Introduction: Navigating the Global Market for electric cars automtico

Navigating the rapidly evolving landscape of electric cars automtico presents a pivotal challenge for international B2B buyers aiming to stay ahead in a competitive market. With the increasing demand for sustainable transportation solutions, understanding the nuances of electric vehicle (EV) technologies—particularly automatic transmission systems—has become essential. This guide serves as a comprehensive resource, exploring various types of electric vehicles, their applications across diverse industries, and the critical factors influencing supplier selection.

In addition to examining the cost implications associated with electric cars, we delve into the intricacies of performance metrics and maintenance requirements that are unique to automatic transmissions. By providing actionable insights into the sourcing process, our guide empowers buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Nigeria—to make informed purchasing decisions. As the automotive landscape shifts towards electrification, leveraging this knowledge will not only facilitate optimal investment choices but also foster sustainable business practices. Whether you’re looking to enhance your fleet or explore new market opportunities, this guide is designed to equip you with the expertise needed to navigate the global market for electric cars automtico effectively.

Understanding electric cars automtico Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single-Speed Transmission | Utilizes a direct drive system, offering constant torque. | Fleet vehicles, urban transport solutions | Pros: Simplicity, lower maintenance costs. Cons: Limited performance tuning options. |

| Multi-Speed Transmission | Equipped with multiple gears for optimized performance. | High-performance fleets, luxury transport | Pros: Enhanced speed and efficiency. Cons: More complex maintenance requirements. |

| Direct Drive Systems | No traditional gears; power is transferred directly to wheels. | Delivery services, ride-sharing platforms | Pros: Instant power delivery, reduced driver fatigue. Cons: Less engaging for driving enthusiasts. |

| Hybrid Electric Vehicles | Combines electric and internal combustion engines. | Long-distance transport, logistics companies | Pros: Flexibility in fuel sources. Cons: Higher initial costs, complex systems. |

| Performance-Oriented EVs | Designed for speed, often with advanced aerodynamics. | Luxury rentals, sports car markets | Pros: Exceptional acceleration, brand prestige. Cons: Higher purchase and insurance costs. |

What are the Characteristics of Single-Speed Transmission Electric Cars?

Single-speed transmission electric vehicles (EVs) are the most common type on the market. Their design simplifies the driving experience by utilizing a direct drive system that continuously delivers torque without shifting gears. This makes them particularly suitable for fleet operations and urban transport solutions where efficiency and ease of maintenance are critical. B2B buyers should consider the lower operational costs and reduced maintenance needs, making them an attractive option for businesses looking to optimize their transportation expenses.

How Do Multi-Speed Transmission Electric Cars Enhance Performance?

Multi-speed transmission electric cars feature a more complex setup with multiple gears that allow for optimized power delivery and performance at various speeds. This type is ideal for high-performance fleets and luxury transport services, where speed and efficiency are paramount. While they offer enhanced performance, B2B buyers must weigh the benefits against potentially higher maintenance costs and the complexity of the transmission system.

What Advantages Do Direct Drive Systems Offer for Businesses?

Direct drive systems in electric vehicles eliminate traditional gear mechanisms, allowing for immediate power transfer from the motor to the wheels. This results in a more responsive driving experience, reducing driver fatigue—an important consideration for businesses operating in delivery and ride-sharing sectors. B2B buyers will appreciate the simplicity and reliability of these systems, but should note that they may lack the engagement of traditional manual systems, which might deter some driving enthusiasts.

Why Should Businesses Consider Hybrid Electric Vehicles?

Hybrid electric vehicles (HEVs) combine electric and internal combustion engines, providing flexibility in fuel sources. This makes them suitable for long-distance transport and logistics companies, where range and fuel efficiency are essential. B2B buyers should evaluate the initial costs against the potential savings in fuel and maintenance over time. While they offer greater versatility, the complexity of hybrid systems may necessitate specialized maintenance, which could impact operational efficiency.

What Makes Performance-Oriented EVs a Unique Choice for Luxury Markets?

Performance-oriented electric vehicles are engineered for speed and agility, often featuring advanced aerodynamics and high-performance components. These vehicles are particularly appealing to luxury rental services and sports car markets, where brand prestige and exceptional performance are key selling points. B2B buyers must consider the higher purchase and insurance costs associated with these vehicles, but the potential for lucrative rental fees and customer satisfaction can justify the investment.

Key Industrial Applications of electric cars automtico

| Industry/Sector | Specific Application of electric cars automtico | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Public Transportation | Electric taxi and ride-sharing services | Lower operational costs and reduced carbon footprint | Availability of charging infrastructure; fleet management software |

| Logistics and Delivery | Electric delivery vans for last-mile logistics | Enhanced efficiency and lower fuel costs | Vehicle range, payload capacity, and maintenance support |

| Tourism and Hospitality | Electric shuttles for hotel and airport transport | Improved guest experience and sustainability image | Vehicle size options; local regulations on EV use |

| Agricultural Transport | Electric utility vehicles for farm operations | Cost savings on fuel and maintenance | Terrain adaptability; battery life and charging options |

| Corporate Fleets | Electric company cars for employee commuting | Reduced operational costs and corporate sustainability goals | Fleet management systems; total cost of ownership analysis |

How Are Electric Cars Automático Transforming Public Transportation?

In the public transportation sector, electric taxis and ride-sharing services are gaining traction as cities aim for sustainability. By integrating electric cars automáticos into their fleets, operators can significantly lower operational costs due to reduced fuel and maintenance expenses. Additionally, these vehicles contribute to a decreased carbon footprint, aligning with global environmental goals. For international buyers, especially from regions like Africa and the Middle East, ensuring access to robust charging infrastructure and reliable fleet management software is crucial for successful implementation.

What Are the Benefits of Electric Delivery Vans in Logistics?

Electric delivery vans are revolutionizing last-mile logistics by offering an eco-friendly alternative to traditional combustion engine vehicles. Companies can achieve enhanced efficiency and lower fuel costs, making their operations more sustainable. As international buyers from South America and Europe consider this shift, they must evaluate vehicle range, payload capacity, and the availability of maintenance support to ensure optimal performance in diverse environments.

How Are Electric Shuttles Enhancing Tourism Experiences?

In the tourism and hospitality industry, electric shuttles are being adopted for hotel and airport transport, providing a seamless travel experience for guests. These vehicles not only improve guest satisfaction but also bolster a brand’s sustainability image. For B2B buyers, understanding local regulations on electric vehicle use and exploring various vehicle size options are key to successful integration into their operations.

What Role Do Electric Utility Vehicles Play in Agriculture?

Electric utility vehicles are increasingly utilized in agricultural settings for tasks such as crop monitoring and equipment transport. By adopting electric cars automáticos, farms can achieve significant cost savings on fuel and maintenance while reducing their environmental impact. Buyers in this sector should consider the vehicles’ adaptability to various terrains, battery life, and available charging options to meet their operational needs effectively.

How Are Electric Company Cars Supporting Corporate Sustainability?

Corporate fleets are increasingly incorporating electric company cars for employee commuting, aligning with corporate sustainability goals and reducing operational costs. This transition not only lowers fuel expenses but also enhances the company’s public image as a responsible corporate citizen. For international B2B buyers, conducting a total cost of ownership analysis and integrating effective fleet management systems are essential for maximizing the benefits of electric vehicles in their operations.

3 Common User Pain Points for ‘electric cars automtico’ & Their Solutions

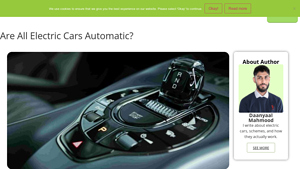

Scenario 1: Misconceptions about Electric Vehicle Transmission Types

The Problem: Many B2B buyers, particularly fleet managers and corporate procurement teams, are uncertain about the types of transmissions available in electric vehicles (EVs). This confusion can lead to misinformed purchasing decisions. Buyers may assume all electric cars are fully automatic, leading to concerns about performance and compatibility with their driving needs. In regions where manual driving is still prevalent, such as parts of Africa and the Middle East, this misconception can create a barrier to adoption.

The Solution: To effectively navigate this challenge, B2B buyers should conduct thorough research on the specifications of electric vehicles they are considering. Engaging with manufacturers and dealers to understand the different types of transmissions, including single-speed and multi-speed systems, is crucial. Buyers should request detailed product sheets that outline the operational mechanics of the vehicles, as well as performance metrics in various driving conditions. Furthermore, incorporating test drives into the procurement process can provide firsthand experience and alleviate concerns about transmission types. By prioritizing education on the subject, buyers can make informed decisions that align with their operational needs.

Scenario 2: Concerns Over Maintenance and Repair Costs

The Problem: A prevalent worry among B2B buyers considering electric cars is the perceived high cost of maintenance and repairs compared to traditional vehicles. While electric vehicles generally have fewer moving parts and lower maintenance requirements, there remains a fear of unexpected costs, especially in regions with limited access to specialized EV service centers. This concern can deter companies from fully committing to electric fleets, impacting sustainability goals and operational efficiency.

The Solution: To mitigate these concerns, buyers should look for comprehensive maintenance packages offered by manufacturers or dealerships that specialize in electric vehicles. Establishing relationships with certified service providers can also ensure that maintenance is performed correctly and efficiently, reducing the risk of unforeseen expenses. Additionally, B2B buyers should explore warranties that cover key components of electric vehicles, such as the battery and electric drive systems, which can provide peace of mind. Investing in training for in-house mechanics to handle basic repairs can further reduce dependency on external services, thereby lowering long-term costs.

Scenario 3: Limited Charging Infrastructure in Emerging Markets

The Problem: In many regions, particularly in Africa and South America, inadequate charging infrastructure presents a significant challenge for businesses looking to adopt electric vehicles. B2B buyers may hesitate to invest in electric fleets due to concerns about the availability and reliability of charging stations, which can lead to operational disruptions and range anxiety among drivers.

The Solution: To address this issue, B2B buyers should advocate for and participate in local partnerships aimed at enhancing charging infrastructure. Collaborating with governmental bodies and private sector players to establish charging networks can create a more supportive ecosystem for electric vehicle adoption. Additionally, companies can consider investing in on-site charging solutions, such as installing charging stations at their facilities, to ensure that their electric vehicles are always ready for use. Leveraging technology solutions that provide real-time data on charging station availability can also help drivers plan their routes effectively, minimizing the impact of charging limitations. By proactively addressing infrastructure concerns, businesses can confidently transition to electric vehicles and realize their sustainability objectives.

Strategic Material Selection Guide for electric cars automtico

What Are the Key Materials Used in Electric Cars?

Electric vehicles (EVs), particularly automatic ones, rely on a variety of materials that significantly influence their performance, durability, and cost-effectiveness. Understanding these materials is essential for international B2B buyers who are looking to source components or manufacture electric vehicles. Below, we analyze four common materials used in electric cars, highlighting their properties, advantages, disadvantages, and considerations specific to various international markets.

How Does Aluminum Benefit Electric Cars?

Aluminum is a popular choice in the automotive industry due to its lightweight properties, which contribute to improved energy efficiency and range for electric vehicles. With a high strength-to-weight ratio, aluminum components can withstand the operational stresses of EVs while keeping the overall weight low. Additionally, aluminum exhibits excellent corrosion resistance, making it suitable for various environmental conditions.

Pros: Lightweight, corrosion-resistant, and recyclable.

Cons: Higher manufacturing costs compared to steel and potential issues with fatigue over time.

Impact on Application: Aluminum is often used in the chassis and body panels of electric cars, enhancing performance without compromising safety.

Considerations for Buyers: Compliance with international standards like ASTM and DIN is crucial. Buyers in regions like Europe may prefer aluminum for its recyclability, aligning with sustainability goals.

What Role Does Steel Play in Electric Vehicle Manufacturing?

Steel remains a staple material in the automotive sector, including electric vehicles. Its high tensile strength and durability make it ideal for structural components. Advanced high-strength steel (AHSS) is increasingly used in EVs, providing the necessary strength while minimizing weight.

Pros: Cost-effective, readily available, and excellent strength properties.

Cons: Heavier than aluminum, which can negatively impact range and efficiency.

Impact on Application: Steel is commonly used for the frame and safety structures of electric cars, ensuring passenger protection.

Considerations for Buyers: Compliance with local standards is essential, especially in regions like South America, where cost-effectiveness is a priority.

Why Is Carbon Fiber Gaining Popularity in Electric Cars?

Carbon fiber is emerging as a premium material in electric vehicle design due to its exceptional strength and lightweight characteristics. This composite material can significantly enhance performance and efficiency, making it particularly attractive for high-performance electric vehicles.

Pros: Extremely lightweight, high strength, and excellent fatigue resistance.

Cons: High manufacturing costs and complexity in production.

Impact on Application: Carbon fiber is often used in body panels and interior components, contributing to reduced weight and improved aesthetics.

Considerations for Buyers: International buyers, especially in the Middle East, may seek carbon fiber for luxury EV models, necessitating awareness of supply chain logistics and costs.

How Does Lithium-Ion Battery Technology Influence Material Selection?

Lithium-ion batteries are critical to the performance of electric vehicles. The materials used in battery construction, such as lithium, cobalt, and nickel, are vital for energy density and longevity. The choice of materials directly affects the battery’s efficiency, weight, and overall vehicle performance.

Pros: High energy density, long cycle life, and low self-discharge rates.

Cons: Environmental concerns regarding mining and resource availability, along with high costs.

Impact on Application: Battery materials are crucial for determining the vehicle’s range and charging capabilities.

Considerations for Buyers: Buyers from Africa and South America should consider the sustainability of sourcing these materials and adhere to international regulations regarding battery disposal and recycling.

Summary Table of Materials for Electric Cars

| Material | Typical Use Case for electric cars automtico | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Chassis and body panels | Lightweight and corrosion-resistant | Higher manufacturing costs | Medium |

| Steel | Frame and safety structures | Cost-effective and strong | Heavier than aluminum, impacting range | Low |

| Carbon Fiber | Body panels and interior components | Extremely lightweight and high strength | High manufacturing costs | High |

| Lithium-Ion | Battery packs | High energy density and long cycle life | Environmental concerns and high costs | High |

This comprehensive analysis provides B2B buyers with actionable insights into material selection for electric vehicles, enabling informed decisions that align with performance, cost, and regulatory considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for electric cars automtico

What Are the Key Stages in the Manufacturing Process for Electric Cars Automtico?

The manufacturing process of electric cars automtico encompasses several critical stages, each essential for ensuring the final product meets performance and quality standards. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Electric Cars?

Material preparation is a foundational step where raw materials, such as metals, plastics, and composites, are sourced and processed. Manufacturers typically engage in thorough supplier audits to ensure materials meet industry standards and specifications. This stage involves various techniques, including:

- Material Sourcing: Identifying and selecting materials that are lightweight yet strong, such as aluminum for the chassis and high-strength steel for structural components.

- Material Testing: Conducting tests to verify the properties of the materials, such as tensile strength and thermal stability, ensuring they can withstand the demands of electric vehicle operation.

What Techniques Are Used in the Forming Stage?

The forming stage involves transforming raw materials into components through techniques like stamping, forging, and casting. This stage is critical for producing parts such as the body panels and battery enclosures. Key techniques include:

- Stamping: Used for creating complex shapes from sheet metal, which is essential for the vehicle’s exterior design.

- Injection Molding: Common for producing plastic components, this method allows for precise designs and reduced waste.

- Die Casting: Employed for producing high-volume parts with intricate shapes, such as engine blocks and housings.

These techniques are enhanced by advancements in automation and robotics, improving precision and efficiency while reducing production time.

How Are Components Assembled in Electric Cars?

Assembly is where individual components come together to form the complete vehicle. This stage is characterized by:

- Modular Assembly Lines: Utilizing modular design principles, assembly lines are configured to streamline the production process, allowing for flexible adaptation to different models.

- Automated Assembly: Robotics play a significant role in ensuring consistency and quality in the assembly of components like battery packs and electric motors.

- Integration of Technology: Advanced manufacturing technologies, such as augmented reality and the Internet of Things (IoT), aid in monitoring and optimizing assembly processes.

Each assembly line typically incorporates quality control checks to ensure that components meet specified tolerances before moving on to the next stage.

What Finishing Processes Are Involved in Electric Car Manufacturing?

The finishing stage focuses on enhancing the vehicle’s aesthetics and performance. This includes:

- Painting and Coating: High-quality paints and coatings are applied to protect the vehicle from corrosion and provide a visually appealing finish.

- Quality Assurance Checks: Conducting final inspections to ensure all systems function correctly, including electrical systems, battery management, and safety features.

- Detailing: This final touch enhances the vehicle’s appearance, ensuring it meets customer expectations.

What Quality Assurance Standards Are Relevant for Electric Cars Automtico?

Quality assurance is crucial in the manufacturing of electric cars automtico, ensuring that products meet international standards and customer expectations. Key standards include:

- ISO 9001: This international standard focuses on quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements.

- CE Marking: Particularly relevant in Europe, this certification indicates that products comply with health, safety, and environmental protection standards.

- API Standards: For components that may require oil or gas applications, adherence to American Petroleum Institute (API) standards ensures reliability and safety.

What Are the Key Quality Control Checkpoints in Electric Car Manufacturing?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to identify and mitigate potential issues. Common checkpoints include:

- Incoming Quality Control (IQC): At this stage, raw materials and components are inspected upon arrival to verify compliance with specifications.

- In-Process Quality Control (IPQC): This involves ongoing inspections during production, focusing on critical aspects such as assembly precision and functionality.

- Final Quality Control (FQC): Conducted after assembly, FQC ensures that the finished vehicle meets all performance and safety standards before delivery.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must ensure that their suppliers adhere to rigorous quality control practices. Here are effective strategies for verification:

- Conduct Supplier Audits: Regular audits help assess the supplier’s adherence to quality standards and manufacturing processes. This can include site visits and reviews of quality documentation.

- Request Quality Assurance Reports: Buyers should obtain detailed reports on the supplier’s quality control processes, including failure rates and corrective actions taken.

- Engage Third-Party Inspectors: Hiring independent inspection services can provide unbiased assessments of a supplier’s quality control measures and product quality.

What Are the Nuances of Quality Control for International B2B Buyers?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, face unique challenges in quality control. Key considerations include:

- Understanding Regional Standards: Different regions may have varying standards and certifications. Buyers must familiarize themselves with local regulations and ensure their suppliers comply.

- Cultural and Communication Barriers: Effective communication is vital for successful quality assurance. Establishing clear expectations and guidelines can help mitigate misunderstandings.

- Logistics and Supply Chain Management: Delays in shipping or customs can affect product quality. Buyers should work closely with suppliers to ensure timely delivery and maintain quality throughout the supply chain.

By understanding these aspects of the manufacturing process and quality assurance for electric cars automtico, B2B buyers can make informed decisions and foster successful partnerships with suppliers, ensuring high-quality products that meet market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric cars automtico’

Introduction

This guide serves as a practical checklist for B2B buyers seeking to procure electric cars with automatic transmissions, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. As the demand for electric vehicles (EVs) rises, understanding the nuances of sourcing these vehicles is critical for making informed purchasing decisions. This checklist will help you navigate the essential steps to ensure a successful procurement process.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your procurement process. Consider factors such as range, battery capacity, charging time, and any specific features required for your target market. This clarity will help you communicate effectively with suppliers and ensure that the vehicles meet your operational needs.

Step 2: Research Market Trends and Regulations

Understanding the current market landscape and regulatory requirements in your region is vital. Research local incentives for electric vehicles, import tariffs, and environmental regulations that may impact your purchase. This knowledge will help you identify suitable suppliers and negotiate favorable terms.

Step 3: Identify Potential Suppliers

Creating a list of potential suppliers is crucial for diversifying your options. Look for manufacturers or distributors with a proven track record in electric vehicles, particularly those with experience in automatic transmission models. Utilize industry reports, trade shows, and online platforms to discover credible suppliers.

Step 4: Evaluate Supplier Certifications and Compliance

Verifying supplier certifications ensures that the vehicles meet international quality and safety standards. Check for certifications such as ISO, CE, or specific electric vehicle standards relevant to your region. This step is essential to mitigate risks associated with product quality and compliance with local regulations.

Step 5: Request Detailed Proposals

Once you have shortlisted suppliers, request detailed proposals that outline pricing, delivery timelines, warranty terms, and after-sales support. A comprehensive proposal will provide insights into the supplier’s capabilities and help you compare different offerings effectively. Look for any additional services like maintenance packages or training for your staff.

Step 6: Conduct Site Visits and Factory Audits

If possible, conduct site visits or factory audits to assess the supplier’s production capabilities and quality control processes. Observing the manufacturing environment firsthand can provide reassurance about the supplier’s commitment to quality and innovation. Pay attention to the technology used and the overall efficiency of their operations.

Step 7: Negotiate Terms and Finalize the Agreement

Once you are satisfied with the proposals and supplier evaluations, it’s time to negotiate terms. Discuss pricing, payment schedules, delivery timelines, and any additional services. Ensure that all agreements are documented in a formal contract to protect both parties and clarify expectations.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing electric cars with automatic transmissions, ensuring a successful procurement process that meets their business needs.

Comprehensive Cost and Pricing Analysis for electric cars automtico Sourcing

What Are the Key Cost Components for Electric Cars Automático?

Understanding the cost structure of electric cars (EVs) is crucial for international B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. The primary cost components include:

-

Materials: The cost of materials is significant, particularly for batteries, which often constitute a large portion of the overall vehicle cost. Lithium, cobalt, and nickel are critical components in battery production, and fluctuations in their prices can directly impact the overall cost of EVs.

-

Labor: Labor costs vary by region, influenced by local wage standards and skill availability. Countries with advanced manufacturing capabilities may have higher labor costs but can offer better quality assurance and skilled labor, affecting the final pricing.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and administrative expenses. Efficient manufacturing processes can reduce overhead costs, which is vital for competitive pricing.

-

Tooling: The initial investment in tooling for electric vehicle production can be substantial. This includes molds for body parts and machinery for assembly. As production scales, these costs are amortized over a larger volume, reducing the per-unit cost.

-

Quality Control (QC): Ensuring product quality is essential in the automotive industry, especially for electric vehicles where safety and performance are paramount. Investing in robust QC processes can lead to higher upfront costs but can save money in the long run by reducing warranty claims and recalls.

-

Logistics: Transportation of parts and finished vehicles adds another layer of cost. Efficient logistics management is critical for minimizing these expenses, especially for international shipments that may involve tariffs and customs duties.

-

Margin: Manufacturer and dealer margins can vary significantly based on market conditions and competition. In regions with high demand for EVs, margins may be higher, but competitive pressures can force them lower.

How Do Price Influencers Impact Sourcing Electric Cars Automático?

Several factors influence the pricing of electric vehicles, which B2B buyers must consider when sourcing:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in bulk can lead to significant discounts. Suppliers are often more willing to negotiate prices with buyers who can commit to larger orders.

-

Specifications and Customization: Customizing vehicles to meet specific requirements can increase costs. Buyers should balance their needs for unique features against the potential price increases.

-

Materials: The choice of materials impacts both cost and vehicle performance. Higher-quality materials may lead to increased costs but can enhance durability and efficiency.

-

Quality and Certifications: Compliance with international quality standards and certifications can influence pricing. Vehicles that meet stringent regulations may command higher prices but offer better reliability.

-

Supplier Factors: The supplier’s reputation, production capacity, and location can significantly affect pricing. Establishing strong relationships with reliable suppliers can lead to better pricing and service.

-

Incoterms: Understanding the terms of trade (Incoterms) is crucial for managing costs related to shipping, insurance, and responsibilities. Buyers should clarify these terms to avoid unexpected expenses.

What Are the Best Buyer Tips for Negotiating Costs of Electric Cars Automático?

To effectively navigate the sourcing of electric cars, particularly in international markets, consider the following tips:

-

Negotiate Pricing: Leverage your purchasing power by negotiating with suppliers. Presenting data on market prices and competitor offerings can strengthen your position.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes not just the purchase price but also maintenance, energy consumption, and resale value. This holistic view can help justify higher upfront costs for more efficient models.

-

Be Aware of Pricing Nuances: Understand the market dynamics in your region. Prices may vary significantly based on local demand, government incentives for EVs, and currency fluctuations.

-

Research Local Regulations: Compliance with local laws and regulations can influence both the cost and availability of electric vehicles. Being informed can help avoid delays and additional costs.

-

Consider Future Trends: The EV market is rapidly evolving. Staying abreast of technological advancements and market trends can provide leverage in negotiations and sourcing strategies.

Disclaimer on Indicative Prices

Prices for electric cars automáticos can vary widely based on specifications, regional market conditions, and other factors mentioned above. It is advisable to conduct thorough market research and engage with multiple suppliers to obtain the most accurate and competitive pricing.

Alternatives Analysis: Comparing electric cars automtico With Other Solutions

Understanding Alternatives to Electric Cars Automtico

In today’s evolving automotive landscape, electric cars automtico (automatic electric vehicles) represent a significant shift towards sustainable transportation. However, various alternative solutions also aim to meet the needs of businesses and consumers alike. This section explores how electric cars automtico compare to other viable alternatives, including hybrid vehicles and traditional internal combustion engine (ICE) vehicles. Each solution has unique advantages and considerations, making it essential for B2B buyers to understand the nuances of each option.

Comparison Table

| Comparison Aspect | Electric Cars Automtico | Hybrid Vehicles | Traditional Internal Combustion Engine (ICE) Vehicles |

|---|---|---|---|

| Performance | Instant torque, rapid acceleration | Moderate torque, less responsive than EVs | Varies by model, generally good acceleration |

| Cost | Higher upfront costs, lower long-term maintenance | Moderate upfront costs, better fuel efficiency | Lower upfront costs, higher fuel and maintenance costs |

| Ease of Implementation | Requires charging infrastructure | Flexible fueling options | Widely available fueling infrastructure |

| Maintenance | Lower due to fewer moving parts | Moderate, more complex than EVs | Higher due to more moving parts and systems |

| Best Use Case | Urban environments, short to medium-range travel | Versatile for varied driving conditions | Long-distance travel and regions with limited charging |

Pros and Cons of Alternatives

Hybrid Vehicles

Hybrid vehicles combine a conventional internal combustion engine with an electric propulsion system. This dual approach allows for improved fuel efficiency and reduced emissions compared to traditional ICE vehicles. However, hybrids often require more complex maintenance due to their dual systems. They are ideal for businesses operating in regions where charging infrastructure is still developing, as they can run on gasoline when electric power is not available.

Traditional Internal Combustion Engine (ICE) Vehicles

ICE vehicles have long been the standard in transportation, offering a wide range of models and price points. They are generally less expensive upfront and have established fueling infrastructure, making them convenient for long-distance travel. However, they come with higher fuel and maintenance costs, and their environmental impact is significantly greater than that of electric or hybrid vehicles. Businesses that require extensive travel in areas with limited charging infrastructure may find ICE vehicles to be a more practical choice.

Conclusion: How to Choose the Right Solution for Your Business

When evaluating the best transportation solution for your business needs, consider factors such as performance requirements, cost constraints, and the availability of charging infrastructure. Electric cars automtico offer a sustainable, low-maintenance option ideal for urban settings, while hybrid vehicles provide flexibility for varied driving conditions. Traditional ICE vehicles may still be relevant for long-distance travel in regions lacking charging capabilities. By assessing these alternatives against your specific operational demands, you can make an informed decision that aligns with your business objectives and sustainability goals.

Essential Technical Properties and Trade Terminology for electric cars automtico

What Are the Key Technical Properties of Electric Cars Automático?

When evaluating electric cars automático, understanding critical technical specifications is essential for B2B buyers. Here are six vital properties that significantly influence performance, cost, and operational efficiency:

-

Battery Capacity (kWh)

Battery capacity, measured in kilowatt-hours (kWh), indicates the amount of energy stored in the battery. A higher capacity allows for longer driving ranges, which is crucial for fleet operators and commercial users. For example, vehicles with a 60 kWh battery can typically travel between 200-300 kilometers on a single charge, making them suitable for logistics and transportation businesses. -

Power Output (kW)

Power output, expressed in kilowatts (kW), reflects the performance of the electric motor. Higher power output translates to quicker acceleration and enhanced performance, which can be critical for commercial vehicles requiring swift deliveries. For B2B buyers, understanding the power output helps align vehicle capabilities with operational needs. -

Torque (Nm)

Torque, measured in Newton-meters (Nm), is essential for assessing the vehicle’s ability to start and climb inclines. Electric motors provide maximum torque instantly, which can improve the vehicle’s handling and responsiveness. This property is particularly important for businesses involved in logistics, where load capacity and acceleration are key operational factors. -

Charging Time (Hours)

The charging time of an electric vehicle is a crucial consideration for fleet management. Depending on the charging infrastructure and battery capacity, charging can take anywhere from 30 minutes (fast charging) to several hours (standard charging). Understanding charging times helps businesses plan operational schedules effectively, minimizing downtime. -

Regenerative Braking Efficiency

Regenerative braking systems recover energy during braking, converting it back into stored energy in the battery. This feature enhances overall energy efficiency and extends driving range, which is beneficial for businesses looking to reduce operational costs. B2B buyers should consider the efficiency of regenerative braking systems when evaluating electric vehicles for commercial use. -

Vehicle Weight (kg)

The weight of the electric vehicle affects its efficiency, range, and performance. Heavier vehicles may have a shorter range due to increased energy consumption. For fleet operators, understanding vehicle weight is crucial for compliance with regulations and for optimizing load capacities.

What Are Common Trade Terms in the Electric Vehicle Industry?

Familiarity with industry jargon is vital for effective communication and negotiation. Here are six essential trade terms relevant to electric cars automático:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the electric vehicle sector, OEMs are critical as they supply the essential components, including batteries and electric motors, to vehicle manufacturers. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of products that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers as it affects inventory management and procurement strategies. For electric vehicles, MOQs can significantly influence the purchasing decisions of fleet operators. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting price quotes for specific products or services. B2B buyers in the electric vehicle market often use RFQs to compare costs and negotiate better terms with suppliers, making it an essential part of the procurement process. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. They clarify aspects such as shipping costs, insurance, and risk management, which are particularly relevant for businesses importing electric vehicles from different countries. -

EVSE (Electric Vehicle Supply Equipment)

EVSE refers to the equipment used to charge electric vehicles, including charging stations and connectors. Understanding EVSE is vital for businesses looking to establish charging infrastructure for fleets or commercial operations. -

Lifecycle Cost (LCC)

LCC is the total cost of ownership over the vehicle’s lifespan, including purchase price, maintenance, fuel (or electricity), and depreciation. For B2B buyers, assessing LCC is crucial for making informed investment decisions in electric vehicles, as it provides a comprehensive view of long-term financial implications.

Understanding these technical properties and trade terms can significantly enhance decision-making for international B2B buyers in the electric vehicle market, ensuring alignment with operational needs and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the electric cars automtico Sector

What Are the Key Market Drivers for Electric Cars Automtico?

The electric cars automtico sector is witnessing significant growth driven by various global factors. Key market drivers include heightened environmental awareness, government regulations promoting electric vehicles (EVs), and advancements in battery technology that enhance performance and reduce costs. In regions like Africa, South America, the Middle East, and Europe, the transition to electric vehicles is further propelled by rising fuel prices and the push for sustainable urban mobility solutions. International B2B buyers are increasingly looking to align with manufacturers that offer innovative, efficient, and reliable electric vehicles that meet local market needs.

Emerging trends in technology and sourcing are shaping the competitive landscape. Manufacturers are integrating advanced features like regenerative braking, artificial intelligence for predictive maintenance, and enhanced connectivity options to improve user experience and operational efficiency. Additionally, the shift towards direct sourcing from manufacturers is becoming more prevalent among B2B buyers, allowing them to negotiate better terms and ensure product quality. As the market matures, understanding the nuances of regional preferences and regulatory environments will be crucial for successful sourcing strategies.

How Can Sustainability and Ethical Sourcing Be Integrated into the Electric Cars Automtico Sector?

Sustainability is at the forefront of the electric cars automtico sector, influencing purchasing decisions for B2B buyers. The environmental impact of electric vehicles is significantly lower compared to traditional combustion engines, particularly in terms of greenhouse gas emissions. However, the sourcing of materials for batteries—such as lithium, cobalt, and nickel—raises ethical concerns regarding mining practices and labor conditions. B2B buyers must prioritize suppliers who demonstrate a commitment to ethical sourcing practices and transparency in their supply chains.

The importance of ‘green’ certifications is also growing. B2B buyers should seek manufacturers that adhere to recognized sustainability standards, such as ISO 14001 for environmental management and certifications from the Global Battery Alliance. Additionally, sourcing materials that are recycled or derived from sustainable practices can enhance brand reputation and meet consumer demand for responsible products. By integrating sustainability into their sourcing strategies, businesses can not only reduce their environmental footprint but also align themselves with the values of increasingly eco-conscious consumers.

What Is the Historical Context of Electric Cars Automtico for B2B Buyers?

The evolution of electric cars automtico has roots dating back to the late 19th century when early electric vehicles were introduced. However, the modern era of electric vehicles began in earnest in the early 21st century, driven by technological advancements and a growing awareness of climate change. The introduction of mass-market electric vehicles, such as the Tesla Model S, catalyzed interest and investment in the sector, leading to a proliferation of models from various manufacturers.

Today, electric cars automtico are not merely an alternative to traditional vehicles; they represent a paradigm shift in transportation. For B2B buyers, understanding this historical context is essential as it informs current market dynamics and consumer expectations. The ongoing transition towards electrification is a testament to the industry’s adaptability and innovation, making it imperative for businesses to stay informed and agile in their sourcing strategies. As the sector continues to evolve, aligning with manufacturers that embrace technological advancements and sustainability will be key to securing a competitive edge in the market.

Frequently Asked Questions (FAQs) for B2B Buyers of electric cars automtico

-

How do I evaluate the quality of electric cars automtico from different suppliers?

To assess the quality of electric cars automtico, start by reviewing the supplier’s certifications and compliance with international automotive standards, such as ISO and UNECE regulations. Request detailed specifications, performance data, and quality assurance documentation. Additionally, consider conducting third-party inspections and seeking testimonials or case studies from other B2B clients. Engaging in direct communication with suppliers about their manufacturing processes and quality control measures can also provide insights into their reliability and product quality. -

What is the best electric car automtico for commercial fleet use?

The ideal electric car automtico for commercial fleet use depends on your specific needs, such as range, cargo capacity, and operational costs. Models like the Tesla Model 3 and the Nissan Leaf are popular due to their efficiency and lower maintenance costs. Additionally, consider vehicles designed for commercial applications, such as the Ford E-Transit, which offers a spacious cargo area. Evaluate total cost of ownership, including purchase price, charging infrastructure, and potential tax incentives, to determine the best fit for your fleet. -

What are the minimum order quantities (MOQ) for electric cars automtico?

Minimum order quantities (MOQ) for electric cars automtico can vary significantly by manufacturer and region. Some suppliers may require a minimum of 10-20 units to fulfill an order, while others might accommodate smaller orders for new clients or specific model types. It’s essential to negotiate terms and understand the implications of MOQ on pricing and delivery timelines. Always clarify the terms with potential suppliers to ensure alignment with your procurement strategy. -

What payment terms should I expect when purchasing electric cars automtico?

Payment terms for electric cars automtico can vary widely, typically ranging from 30% upfront payment to full payment upon delivery. Some suppliers may offer financing options or installment plans, especially for bulk orders. It’s crucial to negotiate favorable terms that align with your cash flow needs. Always ensure that the payment structure is documented in a formal contract to protect your interests and facilitate smooth transactions. -

How can I customize electric cars automtico for my business needs?

Customization options for electric cars automtico often include modifications in specifications, branding, and additional features tailored to your business requirements. Engage with suppliers early in the procurement process to discuss available customization options such as battery capacity, interior layout, and technology integrations. Understand the implications of customizations on lead times and costs, and ensure that all specifications are documented in the contract to avoid misunderstandings. -

What logistics considerations should I keep in mind when importing electric cars automtico?

When importing electric cars automtico, consider logistics factors such as shipping methods, customs regulations, and delivery timelines. Ensure compliance with local import regulations and tariffs specific to electric vehicles in your region. Collaborate with logistics providers experienced in automotive shipping to streamline the process. Additionally, factor in the cost of transportation insurance and potential delays due to customs clearance to avoid unexpected expenses. -

How do electric cars automtico perform in terms of maintenance and servicing?

Electric cars automtico generally require less maintenance than traditional internal combustion engine vehicles due to fewer moving parts and simpler drivetrains. Key maintenance aspects include battery health monitoring, tire rotations, and brake inspections. For B2B buyers, it’s important to establish a service agreement with qualified technicians familiar with electric vehicle technology to ensure timely and effective maintenance. This proactive approach can enhance vehicle longevity and reduce operational disruptions. -

What are the key factors affecting the resale value of electric cars automtico?

The resale value of electric cars automtico is influenced by several factors, including battery condition, vehicle mileage, brand reputation, and market demand for electric vehicles. Models with robust charging infrastructure and favorable reviews tend to retain value better. Additionally, government incentives and regional policies promoting electric vehicle adoption can impact resale prices. Regular maintenance and keeping detailed service records can also help maintain a higher resale value when the time comes to sell or upgrade your fleet.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Electric Cars Automtico Manufacturers & Suppliers List

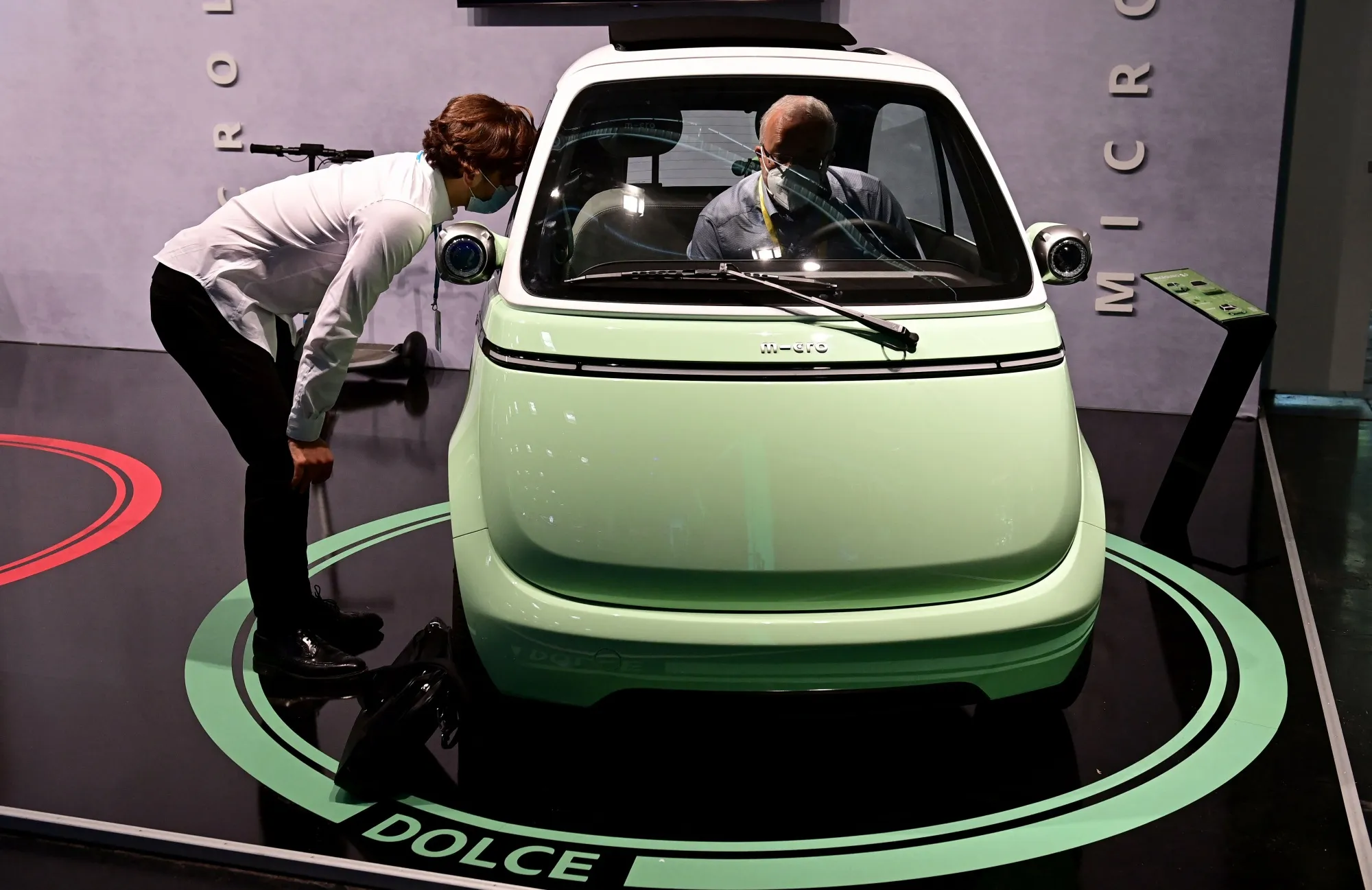

1. Motoring Electric – Electric Cars Overview

Domain: motoringelectric.com

Registered: 2018 (7 years)

Introduction: Most electric cars are automatic, using a single gear for acceleration and top speed. They have a reverse switch (R), neutral (N), and park (P) modes, with some offering sport (S) and eco (E) driving modes. High-performance models like the Audi E-tron GT and Porsche Taycan feature two-speed gearboxes for enhanced performance. Currently, no electric cars come with a manual gearbox, but Toyota is de…

2. Pimp My EV – Automatic Gear Solutions

Domain: pimpmyev.com

Registered: 2020 (5 years)

Introduction: This company, Pimp My EV – Automatic Gear Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. DS Automobiles – DS 3 CROSSBACK E-TENSE

Domain: dsautomobiles.co.uk

Registered: 2015 (10 years)

Introduction: The majority of electric cars are automatic, featuring only two pedals: the accelerator and brake. They typically have a single-speed setup, delivering constant and instant power without the need for a clutch or gears. The DS 3 CROSSBACK E-TENSE offers driving modes such as ‘Sport’ for enhanced performance and ‘Eco’ for efficiency. Electric vehicles (EVs) do not have traditional reverse gears but …

4. Mercedes-Benz – Electric Vehicles

Domain: mbusa.com

Registered: 1996 (29 years)

Introduction: Mercedes-Benz offers a lineup of fully electric vehicles (EVs) that include features such as a high-power charging network for effortless public charging, preferential access for Mercedes-Benz drivers, and various shopping tools for building and customizing vehicles. The brand emphasizes luxury and convenience in its electric vehicle offerings, along with support for owners through apps and servic…

5. Fleet Evolution – Electric Vehicles

Domain: fleetevolution.com

Registered: 2010 (15 years)

Introduction: Electric cars are nearly all automatic, utilizing a single-speed transmission that eliminates the need for gear changes, making them easier and smoother to drive. They do not have a gearbox with multiple gears, clutch, or gear stick, often featuring a simple selector like a dial or button. Electric motors provide instant torque and operate efficiently with just one gear. Most modern hybrid cars al…

Strategic Sourcing Conclusion and Outlook for electric cars automtico

In the rapidly evolving landscape of electric vehicles (EVs), understanding the nuances of automatic transmissions is essential for international B2B buyers. The majority of electric cars utilize single-speed or direct drive systems, which streamline power delivery and significantly enhance efficiency compared to traditional combustion engines. This simplifies maintenance and reduces operational costs, making EVs an attractive investment for businesses in regions like Africa, South America, the Middle East, and Europe.

Strategic sourcing plays a pivotal role in acquiring electric vehicles that align with your operational needs and sustainability goals. By prioritizing suppliers that offer advanced technology and reliable service, businesses can leverage the benefits of electric mobility while ensuring compliance with emerging regulations and consumer demands.

Looking ahead, the transition to electric vehicles is not just a trend; it represents a fundamental shift in transportation. As global markets pivot towards sustainability, now is the time for B2B buyers to engage with leading manufacturers and explore innovative partnerships. Embrace this opportunity to position your business at the forefront of the electric vehicle revolution, ensuring a competitive edge in a rapidly changing marketplace.