Introduction: Navigating the Global Market for triciclos motorizados

In today’s dynamic global market, sourcing high-quality triciclos motorizados presents a unique challenge for international B2B buyers. With diverse applications ranging from urban transportation to delivery services, these three-wheeled vehicles are increasingly favored for their efficiency and adaptability. This comprehensive guide delves into various types of triciclos motorizados, their applications across different industries, and the critical factors to consider when selecting suppliers.

We will explore the nuances of performance specifications, ergonomic designs, and technological advancements that characterize the latest models, such as those offered by industry leaders like Can-Am. Additionally, we will provide insights into supplier vetting processes, helping buyers ensure they partner with reputable manufacturers who can meet their specific needs.

Cost considerations are also a focal point, offering buyers a clear understanding of pricing structures and financing options available in different regions, including Africa, South America, the Middle East, and Europe. With this guide, international B2B buyers will be equipped to make informed purchasing decisions, ensuring they invest in triciclos motorizados that not only enhance operational efficiency but also align with their strategic goals. By navigating the complexities of this market, you can position your business for success in a rapidly evolving landscape.

Understanding triciclos motorizados Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cargo Triciclos | Large cargo space, robust frame, often equipped with a canopy | Delivery services, logistics, construction | Pros: High load capacity, stable. Cons: Limited speed. |

| Passenger Triciclos | Designed for comfort, seating for 1-2 passengers, often enclosed | Public transportation, tourism | Pros: Comfortable ride, versatile. Cons: Higher operating costs. |

| Recreational Triciclos | Sporty design, powerful engines, enhanced maneuverability | Leisure activities, tourism, rentals | Pros: High performance, attractive. Cons: Not suitable for heavy loads. |

| Utility Triciclos | Versatile design, can be adapted for various tasks | Municipal services, agriculture | Pros: Multi-functional, customizable. Cons: May require additional investment for modifications. |

| Electric Triciclos | Eco-friendly, quiet operation, lower maintenance | Urban transport, eco-conscious businesses | Pros: Sustainable, cost-effective in long term. Cons: Limited range, higher upfront cost. |

What Are the Characteristics and Suitability of Cargo Triciclos?

Cargo triciclos are built with a robust frame and a spacious cargo area, making them ideal for businesses involved in logistics and delivery services. Their design often includes a canopy for weather protection, enhancing the utility in various climates. Buyers should consider the load capacity and stability, as these vehicles are typically slower but provide excellent stability for transporting goods.

How Do Passenger Triciclos Serve B2B Needs?

Passenger triciclos are tailored for comfort, accommodating 1-2 passengers and often featuring enclosed designs for protection against the elements. They are well-suited for public transportation and tourism industries, providing an efficient means of moving people in urban settings. When purchasing, businesses should evaluate comfort levels and operational costs, as these vehicles may have higher maintenance expenses.

What Makes Recreational Triciclos Attractive for Businesses?

Recreational triciclos boast a sporty aesthetic and are equipped with powerful engines, making them appealing for leisure activities, tourism, and rental businesses. Their enhanced maneuverability allows for enjoyable rides in various terrains. B2B buyers should assess performance metrics and market demand, as these vehicles may not be ideal for heavy-duty applications.

Why Are Utility Triciclos Considered Versatile?

Utility triciclos are designed for adaptability, suitable for a range of tasks from municipal services to agricultural applications. Their versatile nature allows businesses to customize them for specific needs, enhancing operational efficiency. When considering a purchase, buyers should focus on the adaptability and potential modifications required to meet their operational requirements.

What Are the Benefits of Electric Triciclos for Eco-Conscious Businesses?

Electric triciclos present an eco-friendly alternative, characterized by quiet operation and reduced maintenance needs. They are increasingly popular among urban transport services and businesses looking to minimize their carbon footprint. However, potential buyers should weigh the initial investment against long-term savings and consider the range limitations that may affect operational efficiency.

Key Industrial Applications of triciclos motorizados

| Industry/Sector | Specific Application of triciclos motorizados | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics and Delivery | Last-mile delivery solutions | Enhanced efficiency and reduced operational costs | Load capacity, fuel efficiency, and maintenance support |

| Agriculture | Transporting goods within farms | Improved productivity and reduced labor costs | Durability, terrain adaptability, and custom attachments |

| Tourism and Recreation | Guided tours and rentals | Increased customer engagement and revenue streams | Comfort features, safety standards, and branding opportunities |

| Waste Management | Collection and transport of waste | Streamlined operations and reduced environmental impact | Compliance with local regulations and waste handling capacity |

| Healthcare | Patient transport in rural areas | Improved access to medical services | Reliability, ease of access for patients, and medical equipment compatibility |

How Are Triciclos Motorizados Transforming Logistics and Delivery?

In the logistics and delivery sector, triciclos motorizados serve as efficient last-mile delivery vehicles. They are ideal for navigating congested urban areas where larger vehicles may struggle. By utilizing these tricycles, businesses can enhance delivery speed and reduce operational costs. Buyers should consider factors like load capacity, fuel efficiency, and the availability of maintenance support when sourcing these vehicles, especially in regions where service networks may be limited.

What Role Do Triciclos Motorizados Play in Agriculture?

In agriculture, triciclos motorizados are invaluable for transporting goods across farms. They can efficiently move produce, tools, and supplies, thereby improving productivity and lowering labor costs. For buyers in this sector, it is crucial to assess the durability of the vehicles, their ability to adapt to various terrains, and the option for custom attachments tailored to specific agricultural needs. This ensures they meet the unique challenges faced in diverse farming environments.

How Are Triciclos Motorizados Enhancing Tourism and Recreation?

Tourism and recreation industries leverage triciclos motorizados for guided tours and rentals, providing unique experiences to customers. These vehicles can navigate scenic routes while offering comfort and safety. For B2B buyers, key considerations include comfort features, adherence to safety standards, and opportunities for branding. This not only enhances customer engagement but also creates additional revenue streams for businesses in the tourism sector.

What Benefits Do Triciclos Motorizados Offer for Waste Management?

Triciclos motorizados are increasingly used in waste management for the collection and transport of waste materials. Their compact size allows for efficient operations in urban settings, helping to reduce environmental impact. When sourcing these vehicles, businesses must ensure compliance with local waste handling regulations and assess the waste capacity of the tricycles. This is critical for effective waste management strategies in densely populated areas.

How Are Triciclos Motorizados Improving Healthcare Access?

In healthcare, triciclos motorizados facilitate patient transport in rural areas where access to medical facilities can be challenging. They provide a reliable means of transportation, improving access to essential services. Buyers in this sector should prioritize reliability, ease of access for patients, and compatibility with medical equipment when sourcing these vehicles. This ensures that healthcare providers can deliver timely and effective services to communities in need.

3 Common User Pain Points for ‘triciclos motorizados’ & Their Solutions

Scenario 1: Navigating Regulatory Compliance for Importing Triciclos Motorizados

The Problem: B2B buyers often face significant challenges when importing triciclos motorizados due to varying regulatory requirements across different countries. For instance, buyers in Africa and South America may encounter strict safety and emissions standards that differ from those in Europe. These discrepancies can lead to delays in shipments, additional costs for compliance modifications, and even the risk of products being rejected at customs.

The Solution: To overcome these challenges, it is essential to conduct thorough research on the specific regulations governing triciclos motorizados in the target market. Engaging with local regulatory bodies or industry associations can provide clarity on compliance requirements. Additionally, working closely with suppliers who have experience navigating these regulations can streamline the process. Buyers should also consider investing in certifications or modifications that ensure their products meet local standards before shipping. Collaborating with a logistics partner familiar with the import processes can further mitigate risks and ensure timely delivery.

Scenario 2: Addressing Maintenance and Repair Challenges

The Problem: One of the most pressing concerns for businesses that utilize triciclos motorizados is the ongoing maintenance and repair of these vehicles. Without a reliable service network, downtime can significantly impact operations, leading to lost revenue and dissatisfied customers. This is particularly critical in regions where access to spare parts and qualified technicians is limited, such as in certain parts of Africa and South America.

The Solution: To tackle maintenance challenges, buyers should prioritize sourcing triciclos motorizados from manufacturers that offer robust after-sales support and an established service network. Before purchasing, inquire about the availability of spare parts and the proximity of service centers. Additionally, consider training in-house technicians or partnering with local mechanics to provide regular maintenance and repairs. Establishing a preventive maintenance schedule can also help identify potential issues before they lead to major breakdowns, thereby ensuring smoother operations and reducing costs associated with unplanned repairs.

Scenario 3: Ensuring Optimal Performance and Fuel Efficiency

The Problem: B2B buyers often worry about the performance and fuel efficiency of triciclos motorizados, especially in regions with challenging terrains or varying weather conditions. Inconsistent fuel consumption can lead to increased operational costs, and poor performance can affect delivery times and customer satisfaction. Businesses in the Middle East, for example, may struggle with heat-related performance issues that can hinder productivity.

The Solution: To maximize performance and fuel efficiency, it is crucial to select triciclos motorizados that are specifically designed for the intended operational environment. Buyers should evaluate models that offer features like adjustable suspension systems, robust engines suitable for varying terrains, and advanced fuel management technologies. Conducting field tests in the actual operating conditions can provide insights into how well a vehicle will perform. Moreover, educating drivers on best practices for fuel-efficient driving can further enhance performance. Implementing a fleet management system that monitors vehicle performance and fuel consumption in real time can also help identify areas for improvement, ultimately leading to cost savings and enhanced efficiency.

Strategic Material Selection Guide for triciclos motorizados

When selecting materials for motorized tricycles, it is crucial to consider various factors such as performance, durability, cost, and regional compliance standards. Below, we analyze four common materials used in the construction of motorized tricycles, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What are the Key Properties of Steel in Tricycle Manufacturing?

Steel is one of the most widely used materials in the automotive industry, including motorized tricycles. Its key properties include high tensile strength, excellent durability, and good weldability. Steel can withstand high temperatures and pressures, making it suitable for structural components and frames.

Pros & Cons: The main advantages of steel include its strength and cost-effectiveness. However, it is susceptible to corrosion if not properly treated, which can impact the longevity of the tricycle. Additionally, manufacturing complexity can increase with the need for protective coatings.

Impact on Application: Steel’s compatibility with various media, such as fuels and oils, makes it a reliable choice for tricycle components. However, buyers must consider the environmental conditions in their regions, particularly in humid or coastal areas where corrosion can be a significant issue.

Considerations for International Buyers: Compliance with international standards such as ASTM or DIN is essential. Buyers from regions like Africa and South America should also consider local regulations regarding material sourcing and environmental impact.

How Does Aluminum Compare as a Material for Tricycles?

Aluminum is another popular material due to its lightweight nature and resistance to corrosion. It has a lower density than steel, which can enhance fuel efficiency and performance in motorized tricycles.

Pros & Cons: The primary advantage of aluminum is its lightweight property, which improves maneuverability and reduces overall vehicle weight. However, aluminum can be more expensive than steel and may require specialized welding techniques, increasing manufacturing complexity.

Impact on Application: Aluminum is particularly suitable for components exposed to moisture, as it naturally forms a protective oxide layer. This makes it ideal for tricycles operating in wet or coastal environments.

Considerations for International Buyers: Buyers in Europe, especially Germany, may prefer aluminum due to its recyclability and lower carbon footprint. Compliance with EU regulations regarding material sustainability can influence purchasing decisions.

What Role Does Composite Material Play in Tricycle Design?

Composite materials, such as fiberglass or carbon fiber, are increasingly used in the manufacturing of motorized tricycles. These materials offer high strength-to-weight ratios and excellent resistance to environmental factors.

Pros & Cons: The main advantage of composites is their lightweight nature and high durability, which can enhance the performance and lifespan of tricycles. However, they are generally more expensive and can complicate the manufacturing process due to the need for specialized techniques.

Impact on Application: Composites are well-suited for components that require both strength and reduced weight, such as body panels and fairings. Their resistance to corrosion and UV damage makes them ideal for diverse climates.

Considerations for International Buyers: Buyers must be aware of the specific standards for composites in their regions. For example, compliance with JIS standards in Japan or local regulations in South America may be necessary.

Why is Plastic a Viable Option for Tricycle Components?

Plastic is commonly used for various components in motorized tricycles, such as dashboards and body panels. It is lightweight, resistant to corrosion, and can be molded into complex shapes.

Pros & Cons: The advantages of plastic include low cost and versatility in design. However, its durability may not match that of metals or composites, and it can be susceptible to UV degradation over time.

Impact on Application: Plastic is suitable for non-structural components and can withstand exposure to fuels and oils. However, its performance in high-stress applications may be limited.

Considerations for International Buyers: Buyers should consider the environmental impact of plastic materials and compliance with regulations regarding plastic use in their regions. In Europe, for instance, there are stringent regulations on plastic waste and recycling.

Summary of Material Selection for Triciclos Motorizados

| Material | Typical Use Case for triciclos motorizados | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Frame and structural components | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Lightweight components and frames | Lightweight and corrosion-resistant | Higher cost and manufacturing complexity | High |

| Composite | Body panels and fairings | High strength-to-weight ratio | Expensive and complex to manufacture | High |

| Plastic | Dashboards and non-structural parts | Low cost and versatile design | Limited durability in high-stress applications | Low |

This strategic material selection guide provides valuable insights for B2B buyers looking to optimize their purchasing decisions for motorized tricycles, ensuring they meet performance requirements while adhering to regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for triciclos motorizados

What Are the Main Stages in the Manufacturing Process for Triciclos Motorizados?

The manufacturing process for motorized tricycles, or “triciclos motorizados,” involves several key stages that ensure the vehicles meet quality and performance standards. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Is the Right Material Chosen?

Material selection is critical in the production of motorized tricycles. Manufacturers typically use high-strength steel and lightweight aluminum to balance durability and weight. Advanced composites may also be utilized for certain components to enhance fuel efficiency and performance. Before manufacturing begins, materials undergo rigorous inspections to verify their specifications, including tensile strength and fatigue resistance.

Forming: What Techniques Are Employed in Shaping Components?

The forming stage involves shaping the raw materials into the necessary components. Common techniques include stamping, bending, and welding. For example, the chassis may be stamped from sheets of steel, while the frame components are often welded together for strength and stability. Precision is vital during this stage, as even minor deviations can affect the vehicle’s overall performance and safety.

Assembly: How Are Components Brought Together?

Assembly is where individual components are put together to create the final product. This stage typically follows a sequential process, starting with the chassis and moving on to the installation of the engine, transmission, and electrical systems. Skilled technicians perform this work, often utilizing automated systems to enhance precision and efficiency. Quality control checkpoints during assembly, such as In-Process Quality Control (IPQC), help identify any issues early in the process.

Finishing: What Steps Are Taken to Ensure Quality and Aesthetics?

Finishing involves applying surface treatments, painting, and adding decals or branding. This stage not only enhances the aesthetic appeal but also provides corrosion resistance. Manufacturers may employ techniques such as powder coating or electroplating for durability. A final inspection occurs during this stage to ensure that all components meet the required specifications.

What Quality Assurance Measures Are Essential for Triciclos Motorizados?

Quality assurance (QA) is integral to the manufacturing of motorized tricycles, ensuring that each vehicle meets international and industry-specific standards. Key QA measures include adherence to ISO 9001 standards, which outline a framework for effective quality management systems.

Which International Standards Should Buyers Be Aware Of?

International standards such as ISO 9001 provide guidelines that manufacturers must follow to ensure quality. In addition to ISO, industry-specific certifications such as CE marking in Europe and API standards for specific components may also apply. For B2B buyers, understanding these certifications can provide assurance of product reliability and safety.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are crucial at various stages of the manufacturing process:

- Incoming Quality Control (IQC): This initial checkpoint ensures that raw materials meet specified standards before production begins.

- In-Process Quality Control (IPQC): Conducted during assembly, IPQC verifies that components are assembled correctly and function as intended.

- Final Quality Control (FQC): The final checkpoint occurs after assembly and finishing, where the complete product is tested against performance and safety standards.

What Testing Methods Are Commonly Used in Quality Assurance?

Manufacturers employ a variety of testing methods to validate the performance and safety of motorized tricycles. Common methods include:

- Static and Dynamic Testing: Evaluating the structural integrity of components under load.

- Performance Testing: Assessing engine performance, fuel efficiency, and braking systems.

- Safety Testing: Ensuring compliance with safety standards, including crash tests and stability assessments.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, verifying a supplier’s quality control practices is essential to ensure that products meet their standards. Here are several methods to consider:

- Supplier Audits: Conducting regular audits of suppliers can provide insight into their manufacturing processes and QA practices.

- Quality Reports: Requesting detailed quality reports from suppliers, including results from IQC, IPQC, and FQC checkpoints, can help assess reliability.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of product quality and compliance with international standards.

What Are the Nuances of Quality Control for International Buyers?

International buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. For example, compliance with local regulations and standards may differ significantly from those in the supplier’s country. It is crucial for buyers to understand these differences to avoid potential issues with imports.

Additionally, cultural and logistical factors may affect communication and quality assurance practices. Establishing clear expectations and maintaining open lines of communication can mitigate misunderstandings and enhance collaboration.

Conclusion: Why Is Understanding Manufacturing and Quality Assurance Important for B2B Buyers?

For B2B buyers in the market for motorized tricycles, a comprehensive understanding of manufacturing processes and quality assurance practices is vital. By being informed about the stages of production, relevant standards, and verification methods, buyers can make educated decisions that align with their quality requirements and operational goals. This knowledge not only helps in selecting reliable suppliers but also ensures that the final products meet the high standards expected in today’s competitive marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘triciclos motorizados’

Introduction

This guide serves as a practical checklist for B2B buyers interested in sourcing ‘triciclos motorizados’. The procurement process involves several key steps that ensure you select the right vehicles to meet your operational needs, comply with regulations, and achieve your business objectives. Following this checklist will help you navigate the complexities of the market and make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first crucial step in sourcing ‘triciclos motorizados’. This includes determining the engine capacity, passenger capacity, and specific features required for your business operations, such as cargo space or comfort features.

- Consider local regulations: Ensure that your specifications align with the legal requirements in your target markets, especially regarding emissions and safety standards.

Step 2: Research Market Trends and Demand

Understanding current market trends is essential for making informed purchasing decisions. Analyze the demand for ‘triciclos motorizados’ in your target regions, focusing on factors such as popular models, price points, and features that appeal to consumers.

- Utilize industry reports: Leverage market research reports and analytics to gain insights into consumer preferences and competitor offerings.

Step 3: Identify Potential Suppliers

Once your specifications are defined, compile a list of potential suppliers. Look for manufacturers with a proven track record in producing ‘triciclos motorizados’ that meet your requirements.

- Check for certifications: Verify that suppliers hold relevant certifications, such as ISO or industry-specific accreditations, which indicate quality and compliance with international standards.

Step 4: Evaluate Supplier Capabilities

Assess the capabilities of each supplier to ensure they can meet your demands. This includes evaluating their production capacity, technological expertise, and ability to provide after-sales support.

- Request samples: If possible, request product samples or demonstrations to evaluate the quality and functionality of the ‘triciclos motorizados’ firsthand.

Step 5: Negotiate Terms and Pricing

Engage in negotiations with your shortlisted suppliers to establish favorable terms and pricing. This includes discussing payment terms, delivery schedules, and warranty conditions.

- Be prepared to compare offers: Gather quotes from multiple suppliers to ensure you secure the best deal while maintaining quality and service expectations.

Step 6: Conduct Due Diligence

Before finalizing your purchase, conduct thorough due diligence on your selected supplier. This includes checking references, reviewing customer feedback, and assessing financial stability.

- Look for long-term partnerships: Consider suppliers who are willing to establish long-term relationships, as this can lead to better service and support in the future.

Step 7: Finalize the Purchase Agreement

Once due diligence is complete and you are satisfied with your chosen supplier, finalize the purchase agreement. Ensure that all terms discussed are clearly outlined in the contract, including delivery timelines and service agreements.

- Include clauses for contingencies: Protect your investment by including clauses that address potential issues such as delays in delivery or product defects.

By following this checklist, B2B buyers can streamline the sourcing process for ‘triciclos motorizados’, ensuring they make informed decisions that align with their business goals and operational requirements.

Comprehensive Cost and Pricing Analysis for triciclos motorizados Sourcing

What Are the Key Cost Components in Sourcing Triciclos Motorizados?

When sourcing triciclos motorizados, understanding the cost structure is vital for making informed purchasing decisions. The main components that contribute to the total cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materials represent a significant portion of the cost, influenced by the quality and type of components used, such as engines, frames, and electrical systems. Higher-quality materials may lead to increased durability and performance but will also elevate the price.

Labor costs vary based on the region and the skill level required for assembly. Regions with higher labor costs, like parts of Europe, may result in a more expensive product compared to lower-cost labor markets in Africa or South America.

Manufacturing overhead includes utilities, rent, and administrative expenses that indirectly contribute to production costs. Efficient manufacturing processes can help minimize these expenses.

Tooling costs are associated with the equipment and molds needed to produce specific designs. Customization or unique specifications will typically increase tooling costs, which should be factored into the overall price.

Quality Control (QC) is essential for ensuring that the triciclos meet safety and performance standards. Costs associated with QC can vary significantly based on the certification requirements and testing processes involved.

Logistics encompasses shipping, handling, and customs duties. International buyers should consider the implications of different Incoterms (International Commercial Terms) which define responsibilities regarding shipping costs and risk.

Finally, the margin is the profit that suppliers add to cover their business expenses and generate revenue. This margin can fluctuate based on market competition and supplier relationships.

How Do Price Influencers Affect the Cost of Triciclos Motorizados?

Several factors can influence the pricing of triciclos motorizados. Volume/MOQ (Minimum Order Quantity) plays a crucial role; larger orders can often lead to reduced per-unit costs. Suppliers may be willing to negotiate better pricing with buyers who can commit to higher volumes.

Specifications and customization also affect pricing. Custom features or unique designs will generally increase the cost due to the additional labor and materials required. Buyers should clearly communicate their needs to receive accurate quotes.

Quality and certifications are increasingly important, especially in markets with stringent safety regulations. Products that meet international safety standards may carry a premium price but offer better long-term reliability and lower Total Cost of Ownership (TCO).

Supplier factors such as reputation, production capacity, and geographic location can also impact pricing. Suppliers with a proven track record of reliability may command higher prices, but they often offer better customer service and support.

What Negotiation and Cost-Efficiency Tips Should International Buyers Consider?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant cost savings. Establishing long-term relationships with suppliers may provide leverage for better pricing and terms.

Understanding the Total Cost of Ownership (TCO) is crucial. This includes not just the initial purchase price but also ongoing maintenance, insurance, and potential resale value. A higher upfront cost may be justified if the vehicle offers superior quality and lower operational costs over time.

Buyers should also be aware of pricing nuances in different regions. Currency fluctuations, local tariffs, and import duties can significantly affect the final price. Therefore, obtaining quotes in the local currency and understanding the complete cost structure is advisable.

Lastly, conducting market research to compare prices across multiple suppliers can provide valuable insights. This data can empower buyers to negotiate better terms and ensure they are sourcing triciclos motorizados at competitive prices.

Conclusion

While indicative prices for triciclos motorizados can vary widely, understanding the intricate cost structure and price influencers can empower international B2B buyers. By considering the factors outlined above, businesses can make strategic sourcing decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing triciclos motorizados With Other Solutions

When evaluating transportation options for commercial use, it is essential to compare various solutions to determine the best fit for specific operational needs. Triciclos motorizados, or motorized tricycles, are gaining traction for their versatility and cost-effectiveness, but several alternatives may also meet similar objectives. Below, we compare triciclos motorizados with two viable alternatives: electric scooters and traditional delivery vans.

| Comparison Aspect | Triciclos Motorizados | Electric Scooters | Traditional Delivery Vans |

|---|---|---|---|

| Performance | Moderate load capacity; suitable for urban areas | Limited cargo space; ideal for individuals | High load capacity; longer distances |

| Cost | Lower purchase and operating costs | Generally low purchase cost; battery replacement needed | Higher initial investment; higher operating costs |

| Ease of Implementation | Simple to operate and maintain | Requires training for safety | Requires more complex logistics and fleet management |

| Maintenance | Low maintenance; fewer parts | Moderate maintenance; battery issues | High maintenance; more complex systems |

| Best Use Case | Urban deliveries, short distances | Personal transport, food delivery | Bulk deliveries, longer routes |

What Are the Pros and Cons of Electric Scooters Compared to Triciclos Motorizados?

Electric scooters offer an eco-friendly alternative for urban transportation, particularly for personal use and short deliveries. They are generally less expensive to purchase and maintain compared to triciclos motorizados. However, their limited cargo space makes them unsuitable for transporting larger goods. Additionally, while they are easier to maneuver in congested areas, the need for regular battery replacements can add to long-term costs.

How Do Traditional Delivery Vans Stack Up Against Triciclos Motorizados?

Traditional delivery vans provide significant advantages in terms of load capacity and the ability to cover longer distances. They are ideal for businesses that require bulk deliveries and have established logistics systems. However, the higher initial investment and ongoing operational costs, including fuel and maintenance, can be a deterrent for smaller businesses. Furthermore, navigating urban areas can be cumbersome, and parking may pose challenges compared to the agility of triciclos motorizados.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the right transportation solution, B2B buyers should assess their specific operational requirements, such as load capacity, distance, and budget. Triciclos motorizados excel in urban environments for short-distance deliveries, offering a cost-effective and low-maintenance option. In contrast, electric scooters may be suitable for lighter, personal transport needs, while traditional delivery vans are better suited for bulk deliveries over longer distances. Evaluating these factors will help businesses make informed decisions that align with their logistics strategies and operational goals.

Essential Technical Properties and Trade Terminology for triciclos motorizados

What Are the Key Technical Properties of Triciclos Motorizados?

When considering the purchase of motorized tricycles, understanding their essential technical specifications is critical for B2B buyers. Here are some key properties to focus on:

-

Engine Displacement (cc)

Engine displacement, measured in cubic centimeters (cc), indicates the engine’s size and power output. For example, a 900cc engine, like the one found in the Can-Am Ryker, typically offers a balance of performance and fuel efficiency. B2B buyers should consider the displacement relevant to their operational needs, as larger engines often provide better torque for carrying loads. -

Load Capacity (kg)

Load capacity refers to the maximum weight the tricycle can safely carry, including passengers and cargo. This specification is crucial for businesses that rely on motorized tricycles for transportation or delivery services. Understanding the load capacity helps ensure compliance with safety standards and operational efficiency. -

Transmission Type

Motorized tricycles can feature automatic or manual transmissions. Automatic transmissions, such as Continuous Variable Transmission (CVT), are user-friendly and reduce driver fatigue, making them ideal for urban environments. In contrast, manual transmissions may offer better control for specific applications. B2B buyers should assess the driving conditions and user proficiency to choose the appropriate transmission type. -

Braking System

The braking system is vital for safety and performance. Common types include disc brakes and drum brakes. Advanced systems may feature Anti-lock Braking Systems (ABS) for enhanced safety during abrupt stops. Buyers should prioritize tricycles with reliable braking systems to minimize accident risks, especially in crowded urban settings. -

Fuel Efficiency (L/100km)

Fuel efficiency, expressed in liters per 100 kilometers (L/100km), is a key consideration for operational cost management. High fuel efficiency translates to lower running costs, which is essential for businesses operating fleets. Understanding the fuel consumption rates of different models can help buyers make informed decisions that align with their budgetary constraints. -

Warranty and Serviceability

A comprehensive warranty and the availability of spare parts are crucial for minimizing downtime. Buyers should inquire about the warranty period and the manufacturer’s reputation for service support. A robust service network ensures quick repairs and maintenance, which is vital for businesses relying on their vehicles for daily operations.

What Are Common Trade Terms Relevant to Triciclos Motorizados?

Understanding industry jargon can significantly enhance the purchasing process for motorized tricycles. Here are some common trade terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or vehicles that are used in another company’s end products. When sourcing tricycles, buyers may consider OEM options for better customization and quality assurance. Working directly with OEMs can also provide insights into the latest technologies. -

MOQ (Minimum Order Quantity)

MOQ signifies the smallest number of units a supplier is willing to sell. This term is critical for B2B buyers, as it impacts inventory management and cash flow. Understanding the MOQ helps businesses plan their procurement strategies effectively, ensuring they meet demand without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a formal document that a buyer sends to suppliers to request pricing and terms for specific products. This term is vital for negotiating deals and ensuring that buyers receive competitive pricing. Crafting a well-structured RFQ can lead to better supplier relationships and more favorable contract terms. -

Incoterms (International Commercial Terms)

Incoterms are standardized terms that define the responsibilities of buyers and sellers in international trade. These terms clarify who is responsible for shipping, insurance, and tariffs. B2B buyers must understand Incoterms to manage their logistics effectively and mitigate potential disputes. -

Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. This term is crucial for supply chain planning. B2B buyers should factor in lead times when placing orders to ensure timely availability of tricycles for their operations.

By familiarizing themselves with these technical properties and trade terminology, B2B buyers can make informed purchasing decisions that align with their business needs and operational goals.

Navigating Market Dynamics and Sourcing Trends in the triciclos motorizados Sector

What Are the Key Market Dynamics and Trends in the Triciclos Motorizados Sector?

The global market for triciclos motorizados is experiencing dynamic shifts driven by various factors, including urbanization, economic growth, and changing consumer preferences. As cities become more congested, the demand for compact and versatile transportation solutions like three-wheeled motorcycles is on the rise. Buyers in regions such as Africa, South America, the Middle East, and Europe are increasingly interested in these vehicles for both personal use and commercial applications, such as delivery services.

Emerging technologies are playing a crucial role in sourcing and manufacturing trends within this sector. The integration of electric powertrains is becoming more prevalent, aligning with global sustainability goals. Companies are also adopting advanced manufacturing techniques, such as 3D printing, to reduce production costs and improve customization options. Additionally, the rise of e-commerce has spurred demand for triciclos motorizados in logistics, particularly in urban areas where traditional delivery methods face challenges.

B2B buyers should be aware of regional preferences and regulatory environments that can impact sourcing decisions. In Europe, for instance, stricter emissions regulations are pushing manufacturers towards greener alternatives, while in South America, affordability and durability are paramount. Understanding these nuances can help international buyers make informed decisions that align with local market demands.

How Is Sustainability Shaping Sourcing Practices in the Triciclos Motorizados Industry?

Sustainability is no longer a buzzword but a fundamental principle guiding sourcing and procurement strategies in the triciclos motorizados sector. The environmental impact of traditional manufacturing processes has prompted many companies to re-evaluate their supply chains and sourcing practices. Buyers are increasingly seeking suppliers that prioritize ethical sourcing, which includes using sustainable materials and adhering to fair labor practices.

The certification of materials plays a significant role in this transformation. Green certifications, such as ISO 14001 for environmental management, are becoming essential for suppliers to demonstrate their commitment to sustainability. Buyers should look for manufacturers that utilize eco-friendly materials in their production processes, such as recycled metals and biodegradable plastics, which not only reduce waste but also enhance the marketability of the final product.

Moreover, the emphasis on sustainability is extending to the end-of-life management of triciclos motorizados. Innovative recycling programs and take-back schemes are emerging as critical components of responsible manufacturing, allowing for the recovery of materials and reduction of landfill waste. By prioritizing suppliers with robust sustainability initiatives, B2B buyers can contribute to a more circular economy while meeting the growing consumer demand for environmentally responsible products.

What Is the Evolution of Triciclos Motorizados and Its Relevance for B2B Buyers?

The history of triciclos motorizados dates back several decades, originating as practical solutions for transportation in densely populated urban areas. Initially designed for utility purposes, these vehicles have evolved significantly, now encompassing a range of styles and applications, from leisure riding to commercial transport.

This evolution is particularly relevant for B2B buyers as it highlights the versatility and adaptability of triciclos motorizados. Modern models now feature advanced technology, enhanced safety features, and improved fuel efficiency, making them attractive investments for businesses. Understanding this historical context allows buyers to appreciate the innovation and potential of these vehicles, ensuring they make strategic sourcing decisions that align with both current market demands and future trends.

In summary, the triciclos motorizados sector is not only adapting to changing market dynamics but is also positioned to meet the sustainability challenges of the 21st century. B2B buyers must stay informed about these trends to capitalize on opportunities and drive their business success.

Frequently Asked Questions (FAQs) for B2B Buyers of triciclos motorizados

-

How do I choose the right supplier for motorized tricycles?

When selecting a supplier for motorized tricycles, evaluate their experience in the industry, production capacity, and quality certifications. Request references from previous clients and conduct site visits if possible. Additionally, assess their compliance with international safety and environmental standards, as well as their ability to provide after-sales support and spare parts. Establish clear communication to ensure they understand your specific needs and expectations. -

What are the key features to look for in motorized tricycles?

The ideal motorized tricycle should have a reliable engine, sufficient passenger and cargo capacity, and advanced safety features like ABS and stability control. Consider models with customizable ergonomic options for comfort, along with efficient fuel consumption or electric alternatives for sustainability. Additionally, assess the available storage space and the ease of maintenance, as these factors will directly impact operational efficiency. -

What are typical minimum order quantities (MOQs) for motorized tricycles?

Minimum order quantities for motorized tricycles can vary significantly depending on the manufacturer and model. Generally, MOQs may range from 10 to 100 units. Discuss your requirements with potential suppliers to negotiate terms that suit your business needs. Some manufacturers may offer lower MOQs for first-time buyers or provide discounts for bulk orders, so it’s essential to explore all options. -

What payment terms should I expect when sourcing motorized tricycles internationally?

Payment terms for international purchases often include options like letter of credit, advance payment, or payment upon delivery. Terms can vary by supplier and region, so it’s crucial to negotiate favorable conditions that mitigate risk. Ensure you understand the implications of currency fluctuations, and consider using escrow services for large transactions to enhance security. -

How can I ensure quality assurance (QA) for motorized tricycles?

To ensure quality assurance, request detailed specifications and compliance certifications from your supplier. Implement a thorough inspection process, including pre-shipment inspections and in-country testing. Establish a clear return policy for defective units and consider third-party QA services for an unbiased evaluation. Regular communication with the supplier can also foster a culture of quality commitment. -

What are the best logistics practices for importing motorized tricycles?

Efficient logistics practices involve selecting reliable freight forwarders with experience in handling motorized vehicles. Understand the shipping options available—air freight is faster but more expensive, while sea freight is more economical but slower. Ensure all necessary customs documentation is prepared in advance, and consider insurance to cover potential damages during transit. -

How do I handle customs regulations when importing motorized tricycles?

Familiarize yourself with the customs regulations in your country regarding the importation of motorized vehicles. This includes understanding tariffs, duties, and any specific certifications required for compliance. Work closely with a customs broker to streamline the process and ensure all paperwork is accurately completed. Keep up-to-date with any changes in regulations that may affect your shipments. -

Can motorized tricycles be customized to meet specific business needs?

Yes, many manufacturers offer customization options for motorized tricycles to meet specific business requirements. Customization can include modifications to the vehicle’s design, features, and functionality. Discuss your needs with potential suppliers, and inquire about their capabilities for bespoke manufacturing. Ensure that any customization aligns with safety standards and operational efficiency for your intended use.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Triciclos Motorizados Manufacturers & Suppliers List

1. Pinterest – Motorized Drift Trikes

Domain: co.pinterest.com

Registered: 2009 (16 years)

Introduction: Triciclos con motor, Off Road Drift Trike, Drift Trike With Motor, Diy Gas Powered Drift Trike, Motorized Big Wheel, Drift Trike Frame, Go Kart Kits, Electric Drift Trike, Reverse Trike, 50cc Three-wheel Ruckus Style Trike, Custom Trikes, Vintage Mini Bike With Engine.

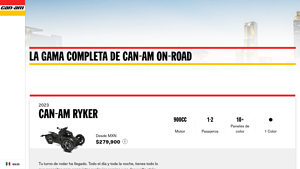

2. Can-Am – CAN-AM RYKER

Domain: can-am.brp.com

Registered: 1995 (30 years)

Introduction: [{‘model’: ‘CAN-AM RYKER’, ‘engine’: ‘900cc’, ‘passengers’: ‘1-2’, ‘storage’: ‘N/A’, ‘colors’: ’10+ Paneles de color, 1 Color’, ‘price’: ‘Desde MXN $279,900’, ‘features’: [‘Rotax® 900 ACE™ 3 cilindros en línea’, ‘Modos Eco y Sport’, ‘Automática (CVT) con función de reversa’, ‘Tecnología de eje de transmisión’, ‘Capacidad de ajuste ergonómico sin herramientas’]}, {‘model’: ‘CAN-AM SPYDER F3’, ‘engi…

3. Pinterest – Triciclo Motorizado y Vehículos Eléctricos

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Triciclo Motorizado, Drift trike motorizado 100cc, Triciclo Motorizado Rewaco HS6 GT Harley-Davidson, Triciclo eléctrico para adultos, Scooter de movilidad, vehículo eléctrico de 3 ruedas, carro de remolque de comida.

4. EvoBike – Triciclos Eléctricos

Domain: evobike.com.mx

Registered: 2023 (2 years)

Introduction: This company, EvoBike – Triciclos Eléctricos, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Mercado Libre – Triciclo Motorizado

Domain: vehiculos.mercadolibre.com.mx

Registered: 1999 (26 years)

Introduction: This company, Mercado Libre – Triciclo Motorizado, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. MooEvo – Triciclos de Reparto Eléctricos

Domain: mooevo.com

Registered: 2020 (5 years)

Introduction: Los triciclos de reparto motorizados eléctricamente son herramientas útiles para mejorar la eficiencia en el delivery y reducir el impacto negativo como el ruido, los atascos o las emisiones. Están diseñados para el transporte y entrega de mercancías que pesan entre diez y cincuenta libras en un radio de diez a veinte millas. A diferencia de los automóviles, son más económicos y compactos, y no re…

7. iStock – Triciclo Motorizado Images

Domain: istockphoto.com

Registered: 2000 (25 years)

Introduction: This company, iStock – Triciclo Motorizado Images, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Guowei Motor – Triciclo Eléctrico GWGM-1A

Domain: gwebike.com

Registered: 2017 (8 years)

Introduction: {“product_name”: “Triciclo eléctrico motorizado de tres ruedas”, “manufacturer”: “Guowei Motor”, “model_number”: “GWGM-1A”, “type”: “Eléctrico”, “usage”: “Carga”, “motor_power”: “350W”, “battery”: “48V20AH”, “voltage”: “48V”, “body_type”: “Abierto”, “certification”: “ISO9001”, “origin”: “Jiangsu, China (Continental)”, “dimensions”: {“size”: “1.02×0.76×0.25 m”, “cargo_box_size”: “1.02*0.82*0.24 m”}…

9. Kiwo – Triciclo de Carga Eléctrico

Domain: waldos.com.mx

Registered: 2003 (22 years)

Introduction: Triciclo de Carga Eléctrico, Kiwo color Gris – Precio: $22,999.99 (antes $28,999.99) – Estado: Agotado; Triciclo de Carga Eléctrico Kiwo, Color Negro – Precio: $22,999.99 (antes $28,999.99) – Estado: Agotado; Triciclo de Carga Eléctrico Kiwo, Color Rojo – Precio: $22,999.99 (antes $28,999.99) – Estado: Agotado.

Strategic Sourcing Conclusion and Outlook for triciclos motorizados

As the global market for triciclos motorizados continues to expand, strategic sourcing emerges as a crucial factor for international B2B buyers. By prioritizing suppliers who offer advanced engineering, robust performance features, and sustainable options, businesses can enhance their competitive edge. The variety of models available, such as the Can-Am series, illustrates the diversity in design and functionality, catering to both urban and leisure markets.

Investing in high-quality, reliable triciclos motorizados not only meets consumer demand but also aligns with the growing emphasis on eco-friendly transportation solutions. Buyers should leverage data analytics and market research to identify trends and make informed sourcing decisions that can lead to increased profitability and customer satisfaction.

Looking ahead, the triciclo motorizado sector is poised for innovation, particularly with the introduction of electric models and smart technology integrations. International buyers from Africa, South America, the Middle East, and Europe are encouraged to engage with manufacturers and suppliers who are at the forefront of these developments. By doing so, they can secure advantageous partnerships that will drive growth in this dynamic market. Seize the opportunity to elevate your sourcing strategy today.