior components. Their key properties include high strength-to-weight ratios and excellent resistance to environmental degradation.

Pros: Composites offer significant weight savings and can be tailored for specific applications, providing flexibility in design. They also exhibit superior resistance to corrosion and chemicals.

Cons: The main limitation of composites is their higher cost and the complexity involved in manufacturing and repairing them. They may also require specialized knowledge for proper handling during assembly.

Impact on Application: Composites are ideal for applications where weight reduction is critical without compromising structural integrity, such as in aerodynamic body designs.

Considerations for International Buyers: Buyers from the Middle East should ensure that composite materials meet local environmental regulations. Understanding the specific standards for composites, such as those set by ASTM, is essential for compliance.

What Are the Advantages of Using Plastics in Tractor Truck Assembly?

Plastics are commonly used in various non-structural components, including interior fittings, light housings, and fuel tanks. Key properties include lightweight, corrosion resistance, and ease of molding into complex shapes.

Pros: Plastics provide significant weight savings and can be produced at a lower cost than metals. They also offer excellent resistance to corrosion and chemicals.

Cons: Plastics may not provide the same level of strength as metals and can be susceptible to UV degradation if not properly treated.

Impact on Application: The lightweight nature of plastics makes them suitable for applications where weight is a concern, but they may not be appropriate for high-stress structural components.

Considerations for International Buyers: Buyers in regions with high UV exposure, like parts of Africa and South America, should consider UV-stabilized plastics. Compliance with international standards for plastics is also necessary to ensure durability and safety.

Summary Table of Material Selection for Tractor Truck Assembly

| Material | Typical Use Case for tractor Truck Assembly | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Chassis, frame, structural components | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Body panels, structural elements | Lightweight and corrosion-resistant | Higher cost and complex manufacturing | High |

| Composites | Body panels, interior components | High strength-to-weight ratio | Higher cost and complex handling | High |

| Plastics | Interior fittings, light housings, fuel tanks | Lightweight and cost-effective | Lower strength and UV degradation potential | Low |

This strategic material selection guide provides actionable insights for international B2B buyers, enabling informed decisions that align with performance, cost, and compliance requirements in tractor truck assembly.

In-depth Look: Manufacturing Processes and Quality Assurance for tractor Truck Assembly

What Are the Main Stages of the Manufacturing Process for Tractor Truck Assembly?

The manufacturing process for tractor truck assembly is a multifaceted operation that involves several distinct stages, each contributing to the overall quality and performance of the final product. Understanding these stages is crucial for B2B buyers looking to partner with reliable suppliers.

Material Preparation: How Are Raw Materials Processed?

The first stage in tractor truck assembly is material preparation. This involves sourcing high-quality raw materials, such as steel, aluminum, and composites, which are essential for the truck’s structural integrity. Advanced techniques such as laser cutting, CNC machining, and stamping are employed to create specific components like chassis frames, body panels, and engine mounts. Precision in this stage is crucial, as any defects can compromise the vehicle’s performance.

Forming: What Techniques Are Used to Shape Components?

Once the materials are prepared, the forming process shapes these components into their final forms. Techniques such as hydroforming and roll forming are often used to create complex shapes that are lightweight yet strong. For instance, the chassis may undergo a process where it is molded to achieve both aerodynamics and structural strength, ensuring that the truck can handle heavy loads and rough terrains.

Assembly: How Are Components Brought Together?

The assembly stage is where the individual components come together to form the complete tractor truck. This process typically follows a systematic assembly line model, where each workstation is responsible for specific tasks. For example, one station may focus on assembling the chassis, while another handles the installation of the engine and drivetrain. Automation plays a significant role here, with robotics assisting in tasks such as welding and fastening, enhancing efficiency and precision.

Finishing: What Is Involved in Finalizing the Truck?

The finishing stage involves painting, detailing, and quality checks. The trucks are painted using advanced techniques such as electrostatic spraying, ensuring even coverage and durability. After painting, trucks undergo a thorough inspection to identify any cosmetic or structural defects. This stage not only enhances the truck’s aesthetics but also provides protective coatings that are essential for longevity, especially in harsh environments.

What Quality Assurance Standards Are Relevant for Tractor Truck Assembly?

Quality assurance (QA) is paramount in the manufacturing process of tractor trucks, ensuring that every vehicle meets industry standards and customer expectations. Various international and industry-specific standards guide these processes.

Which International Standards Should B2B Buyers Be Aware Of?

For B2B buyers, understanding relevant international standards is crucial. ISO 9001 is a widely recognized standard that outlines the requirements for a quality management system. Compliance with this standard ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards for components related to oil and gas industries are also significant. These certifications indicate that the products meet stringent safety and performance criteria.

What Are the Key Quality Control Checkpoints in the Assembly Process?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to ensure that every aspect of the tractor truck assembly meets established standards.

How Do Incoming Quality Control (IQC) Measures Work?

Incoming Quality Control (IQC) involves inspecting raw materials and components upon arrival at the manufacturing facility. This step ensures that only materials meeting specified quality standards are used in the assembly process. Common practices include visual inspections and testing for material specifications.

What Is In-Process Quality Control (IPQC)?

In-Process Quality Control (IPQC) is conducted at various stages during assembly. This includes monitoring welding quality, alignment of components, and adherence to assembly specifications. Employing statistical process control (SPC) techniques can help in identifying trends and variations early, allowing for corrective actions before defects occur.

What Role Does Final Quality Control (FQC) Play?

Final Quality Control (FQC) is the last line of defense before the tractor truck is delivered to customers. This comprehensive inspection covers all aspects of the truck, from functionality tests to visual inspections for cosmetic flaws. FQC ensures that the vehicle is fully operational and meets all safety standards.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying the quality control processes of potential suppliers is essential to mitigate risks associated with subpar products.

What Are the Best Practices for Conducting Supplier Audits?

Conducting supplier audits is one of the most effective methods for verifying quality control processes. These audits can assess compliance with international standards, the effectiveness of quality management systems, and the overall manufacturing capabilities of the supplier. Buyers should look for suppliers who are open to regular audits and willing to share their quality management documentation.

How Important Are Quality Control Reports?

Quality control reports provide insight into the performance of the manufacturing process. B2B buyers should request these reports to understand the supplier’s historical quality performance, including defect rates and corrective actions taken. This documentation is vital for making informed sourcing decisions.

Should Buyers Consider Third-Party Inspections?

In certain cases, engaging third-party inspection services can add an extra layer of assurance. These independent entities can conduct audits and inspections at various stages of the manufacturing process, providing an unbiased assessment of quality compliance.

What Are the Nuances of Quality Control and Certification for International Buyers?

When engaging with suppliers from different regions, B2B buyers should be aware of the nuances in quality control and certification processes.

How Do Regional Standards Impact Quality Assurance?

Different regions may have varying quality standards and regulatory requirements. For instance, European buyers may prioritize CE certification, while buyers in the Middle East may focus on local compliance standards. Understanding these regional differences is crucial for ensuring that the products meet local regulations.

What Should Buyers Know About Cultural and Operational Differences?

Cultural attitudes towards quality and operational practices can vary widely across regions. Buyers should consider these factors when evaluating suppliers, as they can significantly impact quality assurance processes. Establishing clear communication channels and expectations can help bridge these gaps.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures in tractor truck assembly is essential for B2B buyers. By focusing on these elements, buyers can make informed decisions that align with their operational needs and market requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tractor Truck Assembly’

Introduction

Sourcing tractor truck assembly services requires a strategic approach to ensure that you partner with the right suppliers who can meet your operational needs. This guide provides a step-by-step checklist designed to help international B2B buyers navigate the complexities of procuring assembly services efficiently and effectively. By following these steps, you can ensure that you select a supplier that aligns with your technical specifications, quality standards, and budget.

Step 1: Define Your Technical Specifications

Start by outlining your specific requirements for the tractor truck assembly. Consider factors such as weight classification, engine type, and any customization options needed for your operations. Having clear specifications helps potential suppliers provide accurate proposals and ensures that the final product meets your expectations.

- Identify key components: Determine the essential parts required for assembly, such as chassis, engine, and drivetrain.

- Consider regulatory compliance: Ensure that your specifications align with international and local regulations, particularly in the regions you plan to operate.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in tractor truck assembly. Look for companies with a proven track record in the industry and positive reviews from previous clients.

- Utilize online resources: Platforms like industry-specific directories and trade shows can provide valuable insights into potential suppliers.

- Evaluate their portfolio: Review case studies and previous projects to assess their capabilities and experience.

Step 3: Verify Supplier Certifications

Before engaging with a supplier, confirm that they possess the necessary certifications and adhere to international quality standards. This step is crucial for ensuring the reliability and safety of the assembled trucks.

- Check for ISO certifications: Look for compliance with ISO 9001 for quality management and ISO 14001 for environmental management.

- Assess safety standards: Ensure they meet safety regulations pertinent to your target markets.

Step 4: Evaluate Customization Capabilities

Customization is often essential in the heavy-duty truck market. Assess whether potential suppliers can accommodate your unique specifications and preferences.

- Discuss design flexibility: Inquire about their ability to modify existing designs or create bespoke solutions.

- Review past customization projects: Ask for examples of previous customizations to gauge their expertise and experience.

Step 5: Assess Technology Integration

Modern tractor trucks increasingly require advanced technologies for efficiency and performance. Evaluate how well potential suppliers can integrate these technologies into their assembly process.

- Inquire about automation: Check if they use automation and robotics in their assembly lines, which can enhance precision and reduce lead times.

- Explore telematics and GPS options: Ensure they can incorporate modern tracking and monitoring systems to optimize fleet management.

Step 6: Request Detailed Quotes

Once you’ve narrowed down your options, request detailed quotes from your shortlisted suppliers. This will allow you to compare pricing structures and understand what is included in the assembly service.

- Breakdown of costs: Ensure the quotes include all components, labor, customization, and any additional services.

- Evaluate payment terms: Understand their payment schedule and any warranties offered on the assembly work.

Step 7: Conduct Site Visits

If possible, arrange site visits to the facilities of your top suppliers. Observing their operations can provide invaluable insights into their production capabilities and quality control processes.

- Assess the assembly process: Look for cleanliness, organization, and adherence to safety protocols.

- Engage with staff: Speak with assembly line workers and management to gauge their expertise and commitment to quality.

By following this checklist, you can strategically approach the sourcing of tractor truck assembly services, ensuring that you find a supplier capable of delivering high-quality, customized solutions tailored to your business needs.

Comprehensive Cost and Pricing Analysis for tractor Truck Assembly Sourcing

What Are the Key Cost Components in Tractor Truck Assembly?

When analyzing the costs associated with tractor truck assembly, it is essential to consider several key components that contribute to the overall pricing structure. These include:

-

Materials: The cost of raw materials like steel, aluminum, rubber, and plastics can vary significantly based on market fluctuations and supplier contracts. High-quality materials are crucial for ensuring durability and performance.

-

Labor: Skilled labor is vital for assembly processes, and labor costs can differ based on the region and workforce availability. In markets like Europe and North America, labor costs are typically higher compared to emerging markets in Africa and South America.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and administrative expenses. Efficient overhead management can lead to significant savings.

-

Tooling: Specialized tools and equipment for assembly must be factored into the cost. Custom tooling can increase initial expenses but may lead to greater efficiencies in production.

-

Quality Control (QC): Ensuring that each truck meets safety and performance standards involves dedicated QC processes. This adds to the overall cost but is essential for compliance and customer satisfaction.

-

Logistics: The transportation of components and finished trucks can be a significant cost, especially for international buyers. Factors like shipping methods and distances can influence logistics costs.

-

Margin: Suppliers will typically add a profit margin on top of their costs, which can vary widely based on market conditions and competitive landscape.

How Do Pricing Influencers Impact Tractor Truck Assembly Costs?

Several factors can influence the pricing of tractor truck assembly, making it crucial for buyers to understand these elements:

-

Volume/MOQ: Minimum order quantities (MOQ) can affect pricing significantly. Higher volumes often lead to lower per-unit costs due to economies of scale.

-

Specifications/Customization: Customized trucks designed for specific industries or tasks can increase assembly costs due to additional engineering and materials required.

-

Materials: The choice of materials directly impacts both the cost and quality of the final product. Opting for premium materials can enhance durability but also raise expenses.

-

Quality and Certifications: Compliance with international quality standards can lead to higher costs. However, certifications can also enhance resale value and customer trust.

-

Supplier Factors: The reputation and reliability of suppliers play a significant role in pricing. Established suppliers may charge more but often provide better quality and service.

-

Incoterms: Understanding shipping terms (Incoterms) is crucial for international buyers as they dictate the responsibilities and costs involved in shipping goods.

What Buyer Tips Can Enhance Cost Efficiency in Tractor Truck Assembly?

To maximize cost efficiency in tractor truck assembly, buyers should consider the following strategies:

-

Negotiation: Engage in thorough negotiations with suppliers. Understanding market conditions and having multiple quotes can provide leverage in discussions.

-

Focus on Total Cost of Ownership (TCO): Rather than just the initial purchase price, consider the TCO, which includes maintenance, fuel efficiency, and resale value. A higher upfront cost may lead to lower long-term expenses.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and import duties when sourcing from different regions. This knowledge can help in budgeting and financial planning.

-

Research Local Suppliers: For buyers in Africa, South America, and the Middle East, local suppliers may offer more competitive pricing due to lower logistics costs and a better understanding of regional needs.

-

Evaluate Technological Advancements: Consider suppliers that integrate advanced technologies in their assembly processes, as these can lead to cost savings through improved efficiency and reduced waste.

Conclusion

Understanding the comprehensive cost structure and pricing dynamics of tractor truck assembly is critical for international B2B buyers. By considering the key cost components and pricing influencers, buyers can make informed decisions that optimize their procurement strategies while ensuring high-quality outcomes. As always, it is essential to approach pricing discussions with a comprehensive view of both immediate and long-term costs, especially when engaging with suppliers across different regions.

Disclaimer: Prices and costs mentioned are indicative and may vary based on specific circumstances and market conditions.

Alternatives Analysis: Comparing tractor Truck Assembly With Other Solutions

Understanding Alternatives to Tractor Truck Assembly

In the realm of heavy-duty vehicle manufacturing, the tractor truck assembly process is a well-established method for producing robust trucks tailored to specific operational needs. However, as the industry evolves, alternative solutions have emerged that offer different advantages and may better suit certain business models or operational requirements. This analysis compares tractor truck assembly against other viable methods, helping B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | Tractor Truck Assembly | Modular Truck Manufacturing | Outsourced Truck Assembly |

|---|---|---|---|

| Performance | High efficiency with precision | Flexible design options | Variable quality control |

| Cost | Moderate initial investment | Potentially lower overall costs | Variable costs based on contracts |

| Ease of Implementation | Requires specialized facilities | Easier integration into existing processes | Depends on partner capabilities |

| Maintenance | Regular upkeep needed for machinery | Lower maintenance due to modularity | Maintenance standards vary widely |

| Best Use Case | High-volume production needs | Customizable or niche applications | Cost-sensitive production runs |

What Are the Benefits and Drawbacks of Modular Truck Manufacturing?

Modular truck manufacturing involves creating trucks from pre-assembled components, allowing for flexibility in design and rapid assembly. The primary advantage of this method is its adaptability; businesses can customize trucks according to their specific needs without starting from scratch. Additionally, modular systems often reduce the overall cost of production due to economies of scale in component manufacturing. However, the reliance on standardized parts may limit customization options for specialized vehicles, and achieving the same level of precision as traditional assembly may be challenging.

How Does Outsourced Truck Assembly Compare to In-House Assembly?

Outsourced truck assembly allows manufacturers to delegate the assembly process to specialized third-party providers. This can be an attractive option for companies looking to minimize overhead costs or lacking the infrastructure to support in-house assembly. The flexibility of outsourcing can lead to reduced labor costs and the ability to scale production up or down based on demand. However, the quality control can vary significantly between providers, potentially leading to inconsistencies in the finished product. Additionally, relying on external partners can complicate supply chain management and reduce responsiveness to market changes.

Conclusion: Choosing the Right Assembly Solution for Your Business

When evaluating tractor truck assembly against alternatives like modular manufacturing and outsourced assembly, B2B buyers must consider their specific operational needs, budget constraints, and desired level of customization. For businesses focused on high-volume production with stringent quality requirements, traditional tractor truck assembly may remain the best option. Conversely, those seeking flexibility or cost savings might find modular or outsourced solutions more appealing. Ultimately, the choice will hinge on balancing performance, cost, and operational efficiency tailored to each buyer’s unique requirements.

Essential Technical Properties and Trade Terminology for tractor Truck Assembly

What Are the Key Technical Properties in Tractor Truck Assembly?

In the assembly of tractor trucks, several technical specifications are critical to ensure performance, safety, and durability. Here are some essential properties:

-

Material Grade

Material grade refers to the quality and strength of the materials used, such as steel or aluminum. Higher-grade materials offer enhanced durability and resistance to wear and tear, crucial for vehicles that operate in demanding environments. For B2B buyers, selecting the right material grade can significantly impact the longevity and performance of the trucks. -

Tolerance Levels

Tolerance levels indicate the acceptable limits of variation in dimensions and physical properties of parts. Precision in tolerances is vital in truck assembly as it ensures that components fit together correctly, which affects safety and functionality. For businesses, understanding tolerance requirements helps in selecting suppliers that can meet strict manufacturing standards. -

Load Capacity

Load capacity defines the maximum weight a truck can safely carry. This specification is crucial for businesses in logistics and transportation, where understanding load limits directly influences operational efficiency and compliance with regulations. Buyers need to ensure that the trucks they procure meet their specific load requirements. -

Engine Power Output

The power output of the engine, usually measured in horsepower (HP) or kilowatts (kW), determines the truck’s ability to perform under various conditions. This metric is vital for businesses requiring heavy-duty performance, as it correlates directly with operational capabilities and fuel efficiency. B2B buyers should assess engine specifications to ensure they align with their operational demands. -

Fuel Efficiency

Fuel efficiency is a critical property that measures how far a truck can travel per unit of fuel. In regions where fuel costs are high, such as parts of Africa and Europe, efficient fuel consumption can lead to significant cost savings. Buyers must consider fuel efficiency ratings to optimize their operational budgets. -

Safety Standards Compliance

Compliance with safety standards, such as those set by the International Organization for Standardization (ISO) or regional regulations, ensures that the trucks meet necessary safety protocols. For B2B buyers, understanding these standards is essential to avoid legal repercussions and ensure the safety of drivers and cargo.

Which Trade Terminology Should Buyers Know in Tractor Truck Assembly?

Understanding industry jargon is essential for effective communication and negotiation in the tractor truck assembly sector. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In tractor truck assembly, OEM parts are often preferred due to their guaranteed compatibility and quality, making them a vital consideration for buyers focused on reliability. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it affects inventory management and cash flow. Buyers must negotiate MOQs that align with their operational needs without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for the price of specific products or services. This process is vital for buyers to obtain competitive pricing and terms, making it a key part of procurement strategy in tractor truck assembly. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized standard trade terms that outline the responsibilities of buyers and sellers in shipping and delivery. Familiarity with these terms is crucial for B2B buyers to understand their obligations concerning shipping, risk transfer, and costs. -

Lead Time

Lead time refers to the amount of time from placing an order to receiving the product. In the context of tractor truck assembly, understanding lead times helps buyers plan their operations and manage expectations regarding delivery schedules. -

Quality Assurance (QA)

QA encompasses the processes that ensure the quality of products meets predefined standards. For B2B buyers, robust QA protocols are essential to minimize defects and maintain operational integrity, making it a critical consideration when selecting assembly partners.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their procurement strategies and operational efficiency in tractor truck assembly.

Navigating Market Dynamics and Sourcing Trends in the tractor Truck Assembly Sector

What Are the Key Market Dynamics and Trends Influencing the Tractor Truck Assembly Sector?

The tractor truck assembly sector is currently experiencing a transformative phase driven by several global factors. Key trends include the rise of automation and advanced manufacturing technologies, which enhance productivity and efficiency in assembly lines. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly focusing on suppliers that utilize Industry 4.0 principles, integrating IoT and AI to streamline operations and improve supply chain transparency. This shift not only reduces production costs but also speeds up time-to-market for new models.

Additionally, the demand for customized trucks tailored to specific market needs is on the rise, prompting manufacturers to adopt more flexible assembly processes. Buyers are looking for partners who can offer customization capabilities without compromising on quality. The increasing emphasis on electric and hybrid vehicles is reshaping sourcing strategies, as manufacturers seek components that meet new energy standards. As global supply chains become more complex, the ability to manage logistics effectively is becoming a competitive advantage. This includes securing reliable local suppliers and leveraging technology for real-time tracking of parts and inventory.

How Important Is Sustainability and Ethical Sourcing in Tractor Truck Assembly?

Sustainability is becoming a critical consideration in the tractor truck assembly sector, with environmental impact influencing purchasing decisions. Buyers are increasingly prioritizing suppliers that demonstrate commitment to reducing carbon footprints and utilizing eco-friendly materials. The use of sustainable practices not only mitigates environmental damage but also appeals to consumers who are more conscious of corporate responsibility.

Ethical sourcing is equally vital, as stakeholders demand transparency in supply chains. B2B buyers should seek partners who adhere to international standards for labor practices and environmental stewardship. Certifications such as ISO 14001 for environmental management and LEED for sustainable construction can serve as indicators of a supplier’s commitment to sustainability. Additionally, sourcing materials that are recyclable or derived from renewable resources is becoming essential for companies aiming to enhance their green credentials. As the tractor truck assembly sector evolves, integrating sustainability into sourcing strategies will not only fulfill regulatory requirements but also enhance brand reputation and customer loyalty.

What Is the Historical Context of the Tractor Truck Assembly Sector?

The tractor truck assembly sector has undergone significant evolution since its inception in the early 20th century. Initially characterized by manual assembly and rudimentary manufacturing techniques, the industry has progressively embraced mechanization and automation. The introduction of the assembly line by pioneers like Henry Ford revolutionized production, allowing for mass manufacturing and reduced costs.

In recent decades, advancements in technology have further transformed the sector. The integration of robotics, computer-aided design (CAD), and simulation tools has enabled manufacturers to enhance precision and efficiency in the assembly process. As global competition intensified, companies began to adopt lean manufacturing principles to minimize waste and optimize operations. Today, the sector is at the forefront of innovation, focusing on sustainability and the adoption of electric and autonomous vehicles, positioning itself for the challenges and opportunities of the future.

Frequently Asked Questions (FAQs) for B2B Buyers of tractor Truck Assembly

-

How do I ensure quality when sourcing tractor truck assembly services?

To ensure quality, start by selecting suppliers who adhere to international quality standards, such as ISO certifications. It’s essential to request samples or visit the manufacturing facility to assess their assembly processes and quality control measures. Additionally, inquire about their use of advanced technologies in assembly and whether they have a history of successful projects. Establishing clear quality expectations and maintaining open communication throughout the production process will further safeguard against quality issues. -

What are the key factors to consider when selecting a tractor truck assembly supplier?

When selecting a supplier, consider their experience in the industry, reputation, and compliance with international standards. Evaluate their customization capabilities to ensure they can meet your specific needs. Assess their production capacity and lead times to confirm they can fulfill your orders promptly. Additionally, investigate their supply chain management efficiency and whether they have robust logistics solutions in place for timely delivery. -

What customization options are available for tractor truck assembly?

Customization options can include adjustments to chassis design, engine specifications, cab configurations, and body types tailored for specific industries. Suppliers may also offer choices in terms of materials used, additional features like advanced safety systems, and integrations for telematics or GPS technologies. It’s crucial to communicate your requirements early in the process to ensure that the assembly aligns with your operational needs and industry standards. -

What is the minimum order quantity (MOQ) for tractor truck assembly services?

Minimum order quantities can vary significantly between suppliers and are often influenced by production capabilities and resource availability. Typically, MOQs for tractor truck assembly services may range from a few units to several dozen, depending on the complexity of the assembly and customization required. It’s advisable to discuss your needs directly with potential suppliers to understand their MOQ policies and explore options for smaller orders if needed. -

What payment terms should I expect when sourcing tractor truck assembly?

Payment terms vary by supplier but commonly include options like upfront deposits, progress payments throughout the assembly process, and final payments upon delivery. Some suppliers may offer flexible financing options or credit terms based on your business relationship and order size. Always clarify payment terms in the contract, including any penalties for late payments or discounts for early payments, to avoid misunderstandings later. -

How can I verify the credibility of a tractor truck assembly supplier?

To verify a supplier’s credibility, start by checking their business registration, financial stability, and industry reputation through reviews or testimonials from previous clients. Request references and follow up with them to gauge their experiences. Additionally, investigate any certifications the supplier holds and their compliance with safety and quality regulations. Engaging in a site visit can also provide valuable insights into their operations and business practices. -

What logistics considerations should I keep in mind when sourcing tractor truck assembly?

Logistics considerations include shipping methods, delivery timelines, and customs regulations specific to your region. Ensure that the supplier has a reliable logistics partner to facilitate smooth transportation of the assembled trucks. Discuss potential challenges such as import duties and taxes, as well as the supplier’s capability to handle any required documentation. Establishing a clear logistics plan will help mitigate risks and ensure timely delivery. -

What quality assurance measures are typically implemented in tractor truck assembly?

Quality assurance in tractor truck assembly often involves multi-stage inspections throughout the production process, including material checks, assembly verifications, and final quality tests. Suppliers should employ standardized protocols for testing components and systems to ensure compliance with specifications. Look for suppliers who utilize advanced technologies such as automated inspections and real-time monitoring systems, which can enhance the reliability and quality of the finished product.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Tractor Truck Assembly Manufacturers & Suppliers List

1. Vehicle Assemble – Truck Assembly Line

Domain: vehicleassemble.com

Registered: 2018 (7 years)

Introduction: Truck Assembly Line: A manufacturing process for systematically assembling various components of a truck. It includes workstations for specific tasks, where skilled workers and machines collaborate to build trucks. Key steps in the process include: 1. Assembling the frame: Selection of frame rails, drilling holes for components, spot welding studs, and bolting cross members and other components. 2…

2. Whse – Heavy Duty Truck Assembly Services

Domain: whse.com

Registered: 1998 (27 years)

Introduction: Heavy Duty Truck Assembly Services focus on the production and assembly of large vehicles exceeding 26,000 pounds, typically classified as Class 7 and Class 8 trucks. The assembly process includes several stages: Chassis Assembly (building the frame, suspension, axles, and wheels), Cabin Assembly (crafting the driver’s compartment), Engine and Drivetrain Assembly (assembling engine, transmission, …

3. Light Duty Semi Truck – JE493ZLQ3A

Domain: auto-assemblyplants.com

Registered: 2019 (6 years)

Introduction: Product: Light Duty Semi Truck Assembly Line Auto Assembly Plant Joint Venture Partners

Key Specifications:

– Engine Model: JE493ZLQ3A

– Overall Dimension (L×W×H): 5130 mm × 1910 mm × 2350 mm

– Cargo Body Inside Dimension (L×W×H): 3270 mm × 1810 mm × 400 mm

– Wheel Base: 2600 mm

– Drive Type: 4×2

– Engine Displacement: 2.771 L

– Minimum Order Quantity: 1

Highlights:

– Focus on light duty trucks …

4. eBay – Used Semi Truck Parts

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Used Semi Truck Parts available on eBay, including various categories such as tires, handle assemblies, and other components. Examples include: 1. USED SEMI TRUCK TIRES – Pre-Owned, priced at $165.00 with $90.98 delivery. 2. Paccar R56-1159 Handle Assembly Left LH for Peterbilt Semi Truck – Pre-Owned, rated 5.0 out of 5 stars, priced at $49.00 with $7.99 delivery. 3. Flasher yellow for semi truck …

5. Unique Semi-Truck Configuration – Enhanced Load Management

Domain: practicalmachinist.com

Registered: 2000 (25 years)

Introduction: The discussion revolves around a unique setup of a big semi-truck configuration involving one front tractor and two rear tractors. The rear tractors are believed to assist in pushing the load and may be connected via drawbars for added braking power. The setup requires constant communication among the drivers for coordination, especially during braking. The conversation also references the use of …

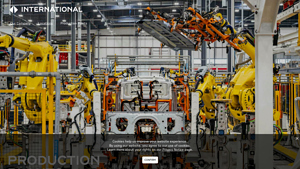

6. International® – Commercial Vehicles and Diesel Engines

Domain: international.com

Registered: 1998 (27 years)

Introduction: International® manufactures a range of commercial vehicles including Class 4 through 8 trucks and buses, diesel engines, and transmissions. Key production facilities include:

1. Escobedo Assembly Plant (Mexico) – Produces Class 8 vehicles and sub-assemblies for trucks.

2. Huntsville Powertrain Plant (Alabama) – Manufactures high-quality diesel engines and transmissions.

3. San Antonio Manufactu…

7. Stellantis – Jeep® Wagoneer Series

Domain: media.stellantisnorthamerica.com

Registered: 2020 (5 years)

Introduction: Products: Jeep® Wagoneer, Wagoneer L, Grand Wagoneer and Grand Wagoneer L

Strategic Sourcing Conclusion and Outlook for tractor Truck Assembly

In the competitive landscape of tractor truck assembly, strategic sourcing emerges as a pivotal element for international buyers. By leveraging robust supply chain management, companies can ensure the availability of high-quality components, minimize production costs, and enhance operational efficiency. Emphasizing customization and adherence to international quality standards will facilitate the development of trucks that meet specific market demands, particularly in diverse regions such as Africa, South America, the Middle East, and Europe.

The integration of advanced technologies, such as automation and telematics, is essential for staying ahead in this rapidly evolving industry. International buyers should prioritize partnerships with assembly service providers that demonstrate a commitment to innovation and sustainability.

Looking ahead, the demand for heavy-duty trucks will only increase as global logistics and transportation needs grow. By investing in strategic sourcing now, businesses can position themselves for long-term success and competitiveness in their respective markets. We encourage you to explore potential partnerships and innovations in tractor truck assembly that will drive your business forward in the coming years.