Introduction: Navigating the Global Market for electric cargo bike belt drive hydraulic

In the rapidly evolving landscape of urban logistics, sourcing electric cargo bike belt drive hydraulic solutions can be a daunting challenge for international B2B buyers. As cities around the globe grapple with congestion and environmental concerns, the demand for efficient, sustainable transportation alternatives is on the rise. This guide provides an extensive exploration of electric cargo bikes featuring belt drive and hydraulic systems, addressing critical aspects such as types, applications, supplier vetting, and cost considerations.

International buyers, particularly those from Africa, South America, the Middle East, and Europe, will find valuable insights tailored to their unique market conditions and regulatory environments. By delving into the nuances of electric cargo bikes, this guide empowers businesses to make informed purchasing decisions that align with their operational needs and sustainability goals. From understanding the advantages of belt drive systems—known for their durability and low maintenance—to the benefits of hydraulic brakes that offer enhanced stopping power, we cover everything you need to know.

Ultimately, this comprehensive resource serves as a roadmap for navigating the complexities of the global market for electric cargo bikes. It equips B2B buyers with the knowledge necessary to identify the right solutions that not only meet their logistical demands but also contribute to a greener future.

Understanding electric cargo bike belt drive hydraulic Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Front-Loading Cargo Bikes | Cargo area in front of the rider, enhanced stability | Urban delivery services, childcare | Pros: Excellent visibility, stable handling; Cons: May require more effort to mount/dismount. |

| Midtail Cargo Bikes | Extended rear section for cargo, compact design | Small businesses, food delivery | Pros: Maneuverable in tight spaces; Cons: Limited cargo capacity compared to longtails. |

| Longtail Cargo Bikes | Longer frame with extended rear for larger loads | E-commerce, family transport | Pros: High cargo capacity, stable on hills; Cons: Requires more storage space. |

| Belt Drive Systems | Gates carbon belt for smooth, low-maintenance operation | Freight transport, rental services | Pros: Durable, quiet operation; Cons: Higher initial cost compared to chain systems. |

| Hydraulic Disc Brake Systems | Enhanced stopping power, improved safety | Logistics, delivery services | Pros: Superior braking performance, reliable in wet conditions; Cons: More complex maintenance. |

What are the Characteristics of Front-Loading Cargo Bikes?

Front-loading cargo bikes feature a unique design where the cargo area is positioned in front of the rider. This configuration enhances visibility and stability, making it ideal for urban environments. B2B buyers in sectors like childcare or urban delivery services find these bikes particularly useful for transporting children or goods, as they allow for easy loading and unloading. However, the design may require some adjustment for riders when mounting and dismounting.

Why Choose Midtail Cargo Bikes for Your Business?

Midtail cargo bikes strike a balance between size and capacity, featuring an extended rear section that allows for cargo without sacrificing maneuverability. This makes them suitable for small businesses, such as local food delivery services, where navigating tight spaces is crucial. Their compact design, however, may limit the maximum cargo capacity compared to other types, which is an important consideration for B2B buyers needing to transport larger loads.

How Do Longtail Cargo Bikes Meet Diverse Transport Needs?

Longtail cargo bikes are designed with an extended frame that accommodates larger loads in the rear. They are particularly effective for e-commerce businesses and family transport, offering significant cargo capacity and stability, especially on inclines. B2B buyers should consider their storage requirements, as the longer frame necessitates more space for parking and transport.

What Advantages Do Belt Drive Systems Offer for B2B Buyers?

Belt drive systems, such as those from Gates, are known for their durability and low maintenance needs. These systems provide a smooth and quiet ride, making them appealing for businesses focused on freight transport or rental services. While the initial investment may be higher than traditional chain systems, the long-term benefits of reduced maintenance and increased lifespan can be advantageous for B2B buyers looking for reliable transport solutions.

Why Are Hydraulic Disc Brake Systems Important for Safety?

Hydraulic disc brake systems provide enhanced stopping power, crucial for B2B applications in logistics and delivery services. These brakes perform reliably in various weather conditions, ensuring safety during operations. However, buyers should be aware that these systems require more complex maintenance, which may lead to higher long-term operational costs. For businesses prioritizing safety and performance, investing in hydraulic systems can be a worthwhile consideration.

Key Industrial Applications of electric cargo bike belt drive hydraulic

| Industry/Sector | Specific Application of electric cargo bike belt drive hydraulic | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| E-commerce & Last-Mile Delivery | Utilizing electric cargo bikes for efficient delivery of goods in urban areas | Reduces delivery times, lowers operational costs, and minimizes carbon footprint | Evaluate battery capacity, load capacity, and range for urban routes |

| Food & Beverage Distribution | Transporting fresh produce and beverages from suppliers to retailers | Ensures timely deliveries, maintains product quality, and reduces reliance on vehicles | Consider temperature control options and cargo space for perishables |

| Construction & Landscaping | Moving tools, equipment, and materials across job sites | Enhances mobility in tight spaces and reduces fuel costs | Assess durability, load capacity, and off-road capabilities |

| Waste Management | Collecting recyclables and waste from urban areas | Promotes sustainability and reduces traffic congestion | Look for models with high cargo capacity and efficient braking systems |

| Healthcare & Pharmaceuticals | Delivering medical supplies and equipment to hospitals and clinics | Ensures timely access to critical supplies and improves service efficiency | Focus on reliability, cargo security features, and battery life |

How is electric cargo bike belt drive hydraulic used in e-commerce and last-mile delivery?

In the e-commerce sector, electric cargo bikes equipped with hydraulic belt drives are increasingly being used for last-mile delivery. These bikes can navigate congested urban areas efficiently, allowing businesses to reduce delivery times significantly. The hydraulic systems provide smooth operation and enhanced load capacity, making them ideal for transporting packages of various sizes. For international buyers, especially in regions like Africa and South America, sourcing bikes that can handle varying road conditions and have robust battery life is crucial to ensure operational efficiency.

What role do electric cargo bikes play in food and beverage distribution?

Electric cargo bikes serve a vital role in the food and beverage distribution industry by enabling the transport of fresh produce and beverages directly from suppliers to retailers. These bikes maintain product quality through quick deliveries and reduce the carbon footprint associated with traditional delivery vehicles. For businesses in the Middle East and Europe, it is essential to consider sourcing options that offer temperature-controlled cargo spaces to protect perishable goods during transit.

How can construction and landscaping industries benefit from electric cargo bikes?

In construction and landscaping, electric cargo bikes are employed to move tools, equipment, and materials across job sites. Their ability to navigate tight spaces and rough terrain makes them invaluable for enhancing productivity and reducing reliance on fuel-powered vehicles. International buyers should prioritize sourcing bikes with high durability and load capacity to meet the demanding needs of construction environments, particularly in regions where road conditions may be challenging.

What advantages do electric cargo bikes provide for waste management?

Electric cargo bikes offer substantial advantages in the waste management sector by efficiently collecting recyclables and waste from urban areas. Their compact design helps reduce traffic congestion and promotes sustainability by minimizing the environmental impact of waste collection. For businesses in this sector, key sourcing considerations include selecting models with high cargo capacities and reliable braking systems to ensure safety during operation, especially in densely populated areas.

How do electric cargo bikes enhance healthcare delivery?

In healthcare, electric cargo bikes facilitate the timely delivery of medical supplies and equipment to hospitals and clinics. This is critical for maintaining service efficiency and ensuring that healthcare providers have access to necessary resources. Buyers in the healthcare sector should focus on sourcing electric cargo bikes that offer reliability, cargo security features, and extended battery life, which are essential for transporting sensitive medical items in a timely manner.

3 Common User Pain Points for ‘electric cargo bike belt drive hydraulic’ & Their Solutions

Scenario 1: Difficulty in Navigating Diverse Terrain with Electric Cargo Bikes

The Problem: Many businesses operating in regions with varied topographies face challenges when using electric cargo bikes. For instance, in mountainous areas of South America or uneven terrains in Africa, the ability to traverse steep hills or rough pathways can significantly impact delivery efficiency. A hydraulic system may enhance braking and stability, but if the bike’s motor lacks sufficient torque, users may struggle to complete their routes without frequent stops or damage to the bike.

The Solution: When sourcing electric cargo bikes, prioritize models that feature powerful motors with high torque ratings, ideally above 60 Nm. Additionally, consider hydraulic disc brakes for superior stopping power on steep descents, ensuring safety under heavy loads. Look for bikes that offer adjustable pedal assist levels, allowing riders to tailor their power output based on terrain challenges. Furthermore, conducting field tests in real-world conditions can help verify that the chosen models meet operational needs. Collaborating with suppliers who provide robust after-sales support and warranty services can also ensure timely maintenance and repairs, minimizing downtime.

Scenario 2: Managing Maintenance and Repair Costs

The Problem: B2B buyers often encounter unexpected maintenance and repair costs, especially when dealing with complex systems like belt drives and hydraulic brakes. In regions with limited access to specialized bike mechanics, companies may find it challenging to keep their fleets operational. The high cost of replacement parts and labor can strain budgets, leading to operational inefficiencies.

The Solution: To mitigate maintenance costs, invest in electric cargo bikes that utilize durable components, such as Gates Carbon Drive belts, known for their longevity and low maintenance requirements compared to traditional chain systems. Establishing a relationship with local bike shops or mechanics who specialize in electric bikes can provide essential support and training for in-house maintenance. Additionally, consider setting up a preventive maintenance schedule, which includes regular inspections and timely replacements of wear-prone parts. This proactive approach can help identify potential issues before they escalate, ultimately saving costs and ensuring a more reliable fleet.

Scenario 3: Ensuring Compliance with Local Regulations

The Problem: B2B buyers must navigate a complex landscape of regulations that vary significantly by region, particularly regarding electric vehicle specifications and safety standards. In the Middle East and Europe, for example, regulations may dictate the maximum power output, weight limits, and safety features required for electric cargo bikes. Non-compliance can lead to fines or restrictions on operations.

The Solution: To ensure compliance, conduct thorough research on local regulations governing electric cargo bikes in your target market. Collaborate with manufacturers who are well-versed in these regulations and can provide models that meet or exceed them. It may also be beneficial to consult with legal experts or industry associations to stay updated on any changes in legislation. Additionally, consider investing in bikes equipped with features that enhance safety, such as integrated lights, reflective materials, and reliable braking systems. Documenting compliance efforts can also serve as valuable evidence in case of inspections or disputes. By prioritizing compliance from the outset, businesses can operate confidently and avoid costly interruptions.

Strategic Material Selection Guide for electric cargo bike belt drive hydraulic

What Are the Key Materials for Electric Cargo Bike Belt Drive Hydraulic Systems?

When selecting materials for electric cargo bike belt drive hydraulic systems, it’s essential to consider properties such as durability, weight, cost, and compatibility with various environmental conditions. Here, we analyze four common materials: aluminum, carbon fiber, stainless steel, and thermoplastics.

How Does Aluminum Perform in Electric Cargo Bike Applications?

Aluminum is widely used in electric cargo bike frames and components due to its excellent strength-to-weight ratio. Key properties include a high corrosion resistance and good thermal conductivity, making it suitable for various climatic conditions.

Pros: Aluminum is lightweight, which enhances bike performance and efficiency. It is also relatively inexpensive and easy to manufacture, allowing for complex shapes and designs.

Cons: While durable, aluminum can be less robust than steel under extreme stress, which may lead to deformation over time. It is also susceptible to fatigue, especially in high-stress applications.

Impact on Application: Aluminum is compatible with hydraulic fluids and can withstand moderate temperature and pressure ratings, making it suitable for hydraulic systems.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local standards such as ASTM and ISO, particularly regarding corrosion resistance in humid or coastal environments.

What Are the Benefits of Carbon Fiber in Electric Cargo Bike Design?

Carbon fiber is increasingly popular in high-end electric cargo bikes due to its exceptional strength and lightweight properties. It offers excellent stiffness, allowing for efficient power transfer.

Pros: The primary advantage of carbon fiber is its high strength-to-weight ratio, providing superior performance without adding significant weight. It also has excellent fatigue resistance, making it suitable for long-term use.

Cons: Carbon fiber is more expensive than aluminum and can be challenging to manufacture, requiring specialized techniques. Additionally, it can be brittle, leading to potential failure under impact.

Impact on Application: Carbon fiber is compatible with hydraulic systems and can handle high pressure, making it ideal for advanced hydraulic applications.

Considerations for International Buyers: Buyers should be aware of the high cost and potential supply chain complexities associated with carbon fiber components, especially in regions with less access to advanced manufacturing.

Why Choose Stainless Steel for Durability in Hydraulic Systems?

Stainless steel is a robust material known for its corrosion resistance and durability, making it a common choice for hydraulic components in electric cargo bikes.

Pros: Stainless steel offers excellent strength and resistance to wear and tear, ensuring longevity. It is also resistant to corrosion, which is crucial for bikes exposed to various weather conditions.

Cons: The primary downside is its weight; stainless steel is heavier than aluminum and carbon fiber, which can affect bike performance. It is also more expensive than aluminum.

Impact on Application: Stainless steel can withstand high temperatures and pressures, making it suitable for hydraulic systems that require reliability under demanding conditions.

Considerations for International Buyers: Compliance with international standards is crucial, especially in markets like Europe where stringent regulations exist. Buyers should also consider the weight implications for cargo capacity.

How Do Thermoplastics Enhance Electric Cargo Bike Functionality?

Thermoplastics are increasingly used in electric cargo bike components, particularly in non-structural applications. They offer flexibility and can be molded into complex shapes.

Pros: Thermoplastics are lightweight, resistant to corrosion, and can be produced at a lower cost compared to metals. They also provide good impact resistance.

Cons: While thermoplastics are generally durable, they may not withstand high temperatures or pressures as effectively as metals, limiting their use in certain hydraulic applications.

Impact on Application: They are suitable for hydraulic systems that operate under moderate conditions but may require additional reinforcement for higher pressures.

Considerations for International Buyers: Buyers should assess the specific thermoplastic grades used in their applications to ensure compliance with local standards and compatibility with hydraulic fluids.

Summary Table of Material Selection for Electric Cargo Bike Belt Drive Hydraulic Systems

| Material | Typical Use Case for electric cargo bike belt drive hydraulic | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Frame and hydraulic components | Lightweight and cost-effective | Less robust under extreme stress | Medium |

| Carbon Fiber | High-end frames and components | High strength-to-weight ratio | Expensive and brittle | High |

| Stainless Steel | Hydraulic components | Excellent durability and corrosion resistance | Heavier than alternatives | Medium |

| Thermoplastics | Non-structural components | Lightweight and cost-effective | Limited high-temperature performance | Low |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, helping them make informed decisions based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for electric cargo bike belt drive hydraulic

What Are the Main Stages in the Manufacturing Process of Electric Cargo Bikes with Belt Drive and Hydraulic Systems?

The manufacturing process of electric cargo bikes equipped with belt drive and hydraulic systems involves several key stages. Each stage is crucial to ensuring the final product meets quality and performance standards suitable for B2B buyers.

Material Preparation: What Raw Materials Are Used?

The first stage begins with the selection and preparation of raw materials. High-quality aluminum or steel frames are typically used for their strength and lightweight properties. Carbon fiber may also be utilized for specific components to enhance performance and durability. The belt drive system often comprises advanced composite materials that provide resistance to wear and tear. Hydraulics require specialized components like hydraulic fluid, seals, and hoses, which must be sourced from certified suppliers to ensure reliability.

Forming: How Are Components Shaped and Fabricated?

In the forming stage, various manufacturing techniques are employed to shape the materials into the necessary components. This includes processes such as:

- CNC Machining: Utilized for precision parts, ensuring that components fit together seamlessly.

- Metal Stamping: Often used for the frame and other structural parts to achieve complex shapes quickly.

- Injection Molding: Common for producing plastic components such as cable housings and grips.

- Bending and Welding: Essential for assembling the frame and integrating the hydraulic systems securely.

Each technique is selected based on the material properties and the design requirements of the bike.

Assembly: How Are Components Integrated into a Complete Product?

The assembly stage is where the bike begins to take shape. Skilled technicians assemble the frame, install the belt drive system, and integrate the hydraulic components. This stage may involve:

- Sub-Assembly: Components like the electric motor, battery, and hydraulic brakes are assembled separately before being integrated into the main frame.

- Wiring and Electrical Integration: Technicians ensure that the electric systems are properly wired and tested for functionality.

- Quality Checks: Throughout assembly, various checks are performed to confirm that parts align correctly and function as intended.

What Finishing Techniques Enhance the Durability of Electric Cargo Bikes?

Finishing processes are crucial for enhancing the durability and aesthetic appeal of electric cargo bikes. Common techniques include:

- Powder Coating: Provides a protective layer that guards against corrosion and wear, while also allowing for customization in color.

- Anodizing: Often applied to aluminum parts to improve corrosion resistance and surface hardness.

- Final Assembly Inspection: A thorough check post-assembly to identify any defects before the bike is packaged and shipped.

What International Standards and Quality Control Measures Are Relevant for B2B Buyers?

Quality assurance is critical in manufacturing electric cargo bikes, especially for international B2B buyers. Compliance with international standards ensures that products meet safety and performance benchmarks.

Which International Standards Should Manufacturers Adhere To?

Manufacturers should adhere to several key standards, including:

- ISO 9001: This standard focuses on quality management systems, ensuring consistent product quality and customer satisfaction.

- CE Marking: Required for products sold in the European market, this indicates compliance with health, safety, and environmental protection standards.

- API Standards: Relevant for hydraulic components, these standards ensure that parts are safe and reliable.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) is integrated at various checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified quality standards.

- In-Process Quality Control (IPQC): Ongoing checks during manufacturing to catch defects early. This includes monitoring assembly techniques and component integration.

- Final Quality Control (FQC): A comprehensive inspection of the completed bike, focusing on functionality, safety, and aesthetic quality.

What Common Testing Methods Are Employed to Ensure Quality?

Testing methods are vital for validating the performance and safety of electric cargo bikes. Common tests include:

- Performance Testing: Evaluating the bike’s electric assist, battery life, and torque output under various conditions.

- Load Testing: Assessing the bike’s ability to carry specified weights safely, simulating real-world usage.

- Durability Testing: Subjecting the bike to rigorous conditions to evaluate its longevity, including exposure to weather elements and rough terrain.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to ensure that suppliers maintain high-quality standards. Here are effective strategies:

- Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes, quality control measures, and compliance with international standards.

- Requesting Quality Reports: Buyers should ask for detailed quality assurance reports that outline testing results, compliance with standards, and any certifications the manufacturer holds.

- Third-Party Inspections: Engaging independent inspectors can provide an unbiased evaluation of the manufacturing facility and quality control processes.

What Are the QC and Certification Nuances for International Markets?

B2B buyers from regions like Africa, South America, the Middle East, and Europe must be aware of local regulations and certification requirements:

- Regional Compliance: Different regions may have specific standards that must be met for products to be sold. For instance, the Middle East may require specific certifications for electrical components.

- Customs and Tariffs: Understanding the import regulations, including tariffs and taxes, is essential for smooth transactions and compliance.

By understanding these manufacturing processes and quality assurance measures, international B2B buyers can make informed decisions when sourcing electric cargo bikes with belt drive and hydraulic systems, ensuring they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric cargo bike belt drive hydraulic’

In this guide, we aim to provide a comprehensive checklist for B2B buyers seeking to procure electric cargo bikes with belt drive and hydraulic systems. This step-by-step approach will help ensure that your investment meets your operational needs while maximizing value and reliability.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is crucial before engaging with suppliers. Consider the bike’s intended use—whether for transporting goods, children, or both. Pay attention to specifications such as weight capacity, battery range, and motor power, as these will directly impact performance and usability in various terrains and distances.

Step 2: Research Market Trends and Innovations

Staying informed about the latest trends in electric cargo bikes can provide a competitive edge. Look for advancements in battery technology, motor efficiency, and frame design. This knowledge will not only help you select the most suitable bike but also enable you to negotiate better terms with suppliers based on current market offerings.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their production capabilities and quality control processes to ensure they can meet your specifications reliably.

- Check for Certifications: Verify that the suppliers comply with international standards and regulations, which can affect product quality and safety.

- Review Customer Feedback: Look for reviews or testimonials from other businesses to gauge satisfaction and service levels.

Step 4: Request Product Samples

Always request samples of the electric cargo bikes before making a bulk purchase. This allows you to evaluate the build quality, comfort, and functionality of the bikes firsthand. Pay particular attention to the belt drive and hydraulic systems, as these components are critical for performance and maintenance.

Step 5: Analyze Total Cost of Ownership

Understanding the total cost of ownership (TCO) is essential for making an informed purchasing decision. TCO includes not just the initial purchase price but also maintenance, repair, and operational costs over the bike’s lifecycle. Look for warranties and service agreements that can mitigate long-term expenses.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, engage in negotiations to secure favorable terms. Discuss payment terms, delivery timelines, and after-sales support. Ensure that you have clear agreements on warranty coverage and any potential liabilities.

Step 7: Plan for Training and Maintenance

Implement a plan for staff training and ongoing maintenance of the electric cargo bikes. Proper training will ensure that users can operate the bikes efficiently and safely. Regular maintenance checks will enhance the lifespan of the bikes and reduce the likelihood of operational disruptions.

By following this practical sourcing guide, B2B buyers can make informed decisions when procuring electric cargo bikes with belt drive and hydraulic systems, ensuring they meet their business needs effectively.

Comprehensive Cost and Pricing Analysis for electric cargo bike belt drive hydraulic Sourcing

What Are the Key Cost Components of Electric Cargo Bike Belt Drive Hydraulic Sourcing?

When sourcing electric cargo bikes with belt drive hydraulic systems, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The quality of materials significantly impacts pricing. High-performance components such as aluminum frames, carbon fiber belts, and hydraulic brakes generally lead to higher costs. Sourcing materials from reputable suppliers can enhance durability and performance, but also increases the overall expense.

-

Labor: Labor costs can vary based on geographical location and the skill level required for assembly. In regions with higher labor costs, such as parts of Europe, expect to pay more. Conversely, sourcing from countries with lower labor costs may be economically advantageous, provided that quality standards are maintained.

-

Manufacturing Overhead: This encompasses utilities, rent, and administrative costs associated with production facilities. Efficient manufacturing processes can help reduce overhead, thus lowering the final price for buyers.

-

Tooling: Specialized tools for assembly and maintenance of electric cargo bikes can add to the initial cost. Custom tooling for specific designs or modifications increases upfront costs but can lead to better efficiency in production.

-

Quality Control (QC): Implementing rigorous quality control measures ensures that each bike meets safety and performance standards. While this incurs additional costs, it minimizes returns and enhances brand reputation, ultimately benefiting long-term profitability.

-

Logistics: Transportation and warehousing costs are critical, particularly for international buyers. Shipping costs can fluctuate based on fuel prices, trade tariffs, and logistics provider efficiency. Understanding Incoterms can help buyers clarify responsibilities related to shipping costs and risks.

-

Margin: Suppliers typically add a margin to cover their expenses and ensure profit. This margin can vary widely, depending on the supplier’s market position and the competitive landscape.

How Do Price Influencers Affect Sourcing Electric Cargo Bikes?

Several factors influence the pricing of electric cargo bikes, particularly for international B2B buyers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to reduced per-unit costs due to economies of scale. Buyers should negotiate for lower prices based on anticipated order volumes.

-

Specifications and Customization: Custom features, such as advanced battery systems or unique frame designs, can significantly affect pricing. Buyers should carefully assess which features provide value versus those that inflate costs unnecessarily.

-

Materials and Quality Certifications: Higher quality materials and certifications (e.g., ISO, CE) can increase costs but provide assurance of safety and performance. Buyers in markets with stringent regulations, such as Europe, may prioritize certified products, impacting overall sourcing costs.

-

Supplier Factors: The reputation, reliability, and financial stability of suppliers can influence pricing. Established suppliers with proven track records may charge a premium but often deliver better quality and service.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is crucial for cost management. These terms dictate who pays for shipping, insurance, and tariffs, affecting the total landed cost of goods.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing?

For B2B buyers, particularly from Africa, South America, the Middle East, and Europe, here are actionable tips to optimize sourcing of electric cargo bikes:

-

Negotiate Effectively: Leverage your volume requirements to negotiate better pricing. Establishing long-term relationships with suppliers can also lead to more favorable terms.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, energy consumption, and potential resale value. A higher initial cost may lead to lower TCO if the bike has superior durability and efficiency.

-

Research and Compare Suppliers: Conduct thorough market research to compare pricing and service offerings. Engage multiple suppliers to understand the market rate and identify the best value.

-

Be Aware of Pricing Nuances: International buyers should consider fluctuations in currency exchange rates and geopolitical factors that may affect pricing. Establishing contracts in stable currencies can mitigate risks.

-

Plan for Future Needs: Anticipate future demands and potential expansions in your fleet. This foresight can influence negotiations and supplier selection, ensuring you secure the best pricing structure for long-term partnerships.

In conclusion, understanding the cost components and pricing influencers of electric cargo bikes with belt drive hydraulic systems is essential for B2B buyers. By applying strategic sourcing approaches and leveraging market insights, companies can optimize their procurement processes and achieve better financial outcomes.

Alternatives Analysis: Comparing electric cargo bike belt drive hydraulic With Other Solutions

Understanding Alternatives for Electric Cargo Bike Belt Drive Hydraulic

As the demand for sustainable urban transport solutions grows, B2B buyers are increasingly exploring various alternatives to electric cargo bikes with belt drive hydraulic systems. The choice of transportation method can significantly impact operational efficiency, cost-effectiveness, and environmental sustainability. In this analysis, we will compare the electric cargo bike belt drive hydraulic with two viable alternatives: traditional electric cargo bikes with chain drives and cargo vans.

Comparison Table

| Comparison Aspect | Electric Cargo Bike Belt Drive Hydraulic | Traditional Electric Cargo Bike (Chain Drive) | Cargo Van |

|---|---|---|---|

| Performance | High torque, smooth operation, low noise | Moderate torque, may require more maintenance | High capacity, fast speed |

| Cost | Moderate to high initial investment | Generally lower initial cost | High initial investment |

| Ease of Implementation | Quick setup, minimal infrastructure needed | Similar to belt drives, easy to set up | Requires more infrastructure (parking, maintenance) |

| Maintenance | Low maintenance, durable components | Higher maintenance due to chain wear | Regular maintenance required (engine, tires) |

| Best Use Case | Urban deliveries, eco-friendly transport | Short to medium urban deliveries | Long-distance deliveries, larger loads |

Detailed Breakdown of Alternatives

Traditional Electric Cargo Bike (Chain Drive)

Traditional electric cargo bikes equipped with chain drives are a popular alternative to belt drive hydraulic systems. These bikes are generally more affordable, with lower initial costs making them attractive for startups and small businesses. However, they require more frequent maintenance due to chain wear and lubrication needs. While they can handle short to medium distances efficiently, they may not offer the same level of torque and quiet operation as belt drive systems, making them less suitable for certain urban environments.

Cargo Van

Cargo vans represent a different approach to transport, offering significant cargo capacity and speed. They are ideal for businesses that need to deliver larger loads over longer distances. However, the initial investment is considerably higher, and operational costs can escalate quickly due to fuel, insurance, and maintenance. Additionally, vans contribute to urban congestion and pollution, making them less attractive for eco-conscious companies. While they are effective for logistics and distribution in suburban and rural areas, they may not align with the growing emphasis on sustainability in urban settings.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the appropriate transport solution, B2B buyers should carefully consider their specific operational needs, budget constraints, and sustainability goals. Electric cargo bikes with belt drive hydraulic systems offer a balance of performance, low maintenance, and environmental benefits, making them ideal for urban deliveries. Traditional electric cargo bikes may be more budget-friendly but come with higher maintenance demands. Conversely, cargo vans are best for larger loads and longer distances but may not align with eco-friendly initiatives. Assessing these factors will empower buyers to make informed decisions that best suit their business requirements.

Essential Technical Properties and Trade Terminology for electric cargo bike belt drive hydraulic

What Are the Key Technical Properties of Electric Cargo Bikes with Belt Drives and Hydraulic Systems?

When evaluating electric cargo bikes, particularly those with belt drive and hydraulic systems, understanding their technical properties is essential for making informed purchasing decisions. Here are some critical specifications to consider:

-

Belt Drive Material Grade

Electric cargo bikes often utilize high-strength materials such as carbon fiber or reinforced polyurethane for belt drives. These materials provide durability and resistance to wear and tear, making them ideal for heavy loads. For B2B buyers, selecting a bike with a high-grade belt drive ensures longevity and reduced maintenance costs, which is particularly important in commercial applications where reliability is paramount. -

Hydraulic Brake System Specifications

Hydraulic brakes are preferred for their superior stopping power and modulation compared to mechanical systems. Key specifications include piston diameter and fluid type, often DOT 5.1 or mineral oil. A properly designed hydraulic system allows for smoother braking, which is crucial when carrying significant cargo. Understanding these specs helps buyers assess safety and performance standards, especially in urban environments. -

Torque Ratings of Electric Motors

The torque rating, typically measured in Newton-meters (Nm), indicates the motor’s capability to handle steep inclines and heavy loads. For cargo bikes, a torque rating of 60 Nm or higher is often recommended. This specification is vital for B2B buyers focused on operational efficiency, as higher torque translates to better performance in demanding conditions, reducing the likelihood of breakdowns. -

Battery Capacity and Range

Battery capacity, measured in watt-hours (Wh), directly affects the bike’s range and performance. A higher capacity (e.g., 500 Wh or more) allows for longer rides without frequent recharging, which is essential for businesses that rely on these bikes for daily operations. Understanding battery specifications helps buyers evaluate the suitability of a bike for their logistics or delivery needs. -

Weight Capacity and Frame Construction

The weight capacity, often exceeding 400 lbs for electric cargo bikes, is a critical specification for B2B applications. The frame material (aluminum, steel, or composite) plays a significant role in weight capacity and overall durability. Buyers must consider these factors to ensure that the bike can handle the intended loads without compromising safety or structural integrity.

What Are Common Trade Terms Used in Electric Cargo Bike Transactions?

Familiarity with industry jargon is crucial for effective communication and negotiation in the B2B landscape. Here are some common terms relevant to electric cargo bikes:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of electric cargo bikes, understanding OEM relationships can aid buyers in sourcing high-quality components that meet specific performance and durability standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is essential for B2B buyers looking to negotiate bulk purchases or secure advantageous pricing structures. Knowing the MOQ helps businesses plan their inventory and budget effectively. -

RFQ (Request for Quotation)

An RFQ is a standard business process where a buyer requests pricing information from suppliers. When considering electric cargo bikes, submitting an RFQ can help businesses compare costs and specifications across different manufacturers, ensuring they make an informed decision. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Familiarity with these terms helps B2B buyers understand their obligations and rights, particularly when importing electric cargo bikes from different regions. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. For businesses that rely on electric cargo bikes for operational efficiency, knowing the lead time can help in planning logistics and ensuring timely delivery of goods and services.

By understanding these technical properties and trade terms, B2B buyers can navigate the complexities of purchasing electric cargo bikes with confidence, ensuring they select the right models for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the electric cargo bike belt drive hydraulic Sector

What Are the Global Drivers and Key Trends in the Electric Cargo Bike Belt Drive Hydraulic Market?

The electric cargo bike sector, particularly those utilizing belt drive and hydraulic systems, is experiencing a notable surge in demand driven by various global factors. Urbanization, rising fuel costs, and an increasing emphasis on sustainable transportation are pivotal in shaping this market. In regions like Africa, South America, the Middle East, and Europe, there is a growing need for efficient and eco-friendly logistics solutions. This has prompted businesses to explore electric cargo bikes as a viable alternative to traditional delivery vehicles.

Emerging technologies such as smart battery management systems and enhanced motor efficiency are transforming the landscape, making electric cargo bikes more reliable and user-friendly. Additionally, the trend towards customization is growing, with manufacturers offering modular designs and accessories that cater to specific business needs—be it family transportation in Brazil or last-mile delivery solutions in Saudi Arabia. The integration of advanced materials, such as lightweight alloys and carbon fiber, is also gaining traction, enhancing durability while minimizing weight.

Moreover, the global market is seeing a shift towards direct-to-consumer sales models, enabling buyers to engage more directly with manufacturers. This trend is particularly beneficial for international B2B buyers, as it allows for better pricing strategies and customization options. Understanding these dynamics is crucial for businesses looking to invest in electric cargo bikes for operational efficiency and sustainability.

How Can Sustainability and Ethical Sourcing Impact the Electric Cargo Bike Industry?

Sustainability is not just a trend; it has become a core principle in the electric cargo bike industry. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing environmental impact. This includes using recyclable materials, sustainable production processes, and energy-efficient technologies. For electric cargo bikes with belt drive systems, the choice of materials—such as eco-friendly belts and lightweight frames—can significantly affect the product’s overall sustainability profile.

Ethical sourcing is equally essential. Buyers must ensure that their suppliers maintain transparent supply chains that uphold labor rights and environmental standards. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to ethical practices. Furthermore, companies that invest in sustainability often enjoy a competitive advantage, as consumers and businesses alike are more inclined to support brands that align with their values.

In addition to ethical considerations, there is a growing market for electric cargo bikes that integrate renewable energy solutions, such as solar-powered charging stations. By sourcing components and materials from certified suppliers, businesses can enhance their brand reputation and appeal to a conscientious customer base, thereby driving sales and fostering long-term partnerships.

What Is the Brief Evolution of Electric Cargo Bikes and Their Impact on B2B Buyers?

The evolution of electric cargo bikes has been marked by rapid technological advancements and an increasing recognition of their utility in urban environments. Initially designed for recreational use, these bikes have transformed into practical solutions for businesses facing the challenges of urban logistics. The introduction of electric assist features has made cargo bikes more accessible, allowing users to transport heavier loads over longer distances with ease.

The integration of belt drive systems has further enhanced the appeal of electric cargo bikes. Belt drives offer a cleaner, quieter, and lower-maintenance alternative to traditional chain systems, making them particularly attractive for businesses focused on sustainability. Hydraulic braking systems have also improved safety and control, which is crucial when transporting goods in busy urban settings.

As the market continues to evolve, international B2B buyers are presented with a diverse range of options that cater to various business needs. From family-oriented models in South America to robust delivery solutions in Europe and the Middle East, the electric cargo bike market is poised for significant growth. Understanding this evolution allows buyers to make informed decisions that align with their operational goals and sustainability commitments.

Frequently Asked Questions (FAQs) for B2B Buyers of electric cargo bike belt drive hydraulic

-

How do I determine the right electric cargo bike for my business needs?

To select the ideal electric cargo bike for your business, consider factors such as cargo capacity, distance requirements, and terrain. Assess your typical load size and the number of passengers, as these will influence the bike’s specifications. Additionally, evaluate battery range and motor power to ensure that the bike can handle your operational needs, especially in hilly areas or over long distances. Engaging with suppliers for test rides can also provide practical insights into performance. -

What are the advantages of belt drive systems in electric cargo bikes?

Belt drive systems offer several benefits over traditional chain systems, including lower maintenance requirements and increased durability. They are cleaner, quieter, and provide a smoother ride, which is essential for businesses that rely on their bikes for daily operations. Furthermore, belt drives are more resistant to wear and tear from environmental factors, making them a long-term investment for B2B buyers. -

What customization options are available for electric cargo bikes?

Many manufacturers offer customization options to tailor electric cargo bikes to specific business needs. These can include different cargo configurations, color choices, and additional features such as child seats or cargo racks. It’s advisable to discuss your requirements with suppliers to explore available modifications that can enhance functionality and appeal to your target market. -

What is the minimum order quantity (MOQ) for electric cargo bikes?

The MOQ for electric cargo bikes can vary significantly depending on the manufacturer and the specific model. Generally, suppliers may require a MOQ ranging from 5 to 50 units to accommodate production schedules and cost efficiencies. It’s beneficial to communicate with potential suppliers to understand their MOQ policies and explore options for bulk purchasing discounts. -

What payment terms should I expect when sourcing electric cargo bikes internationally?

Payment terms can differ widely among suppliers, but common practices include a deposit upon order confirmation followed by the balance upon shipment or delivery. Some suppliers may offer credit terms or financing options for larger orders. Always clarify payment conditions, including currency, methods (e.g., wire transfer, letter of credit), and any applicable taxes or tariffs to avoid unexpected costs. -

How can I ensure the quality of electric cargo bikes during sourcing?

To ensure quality, request detailed specifications and certifications from suppliers, including compliance with international safety standards. Consider conducting factory audits or requesting samples before placing a bulk order. Additionally, look for suppliers with established reputations and positive customer feedback. Implementing a quality assurance process during production can also safeguard against defects. -

What are the logistics considerations for importing electric cargo bikes?

Logistics for importing electric cargo bikes involve several factors, including shipping methods, customs regulations, and delivery timelines. Choose a reliable freight forwarder experienced in handling bicycles and ensure all necessary documentation is prepared, such as bills of lading and customs declarations. Factor in lead times for production and shipping to align with your market demand. -

What after-sales support should I expect from electric cargo bike suppliers?

After-sales support is crucial for maintaining operational efficiency. Reputable suppliers often provide warranties on their products, technical support, and access to spare parts. Inquire about the availability of training for maintenance and repair, as well as the supplier’s responsiveness to service inquiries. Establishing a strong relationship with your supplier can enhance support and foster long-term collaboration.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Electric Cargo Bike Belt Drive Hydraulic Manufacturers & Suppliers List

1. Clever Cycles – Electric Cargo Bikes

Domain: clevercycles.com

Registered: 2006 (19 years)

Introduction: Electric Cargo Bikes available at Clever Cycles include:

1. Urban Arrow FamilyNext Pro – Bosch Cargo Line Smart System – $8,999.00

2. Tern Quick Haul P9 Electric Cargo Bike – $3,099.00

3. Urban Arrow Family Electric Cargo Bike – $5,999.00 (originally $6,999.00)

4. Yuba Kombi E5 Electric Cargo Bike – $2,999.00 (originally $3,299.00)

5. Tern HSD Gen 2 P5i Electric Cargo Bike – $4,975.00

6. Tern Quic…

2. Specialized – Globe Haul ST

Domain: bicycling.com

Registered: 1999 (26 years)

Introduction: Best Overall: Specialized Globe Haul ST – Price: €2,500, Tires: 20 x 3.5 in., Weight: 77 lbs., Cargo Capacity: 419 lbs., Pros: Compact footprint, excellent battery life and power delivery, strong brakes; Cons: Lack of suspension, can only carry one child.

Best Value: Aventon Abound – Price: $1,999 (now $1,599), Tires: 20 x 2.4 in., Weight: 81 lbs., Cargo Capacity: 440 lbs., Pros: Powerful motor, …

3. Reddit – Tern GSD, Riese & Muller Multitinker

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Key products mentioned include the Tern GSD and Riese & Muller Multitinker as cargo ebikes with belt drives. Other brands like Trek, Momentum, and Specialized are noted for chain drives, with a potential mention of the Specialized Globe Hauler LT possibly offering a belt drive option. Additional options discussed include the Omnium with a Shimano battery belt drive and the VELLO SUB, which feature…

4. Momentum – Compakt E+ Cargo E-Bike

Domain: momentum-biking.com

Registered: 2009 (16 years)

Introduction: Compakt E+:

– Versatile cargo e-bike designed for urban environments.

– Compact design for easy storage in limited spaces or RVs.

– Single-size, low-step frame with tool-free adjustable handlebars and stem.

– Adjustable seat for a wide range of riders.

– Impressive payload capacity of 180kg (front rack 15kg, rear rack 27kg).

– Customizable with Momentum’s MIK-HD compatible rear rack and thir…

5. VVolt – Centauri II Electric Bike

Domain: vvolt.com

Registered: 2012 (13 years)

Introduction: {“product_name”: “Centauri II Electric Bike”, “class”: “Class 3”, “motor”: {“type”: “mid-drive”, “power”: “650 peak watts”, “torque”: “120nm peak torque”}, “range”: “up to 60 miles”, “top_assist_speed”: “28 mph”, “weight”: “53 lbs with battery”, “price”: {“original”: “$3,199”, “discounted”: “$2,599”, “discount”: “19%”}, “warranty”: “3-year comprehensive warranty”, “features”: {“transmission”: “aut…

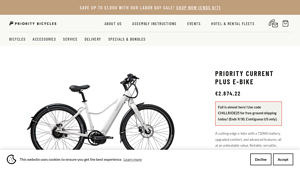

6. Priority Bicycles – Current Plus E-Bike

Domain: prioritybicycles.com

Introduction: Product Name: Priority Current Plus E-Bike

Price: $3,299 (Shimano) / $3,499 (Enviolo)

Battery: 720Wh, removable for easy charging

Motor: Mid-drive motor with updated firmware

Drive System: Gates Carbon Drive belt, low-maintenance, no rust or grease

Throttle: Thumb-activated throttle for easy acceleration

Features: Enhanced stability, increased battery life, optimized components for urban commuting…

7. eBullitt – eBullitt 6100

Domain: larryvsharry.com

Registered: 2007 (18 years)

Introduction: eBullitt – Larry vs Harry

**Models:**

– eBullitt 6100

– eBullitt EP801

**eBullitt 6100:**

– Recommended price: From €5,240 (incl. VAT, excl. dealer fees)

– Assisted speed: Up to 25 km/h

– Total length: 2430mm

– Frame width: 460mm

– Complete bike weight: From 28kg

– Total load capacity: 180kg (including rider)

– Drive Unit: Shimano STePS 6100 (60 Nm torque)

– Battery options: 418, 504 or 630 Wh

-…

Strategic Sourcing Conclusion and Outlook for electric cargo bike belt drive hydraulic

Why is Strategic Sourcing Essential for Electric Cargo Bikes?

In conclusion, the strategic sourcing of electric cargo bikes equipped with belt drive and hydraulic systems presents a significant opportunity for international B2B buyers. These bikes offer numerous advantages, including lower maintenance costs, enhanced durability, and superior performance under various conditions. As urban mobility continues to evolve, the demand for sustainable transportation solutions is rising, making electric cargo bikes a viable alternative to traditional vehicles.

Investing in high-quality electric cargo bikes can not only reduce operational costs but also support environmentally friendly initiatives. Buyers should focus on suppliers that offer customizable options, robust after-sales support, and a comprehensive range of accessories to meet diverse market needs.

As we look ahead, the market for electric cargo bikes is poised for growth, particularly in regions like Africa, South America, the Middle East, and Europe. Now is the time for businesses to capitalize on this trend by sourcing innovative and reliable products. Engage with trusted suppliers to explore the latest models and technologies, positioning your organization at the forefront of the sustainable transport revolution.