Introduction: Navigating the Global Market for electric vehicle with ac

In the rapidly evolving landscape of electric vehicles (EVs), sourcing an electric vehicle with air conditioning (AC) presents a unique challenge for international B2B buyers. As businesses expand into diverse markets such as Africa, South America, the Middle East, and Europe, understanding the intricacies of EV technology, particularly air conditioning systems, is crucial. The efficiency and comfort of an EV are heavily influenced by its climate control capabilities, which can directly impact user experience and operational costs.

This comprehensive guide delves into the various types of electric vehicles equipped with AC systems, exploring their applications across different sectors. It provides insights into essential considerations such as supplier vetting processes, cost analysis, and the latest technological advancements in EV climate control. By addressing key factors such as energy efficiency, battery management during heating and cooling, and the implications of climate on vehicle performance, this guide empowers B2B buyers to make informed purchasing decisions.

Whether you’re in Saudi Arabia looking for robust performance in extreme heat or in Nigeria considering energy efficiency in urban settings, this resource is tailored to help you navigate the global market effectively. Gain a competitive edge by understanding the nuances of electric vehicles with AC systems, enabling your business to thrive in this dynamic industry.

Understanding electric vehicle with ac Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Battery Electric Vehicle (BEV) | Fully electric, reliant on battery power; no internal combustion engine. | Urban fleet operations, logistics. | Pros: Zero emissions, lower operating costs. Cons: Limited range, longer charging times. |

| Plug-in Hybrid Electric Vehicle (PHEV) | Combines battery power with a traditional internal combustion engine. | Delivery services, mixed-use fleets. | Pros: Extended range, flexibility in fuel usage. Cons: More complex maintenance, higher initial costs. |

| Electric Vehicle with Heat Pump | Utilizes a heat pump for efficient heating and cooling, reducing energy consumption. | Public transport, ride-sharing services. | Pros: Energy-efficient, improved range in moderate climates. Cons: Performance drops in extreme cold. |

| Electric Vehicle with Traditional Heater | Uses resistive heating elements, similar to electric heaters. | Short-distance urban transport, personal use. | Pros: Simple design, effective heating. Cons: Higher energy consumption, reduced range in cold weather. |

| Electric Vehicle with Advanced AC Systems | Incorporates AI and smart technologies for optimized climate control. | Luxury vehicle markets, tech-driven fleets. | Pros: Enhanced comfort, predictive energy management. Cons: Higher costs, potential for technical malfunctions. |

What are the Characteristics of Battery Electric Vehicles (BEVs)?

Battery Electric Vehicles (BEVs) are fully electric vehicles powered exclusively by electric batteries, eliminating the need for fossil fuels. They are ideal for urban fleet operations and logistics due to their zero-emission nature and lower operating costs. B2B buyers should consider the infrastructure for charging stations, as the limited range compared to traditional vehicles can be a challenge for longer routes.

How Do Plug-in Hybrid Electric Vehicles (PHEVs) Benefit Mixed-Use Fleets?

Plug-in Hybrid Electric Vehicles (PHEVs) combine electric and gasoline power, offering greater flexibility and range than BEVs. This makes them particularly suitable for businesses that require a mix of urban and longer-distance travel, such as delivery services. B2B buyers should weigh the initial investment against potential savings in fuel and maintenance, as the dual system can complicate repairs.

Why Choose Electric Vehicles with Heat Pumps for Public Transport?

Electric Vehicles equipped with heat pumps provide efficient heating and cooling by transferring heat rather than generating it. This technology is particularly beneficial for public transport and ride-sharing services, where energy efficiency translates to operational savings. B2B buyers should evaluate climate conditions, as heat pumps perform optimally in moderate temperatures but may struggle in extreme cold.

What are the Advantages of Electric Vehicles with Traditional Heaters?

Electric Vehicles that utilize traditional resistive heating systems are straightforward and effective for heating the cabin. They are often found in short-distance urban transport solutions, making them suitable for personal use or small fleets. Buyers should consider the higher energy consumption of these systems, as they can lead to reduced range during colder months.

How Do Advanced AC Systems Enhance Comfort in Electric Vehicles?

Electric Vehicles with advanced air conditioning systems leverage AI and smart technologies to optimize climate control. These systems are increasingly popular in luxury vehicles and tech-driven fleets, enhancing passenger comfort and energy management. However, B2B buyers should be aware of the higher costs associated with these systems and potential technical complexities that may arise.

Key Industrial Applications of electric vehicle with ac

| Industry/Sector | Specific Application of Electric Vehicle with AC | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation & Logistics | Last-Mile Delivery Services | Reduced operational costs through energy efficiency and improved driver comfort in extreme weather. | Reliability of AC systems under diverse climatic conditions; battery capacity and range. |

| Tourism & Hospitality | Electric Shuttle Services | Enhanced guest experience with climate control while minimizing environmental impact. | Comfort features, charging infrastructure, and maintenance support. |

| Public Sector | Municipal Public Transport | Improved air quality and passenger comfort, supporting sustainability goals. | Compliance with local regulations, serviceability, and total cost of ownership. |

| Agriculture | Farm Operations & Logistics | Efficient transport of goods with temperature-controlled environments for perishables. | Durability of AC systems in dusty environments and energy consumption rates. |

| Construction | On-Site Worker Transportation | Comfortable transport for workers in extreme weather conditions, increasing productivity. | Robustness of AC systems, maintenance services, and local support networks. |

How Are Electric Vehicles with AC Used in Transportation & Logistics?

In the transportation and logistics sector, electric vehicles (EVs) with air conditioning are increasingly utilized for last-mile delivery services. These vehicles provide a comfortable environment for drivers, particularly in regions with extreme temperatures, enhancing driver satisfaction and performance. For international buyers, sourcing vehicles that maintain efficient AC systems despite varying climatic conditions is crucial. Additionally, operational costs can be significantly reduced due to lower energy consumption compared to traditional combustion engines.

What Role Do Electric Vehicles with AC Play in Tourism & Hospitality?

Electric shuttles in the tourism and hospitality industry leverage air conditioning to create pleasant travel experiences for guests. These vehicles not only offer a comfortable ride but also align with eco-friendly practices, appealing to environmentally conscious travelers. Buyers in this sector should focus on the integration of charging infrastructure and the availability of maintenance services to ensure optimal performance and guest satisfaction throughout the year.

Why Are Electric Vehicles with AC Important for Public Sector Initiatives?

Municipal public transport systems are increasingly adopting electric vehicles equipped with air conditioning to enhance passenger comfort and support sustainability initiatives. The use of EVs in public transport improves air quality and reduces noise pollution, which is essential in urban environments. For B2B buyers from public sectors, it is important to consider compliance with local emissions regulations and the total cost of ownership, including maintenance and energy efficiency.

How Do Electric Vehicles with AC Benefit Agricultural Operations?

In agriculture, electric vehicles with air conditioning are used for transporting perishable goods, ensuring they remain at optimal temperatures during transit. This capability helps in maintaining product quality and reducing waste. Buyers in this sector need to prioritize the durability of AC systems, especially in dusty or rural environments, as well as the energy consumption rates to optimize operational costs.

What Advantages Do Electric Vehicles with AC Offer in Construction?

Electric vehicles equipped with air conditioning are essential for transporting workers to construction sites, especially in regions experiencing extreme heat or cold. By providing a comfortable working environment, these vehicles can enhance productivity and worker satisfaction. When sourcing these vehicles, businesses should assess the robustness of the AC systems and the availability of local support services to ensure reliable operation in challenging conditions.

3 Common User Pain Points for ‘electric vehicle with ac’ & Their Solutions

Scenario 1: Inefficient Energy Use During Climate Control

The Problem: B2B buyers often face the challenge of managing energy efficiency in electric vehicles, particularly when using air conditioning systems. The energy consumed by AC units can lead to a significant reduction in vehicle range, especially in extreme weather conditions. This is a critical concern for businesses that rely on electric fleets for logistics or transportation. Buyers must balance the need for passenger comfort with the necessity of maximizing battery life and operational efficiency.

The Solution: To tackle this issue, buyers should consider sourcing electric vehicles equipped with advanced climate control technologies, such as heat pumps. These systems are more energy-efficient than traditional electric heaters, especially in moderate temperatures, thereby reducing overall energy consumption. Additionally, implementing strategies like preconditioning vehicles while they are still plugged into a charger can optimize energy use. This practice not only warms or cools the vehicle before use but also preserves battery power for driving. Buyers should also evaluate options that allow for individual climate settings, enabling drivers to adjust the temperature without overusing the AC system. By prioritizing energy-efficient models and adopting smart climate management practices, businesses can enhance operational efficiency while ensuring passenger comfort.

Scenario 2: Maintenance Costs and System Reliability

The Problem: Another pain point for B2B buyers is the high maintenance costs associated with air conditioning systems in electric vehicles. As these systems are different from traditional combustion engine vehicles, they may require specialized knowledge and parts for repairs. This can lead to extended downtimes and increased operational costs, particularly for businesses with large fleets that require consistent reliability. Buyers may feel pressured to find solutions that minimize maintenance expenses while ensuring their vehicles remain operational.

The Solution: To mitigate maintenance challenges, B2B buyers should invest in electric vehicles from reputable manufacturers that offer comprehensive warranties and service packages. This can significantly reduce out-of-pocket expenses for repairs. Additionally, buyers should seek vehicles with easily accessible components and modular designs that simplify repairs and maintenance. Training fleet technicians on the specific needs and workings of electric vehicle AC systems can further enhance reliability and reduce unexpected failures. Establishing a preventative maintenance schedule, including regular inspections of the AC system, can help identify potential issues before they escalate, ensuring the fleet remains operational and cost-effective.

Scenario 3: Limited Cooling and Heating Performance in Extreme Conditions

The Problem: Many B2B buyers operate in regions with extreme temperatures, whether hot or cold, which can severely impact the performance of electric vehicle air conditioning systems. In hot climates, insufficient cooling can lead to driver discomfort and affect productivity. Conversely, in cold environments, inadequate heating can result in unsafe driving conditions due to fogged or frozen windows. This situation poses a significant risk for companies that rely on electric vehicles for daily operations.

The Solution: Buyers should consider selecting electric vehicles that feature robust climate control systems designed for extreme weather conditions. Models equipped with dual-zone climate control or advanced heat pump technology can provide better temperature regulation, ensuring comfort regardless of external temperatures. Additionally, incorporating thermal insulation materials into the vehicle design can help maintain cabin temperature, reducing the load on the AC system. For businesses operating in particularly harsh climates, conducting a thorough analysis of vehicle performance in local conditions before purchasing can ensure that the selected vehicles meet operational needs. Finally, educating drivers on efficient use of the AC system, such as utilizing economy modes or adjusting settings based on the number of passengers, can enhance performance and comfort while conserving battery life.

Strategic Material Selection Guide for electric vehicle with ac

What Are the Key Materials Used in Electric Vehicle Air Conditioning Systems?

In the realm of electric vehicles (EVs) equipped with air conditioning systems, material selection plays a pivotal role in ensuring optimal performance, durability, and cost-effectiveness. Below, we analyze four common materials used in the construction of air conditioning components, focusing on their properties, advantages, disadvantages, and implications for international buyers.

1. Aluminum: The Lightweight Champion

Key Properties: Aluminum is known for its excellent thermal conductivity, low density, and resistance to corrosion. It can withstand temperatures ranging from -40°C to 120°C, making it suitable for various climates.

Pros & Cons: Aluminum is lightweight, which contributes to overall vehicle efficiency and range. It is also relatively easy to manufacture and can be extruded or cast into complex shapes. However, it can be more expensive than other metals and may require additional treatments to enhance its corrosion resistance in certain environments.

Impact on Application: Aluminum is commonly used in heat exchangers and compressor housings. Its compatibility with refrigerants and ability to dissipate heat effectively make it a preferred choice.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local standards regarding aluminum alloys, such as ASTM or DIN specifications, to guarantee performance under varying climatic conditions.

2. Copper: The Thermal Conductor

Key Properties: Copper boasts exceptional thermal conductivity, making it ideal for heat transfer applications. It can handle high pressures and temperatures, typically rated up to 200°C.

Pros & Cons: Copper’s superior thermal properties enhance the efficiency of air conditioning systems. However, it is heavier than aluminum and can be more expensive, particularly in regions where copper is less abundant. Its susceptibility to corrosion in certain environments can also be a concern.

Impact on Application: Copper is predominantly used in refrigerant lines and heat exchangers due to its ability to efficiently transfer heat. Its compatibility with various refrigerants is a significant advantage.

Considerations for International Buyers: Buyers must consider the availability of copper and its price fluctuations in different regions. Compliance with international standards, such as JIS or ASTM, is crucial for ensuring quality and performance.

3. Plastic Composites: The Versatile Option

Key Properties: Plastic composites offer good thermal insulation properties and are lightweight. They can withstand moderate temperatures but may not be suitable for high-pressure applications.

Pros & Cons: These materials are cost-effective and can be molded into complex shapes, making them ideal for various components, such as housing and ducting. However, they may lack durability compared to metals and can degrade under extreme temperatures or UV exposure.

Impact on Application: Plastic composites are often used in non-structural components of the air conditioning system, such as ducting and casings, where weight savings are essential.

Considerations for International Buyers: Buyers should ensure that the selected plastic composites meet local environmental regulations and standards. In regions with high UV exposure, additional treatments may be necessary to enhance durability.

4. Stainless Steel: The Durable Workhorse

Key Properties: Stainless steel is known for its high strength, corrosion resistance, and ability to withstand high temperatures and pressures. It typically operates effectively in temperatures up to 300°C.

Pros & Cons: Stainless steel is extremely durable and resistant to corrosion, making it suitable for harsh environments. However, it is heavier and more expensive than aluminum and plastic composites, which can impact overall vehicle weight and cost.

Impact on Application: Stainless steel is often used in critical components like compressor housings and high-pressure lines, where strength and durability are paramount.

Considerations for International Buyers: Buyers should be aware of the specific grades of stainless steel that comply with local standards, such as ASTM or DIN, to ensure optimal performance in their specific climate conditions.

Summary Table of Material Selection for Electric Vehicle Air Conditioning Systems

| Material | Typical Use Case for electric vehicle with ac | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Heat exchangers, compressor housings | Lightweight and good thermal conductivity | Higher cost, corrosion treatment needed | Medium |

| Copper | Refrigerant lines, heat exchangers | Exceptional thermal conductivity | Heavier, susceptible to corrosion | High |

| Plastic Composites | Ducting, casings | Cost-effective, moldable | Less durable, temperature limitations | Low |

| Stainless Steel | Compressor housings, high-pressure lines | High strength and corrosion resistance | Heavier, more expensive | High |

This material selection guide provides a comprehensive overview for B2B buyers, enabling informed decisions that align with their operational needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for electric vehicle with ac

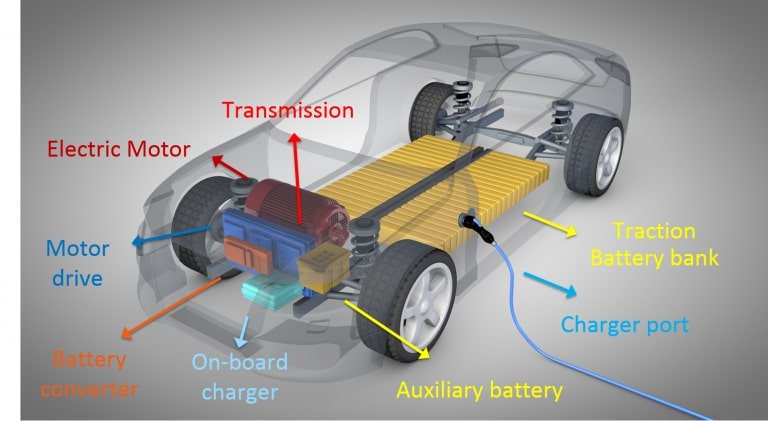

What Are the Main Stages of Manufacturing Electric Vehicles with Air Conditioning?

The manufacturing process of electric vehicles (EVs) equipped with air conditioning (AC) systems involves several critical stages, each requiring specialized techniques and materials. Understanding these stages is essential for B2B buyers looking to source high-quality electric vehicles.

1. Material Preparation: What Raw Materials Are Used in EV Manufacturing?

The first stage involves the careful selection and preparation of materials. Key components include:

- Chassis and Body: Typically made from high-strength steel or aluminum for lightweight and durability.

- Battery Packs: Composed of lithium-ion cells, requiring stringent quality controls due to their safety and performance implications.

- Electrical Components: Includes wiring harnesses, connectors, and control modules, which must meet specific electrical standards.

- HVAC Components: Materials like copper for refrigerant lines and specialized plastics for the AC system are essential.

Material preparation also entails rigorous inspections to ensure that all components meet industry standards, which is crucial for the overall reliability and safety of the vehicle.

2. Forming: How Are the Components Shaped and Assembled?

In the forming stage, raw materials undergo various processes to create the necessary components:

- Stamping: Used for metal parts like body panels, where sheets are formed into specific shapes using high-pressure presses.

- Molding: Plastics used in the HVAC systems are shaped through injection molding techniques to achieve precise dimensions.

- Battery Cell Assembly: This involves stacking and connecting lithium-ion cells in a controlled environment to prevent contamination.

Attention to detail during forming is vital, as even minor imperfections can lead to significant performance issues later in the process.

3. Assembly: What Are the Key Steps in Assembling an Electric Vehicle?

The assembly stage integrates all components into the final vehicle. This process typically follows a structured workflow:

- Chassis Assembly: The vehicle’s frame is constructed first, providing a foundation for the entire build.

- Electrical System Integration: Wiring and electronic components are installed, including the AC system, ensuring that all connections are secure and compliant with electrical standards.

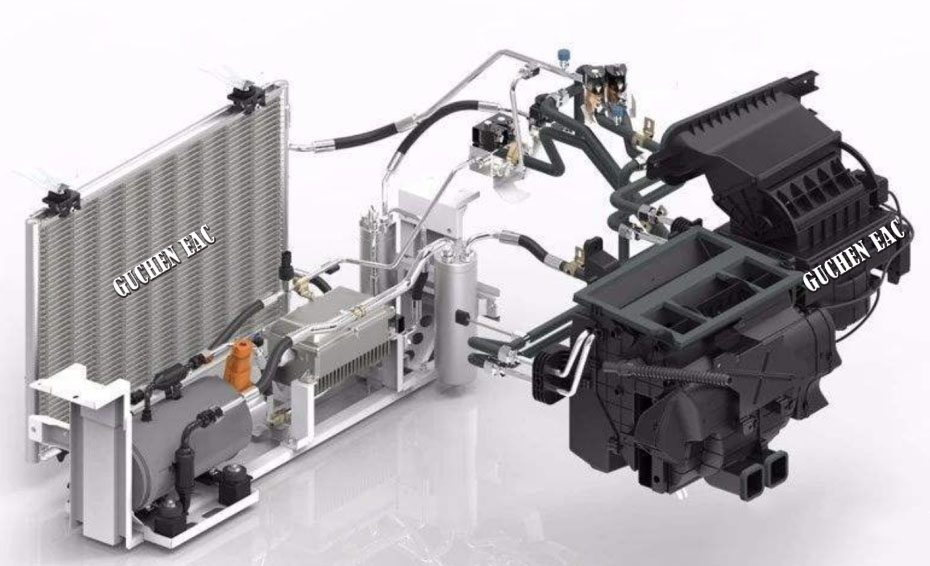

- HVAC System Installation: The air conditioning system is integrated, connecting the compressor, evaporator, and condenser. This step is critical, as any leaks or misalignments can affect performance.

Quality assurance checkpoints are established throughout the assembly process to monitor the integrity and functionality of each component.

4. Finishing: How Are Vehicles Prepared for Quality Assurance?

The finishing stage involves painting, coating, and applying protective layers to the vehicle. This not only enhances aesthetic appeal but also protects against corrosion and wear. The finishing process includes:

- Surface Preparation: Cleaning and priming surfaces to ensure proper paint adhesion.

- Painting: Applying multiple layers of paint, often followed by a curing process to enhance durability.

- Final Inspections: Conducting thorough inspections to check for any defects in the finish or assembly.

What Are the Key Quality Control Measures for Electric Vehicles with AC?

Quality control (QC) is paramount in the manufacturing of electric vehicles, particularly given the complexity of the HVAC systems. Here are key aspects of QC that B2B buyers should consider:

1. What International Standards Should Buyers Be Aware Of?

Electric vehicle manufacturers often adhere to various international standards to ensure product quality and safety. Some of the most relevant include:

- ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements.

- ISO 26262: A standard for functional safety in automotive systems, particularly relevant for electrical and electronic components.

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

Understanding these standards can help buyers assess the credibility and quality of their suppliers.

2. What Are Common QC Checkpoints During Manufacturing?

Quality control checkpoints are implemented at various stages of the manufacturing process:

- Incoming Quality Control (IQC): Inspects raw materials and components upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Conducts checks during the manufacturing stages to identify and rectify issues in real time.

- Final Quality Control (FQC): A comprehensive assessment of the completed vehicle, including functional tests of the AC system and overall performance checks.

These checkpoints help maintain high standards throughout the manufacturing process.

3. What Testing Methods Are Commonly Used?

Several testing methods are employed to ensure the quality and performance of electric vehicles with AC systems:

- Functional Testing: Verifying that the AC system operates correctly under various conditions.

- Leak Testing: Checking refrigerant lines and components for leaks, crucial for system efficiency and safety.

- Environmental Testing: Simulating different weather conditions to assess the performance of HVAC systems in extreme temperatures.

Such rigorous testing protocols are essential for building trust with international B2B buyers.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying the quality control measures of potential suppliers is critical in ensuring product reliability. Here are actionable steps:

- Supplier Audits: Conduct on-site audits to assess the manufacturing processes and QC practices of suppliers.

- Quality Assurance Reports: Request detailed reports outlining the QC measures, test results, and compliance with relevant standards.

- Third-Party Inspections: Engage independent inspection services to evaluate the quality of products before shipment.

What Are the QC and Certification Nuances for International Buyers?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality certification:

- Regional Compliance: Different regions may have unique regulations and standards. Understanding these can help in sourcing compliant products.

- Documentation: Ensure that all quality certifications and test reports are well-documented and readily available.

- Cultural Considerations: Building strong relationships with suppliers can facilitate better communication regarding quality expectations and standards.

By taking these factors into account, B2B buyers can enhance their sourcing strategies and ensure they acquire high-quality electric vehicles with robust air conditioning systems.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric vehicle with ac’

The following guide serves as a practical checklist for B2B buyers interested in procuring electric vehicles (EVs) equipped with air conditioning (AC) systems. By following these steps, buyers can ensure they make informed decisions that align with their operational needs and regional considerations.

Step 1: Define Your Technical Specifications

Establish clear technical requirements for the electric vehicle and its air conditioning system. Consider factors such as cooling capacity, energy efficiency ratings, and the type of heating system (electric heater vs. heat pump) that best suits your climate. This clarity will help you identify models that meet your specific operational requirements.

Step 2: Assess Energy Efficiency and Range

Evaluate the energy efficiency of the vehicle’s AC system, as it directly impacts the overall range of the electric vehicle. Look for vehicles with advanced AC technologies, such as heat pumps, which can offer better performance in moderate temperatures. Understanding the energy consumption of the AC system is essential to ensure the vehicle meets your range expectations.

Step 3: Evaluate Supplier Credentials

Before committing to a supplier, conduct thorough due diligence. Request documentation on their certifications, manufacturing standards, and compliance with international quality norms. Additionally, seek references from other B2B buyers in your region to gauge supplier reliability and product performance.

Step 4: Review Maintenance and Support Options

Investigate the maintenance requirements and support services offered by the supplier. An efficient air conditioning system requires regular servicing, so assess whether the supplier provides adequate support, including warranty terms, spare parts availability, and service networks in your region. This will help ensure long-term operational efficiency.

Step 5: Analyze the Total Cost of Ownership

Consider the total cost of ownership (TCO) when evaluating different models. This includes not only the initial purchase price but also maintenance costs, energy consumption, and potential government incentives for electric vehicles. A lower upfront cost might not always translate to savings in the long run, so a holistic financial analysis is crucial.

Step 6: Conduct Field Trials and Testing

If possible, arrange for test drives or field trials of shortlisted electric vehicles. This hands-on experience allows you to assess comfort, AC performance, and overall driving experience in real-world conditions. Pay attention to how the AC system performs under various weather scenarios, as this will impact user satisfaction.

Step 7: Stay Informed About Industry Trends

Keep abreast of technological advancements and regulatory changes in the electric vehicle market. Innovations in AC systems, such as improved refrigerants and energy management systems, can greatly enhance vehicle performance. Regularly review industry publications and attend trade shows to stay informed about the latest developments.

By following this checklist, B2B buyers can navigate the complexities of sourcing electric vehicles with air conditioning systems effectively, ensuring they make choices that align with their operational needs and regional requirements.

Comprehensive Cost and Pricing Analysis for electric vehicle with ac Sourcing

What Are the Key Cost Components for Electric Vehicles with Air Conditioning?

Understanding the cost structure of electric vehicles (EVs) equipped with air conditioning (AC) systems is essential for B2B buyers looking to make informed procurement decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The core materials for EVs include high-capacity batteries, electric motors, and advanced air conditioning components such as compressors and heat pumps. The choice of refrigerants, insulation materials, and other electronic components significantly impacts the overall cost.

-

Labor: Labor costs involve skilled technicians for assembly and installation of both the vehicle and its AC system. The complexity of integrating advanced technologies, including AI-driven climate control systems, can lead to higher labor expenses.

-

Manufacturing Overhead: This encompasses utilities, maintenance, and facility costs associated with production. As manufacturers invest in more efficient processes and sustainable practices, these overhead costs can fluctuate.

-

Tooling: The initial setup for production lines, including molds and machinery for AC components, represents a significant capital expenditure. Tooling costs can vary based on the customization level of the AC systems.

-

Quality Control (QC): Ensuring that both the EV and its AC system meet stringent international standards requires robust QC processes. This includes testing for energy efficiency, safety, and performance, which adds to the cost.

-

Logistics: Shipping and handling costs are particularly relevant for international buyers. Factors such as distance, mode of transport, and customs duties will influence the final price.

-

Margin: Profit margins for manufacturers and suppliers typically range from 10% to 20%, depending on market dynamics and competition.

What Influences Pricing for Electric Vehicles with AC Systems?

Several factors affect the pricing of electric vehicles with air conditioning systems, which B2B buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to discounts. Negotiating MOQs can significantly reduce per-unit costs.

-

Specifications and Customization: Custom features in AC systems, such as advanced climate control technology or specific refrigerants, can increase costs. Buyers should clearly define their specifications to avoid unexpected expenses.

-

Material Quality and Certifications: The type of materials used and the certifications held by suppliers (such as ISO or environmental certifications) can impact both cost and reliability. Premium materials may lead to higher initial costs but can reduce long-term maintenance expenses.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may command higher prices due to their quality assurance and after-sales support.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers in shipping, which can affect overall costs.

What Are Some Effective Buyer Tips for Cost-Efficient Sourcing?

B2B buyers can leverage several strategies to optimize their purchasing process:

-

Negotiation: Always negotiate terms with suppliers. Establishing long-term relationships can lead to better pricing and favorable terms.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with energy consumption, maintenance, and potential resale value.

-

Pricing Nuances for International Buyers: Buyers in regions like Africa, South America, the Middle East, and Europe should be aware of local market conditions, tariffs, and currency fluctuations that can affect pricing. Understanding these nuances can aid in making informed purchasing decisions.

-

Conduct Market Research: Regularly assess market trends and pricing benchmarks to ensure competitiveness and avoid overpaying.

-

Establish Clear Specifications: Providing precise specifications can help suppliers deliver accurate quotes and reduce the risk of hidden costs.

Disclaimer on Indicative Prices

It is essential to note that pricing for electric vehicles with air conditioning systems can vary widely based on the aforementioned factors. Prospective buyers should conduct thorough research and seek multiple quotes to ensure they are getting the best value for their investment.

Alternatives Analysis: Comparing electric vehicle with ac With Other Solutions

Introduction to Alternatives for Electric Vehicles with AC

As businesses increasingly seek sustainable transportation solutions, the electric vehicle (EV) equipped with air conditioning systems has emerged as a popular choice. However, various alternatives exist that can also meet the needs of B2B buyers, particularly in regions with diverse climatic conditions. This analysis explores viable alternatives, focusing on their performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Electric Vehicle With AC | Hybrid Vehicle | Traditional Internal Combustion Engine (ICE) Vehicle |

|---|---|---|---|

| Performance | High efficiency, quiet operation, but limited range in extreme temperatures | Good fuel efficiency, extended range with gasoline | High power output, but lower fuel efficiency and higher emissions |

| Cost | Higher upfront costs; lower operating costs due to less maintenance | Moderate upfront costs; variable operating costs depending on fuel prices | Lower initial costs; higher long-term fuel and maintenance costs |

| Ease of Implementation | Requires charging infrastructure, best for urban settings | Easier to implement; uses existing fuel infrastructure | Widely available infrastructure; no need for new investments |

| Maintenance | Lower maintenance requirements; fewer moving parts | More complex due to dual systems (electric and combustion) | Higher maintenance due to engine complexity and emissions systems |

| Best Use Case | Ideal for urban environments; short to medium distances | Suitable for mixed driving conditions; long-distance travel | Best for long-distance travel in areas with limited charging stations |

Detailed Breakdown of Alternatives

Hybrid Vehicle

Hybrid vehicles combine an internal combustion engine with an electric motor, offering a versatile solution for businesses. The dual-power system allows for better fuel efficiency and flexibility, making hybrids suitable for mixed driving conditions. However, they require more maintenance due to their complex systems. While they are easier to implement than full EVs, their reliance on fuel can lead to variable operating costs based on market prices.

Traditional Internal Combustion Engine (ICE) Vehicle

Traditional ICE vehicles are still prevalent in many markets due to their lower initial costs and established infrastructure. They offer high power output and are effective for long-distance travel, particularly in regions with limited electric charging options. However, they come with higher long-term costs due to fuel consumption and maintenance, alongside significant environmental concerns due to emissions. As such, they may not be the most sustainable choice for businesses looking to reduce their carbon footprint.

Conclusion: Choosing the Right Solution for Your Business Needs

When selecting the right vehicle solution, B2B buyers must consider their specific operational requirements, environmental goals, and budget constraints. Electric vehicles with AC systems offer significant advantages in urban settings, particularly for companies prioritizing sustainability. However, for businesses operating in mixed driving conditions or those requiring longer ranges, hybrid vehicles may provide a balanced approach. Traditional ICE vehicles remain a viable option in regions where charging infrastructure is lacking, but their environmental impact and operating costs are increasingly scrutinized. Ultimately, the decision should align with the company’s strategic goals and operational realities, ensuring a sustainable and cost-effective transportation solution.

Essential Technical Properties and Trade Terminology for electric vehicle with ac

What Are the Critical Technical Properties of Electric Vehicles with Air Conditioning?

When considering electric vehicles (EVs) equipped with air conditioning (AC), several technical properties are essential for B2B buyers to understand. These properties can significantly affect the vehicle’s performance, energy efficiency, and overall user experience.

-

Cooling Capacity (BTU/Hr)

Cooling capacity refers to the amount of heat the AC system can remove from the vehicle’s interior per hour, typically measured in British Thermal Units (BTU/hr). This property is crucial for maintaining passenger comfort, especially in hot climates. For international buyers, understanding the cooling capacity helps ensure that the AC system will perform adequately in their specific regional climate conditions. -

Energy Efficiency Ratio (EER)

The Energy Efficiency Ratio measures the cooling output of an air conditioning system relative to the energy consumed, typically expressed in BTU/hr per watt. Higher EER ratings indicate more efficient systems, which can lead to lower operational costs and extended driving range for electric vehicles. B2B buyers should prioritize high EER ratings to maximize energy savings and enhance the vehicle’s sustainability profile. -

Refrigerant Type

The type of refrigerant used in the AC system can significantly affect both environmental impact and efficiency. Common refrigerants include R134a and R1234yf, with the latter being more environmentally friendly due to its lower global warming potential. Buyers should consider the refrigerant type as part of their procurement decisions to ensure compliance with local regulations and sustainability goals. -

Heating Capacity (kW)

Similar to cooling capacity, heating capacity indicates how much heat the system can produce, measured in kilowatts (kW). This is particularly important in regions with colder climates where effective heating is necessary for comfort and safety. Understanding the heating capacity helps buyers assess whether the vehicle will meet their needs in various weather conditions. -

Compressor Type

The type of compressor used in the AC system—whether it’s a variable speed or fixed speed compressor—affects the system’s performance and energy consumption. Variable speed compressors adjust their output based on cooling demand, offering better energy efficiency and comfort. Buyers should evaluate the compressor type to align with their operational requirements and energy efficiency goals.

What Are Common Trade Terms Related to Electric Vehicles with Air Conditioning?

Familiarity with industry jargon is essential for effective communication and negotiation in the electric vehicle market. Here are several key terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that manufactures products that are marketed by another company under its brand name. In the context of EVs, OEMs often supply critical components, including air conditioning systems. B2B buyers should engage with reliable OEMs to ensure quality and compliance with industry standards. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for buyers to manage inventory and procurement costs effectively. It also helps in negotiating bulk purchase agreements, which can lead to better pricing. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing information for specific products or services. Issuing RFQs is a common practice in B2B transactions and helps buyers compare prices and terms from different suppliers, ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs. Understanding Incoterms is crucial for B2B buyers to avoid misunderstandings and ensure smooth logistics when procuring electric vehicles. -

TCO (Total Cost of Ownership)

TCO refers to the comprehensive assessment of all costs associated with owning and operating a vehicle over its lifetime, including purchase price, maintenance, fuel (or electricity), and depreciation. Buyers should analyze TCO to make informed decisions that align with their long-term budget and operational goals.

By grasping these technical properties and trade terms, B2B buyers can enhance their procurement strategies, optimize their investments, and improve the overall performance of electric vehicles equipped with air conditioning systems.

Navigating Market Dynamics and Sourcing Trends in the electric vehicle with ac Sector

What Are the Current Market Dynamics and Key Trends in the Electric Vehicle with AC Sector?

The electric vehicle (EV) market, particularly concerning air conditioning (AC) systems, is undergoing significant transformation, driven by global sustainability goals, technological advancements, and shifting consumer preferences. Key drivers include the increasing demand for cleaner transportation solutions, government incentives for EV adoption, and the need for enhanced passenger comfort. B2B buyers from regions like Africa, South America, the Middle East, and Europe must be aware of these dynamics to make informed sourcing decisions.

Emerging trends highlight a focus on energy-efficient HVAC systems, particularly heat pumps, which offer substantial energy savings compared to traditional heating methods. These systems can operate efficiently in various climates, making them ideal for diverse markets. Additionally, the integration of smart technologies, such as AI and IoT, is revolutionizing how AC systems are managed within electric vehicles, allowing for better energy consumption monitoring and improved user experience.

International buyers should also consider the rising importance of local manufacturing and sourcing partnerships. As supply chains evolve, companies that establish relationships with regional suppliers can better navigate logistics challenges and benefit from reduced lead times. The growing trend towards modular and scalable components presents opportunities for businesses to customize their offerings based on regional climate needs, thereby enhancing market competitiveness.

How Does Sustainability and Ethical Sourcing Impact the Electric Vehicle with AC Sector?

Sustainability is at the forefront of the electric vehicle sector, particularly regarding the sourcing of materials for AC systems. B2B buyers must prioritize ethical supply chains that minimize environmental impact and promote responsible sourcing practices. The production of refrigerants, components, and materials used in air conditioning systems can have significant ecological footprints. Therefore, companies that engage in sustainable practices not only comply with regulations but also enhance their brand reputation and appeal to environmentally conscious consumers.

The importance of ‘green’ certifications is paramount in this context. Certifications such as ISO 14001 for environmental management and the Global Reporting Initiative (GRI) standards provide frameworks for companies to demonstrate their commitment to sustainability. Sourcing materials that are recyclable or produced through low-impact methods can also significantly reduce the overall environmental footprint of electric vehicles.

Moreover, implementing transparent supply chains allows businesses to track the sustainability of their materials, ensuring compliance with international environmental standards. This transparency is increasingly demanded by consumers and regulatory bodies alike, making it crucial for B2B buyers to prioritize suppliers who can provide verifiable sustainability credentials.

What Is the Evolution of Air Conditioning in Electric Vehicles?

The evolution of air conditioning in electric vehicles has been marked by a shift from conventional heating methods to more efficient and sustainable technologies. Initially, electric vehicles relied on simple electric resistive heaters, which, while effective, significantly drained battery life. The introduction of heat pump technology represents a turning point, allowing for more efficient temperature regulation by utilizing ambient heat.

Over the years, innovations have continued, with manufacturers integrating advanced cooling systems that not only enhance comfort but also optimize energy consumption. These developments are particularly relevant for international markets, where varying climates require tailored solutions for passenger comfort and vehicle efficiency. As the industry progresses, the focus on energy-efficient AC systems will be crucial for the success of electric vehicles in the global market.

This evolution not only addresses passenger comfort but also aligns with the broader objectives of reducing emissions and promoting sustainability within the automotive sector. B2B buyers should keep abreast of these advancements to make strategic sourcing decisions that align with market needs and environmental standards.

Frequently Asked Questions (FAQs) for B2B Buyers of electric vehicle with ac

-

1. How do I solve the issue of electric vehicle range in hot climates?

To address range concerns in hot climates, consider electric vehicles equipped with advanced air conditioning systems, such as heat pumps, which are more energy-efficient. Additionally, ensure that your fleet includes models with higher battery capacities to withstand the demands of hot weather. Implementing pre-conditioning strategies, where vehicles are cooled while still connected to a charger, can also help conserve battery life during active use. Regular maintenance of the AC system is essential to ensure optimal performance, enhancing both comfort and efficiency. -

2. What is the best air conditioning system for electric vehicles?

The best air conditioning system for electric vehicles typically combines both traditional refrigerant-based systems and heat pump technology. Heat pumps are particularly advantageous for their ability to efficiently heat and cool the cabin while consuming less energy than conventional systems. Look for systems that allow operation while the vehicle is parked, as this can greatly enhance comfort without depleting battery reserves. Evaluating the energy consumption and efficiency ratings of various models can guide you in making the best choice for your fleet. -

3. What should I consider when vetting suppliers for electric vehicles?

When vetting suppliers for electric vehicles, consider their track record in the industry, focusing on their experience with AC systems specifically. Request product specifications, certifications, and customer references to assess reliability. Evaluate their compliance with international standards, especially regarding safety and environmental regulations. Additionally, inquire about their after-sales support, warranty terms, and availability of spare parts to ensure long-term serviceability of the vehicles. -

4. What are the typical minimum order quantities (MOQ) for electric vehicles?

Minimum order quantities for electric vehicles can vary significantly based on the manufacturer and the specific model. Generally, MOQs can range from a few units to several dozen, depending on the supplier’s production capacity and demand. It’s advisable to negotiate MOQs, especially if you are a new buyer or are exploring a customized fleet. Always clarify terms upfront to avoid misunderstandings and to assess whether the supplier can accommodate your purchasing needs. -

5. What payment terms are commonly offered by electric vehicle suppliers?

Payment terms for electric vehicle purchases can vary widely; however, many suppliers offer options such as net 30, 60, or 90 days, depending on the buyer’s creditworthiness and the order size. Some manufacturers may require a deposit upfront, with the balance due upon delivery. It’s essential to review and negotiate these terms to align with your cash flow requirements. Additionally, inquire about any financing options or trade-in programs that may be available. -

6. How can I ensure quality assurance for electric vehicles purchased internationally?

To ensure quality assurance for internationally sourced electric vehicles, establish clear quality standards and specifications before purchase. Request detailed documentation on the manufacturing process, including quality control measures and testing protocols. It’s beneficial to conduct factory audits or inspections, if feasible, to verify compliance with your quality expectations. Additionally, consider third-party inspection services to provide an unbiased assessment of the vehicles before they are shipped. -

7. What logistics considerations should I keep in mind when importing electric vehicles?

When importing electric vehicles, consider logistics factors such as shipping methods, customs clearance, and transportation costs. Ensure that your supplier provides information on shipping timelines and can navigate the complexities of international shipping regulations. Be aware of local laws regarding the importation of electric vehicles, including taxes and tariffs. Collaborating with a logistics partner experienced in automotive imports can streamline the process and minimize delays. -

8. What customization options are available for electric vehicles with AC?

Customization options for electric vehicles with AC often include enhancements to the air conditioning system, such as upgraded compressors or advanced climate control features. Additionally, consider options for battery size, interior finishes, and technology integrations like smart climate control systems. Discuss your specific requirements with suppliers to explore available configurations that meet your fleet’s operational needs. Customization can enhance both vehicle performance and driver comfort, making it a worthwhile investment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Electric Vehicle With Ac Manufacturers & Suppliers List

1. Knauf Automotive – EV Climate Control Systems

Domain: knaufautomotive.com

Registered: 2017 (8 years)

Introduction: Air conditioning and heating systems in electric vehicles (EVs) are designed to maintain cabin temperature for comfort and safety. Key components include: 1. **Refrigerant**: Circulates through the system, changing states to provide cooling or heating. 2. **Compressor**: Powered by the EV’s battery, it compresses the refrigerant and operates independently of the engine. 3. **Heat Pump**: An altern…

2. NeuralConcept – Electric Car Air Conditioning Systems

Domain: neuralconcept.com

Registered: 2018 (7 years)

Introduction: The air conditioning system in electric cars is essential for maintaining a controlled temperature and humidity level, ensuring passenger comfort, filtering out pollutants, and preventing condensation on windows for enhanced safety. It operates based on thermodynamics, utilizing a refrigeration cycle that includes key components such as the AC compressor, condenser, expansion valve, evaporator, an…

3. Cars – EV Range Impact in Hot Weather

Domain: cars.usnews.com

Registered: 1995 (30 years)

Introduction: In hot weather, air conditioning drains an EV’s range. The AC typically uses less power than the onboard resistance heater and will significantly impact range only when temperatures reach 85 degrees Fahrenheit. At 80 degrees, the AC drains 2.8% of the total range; at 90 degrees, it’s 5%; and at 100 degrees, the drain can be as high as 31%. A study by AAA found that 95 degrees outside translates to…

4. GEM – Integrated HVAC System for LSVs

Domain: gemcar.com

Registered: 1998 (27 years)

Introduction: GEM HVAC is an integrated heating, ventilation, and air conditioning system available on GEM’s low-speed vehicles (LSVs) including models e2, e4, e6, and eL XD. Key features include:

– In-cab heat with three dash integrated vents and in-windshield defrost with wiper and washer.

– Removable hard doors with roll-up windows.

– Fully integrated heat and AC systems that charge with the vehicle.

– High…

5. Green Cars – EV Range Loss Insights

Domain: greencars.com

Registered: 1998 (27 years)

Introduction: Electric vehicles (EVs) experience range loss when running air conditioning (AC) in hot weather. Key findings include:

– At 80 degrees Fahrenheit, average range loss is about 2.8%.

– At 90 degrees Fahrenheit, average range loss is about 5%.

– Limited data suggests range loss at 100 degrees could be as high as 31%.

– Cooling the cabin is less energy-intensive than heating it, as EVs do not gene…

6. Eric’s Car Care – Efficient EV Air Conditioning

Domain: ericscarcare.com

Registered: 2021 (4 years)

Introduction: Electric cars (EVs) have a more efficient air conditioning system compared to traditional vehicles. Key features include: 1. Electric Compressor: Operates independently from the car’s motor, allowing constant cooling without interruption. 2. High Voltage Battery: Powers the electric compressor, providing smooth and efficient service. 3. Heat Pump System: Economical, using less energy than conventi…

7. My Jack Frost – Electric Vehicle Air Conditioning System

Domain: myjackfrost.com.au

Introduction: Electric Vehicle Air Conditioning System: 1. Functionality: Cools/heats cabin and regulates battery temperature. 2. Power Source: Operates on stored battery energy; no combustion engine. 3. Compressor: Driven by an electric motor integrated into the high-voltage network. 4. Battery Cooling: Essential for performance and longevity; operates best between 20°C and 25°C. 5. Cooling Methods: Air coolin…

8. Recurrent Auto – EV Range Impact in Hot Weather

Domain: recurrentauto.com

Registered: 2020 (5 years)

Introduction: Study on how hot summer weather affects EV range, based on real-world data from 29,716 electric cars. Key findings include: minimal range loss at 90F (5%), significant range loss at 100F (17-18%). EVs with heat pumps show slightly higher range loss at high temperatures. Recommendations for protecting EVs in heat include avoiding low states of charge, keeping charged to at least 50%, and parking in…

9. Classic Retrofit – Electric Air Conditioning for Classic 911

Domain: classicretrofit.com

Registered: 2011 (14 years)

Introduction: Electric Air Conditioning – Classic Retrofit

1. Classic Retrofit Electric Air Conditioning for Classic 911 (single condenser) – $5,607.00 + VAT

2. Classic Retrofit Electric Air Conditioning for Classic 911 (dual condenser) – $5,967.00 + VAT

3. Classic Retrofit Electric Air Conditioning for Porsche 964 and 993 (two condensers) – From $4,887.00

4. Classic Retrofit Electric Air Conditioning for Clas…

Strategic Sourcing Conclusion and Outlook for electric vehicle with ac

As the electric vehicle (EV) market continues to evolve, the integration of advanced air conditioning (AC) systems becomes increasingly vital for enhancing user experience and vehicle performance. B2B buyers should prioritize sourcing high-quality components that improve energy efficiency and ensure optimal climate control. Understanding the differences in AC technologies—such as traditional compressors versus heat pumps—enables companies to make informed purchasing decisions that align with their operational needs and market demands.

Strategic sourcing in this sector not only reduces operational costs but also contributes to sustainability goals, appealing to environmentally conscious consumers. As regions like Africa, South America, the Middle East, and Europe ramp up their EV infrastructure, the demand for reliable and efficient AC systems will surge.

Looking ahead, international buyers are encouraged to engage with innovative manufacturers and suppliers who prioritize cutting-edge technologies and sustainability in their offerings. By investing in these partnerships, businesses can position themselves at the forefront of the electric vehicle revolution, meeting the growing demand for comfort, safety, and performance in EVs. Embrace this opportunity to lead the charge toward a sustainable future in the automotive industry.