Introduction: Navigating the Global Market for new Tractor Truck Trailer Head

In an increasingly competitive landscape, sourcing new tractor truck trailer heads that meet rigorous operational demands while ensuring profitability can be a daunting challenge for international B2B buyers. This guide serves as a comprehensive resource, addressing the complexities of procuring these essential vehicles. From an overview of various types—such as heavy-duty and regional haul options—to their specific applications in diverse industries, we delve into critical factors that influence purchasing decisions. Additionally, we provide insights on supplier vetting, cost considerations, and the latest technological advancements to help businesses stay ahead.

Navigating the global market for new tractor truck trailer heads requires a strategic approach, especially for buyers in regions like Africa, South America, the Middle East, and Europe, including countries such as Nigeria and Vietnam. This guide empowers you with the knowledge to make informed decisions, ensuring you select products that align with your operational needs and budget. By understanding the intricate details of specifications, compliance standards, and market trends, you can enhance your procurement strategy and optimize your fleet’s performance. Equip yourself with the insights needed to thrive in this dynamic market and drive your business forward.

Understanding new Tractor Truck Trailer Head Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Long Haul Truck | Aerodynamic design, high fuel efficiency, advanced safety features | Long-distance freight transportation | Pros: Fuel-efficient, comfortable for drivers. Cons: Higher initial investment. |

| Regional Haul Truck | Responsive handling, optimized for shorter routes, lower emissions | Regional logistics and distribution | Pros: Cost-effective for shorter distances. Cons: Limited capacity for heavy loads. |

| Heavy-Duty Truck | Robust construction, high horsepower, suitable for extreme conditions | Construction, mining, and heavy transport | Pros: Exceptional durability and load capacity. Cons: Higher operating costs due to fuel consumption. |

| Electric Truck | Zero-emission, quiet operation, advanced battery technology | Urban delivery and environmentally sensitive areas | Pros: Lower environmental impact, reduced operating costs. Cons: Limited range and charging infrastructure. |

| Low-Profile Truck | Enhanced maneuverability, optimized for auto transport | Automotive logistics and specialized transport | Pros: Excellent visibility and handling. Cons: May have lower towing capacity compared to standard trucks. |

What are the Key Characteristics of Long Haul Trucks?

Long haul trucks are designed for extensive travel, often covering thousands of kilometers. Their aerodynamic shape significantly enhances fuel efficiency, making them ideal for businesses focused on reducing operational costs. These trucks typically feature advanced safety systems, ensuring the protection of drivers and cargo. B2B buyers should consider the total cost of ownership, including fuel savings and maintenance when investing in long haul trucks.

How Do Regional Haul Trucks Optimize Logistics?

Regional haul trucks are built for shorter distances, providing a balance between efficiency and capacity. They are designed for responsive handling, making them suitable for urban deliveries and regional logistics. The lower emissions of these trucks align with the growing demand for sustainable transport solutions. Buyers should evaluate the operational needs of their logistics network to determine if a regional haul truck is the right fit.

What Makes Heavy-Duty Trucks Essential for Certain Industries?

Heavy-duty trucks are essential for industries that require transporting heavy loads under challenging conditions, such as construction and mining. These trucks are characterized by their robust build and high horsepower, enabling them to handle extreme demands. While they provide unmatched durability, buyers should be aware of higher fuel consumption and maintenance costs associated with heavy-duty trucks, which can impact overall profitability.

Why Should Businesses Consider Electric Trucks?

Electric trucks represent a significant advancement in sustainable transport, offering zero emissions and quiet operation. They are particularly suited for urban delivery, where environmental regulations are stringent. While the initial investment may be higher, the reduction in fuel and maintenance costs can lead to long-term savings. Businesses must consider the availability of charging infrastructure and the operational range of electric trucks when making purchasing decisions.

What Advantages Do Low-Profile Trucks Offer?

Low-profile trucks are specifically optimized for the auto transport sector, providing enhanced maneuverability and visibility. Their design allows for easier navigation in tight spaces, making them ideal for urban environments. However, potential buyers should assess the towing capacity and ensure it meets their operational requirements, as low-profile trucks may not be suitable for heavier loads.

Key Industrial Applications of new Tractor Truck Trailer Head

| Industry/Sector | Specific Application of new Tractor Truck Trailer Head | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics & Freight | Long-haul transportation of goods | Increased efficiency in transporting bulk goods over long distances, reducing operational costs. | Engine power, fuel efficiency, and load capacity are critical. Look for models with advanced safety features and telematics. |

| Construction | Transporting heavy machinery and materials | Reliable delivery of heavy equipment and materials to job sites, improving project timelines and productivity. | Durability, load capacity, and compatibility with various trailer types are essential. Consider local terrain and climate conditions. |

| Agriculture | Hauling agricultural produce and equipment | Enhances the supply chain for agricultural products, ensuring timely deliveries to markets and processing plants. | Look for tractors with high torque and fuel efficiency. Seasonal demand fluctuations should be considered in procurement. |

| Mining | Transporting minerals and heavy loads | Facilitates the efficient movement of mined materials, reducing downtime and increasing output. | Heavy-duty specifications, robust build quality, and compliance with environmental regulations are crucial. |

| Automotive | Auto transport and delivery services | Streamlines the logistics of delivering vehicles from manufacturers to dealerships, enhancing customer satisfaction. | Customizable features for vehicle transport, fuel efficiency, and safety ratings are important. Ensure compliance with international shipping regulations. |

How is the new Tractor Truck Trailer Head Used in Logistics & Freight?

In the logistics and freight industry, new tractor truck trailer heads are pivotal for long-haul transportation. They enable businesses to move bulk goods efficiently across vast distances, significantly reducing operational costs. Buyers in this sector should prioritize models with high engine power and fuel efficiency to optimize their logistics processes. Advanced safety features and telematics are also essential to ensure compliance with international regulations and enhance fleet management.

What Role Does the Tractor Truck Trailer Head Play in Construction?

In construction, these tractor heads are indispensable for transporting heavy machinery and materials to job sites. Their reliable performance helps improve project timelines and productivity by ensuring that necessary equipment arrives on schedule. Buyers should focus on durability and load capacity when sourcing these vehicles, considering local terrain and climate conditions that may affect transportation.

How Does the Agriculture Sector Benefit from Tractor Truck Trailer Heads?

The agriculture sector utilizes tractor truck trailer heads to haul produce and agricultural equipment effectively. By enhancing the supply chain, these vehicles ensure timely deliveries to markets and processing plants, which is crucial for maintaining product quality. Buyers should look for models with high torque and fuel efficiency, especially given the seasonal fluctuations in demand for agricultural products.

In What Ways Are Tractor Truck Trailer Heads Essential for Mining Operations?

In mining, the new tractor truck trailer heads are vital for transporting minerals and heavy loads. They facilitate the efficient movement of mined materials, which helps reduce downtime and increase output. When sourcing for this application, it’s important to consider heavy-duty specifications, robust build quality, and compliance with environmental regulations to ensure operational efficiency.

How Do Automotive Companies Utilize Tractor Truck Trailer Heads?

Automotive companies rely on tractor truck trailer heads for transporting vehicles from manufacturers to dealerships. This streamlining of logistics enhances customer satisfaction by ensuring timely delivery of vehicles. Buyers should seek customizable features tailored for vehicle transport, emphasizing fuel efficiency and safety ratings, while also ensuring compliance with international shipping regulations.

3 Common User Pain Points for ‘new Tractor Truck Trailer Head’ & Their Solutions

Scenario 1: Navigating Compliance with Emission Standards

The Problem: B2B buyers often face challenges in ensuring that their new tractor truck trailer heads meet local and international emission standards. This is particularly significant in regions like Europe and parts of Africa, where regulations are becoming increasingly stringent. Buyers may struggle to identify which models comply with Euro 6 standards or equivalent, leading to potential fines, increased operational costs, and the risk of being barred from certain markets.

The Solution: To navigate compliance effectively, buyers should conduct thorough research on the emission standards relevant to their operational regions. Engaging with reputable manufacturers who provide detailed specifications about their vehicles’ compliance can simplify this process. It’s also advisable to consult with local regulatory bodies or industry experts to gain insights into upcoming changes in legislation. When selecting a tractor truck trailer head, prioritize models with advanced emission technologies, such as selective catalytic reduction (SCR) and diesel particulate filters (DPF). Additionally, leveraging platforms that aggregate product data and supplier ratings can help in identifying compliant models more efficiently.

Scenario 2: Understanding Total Cost of Ownership (TCO)

The Problem: Many international B2B buyers underestimate the total cost of ownership when purchasing new tractor truck trailer heads. Factors such as fuel efficiency, maintenance costs, and the potential for resale value can significantly impact the financial viability of the investment. Buyers may find themselves overwhelmed by the complexity of calculating TCO, leading to budget overruns and reduced profit margins.

The Solution: To mitigate this issue, buyers should adopt a comprehensive approach to evaluating potential purchases. Start by obtaining detailed fuel consumption data and maintenance schedules from manufacturers, as these can vary widely between models. Utilize online calculators or TCO estimation tools that factor in fuel prices, maintenance costs, and expected lifespan. Additionally, consider exploring financing options that can spread costs over time, making it easier to manage cash flow. Engaging in discussions with current users of the tractor truck trailer head models under consideration can provide practical insights into long-term performance and reliability, further informing purchasing decisions.

Scenario 3: Adapting to Diverse Terrain and Load Requirements

The Problem: Buyers in regions with diverse terrains, such as mountainous areas in South America or rough roads in parts of Africa, often face the challenge of selecting a tractor truck trailer head that can handle varying load requirements and driving conditions. Inadequate vehicle specifications can lead to operational inefficiencies, increased wear and tear, and even accidents, posing risks to both the equipment and the drivers.

The Solution: To address these challenges, buyers should assess their specific operational needs, including the types of loads typically transported and the conditions of the routes. It’s crucial to choose a tractor truck trailer head equipped with adaptable features, such as adjustable suspension systems and robust engine power tailored for heavy loads. Conduct field tests or simulations to evaluate performance in real-world conditions before finalizing a purchase. Collaborating with local dealers who understand the regional landscape can provide valuable insights into the best models suited for diverse terrains. Additionally, consider investing in technology that offers real-time tracking and diagnostics, enabling proactive maintenance and ensuring the vehicle performs optimally under varying conditions.

Strategic Material Selection Guide for new Tractor Truck Trailer Head

What Are the Key Materials for New Tractor Truck Trailer Heads?

When selecting materials for new tractor truck trailer heads, it is essential to consider the performance characteristics, cost-effectiveness, and compliance with international standards. Below are the analyses of four common materials used in the construction of tractor truck trailer heads: steel, aluminum, composite materials, and high-strength plastics.

How Does Steel Perform in Tractor Truck Trailer Heads?

Steel is the most widely used material in the manufacturing of tractor truck trailer heads due to its excellent mechanical properties. It offers high tensile strength, making it suitable for heavy loads and harsh operating conditions. Steel can withstand high temperatures and pressures, which is crucial for long-haul applications.

Pros: Steel is durable, readily available, and cost-effective. Its manufacturing processes are well-established, leading to lower production costs.

Cons: However, steel is susceptible to corrosion, which can be a significant drawback in humid or coastal environments. It is also heavier than other materials, potentially impacting fuel efficiency.

Impact on Application: Steel’s compatibility with various media, such as diesel and other fluids, makes it a reliable choice. However, buyers must consider the need for protective coatings to enhance corrosion resistance.

Considerations for International Buyers: Compliance with standards like ASTM A36 or EN 10025 is crucial. Buyers from regions like Africa and South America should be aware of local environmental conditions that may affect steel performance.

What Advantages Does Aluminum Offer for Tractor Truck Trailer Heads?

Aluminum is increasingly being used in tractor truck trailer heads due to its lightweight nature and corrosion resistance. It is particularly advantageous for applications that prioritize fuel efficiency.

Pros: The primary advantage of aluminum is its reduced weight, which can lead to significant fuel savings. It also offers good resistance to corrosion, making it suitable for various environmental conditions.

Cons: On the downside, aluminum is generally more expensive than steel and can have lower tensile strength, which may not be suitable for all heavy-duty applications.

Impact on Application: Aluminum’s compatibility with various media is favorable, but it may require specific welding techniques during manufacturing.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM B209. In regions like the Middle East, where heat can be a factor, understanding aluminum’s thermal properties is essential.

How Do Composite Materials Enhance Tractor Truck Trailer Head Design?

Composite materials, such as fiberglass and carbon fiber, are gaining traction in the trucking industry due to their unique properties.

Pros: Composites are lightweight and offer excellent corrosion resistance. They can be engineered for specific performance characteristics, making them versatile for various applications.

Cons: The manufacturing process for composites can be complex and costly. Additionally, they may not provide the same load-bearing capacity as metals.

Impact on Application: Composites are ideal for applications where weight savings are critical, but buyers must assess their load requirements carefully.

Considerations for International Buyers: Compliance with international standards for composites is less established than for metals, which may pose challenges in certain markets.

What Role Do High-Strength Plastics Play in Tractor Truck Trailer Heads?

High-strength plastics are emerging as a viable option for specific components of tractor truck trailer heads, particularly in non-structural applications.

Pros: These materials are lightweight, resistant to corrosion, and can be molded into complex shapes, offering design flexibility.

Cons: However, high-strength plastics may not withstand extreme temperatures or heavy loads as effectively as metals.

Impact on Application: They are suitable for applications where weight reduction is necessary, but their load-bearing limitations must be considered.

Considerations for International Buyers: Buyers should look for compliance with standards like ISO 9001 for quality assurance in plastic manufacturing.

Summary of Material Selection for New Tractor Truck Trailer Heads

| Material | Typical Use Case for new Tractor Truck Trailer Head | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components in heavy-duty applications | High tensile strength | Susceptible to corrosion | Low |

| Aluminum | Lightweight trailers for fuel efficiency | Corrosion resistance | Higher cost, lower strength | Med |

| Composite | Non-structural elements requiring weight savings | Lightweight and versatile | Complex manufacturing | High |

| High-Strength Plastic | Components needing design flexibility | Lightweight and moldable | Limited load-bearing capacity | Med |

This guide provides a comprehensive overview of the materials available for new tractor truck trailer heads, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for new Tractor Truck Trailer Head

What Are the Main Stages in the Manufacturing Process of a New Tractor Truck Trailer Head?

The manufacturing process of a new tractor truck trailer head involves several key stages: material preparation, forming, assembly, and finishing. Each stage is crucial in ensuring that the final product meets the high standards expected by B2B buyers.

-

Material Preparation: This initial stage involves selecting high-grade materials that can withstand the rigors of heavy-duty transportation. Common materials include high-strength steel, aluminum alloys, and composite materials. Suppliers often source these materials from certified vendors to ensure compliance with industry standards. Before production begins, materials undergo inspections for quality, thickness, and any pre-existing defects.

-

Forming: In this stage, the prepared materials are shaped into the desired components using techniques such as stamping, bending, and welding. Advanced technologies like CNC (Computer Numerical Control) machining and laser cutting are often employed to achieve precision and consistency in parts. This is especially important for components like the chassis and suspension systems, which require exact specifications to ensure optimal performance and safety.

-

Assembly: Once the individual components are formed, they are assembled into the tractor truck trailer head. This stage may involve robotic assembly lines or skilled labor, depending on the complexity of the design. Quality checks are performed during this phase to ensure that components fit together correctly and meet engineering specifications. The assembly process also includes the installation of critical systems such as the braking system, electrical wiring, and the engine.

-

Finishing: The final stage involves surface treatment and painting to protect against corrosion and wear. Techniques such as powder coating or galvanizing are commonly used to enhance durability. A final inspection is performed to ensure that the tractor head meets aesthetic and functional standards before it is prepared for shipment.

How Is Quality Assurance Implemented in the Manufacturing of Tractor Truck Trailer Heads?

Quality assurance (QA) is paramount in the manufacturing of tractor truck trailer heads, particularly for B2B buyers who depend on the reliability and safety of their vehicles. Here are the key components of an effective quality assurance program.

-

International and Industry-Specific Standards: Compliance with international standards such as ISO 9001 is essential. This standard outlines requirements for a quality management system that can enhance customer satisfaction through effective process management. Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for oil and gas applications provide further assurance of quality.

-

Quality Control Checkpoints: Quality control (QC) checkpoints are integrated throughout the manufacturing process. These typically include:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Ongoing inspections are performed during various stages of manufacturing to identify defects early.

– Final Quality Control (FQC): A comprehensive inspection of the finished product is conducted to verify that it meets all design specifications and quality standards. -

Common Testing Methods: Various testing methods are employed to ensure the performance and safety of tractor truck trailer heads. These include:

– Load Testing: To assess the structural integrity under heavy loads.

– Fatigue Testing: To evaluate how materials respond to repeated stress.

– Environmental Testing: To ensure the vehicle can withstand harsh weather conditions and environments.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control measures is crucial. Here are strategies to ensure that suppliers maintain high-quality standards.

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality control systems. Audits should focus on their adherence to international standards, the effectiveness of their QA processes, and their overall manufacturing capabilities.

-

Quality Assurance Reports: Requesting detailed QA reports from suppliers can offer transparency regarding their quality management practices. These reports should outline inspection results, compliance with standards, and any corrective actions taken to address issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspections can be particularly beneficial for international buyers who may not be able to visit suppliers in person.

-

Certifications and Documentation: Buyers should ask for copies of relevant certifications, such as ISO 9001, CE, and other industry-specific credentials. This documentation can serve as proof of the supplier’s commitment to quality.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various challenges when it comes to quality control in the procurement of tractor truck trailer heads. Understanding these nuances can help in making informed purchasing decisions.

-

Regulatory Compliance: Different regions have varying regulations and standards that may impact the manufacturing and importation of tractor truck trailer heads. Buyers should familiarize themselves with these regulations, such as emissions standards in Europe or safety regulations in North America.

-

Cultural Differences: Cultural factors can influence quality expectations and communication styles. Building strong relationships with suppliers through clear communication and mutual understanding can enhance cooperation and quality outcomes.

-

Logistical Considerations: The logistics of transporting heavy equipment can introduce risks that may affect quality. Buyers should consider the entire supply chain, from manufacturing to delivery, to ensure that products arrive in optimal condition.

-

Continuous Improvement: Engaging in continuous improvement practices with suppliers can lead to better quality outcomes. Buyers should encourage suppliers to adopt methodologies such as Lean Manufacturing or Six Sigma to enhance efficiency and quality in production.

By understanding these aspects of manufacturing processes and quality assurance, B2B buyers can make more informed decisions when sourcing new tractor truck trailer heads, ensuring they select reliable partners that meet their quality standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘new Tractor Truck Trailer Head’

Introduction

This practical sourcing guide is designed for international B2B buyers seeking to procure new tractor truck trailer heads. With a focus on key considerations such as specifications, supplier evaluation, and compliance, this checklist will help you navigate the complexities of sourcing efficiently and effectively.

Step 1: Define Your Technical Specifications

Before initiating your search, it’s essential to clearly outline the technical specifications of the tractor truck trailer head you require. Consider aspects such as engine power (e.g., horsepower), drive configuration (e.g., 4×2 or 6×4), load capacity, and any specific features like air suspension or advanced braking systems. This clarity will enable you to filter options and streamline your discussions with suppliers.

Step 2: Research Available Models and Brands

Once your specifications are defined, conduct thorough research on available models and reputable brands. Look for manufacturers known for reliability and performance in your region. Pay attention to user reviews and case studies that showcase the performance of various models under similar operational conditions.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Check their years of experience, customer service reputation, and whether they offer post-purchase support. Don’t just rely on their website; engage in direct communication to assess their responsiveness and professionalism.

Step 4: Verify Compliance with Local Regulations

Ensure that the tractor truck trailer head complies with local regulations and emission standards applicable in your target market. For instance, if you are sourcing for the European market, ensure the vehicle meets Euro 6 emission standards. This step is vital to avoid costly fines and operational disruptions once the vehicle is in use.

Step 5: Assess Total Cost of Ownership

Evaluate the total cost of ownership beyond the initial purchase price. This includes fuel efficiency, maintenance costs, insurance, and potential resale value. Understanding the long-term financial implications will help you make a more informed purchasing decision, ensuring that the investment aligns with your operational budget and goals.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, engage in negotiations to finalize terms and conditions. Discuss payment options, delivery timelines, warranty provisions, and after-sales service. A well-negotiated contract will protect your interests and clarify expectations, reducing the potential for disputes in the future.

Step 7: Conduct a Final Quality Check

Before finalizing the purchase, perform a final quality check, either through on-site inspections or third-party evaluations. Verify that the specifications match your requirements and that the vehicle is in optimal condition. This step is crucial to ensure that you receive a product that meets your operational needs and standards.

By following this checklist, B2B buyers can make informed decisions when sourcing new tractor truck trailer heads, minimizing risks and maximizing operational efficiency.

Comprehensive Cost and Pricing Analysis for new Tractor Truck Trailer Head Sourcing

What Are the Key Cost Components of New Tractor Truck Trailer Heads?

When considering the procurement of new tractor truck trailer heads, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: High-quality materials such as steel, aluminum, and advanced composites significantly influence the price. The choice of materials can affect durability and performance, impacting long-term operational costs.

-

Labor: Skilled labor is essential for assembling tractor heads. Labor costs vary based on the region and the complexity of the manufacturing process, which can include advanced robotics or manual craftsmanship.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses associated with the production facility. Efficient manufacturing practices can help mitigate these costs.

-

Tooling: Custom tooling for specialized designs or features can be a significant upfront investment. Buyers should consider how tooling costs are factored into the overall price.

-

Quality Control (QC): Ensuring that the tractor heads meet industry standards involves rigorous QC processes. The costs associated with testing and certification can be substantial but are critical for safety and reliability.

-

Logistics: Shipping costs can vary widely depending on the origin of the tractor head and the destination. Factors such as distance, mode of transport, and current fuel prices will impact logistics expenses.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the competitive landscape can help buyers gauge whether margins are reasonable.

How Do Price Influencers Impact Tractor Truck Trailer Head Costs?

Several factors can influence the pricing of tractor truck trailer heads:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in bulk often results in lower per-unit costs. Buyers should assess their capacity to store and manage larger quantities.

-

Specifications and Customization: Custom features or specifications can increase costs. It’s essential for buyers to balance their requirements with budget constraints.

-

Material Quality and Certifications: Higher quality materials and certifications (like Euro 6 emissions compliance) typically command a premium price. Buyers should weigh the benefits of these features against the costs.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may offer better warranties and support but might charge higher prices.

-

Incoterms: The terms of trade (like FOB, CIF) can significantly impact the total cost. Buyers should clearly understand their responsibilities regarding shipping and insurance.

What Tips Can Help B2B Buyers Negotiate Better Prices?

Negotiating effectively is key to achieving favorable pricing for new tractor truck trailer heads:

-

Research and Benchmarking: Buyers should conduct thorough market research to understand pricing trends and competitor offerings. This information can provide leverage during negotiations.

-

Focus on Total Cost of Ownership (TCO): Instead of solely considering the purchase price, buyers should evaluate the TCO, which includes maintenance, fuel efficiency, and resale value. This broader perspective can justify higher initial costs for more efficient models.

-

Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing and terms. Repeat business often results in preferential treatment.

-

Be Flexible with Specifications: If buyers can be flexible with certain specifications or features, they may be able to access more cost-effective options without compromising essential performance metrics.

-

Understand Pricing Nuances for International Transactions: For buyers in regions like Africa, South America, the Middle East, and Europe, currency fluctuations, tariffs, and local regulations can impact pricing. It’s essential to factor these elements into the overall cost assessment.

Disclaimer on Indicative Prices

While pricing for new tractor truck trailer heads can range significantly—from approximately $6,000 for basic models to upwards of $54,000 for high-end options—these figures are indicative and can vary based on multiple factors. Buyers are advised to obtain detailed quotes from suppliers to ensure accurate budgeting and cost planning.

Alternatives Analysis: Comparing new Tractor Truck Trailer Head With Other Solutions

Exploring Alternatives to New Tractor Truck Trailer Heads

When considering the acquisition of a new tractor truck trailer head, it’s essential to evaluate various alternatives that may better suit specific operational needs or budget constraints. Each alternative presents unique advantages and disadvantages that can significantly impact overall efficiency and cost-effectiveness. Below is a detailed comparison of the new tractor truck trailer head against two viable alternatives: traditional flatbed trucks and electric-powered trucks.

| Comparison Aspect | New Tractor Truck Trailer Head | Traditional Flatbed Truck | Electric-Powered Truck |

|---|---|---|---|

| Performance | High torque, multi-terrain capability | Moderate load capacity, limited to flat surfaces | Lower torque, best for urban environments |

| Cost | $26,000 – $50,000+ | $15,000 – $30,000 | $70,000 – $150,000 |

| Ease of Implementation | Requires specialized training and infrastructure | Easy to implement, minimal training needed | Requires charging infrastructure, specialized training |

| Maintenance | Higher maintenance costs due to complexity | Generally lower maintenance; simpler mechanics | Lower maintenance but higher repair costs due to technology |

| Best Use Case | Long-haul, heavy-duty applications | Regional transport of goods | Urban deliveries, eco-conscious operations |

What Are the Pros and Cons of Traditional Flatbed Trucks?

Traditional flatbed trucks have been a staple in the logistics industry for years. They are ideal for transporting bulky or oversized items that do not require an enclosed space. The key advantage of flatbed trucks is their versatility; they can be loaded from the sides, top, or rear, making them suitable for various cargo types. However, their performance is limited to flat surfaces, and they lack the advanced safety features found in newer tractor models, which can lead to increased risks during transport. Additionally, while they are generally more affordable upfront, their lower load capacity may necessitate more trips, ultimately increasing operational costs.

How Do Electric-Powered Trucks Compare?

Electric-powered trucks are gaining traction in the logistics sector, particularly in urban environments where emissions regulations are stringent. They offer significant advantages in terms of sustainability and reduced fuel costs, making them an attractive option for eco-conscious businesses. Furthermore, electric trucks often have lower maintenance costs due to fewer moving parts. However, their high initial purchase price and the need for extensive charging infrastructure can be barriers to entry. Additionally, electric trucks may not provide the torque needed for heavy-duty applications, limiting their effectiveness compared to traditional tractor truck trailer heads.

How Should B2B Buyers Choose the Right Solution?

When selecting the right solution, B2B buyers should conduct a thorough needs analysis. Consider factors such as the type of cargo being transported, the distances involved, and the operational environment. For businesses focused on long-haul transportation of heavy loads, investing in a new tractor truck trailer head may be the best choice due to its superior performance and advanced safety features. Conversely, companies that prioritize cost savings and versatility might find traditional flatbed trucks more suitable. For those leaning towards sustainability and operating in urban settings, electric-powered trucks could provide a forward-thinking solution, despite their higher initial costs. Ultimately, understanding the specific requirements and constraints of your logistics operations will guide you in making an informed decision that aligns with your business objectives.

Essential Technical Properties and Trade Terminology for new Tractor Truck Trailer Head

What Are the Key Technical Properties of a New Tractor Truck Trailer Head?

When considering the purchase of a new tractor truck trailer head, understanding its technical properties is essential for making informed decisions. Here are critical specifications that should be evaluated:

-

Engine Power (HP): Measured in horsepower (HP), this specification determines the truck’s ability to haul loads. A higher horsepower rating often translates to better performance, especially when dealing with heavy loads or steep terrains. For B2B buyers, selecting a tractor head with adequate power ensures efficiency and reliability, reducing downtime and maintenance costs.

-

Drive Configuration (e.g., 6×4): This refers to the number of wheels driven by the engine. A 6×4 configuration means six wheels with four driven, providing better traction and stability. This is particularly important for operations in challenging environments, such as construction sites or rough terrain. Buyers should consider their typical load conditions and choose a configuration that optimizes performance and safety.

-

Towing Capacity: This specification indicates the maximum weight that the tractor head can safely tow. It is crucial for B2B operations to select a model that meets their transportation needs without exceeding safety limits. Understanding towing capacity helps in compliance with legal regulations and enhances operational efficiency.

-

Fuel Efficiency: Fuel consumption rates, often expressed in liters per 100 kilometers (L/100km), significantly impact operational costs. A tractor head that offers better fuel efficiency can lead to substantial savings over time, making it an attractive option for budget-conscious businesses. Evaluating fuel efficiency also aligns with sustainability goals, which is increasingly important for many international buyers.

-

Safety Features: Advanced safety technologies, such as ABS braking systems, electronic stability control, and lane-keeping assistance, are essential in reducing accident risks. Buyers must prioritize safety specifications to protect drivers and cargo while minimizing liability and insurance costs.

-

Emission Standards (e.g., Euro 6): Compliance with emission regulations like Euro 6 is critical in many regions, especially in Europe. These standards dictate the allowable levels of pollutants emitted by the vehicle, impacting environmental sustainability and operational legality. B2B buyers should ensure that the tractor head meets local emission requirements to avoid potential fines and improve corporate responsibility.

What Are Common Trade Terminology and Concepts in the Tractor Truck Industry?

Understanding industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some essential terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of tractor truck trailer heads, OEMs are crucial for ensuring that parts meet specific quality and performance standards. Buyers often seek OEM products to guarantee compatibility and reliability.

-

MOQ (Minimum Order Quantity): MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is important for B2B buyers to understand, as it directly affects purchasing decisions and inventory management. Knowing the MOQ helps in budgeting and planning for future orders.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting a quote for the supply of goods or services. For buyers, submitting an RFQ allows for comparative analysis of costs and terms from multiple suppliers, facilitating better decision-making.

-

Incoterms: Short for International Commercial Terms, Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms is crucial for B2B transactions, as they clarify risk and cost allocation.

-

Lead Time: This term refers to the time it takes from placing an order to receiving the goods. For businesses, understanding lead times is essential for effective supply chain management and scheduling. Longer lead times can impact operational efficiency and customer satisfaction.

-

Warranty: A warranty is a guarantee provided by the manufacturer regarding the condition of the product and the commitment to repair or replace it if necessary. B2B buyers should carefully review warranty terms to protect their investments and ensure long-term value.

By grasping these essential technical properties and trade terminologies, B2B buyers can navigate the complexities of purchasing a new tractor truck trailer head with greater confidence and clarity.

Navigating Market Dynamics and Sourcing Trends in the new Tractor Truck Trailer Head Sector

What Are the Key Market Dynamics Affecting the New Tractor Truck Trailer Head Sector?

The global market for new tractor truck trailer heads is experiencing transformative dynamics, driven by several factors. First, the rising demand for efficient logistics solutions in sectors such as e-commerce and manufacturing is pushing for advanced truck technologies that enhance operational efficiency. Key trends include the integration of telematics and IoT, which enable real-time tracking and data analytics for fleet management. These innovations are particularly relevant for international B2B buyers, as they can optimize supply chains and reduce operational costs.

In emerging markets across Africa, South America, and the Middle East, infrastructure development is crucial. Countries like Nigeria and Vietnam are investing heavily in road networks, thereby increasing the demand for heavy-duty trucks capable of handling diverse terrains. Additionally, buyers are increasingly looking for customizable solutions that cater to specific regional needs, such as varying load capacities and fuel types. The trend towards electric and hybrid tractor heads is also gaining momentum, aligning with global efforts to reduce carbon emissions and meet evolving regulatory standards.

How Does Sustainability Influence Sourcing Decisions in the New Tractor Truck Trailer Head Market?

Sustainability is becoming a cornerstone in the decision-making process for B2B buyers in the tractor truck trailer head sector. Environmental concerns are prompting businesses to prioritize suppliers that demonstrate a commitment to eco-friendly practices. This includes the adoption of sustainable materials and manufacturing processes that minimize waste and energy consumption. For instance, buyers are increasingly interested in products that feature advanced fuel-efficient technologies and lower emissions, such as Euro 6 compliant engines or electric models.

Moreover, ethical sourcing is gaining traction, with companies seeking transparency in their supply chains. This means working with manufacturers that adhere to strict labor standards and environmental regulations. Certifications like ISO 14001 (Environmental Management) and adherence to the UN Global Compact can serve as indicators of a supplier’s commitment to sustainability. By choosing partners who prioritize ethical practices, B2B buyers not only enhance their brand reputation but also contribute to a more sustainable industry.

What Is the Historical Context Behind the Evolution of Tractor Truck Trailer Heads?

The evolution of tractor truck trailer heads can be traced back to the industrial revolution, where the need for efficient transportation solutions became paramount. Initially, trucks were simple mechanical systems designed primarily for hauling goods over short distances. However, as global trade expanded and supply chains became more complex, the demand for more robust and efficient vehicles grew.

Throughout the 20th century, technological advancements led to the development of more powerful engines, improved safety features, and better fuel efficiency. The introduction of regulations, such as emission standards, further pushed manufacturers to innovate. Today, the sector is on the brink of a technological leap with the integration of electric and autonomous vehicles, setting the stage for the future of logistics and transportation. Understanding this history is vital for B2B buyers as it highlights the continuous evolution and the importance of staying abreast of technological advancements and regulatory changes in the market.

Frequently Asked Questions (FAQs) for B2B Buyers of new Tractor Truck Trailer Head

-

How do I choose the right Tractor Truck Trailer Head for my business needs?

Choosing the right Tractor Truck Trailer Head involves evaluating your specific hauling requirements, including load capacity, distance, and terrain. Consider factors such as engine power, fuel efficiency, and maintenance costs. Additionally, assess the vehicle’s specifications, including transmission type, axle configuration, and safety features. Researching different brands and models, and consulting with suppliers can also provide insights into which truck best aligns with your operational needs. -

What are the key specifications to look for in a new Tractor Truck Trailer Head?

When sourcing a new Tractor Truck Trailer Head, focus on key specifications like horsepower, torque, engine type, and fuel efficiency. Consider the vehicle’s axle configuration (e.g., 4×2, 6×4), braking system, and suspension type for optimal performance. Safety features such as ABS, traction control, and driver assistance technologies are crucial. Additionally, ensure the vehicle meets local emission standards, especially for international buyers in regions like Europe or Africa. -

What are the common payment terms for purchasing new Tractor Truck Trailer Heads?

Payment terms can vary significantly among suppliers, but common practices include a down payment followed by installments or payment upon delivery. International buyers should negotiate terms that align with their cash flow, considering factors like import duties and shipping costs. It’s advisable to use secure payment methods, such as letters of credit or escrow services, to protect both parties during the transaction. -

How can I vet suppliers for new Tractor Truck Trailer Heads?

Vetting suppliers involves checking their credentials, such as years in business, customer reviews, and industry certifications. Request references and case studies to gauge their reliability and service quality. Conducting on-site visits or virtual tours can provide insights into their manufacturing processes. Additionally, ensure they adhere to international quality standards and have a transparent warranty and return policy. -

What is the typical minimum order quantity (MOQ) for Tractor Truck Trailer Heads?

Minimum order quantities (MOQ) can vary based on the manufacturer and the model of the Tractor Truck Trailer Head. Some suppliers may offer MOQs as low as one unit, while others may require orders of five or more to benefit from competitive pricing. When negotiating, clarify the MOQ upfront to avoid misunderstandings and explore the possibility of customizing your order based on your business scale. -

What are the logistics considerations for importing Tractor Truck Trailer Heads?

Logistics for importing Tractor Truck Trailer Heads include shipping, customs clearance, and delivery to your location. Choose a reliable freight forwarder familiar with international regulations and customs procedures. Ensure all shipping documents are in order, including invoices and certificates of origin. Additionally, factor in transit times and potential delays due to customs inspections, especially when importing from regions with stringent regulations. -

How do I ensure quality assurance for my Tractor Truck Trailer Head purchase?

To ensure quality assurance, request detailed specifications and quality certifications from suppliers. Consider third-party inspections before shipment to verify compliance with agreed-upon standards. Establish a clear warranty policy that covers defects and provides options for repairs or replacements. Engaging with suppliers who have a robust quality control process can also help mitigate risks associated with defects and performance issues. -

What are the advantages of customizing a Tractor Truck Trailer Head?

Customizing a Tractor Truck Trailer Head allows you to tailor the vehicle to meet specific operational needs, enhancing efficiency and productivity. Custom features might include specialized cargo handling systems, enhanced safety technologies, or modifications for specific terrains. While customization may increase initial costs, it can lead to long-term savings through improved fuel efficiency and reduced maintenance. Discuss your requirements with suppliers to explore available customization options.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 New Tractor Truck Trailer Head Manufacturers & Suppliers List

1. SINOTRUK – HOWO A7 Tractor Truck

Domain: sinotruk-international.com

Registered: 2015 (10 years)

Introduction: Product Name: SINOTRUK HOWO A7 Tractor Truck LHD 6X4 Euro2 336HP ZZ4257N3247N1B

Loading Capacity: 60-70 Tons

Price Range: USD38500-USD39000/UNIT (negotiable)

Place of Origin: China

Brand Name: SINOTRUK HOWO A7

Certifications: ISO, 3C, BV, IFA, SGS

Model Number: ZZ4257N3247N1B

Drive Type: 6×4

Engine: WD615.69, 336HP (Euro II), 6 cylinder in-line, water cooling, turbo-charging & inter-cooling, 4 str…

2. Reddit – Trainer Version Seat

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – Trainer Version Seat, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Accio – Tractor Head Trailers

Domain: accio.com

Registered: 1997 (28 years)

Introduction: Tractor Head Trailers: Key Models & Suppliers for Heavy-Duty Hauling. Unit Price Range: $350 – $54,000+. Key Product Attributes: Diesel Engine, 6×4 Drive, 400 HP, Air Suspension, ABS Braking, 12-Speed Transmission, 50 Ton Load Capacity, Hydraulic Steering, Euro 6 Emission Standard, 1200 Nm Torque. Notable Models: HOWO Sinotruk Tractor Head ($8,000), Shacman Delong X5000 ($10,850), Used HOWO 371-41…

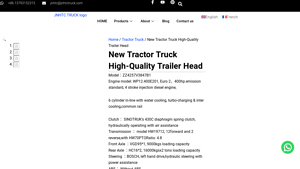

4. JNHTC – ZZ4257V3847B1 Truck

Domain: jnhtctruck.com

Registered: 2023 (2 years)

Introduction: Model: ZZ4257V3847B1

Engine Model: WP12.400E201, Euro 2, 400hp, 4 stroke injection diesel engine, 6 cylinder in-line, water cooling, turbo-charging & inter cooling, common rail

Clutch: SINOTRUK’s 430C diaphragm spring clutch, hydraulically operating with air assistance

Transmission: HW19712, 12 forward and 2 reverse, HW70PTORatio: 4.8

Front Axle: VGD95*1, 9000kgs loading capacity

Rear Axle: HC16*2…

5. TruckPaper – New and Used Trucks & Trailers

Domain: truckpaper.com

Registered: 1996 (29 years)

Introduction: TruckPaper.com offers a wide range of new and used trucks and trailers for sale, including:

– Sleeper Trucks

– Day Cab Trucks

– Dump Trucks

– Box Trucks

– Tow Trucks

– Cab & Chassis Trucks

– Service Trucks / Utility Trucks / Mechanic Trucks

– Flatbed Trucks

– Vans

– Various types of Semi-Trailers (e.g., Dry Van, Reefer, Flatbed, Lowboy, Tank, Hopper/Grain)

– Components and Dismantled Tr…

6. Alloy – 1/64 Simulation Truck Model

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“title”:”1/64 Alloy simulation truck model tractor truck trailer head 4 color”,”price”:”US $59.50″,”condition”:”New”,”color_options”:[“Black”,”Blue”,”Black + red”],”shipping”:”Free eBay SpeedPAK Standard”,”location”:”SHENZHEN, China”,”delivery_estimate”:”Estimated between Mon, Sep 15 and Mon, Sep 29 to 20147″,”returns”:”60 days returns, buyer pays for return shipping”,”payment_options”:[“Diners C…

7. Shutterstock – API Solutions for Developers

Domain: shutterstock.com

Registered: 2003 (22 years)

Introduction: API for business and developers, powers over 10,000 integrations, contact number 1-866-663-3954.

Strategic Sourcing Conclusion and Outlook for new Tractor Truck Trailer Head

In today’s competitive logistics landscape, the strategic sourcing of new tractor truck trailer heads presents a significant opportunity for international B2B buyers. Key considerations include evaluating the total cost of ownership, understanding the latest technological advancements in fuel efficiency and safety, and ensuring compliance with regional emissions standards. Buyers should prioritize suppliers who offer customizable solutions tailored to specific operational needs, as well as robust after-sales support.

As the demand for sustainable transportation solutions grows, investing in electric and hybrid models can enhance not only your fleet’s efficiency but also your brand’s reputation in an eco-conscious marketplace. Collaborating with reputable manufacturers ensures access to cutting-edge designs that boost productivity and driver comfort while minimizing environmental impact.

Looking ahead, B2B buyers in regions such as Africa, South America, the Middle East, and Europe should seize the opportunity to leverage strategic sourcing as a means to enhance operational capabilities. By aligning with innovative suppliers and focusing on long-term partnerships, businesses can ensure they remain competitive in an evolving industry. Take the next step in your sourcing journey—explore available options and engage with trusted suppliers today to drive your business forward.