Introduction: Navigating the Global Market for electric cargo flatbed

In the rapidly evolving landscape of logistics, sourcing electric cargo flatbeds presents a formidable challenge for international B2B buyers. As businesses increasingly prioritize sustainability and efficiency, the demand for electric cargo solutions is surging, particularly in regions like Africa, South America, the Middle East, and Europe. This guide serves as a comprehensive resource, addressing the intricacies of sourcing electric cargo flatbeds, from understanding different types and applications to effectively vetting suppliers and evaluating costs.

International buyers face unique hurdles, including diverse regulatory environments and varying market dynamics. This guide empowers decision-makers by providing actionable insights tailored to their specific contexts. It covers essential aspects such as the latest innovations in electric flatbed technology, the benefits of adopting eco-friendly transportation solutions, and strategies for maximizing return on investment.

By delving into the nuances of electric cargo flatbeds, this resource equips businesses with the knowledge to make informed purchasing decisions that align with their operational needs and sustainability goals. Whether you are exploring options for urban deliveries, agricultural transport, or warehouse logistics, understanding the global market for electric cargo flatbeds is crucial for staying competitive in a dynamic marketplace.

Understanding electric cargo flatbed Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electric Cargo Tricycle | Three-wheeled design, spacious flatbed, electric assist, high load capacity | Last-mile delivery, urban transport | Pros: Maneuverable, eco-friendly, customizable branding. Cons: Limited speed compared to larger vehicles. |

| Electric Flatbed Cargo Van | Enclosed cargo space, high payload capacity, advanced battery technology | E-commerce logistics, food delivery | Pros: Weather protection, larger cargo capacity. Cons: Higher initial investment, maintenance costs. |

| Electric Cargo Trailer | Lightweight, towed behind electric bikes, compact design | Short-distance transport, personal use | Pros: Cost-effective, easy to store. Cons: Limited load capacity, requires a compatible towing vehicle. |

| Electric Flatbed Utility Truck | Robust build, high torque, optimized for heavy loads | Construction, agriculture, urban logistics | Pros: High payload capacity, powerful performance. Cons: Larger footprint, higher operational costs. |

| Electric Delivery Scooter | Two-wheeled, compact design, ideal for quick deliveries | Food delivery, small parcel transport | Pros: Highly maneuverable, low operational costs. Cons: Limited cargo space, not suitable for heavy loads. |

What Are the Characteristics of Electric Cargo Tricycles?

Electric cargo tricycles are designed for urban environments, featuring a three-wheeled configuration that enhances stability and maneuverability. With a spacious flatbed, these vehicles can carry significant loads, making them ideal for last-mile delivery services. Businesses can benefit from their electric assist feature, which reduces physical strain and improves efficiency. When considering a purchase, B2B buyers should assess the model’s load capacity and battery range, as well as the potential for branding customization.

How Do Electric Flatbed Cargo Vans Serve Businesses?

Electric flatbed cargo vans offer an enclosed cargo area, making them suitable for transporting sensitive goods in various weather conditions. Their high payload capacity and advanced battery technology enable businesses to conduct e-commerce logistics and food delivery efficiently. Buyers should consider the initial investment cost and maintenance requirements, as these vehicles may have higher operational costs compared to smaller alternatives. The versatility of these vans can significantly enhance a company’s logistics capabilities.

What Advantages Do Electric Cargo Trailers Provide?

Electric cargo trailers are a lightweight option that can be towed behind electric bikes, making them an economical choice for short-distance transport. Their compact design allows for easy storage and transport when not in use, making them ideal for personal use or small-scale deliveries. B2B buyers should evaluate the compatibility of the trailer with existing vehicles and consider the limited load capacity, which may restrict their application for larger deliveries.

Why Choose Electric Flatbed Utility Trucks?

Electric flatbed utility trucks are designed for demanding applications, such as construction and agriculture, where high torque and payload capacity are essential. Their robust build and performance capabilities make them suitable for various heavy-duty tasks. However, potential buyers should be aware of the larger footprint and higher operational costs associated with these vehicles. Assessing the specific needs of the business will help in determining if this type of electric cargo vehicle is a worthwhile investment.

How Do Electric Delivery Scooters Fit into Urban Logistics?

Electric delivery scooters are compact and highly maneuverable, making them perfect for quick deliveries in congested urban areas. They are particularly effective for food delivery services and small parcel transport, where speed is essential. However, their limited cargo space means they are not suitable for heavier loads. B2B buyers should consider the operational costs and battery life when evaluating these scooters for their delivery needs, as they can offer substantial savings and efficiency in the right contexts.

Key Industrial Applications of electric cargo flatbed

| Industry/Sector | Specific Application of electric cargo flatbed | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics and Delivery | Last-mile delivery in urban areas | Reduces delivery times and operational costs | Battery range, load capacity, charging infrastructure |

| Agriculture | Transporting produce from farms to markets | Enhances efficiency and reduces spoilage | Durability, terrain handling, weather resistance |

| Construction | Moving tools and materials on-site | Streamlines workflow and reduces manual labor | Load capacity, vehicle dimensions, safety features |

| Retail and E-commerce | Delivering goods to customers | Improves customer satisfaction and reduces costs | Customization options, branding, delivery range |

| Waste Management | Collecting and transporting waste | Supports sustainability and compliance with regulations | Environmental impact, maintenance costs, payload capacity |

How is Electric Cargo Flatbed Used in Logistics and Delivery?

In the logistics and delivery sector, electric cargo flatbeds are pivotal for last-mile delivery in densely populated urban areas. They facilitate the efficient transport of goods from distribution hubs to end customers, particularly in locations where traditional vehicles may struggle due to congestion or limited access. These vehicles help businesses reduce delivery times and operational costs by utilizing electric power, which is often more economical than fuel. International buyers should consider battery range and load capacity to ensure that the vehicles can meet their specific delivery needs.

What Role Does Electric Cargo Flatbed Play in Agriculture?

Electric cargo flatbeds are increasingly used in agriculture for transporting produce from farms to local markets. Their flatbed design allows for easy loading and unloading of bulk goods, significantly enhancing operational efficiency. By minimizing the time between harvest and sale, these vehicles help reduce spoilage and ensure fresher products reach consumers. Buyers in agricultural regions should focus on durability, terrain handling capabilities, and weather resistance when sourcing these vehicles to accommodate diverse agricultural environments.

How Does Electric Cargo Flatbed Benefit Construction Projects?

In the construction industry, electric cargo flatbeds are essential for moving tools, materials, and equipment on-site. Their capacity to carry heavy loads while navigating narrow construction pathways streamlines workflows and reduces the need for manual labor. This not only speeds up project timelines but also enhances safety by minimizing the risks associated with manual material handling. For international buyers, key considerations include load capacity, vehicle dimensions, and safety features to comply with local regulations and site requirements.

Why is Electric Cargo Flatbed Important for Retail and E-commerce?

For retail and e-commerce businesses, electric cargo flatbeds are crucial for delivering goods directly to customers. They enable businesses to enhance customer satisfaction through timely deliveries while simultaneously reducing transportation costs. The ability to customize these vehicles for branding purposes adds value by promoting the business during transit. Retailers should prioritize sourcing options that offer customization, delivery range, and operational efficiency to maximize their logistics capabilities.

How is Electric Cargo Flatbed Used in Waste Management?

Electric cargo flatbeds play a significant role in waste management by facilitating the collection and transport of waste materials. Their eco-friendly design supports sustainability initiatives, helping municipalities comply with environmental regulations while reducing carbon footprints. These vehicles can operate in urban settings with minimal noise and emissions, making them ideal for city waste collection. International buyers should focus on the environmental impact, maintenance costs, and payload capacity to ensure compliance with local waste management standards.

3 Common User Pain Points for ‘electric cargo flatbed’ & Their Solutions

Scenario 1: Navigating Urban Regulations and Compliance

The Problem: B2B buyers in regions with strict urban regulations often struggle to ensure their electric cargo flatbed vehicles comply with local laws. This includes requirements for emissions, safety standards, and even specific vehicle classifications. For instance, cities in Europe and parts of the Middle East may have stringent regulations aimed at reducing urban congestion and pollution, which can make it challenging for businesses to operate their electric cargo fleets legally and efficiently.

The Solution: To overcome this compliance challenge, buyers should engage with local regulatory bodies early in the purchasing process. Conduct a thorough review of local regulations and ensure that the electric cargo flatbed they are considering meets or exceeds these requirements. Buyers should also look for manufacturers that offer vehicles certified for urban use. Many manufacturers provide documentation outlining compliance with safety and emissions standards, which can simplify the registration process. Additionally, seeking vehicles that are adaptable, allowing for modifications to align with evolving regulations, can provide a strategic advantage. Regular training for staff on compliance can also mitigate risks associated with non-compliance.

Scenario 2: Addressing Range Anxiety in Logistics Operations

The Problem: One of the most significant concerns for businesses considering electric cargo flatbeds is range anxiety—the fear that the vehicle will not have enough battery power to complete its routes, especially in logistics and delivery applications. In regions with vast distances between delivery points or where charging infrastructure is lacking, this concern can lead to operational inefficiencies and increased costs.

The Solution: To effectively mitigate range anxiety, businesses should conduct a comprehensive analysis of their delivery routes to understand the average distance traveled. This analysis should include peak delivery times and the payload that will be carried. With this data, buyers can select electric cargo flatbeds with battery capacities that meet their specific operational needs, ensuring a suitable range. Furthermore, investing in a robust charging infrastructure, including fast-charging stations at strategic locations, will enhance operational efficiency. For companies operating in regions with limited charging options, consider vehicles that offer swappable battery technology, allowing for quick replacements and minimizing downtime. Partnering with local charging solution providers can also facilitate access to a wider network of charging stations.

Scenario 3: Managing Total Cost of Ownership (TCO)

The Problem: B2B buyers often face challenges in understanding the total cost of ownership (TCO) associated with electric cargo flatbeds compared to traditional fossil fuel vehicles. This encompasses not only the initial purchase price but also ongoing maintenance, energy costs, and potential subsidies or tax incentives. Miscalculating TCO can lead to unexpected expenses that impact the overall profitability of logistics operations.

The Solution: To gain a clear picture of TCO, buyers should start with a detailed financial analysis that factors in all costs associated with ownership over the vehicle’s lifespan. This includes initial purchase costs, expected maintenance expenses, energy consumption, and any potential government incentives for electric vehicle adoption. Buyers should consult with financial experts who specialize in fleet management to develop a comprehensive cost model. Additionally, selecting electric cargo flatbeds known for their low maintenance requirements and energy efficiency can significantly reduce TCO. Engaging with suppliers who provide transparent pricing and warranty details will also help buyers forecast long-term costs accurately. Finally, consider leveraging telematics systems to monitor vehicle performance and optimize energy use, further enhancing cost savings.

Strategic Material Selection Guide for electric cargo flatbed

What Are the Common Materials Used in Electric Cargo Flatbeds?

In the production of electric cargo flatbeds, selecting the right materials is crucial for ensuring performance, durability, and cost-effectiveness. Below is an analysis of four common materials used in electric cargo flatbeds, focusing on their properties, advantages, limitations, and considerations for international B2B buyers.

How Does Aluminum Perform in Electric Cargo Flatbeds?

Aluminum is a lightweight, corrosion-resistant metal often used in electric cargo flatbeds. Its key properties include a high strength-to-weight ratio, excellent thermal conductivity, and resistance to corrosion, making it ideal for outdoor applications. However, while aluminum is durable, it can be more expensive than steel and may require specialized manufacturing processes, such as welding and anodizing, which can add to production costs.

For international buyers, aluminum’s compatibility with various environmental conditions is advantageous, especially in humid or coastal regions. Compliance with standards such as ASTM and ISO is essential to ensure quality and performance.

What Role Does Steel Play in Electric Cargo Flatbeds?

Steel, particularly high-strength low-alloy (HSLA) steel, is another common material for electric cargo flatbeds. It offers excellent tensile strength and durability, making it suitable for heavy loads. Steel’s resistance to deformation under stress is a significant advantage, but it is heavier than aluminum, which can impact energy efficiency in electric vehicles.

While steel is generally more affordable than aluminum, it is prone to corrosion unless treated with protective coatings. International buyers should consider the need for regular maintenance and compliance with local standards, such as DIN in Europe, to ensure longevity and performance.

Why Is Composite Material Gaining Popularity in Electric Cargo Flatbeds?

Composite materials, such as fiberglass-reinforced plastic (FRP), are increasingly used in electric cargo flatbeds due to their lightweight and corrosion-resistant properties. Composites can be engineered to provide specific performance characteristics, such as enhanced impact resistance and thermal insulation.

The main drawback is the higher manufacturing complexity, which can lead to increased costs. For international buyers, understanding local regulations regarding composite materials is crucial, as some regions may have specific requirements for material certification and environmental impact.

How Do Advanced Polymers Enhance Electric Cargo Flatbeds?

Advanced polymers, such as polyethylene and polypropylene, are often used for components of electric cargo flatbeds, particularly for non-structural elements like cargo liners or covers. These materials are lightweight, resistant to moisture, and provide good impact resistance.

However, they may not withstand high temperatures or heavy loads as effectively as metals. For B2B buyers in warmer climates, the thermal stability of these materials should be a consideration. Compliance with material safety standards and recyclability can also influence purchasing decisions.

Summary Table of Material Selection for Electric Cargo Flatbeds

| Material | Typical Use Case for electric cargo flatbed | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Structural components and flatbed frame | Lightweight and corrosion-resistant | Higher cost and complex manufacturing | High |

| Steel | Load-bearing structures | High strength and durability | Heavier and prone to corrosion | Medium |

| Composite | Non-structural components | Customizable and lightweight | Higher manufacturing complexity | High |

| Advanced Polymers | Cargo liners and covers | Moisture-resistant and lightweight | Limited temperature and load resistance | Medium |

This strategic material selection guide aims to empower international B2B buyers with the necessary insights to make informed decisions regarding the materials used in electric cargo flatbeds. Understanding the properties, advantages, and limitations of each material will facilitate better procurement strategies tailored to specific regional needs and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for electric cargo flatbed

What Are the Key Stages in the Manufacturing Process of Electric Cargo Flatbeds?

The manufacturing of electric cargo flatbeds involves a series of meticulously planned stages to ensure the final product meets the stringent demands of the market.

Material Preparation: What Materials Are Used?

The first stage of manufacturing is material preparation, where manufacturers select high-quality materials that will contribute to the durability and functionality of the flatbeds. Common materials include:

- Steel and Aluminum: Used for the frame and body due to their strength-to-weight ratio.

- Lithium-ion Batteries: These are crucial for energy efficiency and long-range performance.

- Electrical Components: Including motors, wiring, and control systems that are essential for the vehicle’s operation.

How Is the Forming Process Executed in Electric Cargo Flatbed Production?

Once materials are prepared, the forming process begins. This includes techniques such as:

- Metal Fabrication: Techniques like cutting, bending, and welding are employed to create the frame and body of the flatbed. Advanced CNC (Computer Numerical Control) machines are often utilized for precision.

- Molding and Casting: For components like battery housings and other structural parts, molding processes can be used to achieve complex shapes.

What Assembly Techniques Are Commonly Used in Electric Cargo Flatbed Manufacturing?

After the components are formed, the next step is assembly. This stage involves:

- Sub-assembly: Smaller components, such as the battery pack and electric motor, are assembled separately before being integrated into the main vehicle structure.

- Main Assembly Line: The primary frame is constructed, and all components—including the flatbed, wheels, and electrical systems—are assembled. Robotics and automated systems may be employed to enhance efficiency and precision.

- Integration of Safety Features: This includes the installation of braking systems, lighting, and safety sensors that comply with international standards.

What Finishing Processes Are Necessary for Electric Cargo Flatbeds?

Finishing touches are crucial for the aesthetics and longevity of the electric cargo flatbed. This phase involves:

- Surface Treatment: Coatings such as powder coating or galvanization are applied to protect against corrosion and enhance appearance.

- Quality Control Inspections: Before the final product is packaged and shipped, a thorough quality check is performed to ensure that all components function as intended.

How Is Quality Assurance Implemented in Electric Cargo Flatbed Manufacturing?

Quality assurance is a critical aspect of the manufacturing process, ensuring that products meet both international and industry-specific standards.

What International Standards Should B2B Buyers Be Aware Of?

B2B buyers should be familiar with various international quality standards that manufacturers must adhere to, including:

- ISO 9001: This standard focuses on quality management systems and is applicable to any organization looking to enhance customer satisfaction through consistent quality.

- CE Marking: Particularly important in Europe, CE marking indicates that the product complies with EU safety, health, and environmental protection standards.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) encompasses several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Raw materials and components are inspected upon arrival to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): During the assembly phase, inspections are conducted at various stages to catch defects early.

- Final Quality Control (FQC): After assembly, the finished product undergoes thorough testing to ensure functionality, safety, and compliance with standards.

What Testing Methods Are Commonly Used to Ensure Product Quality?

Manufacturers employ several testing methods to validate the performance and safety of electric cargo flatbeds:

- Load Testing: To ensure the flatbed can handle its maximum load capacity without failure.

- Battery Performance Testing: Assessing charge times, range, and efficiency of lithium-ion batteries.

- Safety Testing: Evaluating braking systems, lighting, and overall vehicle safety features.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying the quality control processes of suppliers is crucial. Here are some methods to ensure compliance and quality:

- Supplier Audits: Conducting regular audits of suppliers helps assess their manufacturing processes and adherence to quality standards.

- Quality Reports: Requesting detailed QC reports, including inspection results and testing data, can provide insights into the supplier’s quality management practices.

- Third-Party Inspections: Engaging independent inspection agencies can help validate the manufacturer’s claims and ensure that products meet required standards before shipment.

What Are the Nuances of Quality Control for International B2B Buyers?

International buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

- Regulatory Compliance: Different regions may have varying regulatory requirements, necessitating thorough research into local laws and standards.

- Cultural Considerations: Understanding cultural differences in business practices can aid in building trust and effective communication with suppliers.

- Logistical Challenges: Consideration of transportation and shipping logistics, including potential delays or damage during transit, is vital in ensuring product integrity upon arrival.

By understanding these manufacturing processes and quality assurance protocols, B2B buyers can make informed decisions when selecting electric cargo flatbeds, ensuring they invest in reliable and compliant products tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric cargo flatbed’

Introduction

This sourcing guide is designed to assist B2B buyers in navigating the procurement process for electric cargo flatbeds. By following this step-by-step checklist, businesses can ensure they select the right vehicle that meets their operational needs, adheres to safety standards, and offers long-term value.

Step 1: Define Your Technical Specifications

Before diving into the market, clearly outline your technical requirements. Consider factors such as load capacity, battery life, range, and motor power. A well-defined specification helps in narrowing down options that align with your operational needs, ensuring you invest in a vehicle that can efficiently handle your logistics.

- Load Capacity: Ensure the flatbed can carry the weight of the goods you typically transport.

- Range and Battery Life: Assess your daily travel distance to select a vehicle that won’t run out of charge during operations.

Step 2: Research Market Trends and Innovations

Stay informed about the latest trends in electric cargo vehicles. This includes understanding advancements in battery technology, motor efficiency, and eco-friendly designs. Being aware of these trends can help you choose a model that not only meets current standards but is also future-proof.

- Battery Technology: Look for vehicles with lithium-ion batteries, which offer better efficiency and longevity.

- Sustainability: Consider models that promote eco-friendly practices, which can enhance your brand’s reputation.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they meet your quality and service standards. Request detailed company profiles, product specifications, and references from other businesses in your industry. This step is critical to establish trust and ensure you’re partnering with a reliable manufacturer.

- Customer Testimonials: Seek feedback from previous customers about their experience with the supplier.

- Industry Certifications: Confirm that the supplier holds necessary certifications, indicating compliance with safety and quality standards.

Step 4: Analyze Total Cost of Ownership (TCO)

When selecting an electric cargo flatbed, consider not just the purchase price but the total cost of ownership. This includes maintenance, operational costs, and potential savings on fuel. A comprehensive TCO analysis will help you understand the long-term financial implications of your investment.

- Maintenance Costs: Investigate the typical upkeep costs associated with the models you are considering.

- Operational Expenses: Calculate potential savings from fuel and other running costs compared to traditional vehicles.

Step 5: Verify Warranty and Support Services

Review the warranty terms and after-sales support provided by the supplier. A robust warranty can protect your investment and reduce future costs related to repairs or replacements. Additionally, reliable customer support is essential for addressing any issues that may arise during operation.

- Warranty Duration: Look for extended warranties that cover key components like the battery and motor.

- Customer Support: Ensure the supplier offers accessible support channels for troubleshooting and repairs.

Step 6: Consider Customization Options

Evaluate whether the supplier provides customization options that align with your branding and operational needs. Customization can enhance your business visibility while ensuring the vehicle fits specific logistical requirements.

- Branding Opportunities: Inquire about options for adding your company’s logo or colors to the vehicle.

- Configuration Flexibility: Assess if the flatbed can be adapted for different types of cargo or operational scenarios.

Step 7: Finalize Logistics and Delivery Terms

Once you have selected a supplier and model, confirm the logistics and delivery terms. This includes shipping costs, expected delivery timelines, and installation services if applicable. Clear communication at this stage can help avoid unexpected delays and expenses.

- Shipping Arrangements: Clarify how and when the vehicle will be delivered to your location.

- Installation Services: Determine if the supplier provides installation support for any additional equipment or modifications.

By following these steps, B2B buyers can make informed decisions when sourcing electric cargo flatbeds, ultimately enhancing their operational efficiency and sustainability.

Comprehensive Cost and Pricing Analysis for electric cargo flatbed Sourcing

What Are the Key Cost Components of Electric Cargo Flatbeds?

When analyzing the cost structure for electric cargo flatbeds, several components must be considered.

-

Materials: The choice of materials significantly influences the cost. High-quality aluminum or steel frames, electric motors, and battery systems represent the bulk of material costs. For instance, a robust 500W brushless motor and a lithium-ion battery are essential for performance but can vary in price based on quality and sourcing.

-

Labor: Labor costs include manufacturing, assembly, and quality control personnel. Skilled labor is essential for ensuring the reliability and safety of electric cargo flatbeds, which can lead to higher costs in regions where wages are elevated.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help mitigate overhead costs.

-

Tooling: Initial tooling costs can be significant, especially for customized or specialized designs. These costs are often amortized over larger production runs, making economies of scale crucial.

-

Quality Control (QC): Ensuring product quality through rigorous testing and compliance certifications adds to the overall cost but is essential for maintaining safety and reliability standards.

-

Logistics: Transportation costs, including freight, customs duties, and handling, must be factored in, particularly for international shipments. These costs can vary widely based on shipping distances and Incoterms.

-

Margin: Finally, the manufacturer’s profit margin will influence the final price. Competitive markets may drive margins down, while unique offerings or proprietary technologies could allow for higher margins.

How Do Price Influencers Impact Electric Cargo Flatbed Costs?

Several factors can influence the pricing of electric cargo flatbeds:

-

Volume/MOQ: Purchasing in bulk often results in significant discounts. Buyers should assess their needs and negotiate minimum order quantities (MOQ) to optimize cost savings.

-

Specifications and Customization: Custom designs or specific technical specifications can increase costs. Buyers should clearly outline their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: Higher-grade materials and certifications (such as ISO or CE) can lead to increased costs but often correlate with enhanced durability and performance.

-

Supplier Factors: The choice of supplier plays a critical role. Established suppliers with robust reputations may charge a premium, but their products often come with guarantees of quality and reliability.

-

Incoterms: Understanding and negotiating Incoterms is vital for international buyers. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect total costs and responsibilities.

What Are the Best Negotiation Strategies for B2B Buyers?

-

Understand Total Cost of Ownership (TCO): Beyond the initial purchase price, consider long-term costs such as maintenance, energy consumption, and resale value. Electric cargo flatbeds typically offer lower operational costs compared to traditional vehicles, making them an attractive option over time.

-

Leverage Competitive Bids: Gather multiple quotes from different suppliers to create a competitive environment. This can provide leverage in negotiations and help secure better pricing.

-

Build Relationships: Establishing a rapport with suppliers can lead to preferential pricing and terms. Long-term partnerships often yield better support and flexibility.

-

Be Open to Alternative Solutions: If a supplier cannot meet a desired price, explore alternative specifications or payment terms that could reduce costs without compromising quality.

-

Stay Informed on Market Trends: Knowledge of market conditions, such as material shortages or changes in demand, can empower buyers during negotiations.

What Pricing Nuances Should International Buyers Consider?

International buyers from regions like Africa, South America, the Middle East, and Europe should be aware of several pricing nuances:

-

Currency Fluctuations: Exchange rate volatility can impact costs when purchasing from foreign suppliers. It is prudent to negotiate prices in a stable currency.

-

Import Duties and Taxes: Understanding local import regulations and potential tariffs is crucial for calculating the total landed cost of electric cargo flatbeds.

-

Cultural Differences in Negotiation: Different regions may have varying negotiation styles and expectations. Being culturally aware can facilitate smoother discussions and agreements.

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on market conditions, supplier capabilities, and specific buyer requirements. It is essential for buyers to conduct thorough research and due diligence when sourcing electric cargo flatbeds to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing electric cargo flatbed With Other Solutions

Exploring Viable Alternatives to Electric Cargo Flatbeds

As businesses seek efficient solutions for transporting goods, electric cargo flatbeds have gained significant traction. However, various alternatives also exist, each with unique advantages and limitations. This analysis compares electric cargo flatbeds with two other solutions: electric cargo tricycles and cargo trailers, helping B2B buyers make informed decisions.

| Comparison Aspect | Electric Cargo Flatbed | Electric Cargo Tricycle | Cargo Trailer |

|---|---|---|---|

| Performance | High payload capacity (up to 660 lbs), speeds up to 20 mph, suitable for urban delivery. | Moderate capacity (up to 660 lbs), speeds up to 20 mph, ideal for last-mile deliveries. | Low capacity (up to 100 lbs), dependent on towing vehicle speed. |

| Cost | Generally higher upfront cost, but lower operational costs due to electric efficiency. | Lower initial investment (around $4,899), but may have limited applications. | Affordable (around $319.95), but requires a compatible bike or vehicle for towing. |

| Ease of Implementation | Requires dedicated infrastructure for charging and maintenance; some training may be needed. | Simple operation, no special licensing required; easy to integrate into existing workflows. | Easy to attach and detach; requires a compatible bike, but no additional infrastructure needed. |

| Maintenance | Low maintenance costs but may require specialized service for electric components. | Minimal maintenance; basic bike repairs suffice. | Low maintenance; primarily mechanical care for the trailer. |

| Best Use Case | Suitable for urban logistics, e-commerce deliveries, and businesses needing high payload capacity. | Ideal for local deliveries, small businesses, and urban commuting where space is limited. | Best for light cargo transport and recreational use, where mobility is key. |

Understanding the Pros and Cons of Electric Cargo Tricycles

Electric cargo tricycles, such as the Mobility Star Electric Flatbed Cargo Tricycle, offer a versatile solution for transporting goods in urban environments. They combine the benefits of electric power with a compact design, making them ideal for last-mile deliveries. The tricycles can handle hilly terrains and have a decent range of around 40 miles per charge. However, their payload capacity is lower compared to traditional flatbeds, limiting their use for heavier loads. Additionally, while they are easy to maneuver, they may not be suitable for all types of cargo.

Evaluating Cargo Trailers for Light Transport Needs

Cargo trailers, like the Burley Flatbed Cargo Trailer, present an economical option for businesses needing to transport lighter loads. With a weight limit of 100 lbs, these trailers can be towed by bicycles, making them highly mobile and easy to store. Their affordability is a significant advantage, especially for startups or small businesses. However, their dependency on a towing vehicle means that they may not be as versatile as electric cargo flatbeds or tricycles for urban deliveries. Additionally, their limited cargo capacity may restrict their application in certain business scenarios.

Making the Right Choice for Your Business Needs

When selecting between electric cargo flatbeds and their alternatives, businesses should consider their specific operational requirements. If high payload capacity and longer ranges are critical, electric cargo flatbeds are likely the best choice. For companies focused on local deliveries with lighter loads, electric cargo tricycles or cargo trailers might be more appropriate and cost-effective. Ultimately, the decision should align with the business’s logistics strategy, budget constraints, and operational efficiency goals. Understanding these factors will empower B2B buyers to choose a solution that not only meets their current needs but also supports future growth.

Essential Technical Properties and Trade Terminology for electric cargo flatbed

What are the Key Technical Properties of Electric Cargo Flatbeds?

Electric cargo flatbeds are essential for modern logistics, particularly in urban environments. Understanding their technical properties helps B2B buyers make informed purchasing decisions. Here are some critical specifications:

-

Load Capacity

The load capacity indicates the maximum weight the flatbed can safely transport. Typical electric cargo flatbeds can carry between 500 to 1,500 kg. Knowing the load capacity is vital for businesses to ensure they comply with safety standards while meeting operational demands. -

Battery Voltage and Type

Most electric flatbeds operate on a 48V lithium-ion battery system. This specification affects the vehicle’s range, charging time, and overall efficiency. A higher voltage typically translates to better performance and longer operational periods, which is crucial for businesses relying on timely deliveries. -

Range per Charge

The range refers to how far the vehicle can travel on a single battery charge, commonly ranging from 40 to 80 km. For B2B buyers, understanding the range is crucial for planning logistics and ensuring that vehicles can complete their routes without requiring frequent recharging. -

Motor Power

The power of the electric motor, usually expressed in kilowatts (kW), determines the flatbed’s performance, including speed and ability to handle inclines. Motors typically range from 2 kW to 10 kW. A more powerful motor enhances operational efficiency, particularly in hilly areas or when carrying heavy loads. -

Charging Time

Charging time varies widely but generally falls between 3 to 12 hours. Shorter charging times allow for quicker turnaround and increased vehicle utilization. This is particularly important for businesses that operate on tight schedules. -

Dimensions and Weight

The dimensions of the flatbed affect maneuverability and storage. Knowing the vehicle’s length, width, and height can help businesses assess whether it can navigate urban spaces and fit into loading docks. Additionally, the weight of the flatbed impacts fuel efficiency and overall handling.

What Trade Terminology Should B2B Buyers Know When Considering Electric Cargo Flatbeds?

Understanding industry jargon is crucial for effective communication and negotiation in the electric cargo flatbed market. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of electric cargo flatbeds, OEMs provide the essential components such as motors and batteries. Buyers should consider OEM reputation and reliability when sourcing vehicles. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For electric cargo flatbeds, knowing the MOQ is important for budgeting and inventory planning. It can also impact the total cost of procurement, as purchasing below the MOQ may lead to higher per-unit prices. -

RFQ (Request for Quotation)

An RFQ is a document that solicits price quotes from suppliers. Businesses typically issue RFQs when they are ready to purchase. Crafting a detailed RFQ can help ensure that buyers receive accurate and competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping. Familiarity with terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) helps B2B buyers understand shipping costs and risks associated with transportation. -

LTL (Less Than Truckload)

LTL shipping refers to transporting small freight that does not require a full truckload. For businesses purchasing multiple flatbeds, understanding LTL options can lead to cost savings and more efficient logistics. -

TCO (Total Cost of Ownership)

TCO is a financial estimate that helps buyers understand the direct and indirect costs of owning a vehicle over its entire lifecycle. This includes purchase price, maintenance, fuel, and depreciation. For electric cargo flatbeds, TCO is especially relevant, as electric vehicles often have different operational costs compared to traditional fuel-powered vehicles.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can navigate the electric cargo flatbed market more effectively, making choices that align with their operational needs and budget constraints.

Navigating Market Dynamics and Sourcing Trends in the electric cargo flatbed Sector

What Are the Current Market Dynamics and Key Trends in the Electric Cargo Flatbed Sector?

The electric cargo flatbed sector is experiencing significant growth, driven by global trends towards sustainability and the urgent need for efficient urban logistics. Key drivers include rising fuel costs, stringent environmental regulations, and the shift towards e-commerce, which demands innovative last-mile delivery solutions. In regions such as Africa, South America, the Middle East, and Europe, urbanization is creating challenges that electric cargo vehicles can address effectively. For instance, cities in these areas are grappling with congestion and pollution, prompting governments and businesses alike to invest in cleaner transportation alternatives.

Emerging B2B technologies are reshaping sourcing trends in this sector. Advanced battery technology, for example, is enhancing the range and efficiency of electric cargo vehicles, making them more viable for commercial use. The integration of IoT (Internet of Things) solutions allows for real-time tracking and fleet management, optimizing delivery routes and reducing operational costs. Additionally, businesses are increasingly looking for customizable electric cargo flatbeds that can be tailored to their specific logistics needs, enhancing brand visibility while promoting eco-friendly practices.

Moreover, international buyers should be aware of the competitive landscape, as numerous manufacturers are entering the market, often with aggressive pricing strategies. For instance, significant discounts can be found for electric cargo flatbeds, making it essential for buyers to negotiate effectively and consider total cost of ownership, including maintenance and operational efficiencies.

How Does Sustainability and Ethical Sourcing Impact the Electric Cargo Flatbed Sector?

Sustainability is at the core of the electric cargo flatbed sector, with environmental impact considerations driving purchasing decisions. Electric vehicles (EVs) significantly reduce greenhouse gas emissions compared to traditional diesel-powered trucks, offering an immediate advantage in urban areas striving for cleaner air. For international B2B buyers, understanding the environmental benefits of electric cargo flatbeds can inform their procurement strategies, aligning their operations with global sustainability goals.

Ethical sourcing is equally critical. Buyers should prioritize manufacturers who demonstrate commitment to ethical supply chains, utilizing responsibly sourced materials and sustainable production processes. Certifications such as ISO 14001 for environmental management systems or Green Seal can help identify manufacturers who adhere to high environmental standards. Additionally, incorporating recyclable materials into the design of electric cargo flatbeds not only minimizes waste but also enhances the overall sustainability profile of the product.

Investing in electric cargo flatbeds that come with these green certifications can bolster a company’s reputation and appeal to environmentally-conscious consumers, providing a competitive edge in the market. As sustainability continues to gain traction, aligning purchasing decisions with ethical sourcing practices will be vital for long-term success in this sector.

What Is the Evolution and History of Electric Cargo Flatbeds in the B2B Market?

The evolution of electric cargo flatbeds has been marked by technological advancements and changing market demands. Initially, the electric vehicle market was limited to passenger cars, but as urban logistics challenges became more pronounced, manufacturers began developing electric solutions for commercial use. The introduction of electric cargo flatbeds has provided businesses with a cleaner, more efficient means of transporting goods, particularly in congested urban environments.

In the past decade, improvements in battery technology and electric drivetrains have significantly enhanced the performance and viability of these vehicles. Innovations such as regenerative braking and lightweight materials have further improved efficiency and payload capacities. As a result, electric cargo flatbeds are now viewed not just as alternatives, but essential components of modern logistics strategies, particularly for last-mile delivery.

With increasing investment in green technologies and a growing emphasis on sustainability, the electric cargo flatbed sector is poised for continued growth. As international B2B buyers navigate this evolving landscape, understanding the historical context and technological advancements will be crucial for making informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of electric cargo flatbed

-

How do I determine the right electric cargo flatbed for my business needs?

Selecting the appropriate electric cargo flatbed involves assessing your specific requirements, such as load capacity, range, and terrain types. Consider the maximum weight you will be transporting, as well as the distance for deliveries. Evaluate the vehicle’s motor power and battery life to ensure it can handle your operational demands efficiently. Additionally, look for features that enhance functionality, such as customizable branding options and safety features. It’s advisable to consult with suppliers to discuss your needs and get recommendations tailored to your business. -

What are the key specifications to look for in an electric cargo flatbed?

When sourcing an electric cargo flatbed, focus on essential specifications including motor power (measured in watts), battery capacity (in volts and amp-hours), load capacity (maximum weight), and range (miles per charge). Additionally, check for safety features such as brakes and lights, as well as ease of loading and unloading through flatbed design. Consider the top speed and charging time to ensure the vehicle aligns with your operational timeline. Understanding these specifications will help you make an informed decision that meets your logistics needs. -

What payment terms are typically offered for purchasing electric cargo flatbeds?

Payment terms can vary significantly among suppliers. Common options include upfront payment, installment plans, or financing arrangements. Some suppliers may accept letters of credit or trade financing, especially for international transactions. It’s crucial to clarify payment options before finalizing a purchase to avoid surprises. Additionally, inquire about any potential discounts for bulk orders or long-term contracts, which could enhance your overall purchasing strategy and budget management. -

How can I vet suppliers of electric cargo flatbeds effectively?

Vetting suppliers requires a thorough evaluation of their credibility and product offerings. Start by checking their industry experience, customer reviews, and certifications. Request references from previous clients to gain insights into their reliability and product quality. Additionally, assess their warranty and after-sales service policies, as these reflect their commitment to customer satisfaction. Engaging in direct communication with suppliers to discuss your needs can also help gauge their responsiveness and expertise. -

What are the minimum order quantities (MOQ) for electric cargo flatbeds?

Minimum order quantities for electric cargo flatbeds can differ based on the supplier and model. Some manufacturers may have a low MOQ for standard models, while custom options may require larger orders. It is advisable to confirm the MOQ with potential suppliers early in the negotiation process. Understanding the MOQ will help you plan your inventory and budget, ensuring you can meet demand without overcommitting resources. -

How can I customize electric cargo flatbeds for my brand?

Many manufacturers offer customization options for electric cargo flatbeds, allowing you to enhance brand visibility. Customization may include applying your company logo, selecting specific colors, or modifying the design to suit operational needs. Discuss your requirements with suppliers to understand the extent of customization available and any associated costs. This branding can serve as a mobile advertisement, increasing brand awareness as your vehicles operate in various locations. -

What logistics considerations should I keep in mind when importing electric cargo flatbeds?

When importing electric cargo flatbeds, consider logistics factors such as shipping methods, customs regulations, and import duties. Choose a reliable freight forwarder who is familiar with regulations in your country to streamline the process. Ensure you have all necessary documentation, including invoices and shipping manifests, to facilitate customs clearance. Additionally, account for shipping times and costs in your overall budget to avoid unexpected delays or expenses. -

What quality assurance measures should I look for in electric cargo flatbeds?

Quality assurance is crucial in ensuring that the electric cargo flatbeds meet safety and performance standards. Look for suppliers who comply with international quality certifications such as ISO 9001. Inquire about their manufacturing processes, including testing protocols for components like batteries and motors. Request information on warranties and service agreements, as these indicate the supplier’s confidence in their product quality. Establishing a clear understanding of QA measures will help safeguard your investment and operational efficiency.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Electric Cargo Flatbed Manufacturers & Suppliers List

1. Burley – Flatbed Cargo Trailer

Domain: electriccyclery.com

Registered: 2003 (22 years)

Introduction: {“name”: “Burley Flatbed Cargo Trailer”, “color”: “Black”, “price”: “$319.95”, “load_capacity”: “100 pounds”, “design”: “Two-wheel design”, “features”: [“Aluminum frame”, “Burley hitch system”, “16-inch spoked alloy wheels with push button release”, “Compact fold for storage and transportation”, “Flex connector allows bike to lay flat while trailer remains upright”], “interior_dimensions”: {“lengt…

2. Mahindra – Treo Zor Flatbed Electric Cargo Vehicle

Domain: mahindralastmilemobility.com

Registered: 2022 (3 years)

Introduction: Product Name: Mahindra Treo Zor Flatbed

Type: Electric Cargo Vehicle

Payload Capacity: 578 kg

Running Cost: ₹ 11 paise/km

Charging Time: 3 hours 50 minutes

Real World Range: 80 km per charge

Top Speed: 50 km/h

Battery Type: Lithium-ion, 48 V

Warranty: 3 years or 80,000 km

Peak Power: 8 kW

Torque: 42 Nm

Design: Minimalist and sturdy, flatbed configuration for easy loading/unloading

Safety Features:…

3. Epic Wheelz – Burley Flatbed Cargo Trailer

Domain: epicwheelz.com

Registered: 2019 (6 years)

Introduction: Electric Bike Burley Flatbed Cargo Trailer

Price: $350.00

Carrying Capacity: 100 lbs

Weight: 19 lbs

Dimensions: 33 x 27 x 8 in

Description: Aluminum frame, two wheel chassis, Burley hitch system, 16″ spoke alloy wheels with push button release, compact fold for storage and transportation, flex connector allows bike to lay flat while trailer remains upright.

Interior Dimensions: L 32.5″ x W 20.5″ x…

4. Cozy Trikes – Electric Flatbed Cargo Trike EFC-100X

Domain: cozytrikes.com

Registered: 2010 (15 years)

Introduction: Product Name: Electric Flatbed Cargo Trike Tricycle Model: EFC-100X

Current Price: $8,900.00 (Original Price: $11,900.00)

Discount: Save $200.00 by paying with check or bank transfer; additional $200.00 off with coupon code SAVETODAY.

Shipping: Free shipping, ships in 7-10 days from the USA.

Color: Black

Stock: Two in stock

Specifications:

– Frame: GTAW-Reinforced Tig welded Steel

– Wheel: Aluminu…

5. MobilityScooTrike – Electric Flatbed Cargo Trike

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“product_name”: “Electric flatbed cargo trike bike heavy-duty industrial delivery tricycle cart”, “brand”: “MobilityScooTrike”, “condition”: “New”, “price”: “$4,999.00”, “monthly_payment”: “as low as $239.99/mo”, “shipping”: “Free USPS Ground Advantage”, “location”: “Fountain Hills, Arizona, United States”, “delivery_estimate”: “between Thu, Sep 11 and Wed, Sep 17”, “returns”: “14 days returns, b…

6. Ninebot – Hase Bikes with Omnium Cargo Flatbed

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Ninebot escorter on Hase bikes with Omnium cargo flatbed.

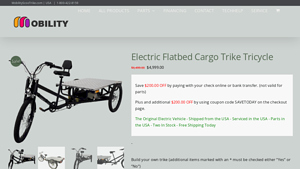

7. Mobility Scootrike – Electric Flatbed Cargo Trike EFC-100X

Domain: mobilityscootrike.com

Registered: 2023 (2 years)

Introduction: Product Name: Electric Flatbed Cargo Trike Tricycle

Model: EFC-100X

Price: $4,999.00 (original price $6,499.00, save $200.00 with online check or bank transfer, additional $200.00 off with coupon code SAVETODAY)

Shipping: Free shipping, ships in 7-10 days from the USA

Power Options: PowerBooster available for $489.50 (increases power to 1500 Watts)

Warranty: Standard 1-year warranty, extended 2-ye…

8. Urban Arrow – Flatbed Cargo L

Domain: dutchcargobike.com.au

Introduction: {“product_name”:”Urban Arrow Flatbed Cargo L”,”type”:”Cargo Bike”,”features”:[“Flatbed design for versatile cargo transport”,”Durable construction”,”Electric assist for easy riding”,”Spacious cargo area”,”Suitable for urban environments”],”dimensions”:”Not specified”,”weight”:”Not specified”,”color_options”:[“Black”,”White”],”price”:”Not specified”,”warranty”:”Not specified”}

Strategic Sourcing Conclusion and Outlook for electric cargo flatbed

As the demand for sustainable and efficient transportation solutions grows globally, electric cargo flatbeds emerge as a pivotal investment for businesses seeking to enhance their logistics operations. Key takeaways highlight the importance of selecting models that offer robust performance, low maintenance costs, and adaptability for diverse cargo needs. The strategic sourcing of electric cargo flatbeds not only contributes to operational efficiency but also aligns with the increasing regulatory pressures for greener practices.

By leveraging the advantages of electric cargo vehicles, businesses can significantly reduce their carbon footprint while optimizing last-mile delivery processes. The growing trend towards eco-friendly transportation solutions is particularly relevant in regions like Africa, South America, the Middle East, and Europe, where urbanization and environmental concerns are paramount.

As you consider your options, prioritize suppliers who provide comprehensive support, customization opportunities, and reliable warranties. Investing in electric cargo flatbeds today positions your business to thrive in a competitive landscape while contributing positively to environmental sustainability. Embrace this transformative opportunity and lead the charge towards a greener future in logistics.