Introduction: Navigating the Global Market for electric cargo bike mid drive

In an increasingly competitive global market, sourcing electric cargo bike mid drive solutions presents a unique challenge for B2B buyers. As urban logistics evolve and the demand for sustainable transportation options grows, businesses must navigate a diverse landscape of models, features, and applications. This guide offers a comprehensive overview of electric cargo bikes, focusing on mid-drive systems that enhance performance and reliability. We will delve into the various types of electric cargo bikes available, explore their practical applications in urban settings, and provide essential insights into supplier vetting, cost considerations, and market trends.

For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including emerging markets like Vietnam and Nigeria—making informed purchasing decisions is crucial. This guide empowers you with the knowledge to identify the right electric cargo bike mid drive for your specific needs, ensuring that you can optimize your logistics and reduce your carbon footprint. By understanding the intricacies of electric cargo bike technology and market dynamics, you can confidently select products that not only meet your operational requirements but also align with your sustainability goals. Whether you are looking to enhance delivery capabilities, improve urban mobility, or support local economies, this guide serves as your roadmap to success in the electric cargo bike market.

Understanding electric cargo bike mid drive Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Long-Tail Cargo | Extended frame for increased cargo capacity, stable handling | Family transport, food delivery, logistics | Pros: High load capacity, versatile. Cons: Larger footprint may limit maneuverability. |

| Short-Tail Cargo | Compact design, easy to maneuver, often with a lower center of gravity | Urban deliveries, rental services, personal use | Pros: Agile, easy to park. Cons: Limited cargo space compared to long-tail models. |

| Utility Cargo | Built for practicality, often with integrated storage options | Commercial deliveries, trades, services | Pros: Functional design, often customizable. Cons: May lack speed compared to other types. |

| Heavy-Duty Cargo | Robust construction, high weight capacity, often with advanced motor systems | Construction, industrial applications | Pros: Exceptional durability, high performance. Cons: Higher cost and weight. |

| Electric Trike Cargo | Three-wheel design for enhanced stability and load distribution | Elderly transport, heavy cargo transport | Pros: Increased stability, suitable for various terrains. Cons: Limited speed and agility. |

What are the Characteristics of Long-Tail Cargo Bikes?

Long-tail cargo bikes feature an extended frame that allows for greater cargo capacity without compromising stability. This design is ideal for businesses that require transporting larger items or multiple passengers, such as families or delivery services. When considering a long-tail bike, B2B buyers should evaluate the frame material, weight limits, and the bike’s ability to navigate urban environments.

How Do Short-Tail Cargo Bikes Differ from Long-Tail Models?

Short-tail cargo bikes are designed for agility, featuring a compact frame that makes them easy to maneuver in tight spaces. They are particularly well-suited for urban deliveries and rental services, where space can be a constraint. Buyers should focus on the bike’s handling characteristics, battery range, and available cargo accessories to ensure it meets their operational needs.

What Makes Utility Cargo Bikes a Practical Choice?

Utility cargo bikes are built with practicality in mind, often incorporating integrated storage solutions and customizable features. They are ideal for tradespeople and businesses requiring reliable transport for tools and equipment. When selecting a utility cargo bike, B2B buyers should consider the bike’s load capacity, ease of access to cargo areas, and the availability of aftermarket accessories.

Why Choose Heavy-Duty Cargo Bikes for Industrial Use?

Heavy-duty cargo bikes are engineered for robustness and high weight capacity, making them suitable for industrial applications such as construction and logistics. These bikes often come equipped with advanced motor systems to handle heavy loads efficiently. Buyers should assess the bike’s durability, maintenance requirements, and performance under load when making purchasing decisions.

What Are the Advantages of Electric Trike Cargo Bikes?

Electric trike cargo bikes offer enhanced stability and load distribution due to their three-wheel design. They are particularly beneficial for transporting heavier cargo or accommodating elderly riders. B2B buyers should evaluate the trike’s turning radius, speed capabilities, and comfort features to ensure it aligns with their operational requirements.

Key Industrial Applications of electric cargo bike mid drive

| Industry/Sector | Specific Application of electric cargo bike mid drive | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| E-commerce & Delivery | Last-mile delivery of goods | Reduces delivery times and operational costs | Battery capacity, payload capacity, and range requirements |

| Food & Beverage | Mobile food delivery services | Enhances customer service and expands delivery reach | Weather resistance, temperature control options |

| Urban Logistics | Transporting goods in congested city areas | Minimizes traffic congestion and environmental impact | Maneuverability, weight distribution, and durability |

| Tourism & Recreation | Guided tours and rental services | Offers unique experiences and promotes eco-tourism | Comfort features, customization options, and safety |

| Waste Management | Collection and transportation of recyclables | Improves efficiency and sustainability in operations | Load capacity, ease of maintenance, and regulatory compliance |

How is the Electric Cargo Bike Mid Drive Revolutionizing E-commerce and Delivery?

In the e-commerce sector, electric cargo bikes with mid-drive systems are increasingly utilized for last-mile delivery. These bikes can navigate urban environments efficiently, allowing businesses to meet customer demands for quick deliveries. The mid-drive motor provides better torque and control, making it easier to carry heavier loads over varied terrains. International buyers should focus on battery capacity and overall payload capabilities to ensure they can meet delivery requirements effectively.

What Role Does the Electric Cargo Bike Mid Drive Play in Food and Beverage Services?

Electric cargo bikes are transforming the food and beverage industry by facilitating mobile delivery services. Restaurants and catering companies can use these bikes to deliver meals directly to customers, enhancing service speed and reliability. The mid-drive system allows for efficient power distribution, making it easier to navigate busy streets while carrying temperature-sensitive items. Buyers should consider weather resistance features and temperature control options to maintain food quality during transport.

How Can Urban Logistics Benefit from Electric Cargo Bike Mid Drive Solutions?

Urban logistics companies leverage electric cargo bikes to transport goods in congested city areas. These bikes help reduce traffic congestion and lower carbon emissions, aligning with sustainability goals. The mid-drive motor offers superior performance in urban settings, allowing for quick stops and starts. When sourcing these bikes, businesses should prioritize maneuverability and durability to withstand the demands of urban logistics.

Why are Electric Cargo Bike Mid Drives Ideal for Tourism and Recreation?

In the tourism sector, electric cargo bikes serve as an innovative solution for guided tours and rental services. They provide a unique way for tourists to explore cities while promoting eco-friendly travel options. The mid-drive motor enhances the riding experience, allowing for easy navigation through various terrains. Buyers in this sector should look for customization options and comfort features to enhance the overall experience for tourists.

How Do Electric Cargo Bike Mid Drives Improve Waste Management Efficiency?

Electric cargo bikes are becoming essential in waste management, particularly for the collection and transport of recyclables. Their mid-drive systems enable efficient loading and unloading, while also minimizing the environmental impact of waste collection. Businesses should focus on load capacity and ease of maintenance when sourcing these bikes to ensure compliance with local regulations and operational efficiency.

3 Common User Pain Points for ‘electric cargo bike mid drive’ & Their Solutions

Scenario 1: Navigating Cargo Capacity Limitations

The Problem:

B2B buyers often struggle with the weight and volume limitations of electric cargo bikes, especially in industries like delivery and logistics where carrying capacity is paramount. For instance, a delivery service in urban areas may find that their mid-drive electric cargo bikes are unable to accommodate larger packages or multiple deliveries at once. This limitation can lead to inefficiencies, increased operational costs, and dissatisfied customers due to delayed deliveries.

The Solution:

To address this challenge, buyers should prioritize sourcing electric cargo bikes with higher payload capacities and versatile cargo configurations. Look for models that can carry upwards of 450 lbs, like the Lectric XPedition 2.0, which is designed for heavy loads while still providing a comfortable ride. Additionally, consider bikes that offer modular accessories, such as expandable cargo racks, additional storage bags, and even child seats, which can optimize space without compromising performance. Engage with manufacturers to discuss customization options that fit specific business needs, ensuring the bikes you choose can handle the diverse range of goods your operation requires.

Scenario 2: Ensuring Battery Reliability and Longevity

The Problem:

Battery performance is a critical concern for B2B buyers of electric cargo bikes, particularly in regions where infrastructure for recharging may be limited or inconsistent. Companies relying on these bikes for daily operations can face significant downtime if batteries fail or need frequent recharging. For example, a logistics company in a developing region might find their delivery schedules severely impacted by insufficient battery range, leading to operational inefficiencies and increased costs.

The Solution:

To mitigate battery-related issues, buyers should conduct thorough research on battery specifications and performance metrics. Opt for electric cargo bikes equipped with high-capacity batteries (e.g., 624-Wh or above), which not only provide longer ranges but also have faster charging capabilities. Additionally, inquire about the availability of spare batteries or battery-swapping solutions from manufacturers. Implementing a battery management system that tracks usage patterns can also optimize battery life and performance, allowing businesses to plan recharging effectively and reduce downtime.

Scenario 3: Overcoming Maintenance and Repair Challenges

The Problem:

Maintenance and repair of electric cargo bikes can be a daunting task for B2B buyers, especially in regions where technical support is limited. Companies may face challenges in keeping their fleet operational due to a lack of access to qualified technicians or replacement parts. For instance, a bike-sharing service in a rural area might find it difficult to maintain their mid-drive bikes, leading to increased repair costs and lost revenue from bikes being out of service.

The Solution:

To counteract maintenance challenges, buyers should select electric cargo bikes from manufacturers that offer comprehensive support packages, including training for in-house technicians and readily available spare parts. Consider partnering with local bike shops or service centers that can provide routine maintenance and emergency repairs. Additionally, investing in a fleet management software that monitors the condition of each bike can help schedule preventative maintenance before issues arise, ultimately extending the lifespan of the bikes and ensuring the fleet remains operational. Engaging in community forums or networks can also provide insights on local maintenance resources, fostering collaboration among businesses facing similar challenges.

Strategic Material Selection Guide for electric cargo bike mid drive

What Materials Are Commonly Used in Electric Cargo Bike Mid Drives?

Electric cargo bikes are increasingly popular in urban environments, and selecting the right materials for their mid-drive systems is crucial for performance, durability, and cost-effectiveness. Below, we analyze four common materials used in the construction of electric cargo bike mid-drives, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Aluminum Impact Electric Cargo Bike Mid Drives?

Aluminum is a lightweight and corrosion-resistant material commonly used in electric cargo bike frames and mid-drive components. It typically has a temperature rating of around 200°C and excellent strength-to-weight ratio, making it ideal for applications where weight savings are crucial.

Pros: Aluminum is durable and resistant to rust, which is advantageous in diverse climates, particularly in humid regions. It is also relatively easy to manufacture, allowing for complex shapes that enhance aerodynamics and aesthetics.

Cons: While aluminum is strong, it can be more brittle than steel, leading to potential failure under extreme stress. Additionally, the cost can be moderate to high depending on the alloy used.

Impact on Application: Aluminum is compatible with various media, including electric components and batteries, making it a versatile choice. However, its performance can be affected by extreme temperatures, which should be considered in regions with significant climate variations.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers from regions like Africa and South America should ensure that the aluminum used meets local regulations for safety and environmental impact.

What Role Does Steel Play in Electric Cargo Bike Mid Drives?

Steel is another popular material, especially for structural components of electric cargo bikes. It offers high tensile strength and can withstand significant loads, making it suitable for heavy-duty applications.

Pros: Steel is incredibly durable and offers excellent impact resistance, which is beneficial for cargo bikes that may encounter rough terrain. It is also generally less expensive than aluminum.

Cons: The primary drawback of steel is its weight, which can hinder the bike’s overall performance. Additionally, steel is prone to corrosion unless properly treated, which may necessitate additional coatings or finishes.

Impact on Application: Steel’s robustness allows it to handle high torque loads, making it ideal for mid-drive motors. However, its heavier weight can affect battery efficiency and overall rideability.

Considerations for International Buyers: Buyers should be aware of the different grades of steel and their compliance with local standards. In regions like the Middle East, where humidity can lead to corrosion, selecting galvanized or stainless steel may be crucial.

How Does Carbon Fiber Enhance Electric Cargo Bike Mid Drives?

Carbon fiber is a high-performance material known for its exceptional strength and lightweight properties, making it increasingly popular in high-end electric cargo bikes.

Pros: Carbon fiber offers superior strength-to-weight ratios and excellent fatigue resistance, which enhances the bike’s performance and longevity. It also has excellent vibration-damping properties, leading to a smoother ride.

Cons: The primary disadvantage of carbon fiber is its high cost and complexity in manufacturing. Additionally, it can be less impact-resistant compared to metals, making it susceptible to damage from sharp objects.

Impact on Application: Carbon fiber is compatible with high-performance electric components, and its lightweight nature can significantly improve battery efficiency. However, its sensitivity to certain environmental conditions, such as extreme heat, should be considered.

Considerations for International Buyers: Buyers need to ensure that carbon fiber components meet relevant safety standards, especially in regions with rigorous regulations. The cost may also be a barrier for buyers in developing markets.

What Benefits Does Plastic Offer for Electric Cargo Bike Mid Drives?

Plastic is often used for non-structural components, such as housing for electrical systems and accessories. It is lightweight and can be molded into complex shapes.

Pros: Plastics are generally low-cost, lightweight, and resistant to corrosion, making them suitable for various applications. They can also be produced in a variety of colors and finishes.

Cons: Plastics may not offer the same durability as metals, especially under high stress or extreme temperatures. They can also degrade over time when exposed to UV light.

Impact on Application: Plastic components can be effective for housing and insulation, but their performance may be compromised under heavy loads or extreme conditions.

Considerations for International Buyers: Buyers should check for compliance with international safety standards and consider the environmental impact of plastic use, especially in regions with increasing regulations on plastic waste.

Summary Table of Material Selection for Electric Cargo Bike Mid Drives

| Material | Typical Use Case for electric cargo bike mid drive | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Frame and structural components | Lightweight and corrosion-resistant | Can be brittle under stress | Medium |

| Steel | Structural components and drivetrain | High durability and impact resistance | Heavier and prone to corrosion | Low |

| Carbon Fiber | High-performance components | Superior strength-to-weight ratio | High cost and impact sensitivity | High |

| Plastic | Non-structural components and housings | Low cost and lightweight | Less durable under stress | Low |

This analysis provides B2B buyers with actionable insights into material selection for electric cargo bike mid drives, ensuring informed decisions that align with regional requirements and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for electric cargo bike mid drive

What Are the Main Stages in the Manufacturing Process of Electric Cargo Bike Mid Drives?

The manufacturing process for electric cargo bike mid drives involves several critical stages, each requiring specialized techniques and equipment to ensure quality and performance. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Electric Cargo Bike Production?

Material preparation is the foundational step in the manufacturing process. It involves selecting high-quality materials such as aluminum or steel for the frame, as well as sourcing durable components for the electric drive system, including batteries, motors, and electronic control units. Suppliers should ensure that materials meet specific mechanical properties and standards, such as tensile strength and corrosion resistance, which are vital for the longevity and safety of the bikes.

What Techniques Are Used in Forming Components for Cargo Bikes?

Once the materials are prepared, the forming stage begins. This typically involves techniques such as welding, bending, and machining. For example, aluminum frames may be extruded or hydroformed to create lightweight yet strong structures. Precision machining is often used for components like the motor housing and brackets, ensuring that all parts fit together seamlessly. The goal in this stage is to achieve the desired shapes while maintaining strict tolerances that adhere to engineering specifications.

How Is the Assembly Process Conducted for Electric Cargo Bikes?

The assembly stage brings together all the prepared components into a finished product. This process often utilizes assembly lines where workers or robotic systems integrate the frame, mid-drive motor, battery packs, and electronic systems. Specialized tools and fixtures are employed to ensure that each component is correctly positioned and securely fastened. Quality control measures are implemented at this stage to catch any misalignments or defects before the bike moves on to the next phase.

What Finishing Techniques Are Employed in Electric Cargo Bike Manufacturing?

Finishing processes enhance both the aesthetics and durability of the electric cargo bikes. Techniques such as powder coating, anodizing, or painting are used to protect metal surfaces from corrosion and wear. Additionally, decals and branding elements are applied during this stage. Rigorous inspections are conducted post-finishing to ensure that the finish meets quality standards and does not impede the bike’s functionality.

What Quality Assurance Measures Are Essential for Electric Cargo Bikes?

Quality assurance (QA) is paramount in the manufacturing of electric cargo bikes, especially for B2B buyers who prioritize reliability and safety. Adhering to international standards such as ISO 9001 is essential for establishing a quality management system that covers all stages of production. Moreover, compliance with industry-specific standards, such as CE marking in Europe or UL certification in the U.S., ensures that the bikes meet safety and performance criteria.

How Are QC Checkpoints Implemented Throughout the Manufacturing Process?

Quality control (QC) checkpoints are integrated into the manufacturing process to monitor and verify quality at different stages. Key checkpoints include:

-

Incoming Quality Control (IQC): This is conducted upon receipt of raw materials and components. Suppliers should perform tests to ensure that incoming materials meet specified standards.

-

In-Process Quality Control (IPQC): During the assembly process, ongoing inspections ensure that components are correctly assembled and functioning as intended. This may involve functional testing of the electric motor and battery systems.

-

Final Quality Control (FQC): Before the bikes leave the factory, a comprehensive inspection is performed, which includes load testing, safety checks, and performance evaluations.

What Testing Methods Are Commonly Used to Ensure Quality?

Testing methods play a critical role in the QC process. Common testing approaches include:

-

Performance Testing: Evaluating the mid-drive motor’s power output, battery life, and overall bike performance under various load conditions.

-

Durability Testing: Subjecting the bikes to stress tests to simulate real-world conditions, such as weight loads and rough terrain, ensures that they can withstand everyday use.

-

Safety Testing: Ensuring compliance with safety standards involves testing electrical components for short circuits, overheating, and other potential hazards.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers should take proactive steps to verify the quality control processes of potential suppliers. Here are some effective strategies:

-

Conduct Supplier Audits: Regular audits can help assess a supplier’s manufacturing capabilities, quality control processes, and adherence to international standards. This can include reviewing documentation, inspecting facilities, and evaluating production processes.

-

Request Quality Reports: Suppliers should provide detailed quality reports that outline their QC processes, test results, and certifications. This documentation is crucial for establishing trust and ensuring compliance with quality standards.

-

Engage Third-Party Inspectors: Hiring independent third-party inspectors to evaluate the manufacturing process and final products can provide an unbiased assessment of quality. This is especially important when dealing with international suppliers where direct oversight may be challenging.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

-

Understanding Regional Standards: Different regions may have varying safety and quality standards. Buyers must be knowledgeable about these requirements to ensure compliance.

-

Logistical Considerations: The transportation of electric cargo bikes involves logistical challenges that can affect product quality. Buyers should consider how products are packed and shipped to minimize damage during transit.

-

Cultural Differences in Quality Perceptions: Different cultures may have varying expectations regarding quality. Effective communication with suppliers is essential to align on quality standards and expectations.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures is essential for B2B buyers in the electric cargo bike market. By focusing on quality at every stage of production and employing robust verification methods, buyers can ensure they are sourcing reliable and high-performance products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric cargo bike mid drive’

Introduction

Sourcing electric cargo bikes equipped with mid-drive motors requires careful consideration and strategic planning. This guide provides a step-by-step checklist designed for B2B buyers, particularly those in emerging markets such as Africa, South America, the Middle East, and Europe. By following these steps, you can ensure that your procurement process is efficient and that you acquire high-quality bikes that meet your operational needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Determine the required payload capacity, range, and battery life based on your intended use—whether it’s for delivery, transportation of goods, or family use.

- Consider the motor type: Mid-drive motors often provide better hill-climbing ability and are more efficient than hub motors, making them ideal for varied terrains.

- Evaluate frame design: Choose between long-tail and short-tail configurations based on your cargo requirements.

Step 2: Research Market Trends and Demand

Understanding market trends and demand in your target regions is critical. Analyze local preferences for electric cargo bikes, including popular styles and features.

- Conduct surveys: Engage potential users to gather insights about their needs and preferences.

- Monitor competitors: Look at what similar businesses are using and the feedback they receive.

Step 3: Identify and Evaluate Potential Suppliers

Finding the right suppliers is essential to ensure quality and reliability. Begin by compiling a list of manufacturers and distributors specializing in electric cargo bikes.

- Request credentials: Ask for company profiles, certifications, and references to assess their credibility.

- Evaluate product range: Ensure they offer a variety of models that fit your specifications and budget.

Step 4: Verify Product Quality and Compliance

Quality assurance is paramount when sourcing electric cargo bikes. Ensure that products meet international safety standards and regulations relevant to your market.

- Request samples: If possible, test a few units to evaluate their performance, comfort, and durability.

- Check for warranties: A robust warranty indicates manufacturer confidence in their product quality.

Step 5: Assess After-Sales Support and Service

After-sales support can significantly impact your long-term satisfaction with your purchase. Investigate the level of service and support offered by potential suppliers.

- Inquire about maintenance services: Understand what support is available for repairs and maintenance.

- Evaluate spare parts availability: Ensure that parts are readily available for future repairs to minimize downtime.

Step 6: Negotiate Pricing and Payment Terms

Once you have identified a suitable supplier, focus on negotiating favorable pricing and payment terms. This step can greatly influence your overall procurement costs.

- Consider bulk discounts: If purchasing multiple units, inquire about discounts for large orders.

- Discuss payment flexibility: Establish terms that align with your cash flow, such as installment payments or deferred payment options.

Step 7: Finalize Contracts and Logistics

After agreeing on terms, finalize contracts with clear specifications and delivery timelines. Ensure that all parties understand their responsibilities.

- Outline delivery schedules: Confirm logistics arrangements to ensure timely delivery.

- Include clauses for potential issues: Protect your interests by including terms for delays or quality issues.

By following this comprehensive checklist, B2B buyers can effectively navigate the sourcing process for electric cargo bikes with mid-drive motors, ensuring they make informed decisions that align with their operational goals.

Comprehensive Cost and Pricing Analysis for electric cargo bike mid drive Sourcing

What Are the Key Cost Components for Electric Cargo Bike Mid Drive Sourcing?

When sourcing electric cargo bikes, especially mid-drive models, understanding the detailed cost structure is crucial. The primary components of the cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts costs. High-quality aluminum or carbon fiber frames increase durability and performance but are more expensive. Additionally, battery technology (e.g., lithium-ion) and motor types (mid-drive versus hub) contribute to material costs, with mid-drive motors typically being pricier due to their complexity.

-

Labor: Labor costs vary widely based on the production location. Countries with lower labor costs can offer competitive pricing, but this may affect the quality of craftsmanship. Skilled labor is essential for assembling mid-drive systems, as they require precise installation and calibration.

-

Manufacturing Overhead: This encompasses indirect costs such as utilities, rent, and administrative expenses. Efficient manufacturing processes can reduce overhead, translating to lower prices for buyers.

-

Tooling: Initial tooling costs can be significant, particularly for custom designs. However, once established, these costs are amortized over production volume, making it essential for buyers to consider expected order quantities.

-

Quality Control (QC): Implementing robust QC processes ensures that each bike meets safety and performance standards. While this adds to the cost, it is a critical investment for minimizing returns and enhancing brand reputation.

-

Logistics: Shipping costs can vary based on distance and method. International buyers should factor in customs duties, taxes, and insurance to understand the total logistics costs accurately.

-

Margin: Suppliers will typically add a markup to cover their costs and ensure profitability. Understanding the typical margin in the industry can help buyers gauge fair pricing.

How Do Price Influencers Impact Electric Cargo Bike Mid Drive Costs?

Several factors influence the pricing of electric cargo bikes, particularly mid-drive models.

-

Volume and Minimum Order Quantity (MOQ): Larger orders usually attract lower per-unit prices due to economies of scale. Buyers should negotiate MOQs with suppliers to secure better pricing.

-

Specifications and Customization: Custom features or modifications can significantly increase costs. Buyers should clearly define their specifications to avoid unexpected expenses.

-

Material Choices: The quality of materials directly affects the price. Buyers must balance cost with the desired quality to ensure long-term satisfaction with the product.

-

Quality Certifications: Compliance with international safety and performance standards can raise manufacturing costs. However, having these certifications can enhance marketability and consumer trust.

-

Supplier Factors: The reputation and reliability of the supplier play a role in pricing. Established suppliers may command higher prices due to their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international buyers. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can affect overall costs.

What Are Some Essential Buyer Tips for Sourcing Electric Cargo Bikes?

-

Negotiation Strategies: Engage suppliers in discussions about pricing, especially for bulk orders. Highlighting potential future orders can incentivize suppliers to offer discounts.

-

Cost-Efficiency Considerations: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and operational costs. Higher upfront costs may be justified if the bike offers lower long-term operational expenses.

-

Pricing Nuances for International Buyers: Different regions may have varying pricing structures due to local market conditions, tariffs, and currency fluctuations. Buyers from Africa, South America, the Middle East, and Europe should conduct thorough market research to understand local pricing dynamics.

-

Quality Assurance: Don’t compromise on quality for the sake of price. A cheaper bike may lead to higher long-term costs due to repairs or replacements.

-

Supplier Reliability: Research suppliers thoroughly, focusing on their delivery timelines, after-sales service, and warranty conditions. A reliable supplier can save you time and money in the long run.

Disclaimer

Prices mentioned in this analysis are indicative and can vary based on numerous factors including market conditions, order volume, and supplier negotiations. Always conduct due diligence before finalizing any purchase agreements.

Alternatives Analysis: Comparing electric cargo bike mid drive With Other Solutions

Understanding Alternatives to Electric Cargo Bike Mid Drive Solutions

In the evolving landscape of transportation solutions for logistics and urban mobility, electric cargo bike mid drives are gaining popularity due to their efficiency and eco-friendliness. However, businesses must consider various alternatives that could also meet their operational needs. This section provides a comparative analysis of electric cargo bike mid drives against other viable solutions such as electric vans and traditional cargo bicycles.

Comparison Table

| Comparison Aspect | Electric Cargo Bike Mid Drive | Electric Van | Traditional Cargo Bicycle |

|---|---|---|---|

| Performance | High torque, good for heavy loads; speeds up to 28 mph | High speed, greater range, can carry larger loads | Limited speed and capacity; best for lighter loads |

| Cost | $1,500 – $2,500 (depending on model) | $25,000 – $50,000 (initial investment) | $500 – $1,500 (low upfront cost) |

| Ease of Implementation | Requires minimal training; easy to integrate into existing fleets | Requires driver training and licensing; more infrastructure needed | Simple to operate; no special licensing required |

| Maintenance | Moderate; requires battery care and occasional component replacements | High; regular servicing and maintenance of vehicle systems | Low; minimal upkeep required, primarily mechanical |

| Best Use Case | Urban deliveries, family transport, local logistics | Long-distance delivery, larger cargo loads, commercial use | Short-distance transport, light cargo, recreational use |

Detailed Breakdown of Alternatives

Electric Van

Electric vans are a robust alternative for businesses needing to transport larger quantities of goods over longer distances. They offer high speed and extended range, making them ideal for urban and intercity logistics. However, they come with a significantly higher upfront cost and ongoing maintenance expenses. Additionally, they may require special licensing for drivers and more extensive charging infrastructure, which could complicate implementation for smaller businesses.

Traditional Cargo Bicycle

Traditional cargo bicycles are the most cost-effective option for transporting goods, especially in urban environments. They have low maintenance requirements and are easy to operate, making them accessible to a wider range of users. However, they are limited in terms of speed and cargo capacity, making them unsuitable for heavier loads or long-distance deliveries. They are best for short-distance transport and light cargo, which may not meet the needs of businesses with more demanding logistical requirements.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting the appropriate transportation solution, B2B buyers should carefully consider their specific operational needs, budget constraints, and the nature of the goods being transported. Electric cargo bike mid drives provide a unique blend of efficiency and versatility for urban logistics, while electric vans excel in larger-scale operations requiring significant capacity and distance. Traditional cargo bicycles may serve well for businesses focused on local, light transport. Ultimately, the decision should align with the strategic goals of the business, including sustainability objectives, budgetary limits, and the ability to adapt to local infrastructure and regulations.

Essential Technical Properties and Trade Terminology for electric cargo bike mid drive

What Are the Key Technical Properties of Electric Cargo Bike Mid Drives?

When evaluating electric cargo bikes, particularly those with mid-drive motors, understanding critical specifications is essential for B2B buyers. Here are some of the most important technical properties:

1. Motor Power (Wattage)

The motor power, typically measured in watts (W), indicates the bike’s performance capability. Mid-drive motors usually range from 250W to 750W. A higher wattage generally means better performance, especially when carrying heavy loads or climbing hills. For B2B buyers, this translates into understanding which models will meet operational needs in various terrains or load conditions.

2. Torque

Torque, measured in Newton-meters (Nm), refers to the rotational force the motor can exert. A mid-drive motor with higher torque (often between 50 to 90 Nm) provides better acceleration and hill-climbing ability. This is vital for businesses that require quick deliveries or operate in hilly areas, as higher torque allows for efficient transport of goods without straining the motor.

3. Battery Capacity

Battery capacity, usually measured in watt-hours (Wh), indicates how much energy the battery can store. Common capacities range from 400Wh to over 800Wh. A larger capacity allows for longer rides, which is crucial for businesses that depend on extended range for deliveries. Understanding battery capacity helps B2B buyers align their operational needs with the right cargo bike model.

4. Payload Capacity

Payload capacity refers to the maximum weight the bike can carry, including the rider and cargo. This is typically expressed in pounds or kilograms. For instance, many mid-drive electric cargo bikes can support payloads ranging from 300 lbs to 450 lbs. Knowing the payload capacity is essential for businesses to ensure that the bike can handle their typical load requirements without compromising safety or performance.

5. Frame Material

The frame material affects the bike’s durability and weight. Common materials include aluminum and steel, with aluminum being lighter and more corrosion-resistant, while steel offers enhanced strength and longevity. B2B buyers should consider the frame material based on their operational environment and the expected lifespan of the bike.

6. Braking System

The type of braking system (e.g., hydraulic disc brakes vs. mechanical disc brakes) influences safety and performance, especially when carrying heavy loads. Hydraulic brakes provide superior stopping power and modulation, which is crucial for safe cargo transport. Buyers should assess the braking system to ensure it aligns with their safety standards and operational requirements.

What Are Common Trade Terms Used in the Electric Cargo Bike Industry?

Familiarity with industry jargon can significantly enhance communication and negotiation for B2B buyers. Here are several essential terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers seeking reliable suppliers of electric cargo bikes or components.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is vital for businesses planning to purchase electric cargo bikes in bulk, as it affects inventory costs and cash flow management.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. It typically includes detailed specifications for the products needed. For B2B buyers, issuing an RFQ can streamline the procurement process and ensure competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping. They clarify who is responsible for shipping costs, insurance, and risks. Understanding Incoterms helps B2B buyers navigate logistics and minimize unexpected costs during international transactions.

5. Lead Time

Lead time is the amount of time it takes from placing an order to receiving the product. This is crucial for businesses that need to align their supply chain with customer demand. Knowing lead times can help buyers manage expectations and plan their inventory effectively.

6. Warranty

A warranty is a promise made by the manufacturer regarding the condition of the product and its repair or replacement. Understanding warranty terms is essential for B2B buyers to ensure they are protected against defects and can maintain operational efficiency.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing electric cargo bikes, ensuring they select models that meet their operational needs while navigating the complexities of international trade.

Navigating Market Dynamics and Sourcing Trends in the electric cargo bike mid drive Sector

What Are the Current Market Dynamics and Key Trends Impacting the Electric Cargo Bike Mid Drive Sector?

The electric cargo bike mid drive sector is experiencing significant growth driven by urbanization, environmental concerns, and the shift towards sustainable transportation. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly looking for efficient logistics solutions to address last-mile delivery challenges. The rise of e-commerce and urban congestion has accelerated the adoption of electric cargo bikes as a viable alternative to traditional delivery vehicles, with advantages in maneuverability and lower operational costs.

Key trends shaping this market include advancements in battery technology, which enhance range and efficiency, and the integration of smart technology for improved user experience. For instance, systems that allow for real-time tracking and security features are becoming standard, making these bikes more appealing for logistics companies. Additionally, the move towards modular designs enables customization to meet diverse operational needs, whether for family transport or commercial use. As the market matures, buyers are advised to look for suppliers offering innovative solutions that align with their specific requirements.

How Important Is Sustainability and Ethical Sourcing in the Electric Cargo Bike Mid Drive Sector?

Sustainability has become a cornerstone of the electric cargo bike industry, reflecting growing consumer demand for environmentally friendly products. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing and sustainability practices. This includes the use of recycled materials, sustainable manufacturing processes, and certifications that validate a product’s environmental impact.

Moreover, the supply chain for electric cargo bikes must emphasize transparency, ensuring that materials are sourced responsibly and that labor practices are ethical. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can help buyers identify suppliers who are committed to reducing their ecological footprint. By focusing on sustainable practices, companies not only enhance their brand reputation but also align with the global push for greener transportation solutions, which is particularly pertinent in emerging markets where environmental regulations are tightening.

How Has the Electric Cargo Bike Mid Drive Sector Evolved Over Time?

The evolution of electric cargo bikes can be traced back to their manual predecessors used by tradesmen in the 19th century for efficient goods transport. Over the decades, these bikes have transformed significantly, with the introduction of electric mid drive systems that offer improved power management and performance. The shift towards electric models began in earnest in the late 20th century as battery technology advanced, making electric cargo bikes more accessible and practical for everyday use.

Today, the market is characterized by a diverse range of designs catering to both personal and commercial use. Innovations such as integrated GPS systems for theft prevention and smart connectivity features have further enhanced their appeal. As urban mobility continues to evolve, electric cargo bikes are positioned to play a crucial role in sustainable transport solutions, reflecting a significant shift in how goods and services are delivered in urban environments. This ongoing evolution presents a wealth of opportunities for international B2B buyers looking to capitalize on this dynamic market.

Frequently Asked Questions (FAQs) for B2B Buyers of electric cargo bike mid drive

-

How do I determine the right electric cargo bike mid drive for my business needs?

To select the right electric cargo bike mid drive, assess your specific business requirements, such as load capacity, range, and intended use. Consider factors like the weight of the goods you plan to transport, the distance of your routes, and the terrain. Additionally, evaluate the bike’s motor power and battery capacity to ensure it can handle your operational demands. Collaborating with suppliers to test different models can provide practical insights into which bike best fits your needs. -

What are the key benefits of using electric cargo bikes for businesses?

Electric cargo bikes offer several advantages, including lower operational costs compared to traditional vehicles, reduced carbon footprint, and increased accessibility in urban areas. They are ideal for last-mile delivery, allowing businesses to navigate congested city streets efficiently. Furthermore, e-cargo bikes can enhance brand image as environmentally friendly options, potentially attracting more customers who value sustainability. -

What should I consider when vetting suppliers for electric cargo bikes?

When vetting suppliers, prioritize their experience, reputation, and product quality. Check for certifications and compliance with international standards. Request references from other businesses that have sourced bikes from them. Additionally, inquire about their customer service, warranty policies, and after-sales support. A supplier with a strong track record in your region can provide valuable local insights and ensure better logistics. -

What are the typical minimum order quantities (MOQ) for electric cargo bikes?

Minimum order quantities can vary significantly by supplier and region. Generally, for electric cargo bikes, MOQs may range from a few units to several dozen, depending on the manufacturer’s capacity and production cycle. It’s beneficial to negotiate terms that suit your business needs, especially if you’re a smaller operation. Some suppliers may offer flexibility for first-time buyers or bulk orders, so it’s advisable to discuss your specific requirements directly. -

What payment terms should I expect when sourcing electric cargo bikes internationally?

Payment terms can differ widely among suppliers, but common practices include a deposit upfront (typically 30-50%) and the remainder upon delivery or before shipment. Some suppliers may also offer credit terms for established businesses. It’s crucial to clarify payment methods accepted (e.g., wire transfer, credit card) and any additional fees that may apply for international transactions. Always ensure that the payment terms are documented in the contract to avoid misunderstandings. -

How can I ensure quality assurance for electric cargo bikes before purchase?

To ensure quality assurance, request detailed specifications and certifications from suppliers. Conduct pre-shipment inspections to verify that the bikes meet your requirements. Additionally, consider sourcing samples or conducting pilot tests before placing a larger order. Establish clear quality standards and communicate them to your supplier. Regular communication during the production process can also help mitigate potential issues. -

What logistics considerations should I keep in mind when importing electric cargo bikes?

When importing electric cargo bikes, consider shipping methods, customs regulations, and potential tariffs or taxes in your country. Choose reliable logistics partners experienced in handling large shipments, as they can help navigate the complexities of international shipping. Additionally, factor in lead times for production and shipping to ensure timely delivery. It’s wise to maintain open communication with your supplier regarding shipping schedules and any potential delays. -

Are there customization options available for electric cargo bikes?

Many suppliers offer customization options for electric cargo bikes to meet specific business needs. This can include modifications to frame size, color, cargo capacity, and additional features like integrated storage solutions or advanced security systems. Discuss your requirements with potential suppliers to explore available options and associated costs. Customization can enhance the functionality of the bikes, making them more suited to your operational demands.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Electric Cargo Bike Mid Drive Manufacturers & Suppliers List

1. Lectric – XPedition 2.0

Domain: electricbikereport.com

Registered: 2010 (15 years)

Introduction: Best Electric Cargo Bikes 2025:

1. **Lectric XPedition 2.0**

– Price: $1399 (base model), $1699 (mid-tier), $1999 (top-tier)

– Battery: 624-Wh (base), 2 x 624-Wh (mid), 2 x 840-Wh (top)

– Cargo Capacity: 300 lbs on rack, 450 lbs total

– Motor: 750W rear hub, 1310W peak output, 85 Nm torque

– Features: Torque sensor, suspension fork, color display, adjustable stem, turn si…

2. Rad Power Bikes – RadWagon™ 5 Electric Cargo Bike

Domain: radpowerbikes.com

Registered: 2015 (10 years)

Introduction: RadWagon™ 5 Electric Cargo Bike

– Price: $2,399

– Top Speed: 28 mph

– Range: 60+ miles

– Power: 750W

– Payload: 375 lb

– Warranty: 2-year

– Rider Height: 4’11” – 6’3″

– Frame Size: Regular

– Inseam Length: 25″ – 37″

– Free shipping

– 30 days return

– Pro Build Available

– Free Just-in-Case Kit with order (over $300 in accessories)

– Offer ends 10/1/25, while supplies last.

3. Surly Bikes – Big Easy Cargo Ebike

Domain: cyclevolta.com

Registered: 2019 (6 years)

Introduction: This company, Surly Bikes – Big Easy Cargo Ebike, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

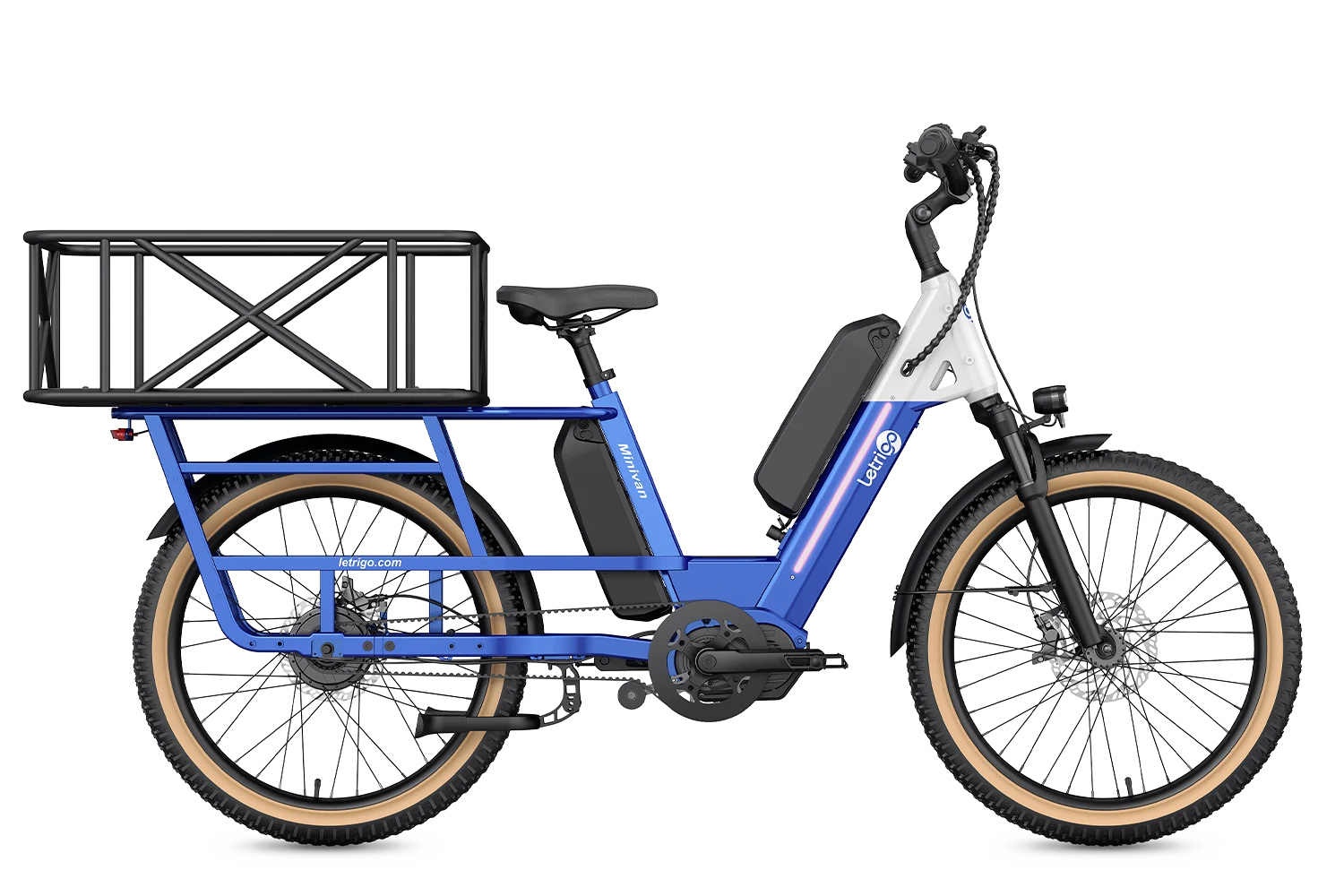

4. Letrigo – Minivan Longtail Cargo eBike

Domain: letrigo.com

Registered: 2023 (2 years)

Introduction: {“product_name”: “Letrigo Minivan Longtail Cargo eBike”, “price”: “$2,999.00 USD”, “availability”: “Gray-Orange currently out of stock in Canada”, “motor”: {“type”: “Ananda Cargoline mid-drive motor”, “rated_power”: “500W”, “peak_power”: “750W”, “peak_torque”: “130Nm”}, “battery”: {“default”: “48V/14AH”, “optional”: [“48V/25AH”], “range”: {“default”: “45 miles”, “with_14AH”: “80 miles”, “with_25AH…

5. Electric Bike Review – Cargo Bikes Insights

Domain: forums.electricbikereview.com

Registered: 2010 (15 years)

Introduction: Cargo bikes tend to be hub drive due to factors such as cost, durability, and the ability to handle heavy loads. Hub motors are generally cheaper and more durable compared to mid-drive systems, which can put more strain on the bike’s drivetrain. Users appreciate the simplicity and lower maintenance of hub drive systems, especially when carrying heavy cargo. Some cargo bikes do feature mid-drive mo…

6. Endless Sphere – Madsen Cargo Bike

Domain: endless-sphere.com

Registered: 2005 (20 years)

Introduction: Madsen cargo bike; Total weight: ~300 pounds (including rider and 3 kids); Cruising speed: 12-20 mph; Desired range: up to 20 miles with pedaling; Riding conditions: paved roads, generally flat with a few moderate hills, occasional flat offroading; Budget: ~$1500; Rear wheel size: 20″, Front wheel size: 26″; Motor options: BBS02 (recommended by Madsen, kit price $1815) and Grin All Axle (high qual…

7. Ferla – Royce MAX Cargo Bike

Domain: ferlafamilybikes.com

Registered: 2019 (6 years)

Introduction: Product Name: Ferla Royce MAX Cargo Bike

Price: $6,999.00

Available Colors: White, Black, Wood, British Green

Motor: 750W Throttle Mid-Drive Motor

Battery Options: 17.5Ah or 35Ah UL 2271 Battery

Weight Capacity: 600 lb total (6-person capacity)

Wheels: Spoke-free Magnesium wheels

Assembly Options: DIY or Professional Assembly ($299)

Dimensions (Assembled Crate): L92″ x W41″ x H55″

Torque: 160Nm

Fr…

8. Specialized – Globe Haul ST

Domain: bicycling.com

Registered: 1999 (26 years)

Introduction: Best Overall: Specialized Globe Haul ST

– Price: €2,500

– Tires: 20 x 3.5 in.

– Weight: 77 lbs.

– Cargo Capacity: 419 lbs.

– Pros: One of the smallest cargo bike footprints, excellent battery life and power delivery, strong brakes.

– Cons: Lack of suspension can mean a harsh ride on rough roads, can only carry one kiddo.

Best Value: Aventon Abound

– Price: $1,999 (Now $1,599)

– Tires: 20 x 2.4 in…

Strategic Sourcing Conclusion and Outlook for electric cargo bike mid drive

As the demand for sustainable transportation solutions continues to rise, electric cargo bikes equipped with mid-drive motors present an attractive option for businesses looking to optimize logistics and reduce carbon footprints. The versatility of these bikes caters to various applications, from urban deliveries to family transport, making them a valuable asset for companies across diverse sectors.

Strategic sourcing of electric cargo bikes involves evaluating models based on key performance indicators such as payload capacity, battery range, and motor power. Brands like Lectric and Aventon have introduced innovative features, including advanced torque sensors and integrated security systems, that enhance the functionality and safety of these vehicles. By investing in quality electric cargo bikes, businesses can significantly improve their operational efficiency while appealing to eco-conscious consumers.

Looking ahead, B2B buyers in regions like Africa, South America, the Middle East, and Europe are encouraged to explore partnerships with reputable suppliers to secure the most effective and reliable electric cargo bike solutions. The transition to electric mobility is not just a trend but a pivotal step toward sustainable growth. Embrace this opportunity to enhance your fleet and contribute to a greener future.