Introduction: Navigating the Global Market for heavy Duty Lifter

In the fast-paced world of heavy-duty lifting solutions, sourcing reliable equipment that meets operational demands can be a formidable challenge for international B2B buyers. Whether you are looking for heavy-duty lifters to facilitate the movement of oversized machinery or specialized tools for lifting heavy furniture, understanding the nuances of the global market is crucial. This guide serves as an essential resource, offering an in-depth analysis of various types of heavy-duty lifters, their applications across different industries, and insights into supplier vetting processes that ensure quality and reliability.

The scope of this guide encompasses a wide array of lifting equipment, including hydraulic lifts, pallet jacks, and specialized load lifters, tailored to meet the diverse needs of businesses in Africa, South America, the Middle East, and Europe. Buyers will gain valuable insights into cost considerations, maintenance requirements, and the latest technological advancements in lifting solutions. By empowering B2B buyers with actionable information, this guide facilitates informed purchasing decisions, helping businesses optimize their operations and enhance productivity.

Navigating the global market for heavy-duty lifters can be complex, but with the right knowledge and tools at your disposal, you can successfully identify and procure the equipment that best aligns with your operational needs and budget.

Understanding heavy Duty Lifter Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Heavy Duty Vehicle Lifts | Designed for lifting heavy vehicles; hydraulic operation | Automotive workshops, fleet maintenance | Pros: Efficient, safe lifting; Cons: High initial investment. |

| Heavy Duty Load Lifters | Adjustable bail positions; robust steel construction | Construction, shipping, and logistics | Pros: Versatile for uneven loads; Cons: Requires overhead lifting equipment. |

| Heavy Duty Mixer Lifts | Soft-close features; holds appliances up to 60 lbs | Commercial kitchens, food service | Pros: Space-saving design; Cons: Limited to specific appliance types. |

| Electric Pallet Jacks | Battery-operated; high lifting capacity | Warehousing, distribution centers | Pros: Reduces manual labor; Cons: Battery maintenance needed. |

| Heavy Duty Furniture Lifters | Lightweight, portable; ideal for moving heavy furniture | Furniture retailers, moving companies | Pros: Easy to use; Cons: Limited weight capacity compared to industrial options. |

What Are Heavy Duty Vehicle Lifts and Their Applications?

Heavy duty vehicle lifts are essential tools for automotive workshops and fleet maintenance facilities, designed specifically to elevate heavy vehicles such as trucks and buses. Utilizing hydraulic systems, these lifts provide a safe and efficient means to perform repairs and maintenance. When considering a purchase, buyers should evaluate the lift’s weight capacity, safety features, and compatibility with their service area dimensions. The initial investment may be significant, but the long-term benefits in efficiency and safety often justify the cost.

How Do Heavy Duty Load Lifters Function in Various Industries?

Heavy duty load lifters are engineered for lifting awkward and unevenly sized loads, making them indispensable in construction and logistics sectors. These devices typically feature adjustable bail positions and are constructed from durable steel, ensuring reliability under heavy use. B2B buyers must consider the compatibility of these lifters with their existing overhead lifting devices, as well as the specific load requirements of their operations. The versatility of these lifters is a key advantage, though they necessitate additional equipment for optimal functionality.

What Makes Heavy Duty Mixer Lifts Ideal for Commercial Kitchens?

Heavy duty mixer lifts are specifically designed to support kitchen appliances, such as mixers, with a weight capacity of up to 60 lbs. Their innovative features, including soft-close mechanisms, enhance user safety and convenience, making them popular in commercial kitchens and food service operations. When purchasing, businesses should assess the lift’s dimensions to ensure it fits within their cabinetry and workflow. While these lifts are space-efficient, their application is limited to specific appliances, which may not suit all kitchen setups.

Why Choose Electric Pallet Jacks for Warehousing Needs?

Electric pallet jacks are a preferred choice in warehousing and distribution centers due to their ability to handle heavy loads with minimal manual effort. These battery-operated devices provide significant lifting capacity, allowing for efficient movement of goods. Buyers should consider the battery life, maintenance requirements, and overall durability of the equipment when making a selection. While they reduce physical strain on workers, the need for regular battery upkeep can be a drawback for some operations.

How Do Heavy Duty Furniture Lifters Assist in Moving Heavy Items?

Heavy duty furniture lifters are practical tools for furniture retailers and moving companies, designed to facilitate the transport of heavy items with ease. Their lightweight and portable design allows for quick setup and operation, making them user-friendly for staff. When considering these lifters, buyers should evaluate their weight capacity and the specific needs of their operations. Although they offer ease of use, their lifting capacity may not match that of industrial-grade options, which could limit their application in heavier lifting tasks.

Key Industrial Applications of heavy Duty Lifter

| Industry/Sector | Specific Application of heavy Duty Lifter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Lifting and positioning heavy machinery and parts | Increases efficiency and safety in operations | Load capacity, durability, and compliance with safety standards |

| Construction | Moving heavy construction materials on-site | Reduces manual labor and risk of injury | Weather resistance, portability, and adaptability to various loads |

| Logistics & Warehousing | Handling heavy pallets and freight | Streamlines inventory management | Space requirements, ease of use, and maintenance needs |

| Automotive | Lifting vehicles for repair and maintenance | Enhances service speed and technician safety | Weight capacity, stability, and compatibility with vehicle types |

| Oil & Gas | Moving heavy equipment and tools in remote locations | Improves operational efficiency in harsh environments | Corrosion resistance, mobility, and load handling capabilities |

How is a Heavy Duty Lifter Used in Manufacturing?

In manufacturing, heavy duty lifters are essential for lifting and positioning large machinery and components. They help streamline assembly lines by allowing workers to lift heavy parts with minimal manual effort, significantly reducing the risk of workplace injuries. Buyers in this sector should focus on lifters with high load capacities and robust construction to ensure reliability under continuous use. Additionally, compliance with local safety regulations is crucial, especially for international buyers in regions like Africa and Europe, where standards may vary.

What Role Does a Heavy Duty Lifter Play in Construction?

In the construction industry, heavy duty lifters facilitate the movement of substantial materials, such as steel beams and concrete blocks. These devices reduce the reliance on manual labor, thus mitigating the risk of injuries associated with heavy lifting. Construction firms must consider factors like portability and weather resistance in their purchasing decisions, particularly when working in diverse climates across South America and the Middle East. Ensuring the lifter can handle various load types and sizes is also vital for project efficiency.

How Does a Heavy Duty Lifter Enhance Logistics and Warehousing Operations?

Heavy duty lifters are pivotal in logistics and warehousing, where they assist in the efficient handling of heavy pallets and freight. By automating the lifting process, these devices enhance inventory management and minimize downtime. Buyers should evaluate the space requirements of the lifters and their ease of operation, especially in crowded warehouses. Maintenance needs and long-term durability are also critical, particularly for businesses in Europe and Africa where logistics operations can be extensive and demanding.

In What Ways is a Heavy Duty Lifter Beneficial for Automotive Services?

In the automotive sector, heavy duty lifters are used to raise vehicles for repair and maintenance, allowing technicians to work safely and efficiently. The ability to lift various vehicle types, from cars to trucks, is essential, and buyers should prioritize stability and weight capacity when sourcing these devices. Safety features are also paramount, as they protect both the vehicle and the technician during repairs. International buyers, especially from regions like Germany, should ensure compliance with local safety standards for automotive service equipment.

How Do Heavy Duty Lifters Support Operations in the Oil and Gas Industry?

In the oil and gas sector, heavy duty lifters are crucial for moving heavy equipment and tools, particularly in remote or harsh environments. These lifters enhance operational efficiency by allowing for quick and safe transportation of materials, which is vital for maintaining productivity. Buyers in this field should consider corrosion resistance and mobility, as equipment often faces challenging conditions. Additionally, understanding the specific load handling capabilities required for various operations is essential for effective sourcing.

3 Common User Pain Points for ‘heavy Duty Lifter’ & Their Solutions

Scenario 1: Difficulty in Handling Heavy and Awkward Loads

The Problem: Many businesses, particularly in manufacturing and warehousing, encounter challenges when lifting heavy and awkwardly shaped items. These loads can be difficult to maneuver, leading to potential safety hazards and inefficiencies in workflow. Workers may struggle to lift items manually, risking injuries and causing delays. Moreover, inadequate lifting equipment can result in damage to products, further complicating operations and increasing costs.

The Solution: To effectively handle heavy and awkward loads, businesses should invest in specialized heavy-duty lifters designed for uneven and irregular shapes. When sourcing these products, consider options that feature adjustable bail positions and robust construction, such as those made from high-strength steel. It’s crucial to ensure that the lifters are compatible with existing overhead lifting devices. Additionally, training employees on proper lifting techniques and equipment usage is essential to maximize safety and efficiency. By integrating these lifters into daily operations, companies can streamline their processes, reduce the risk of injury, and improve overall productivity.

Scenario 2: Inconsistent Performance and Reliability Issues

The Problem: B2B buyers often face issues with the performance and reliability of heavy-duty lifting equipment. Inconsistent lifting capabilities can lead to operational disruptions, as equipment may fail to perform as expected under varying loads. This unpredictability not only affects workflow but can also lead to costly downtime and repairs, impacting the bottom line.

The Solution: To mitigate reliability concerns, buyers should prioritize sourcing heavy-duty lifters from reputable manufacturers known for their quality and durability. Look for equipment that features advanced technology such as built-in shock dampeners and adjustable spring tension, which can enhance performance consistency. Regular maintenance and inspection schedules should also be established to ensure the equipment operates optimally over time. Additionally, consider purchasing equipment that comes with a warranty and reliable customer support, as this can provide peace of mind and assistance in case of unexpected issues.

Scenario 3: High Initial Investment and Cost Management

The Problem: The initial investment for heavy-duty lifters can be significant, posing a challenge for budget-conscious businesses, particularly in developing regions. Many companies may hesitate to invest in high-quality lifting equipment due to concerns about upfront costs, which can lead to using inferior products that compromise safety and efficiency. This reluctance can ultimately hinder growth and operational effectiveness.

The Solution: To manage costs while still acquiring high-quality lifting equipment, buyers should explore financing options or leasing arrangements that can spread out the investment over time. Additionally, conducting a thorough cost-benefit analysis can help justify the initial expenditure by highlighting potential savings from reduced labor costs, increased efficiency, and minimized injury risks. It is also beneficial to consider purchasing from manufacturers that offer scalable solutions, allowing businesses to start with essential models and upgrade as needs grow. Building relationships with suppliers can lead to negotiated discounts for bulk purchases or long-term contracts, further enhancing cost management strategies.

Strategic Material Selection Guide for heavy Duty Lifter

When selecting materials for heavy-duty lifters, it is essential to consider the properties, advantages, and limitations of commonly used materials. This analysis will focus on four materials: Steel, Aluminum, Composite Materials, and Plastic. Each material has unique characteristics that can significantly impact the performance and suitability of heavy-duty lifting equipment in various industrial applications.

What Are the Key Properties of Steel for Heavy Duty Lifters?

Steel is the most widely used material for heavy-duty lifters due to its exceptional strength and durability. It boasts a high tensile strength, making it suitable for lifting heavy loads with minimal deformation. Steel also has excellent temperature and pressure ratings, allowing it to withstand extreme conditions without compromising integrity. However, its susceptibility to corrosion can be a drawback, particularly in humid or chemically aggressive environments.

Pros: Steel offers high durability, excellent load-bearing capacity, and is relatively cost-effective compared to other metals. It is also widely available and can be easily sourced globally.

Cons: The primary disadvantage of steel is its weight, which can make handling and transportation cumbersome. Additionally, it requires protective coatings in corrosive environments, which can increase manufacturing complexity and costs.

How Does Aluminum Compare as a Material for Heavy Duty Lifters?

Aluminum is another popular choice for heavy-duty lifters, particularly in applications where weight is a critical factor. It is significantly lighter than steel, which enhances mobility and ease of use. Aluminum also exhibits good corrosion resistance, making it suitable for outdoor applications or environments with moisture.

Pros: The lightweight nature of aluminum allows for easier handling and transport. Its resistance to corrosion reduces maintenance needs, making it a cost-effective option over time.

Cons: Aluminum has a lower tensile strength compared to steel, which may limit its load-bearing capacity. It is also generally more expensive than steel, which could impact budget considerations for international buyers.

What Role Do Composite Materials Play in Heavy Duty Lifters?

Composite materials, often made from a combination of fibers and resins, are increasingly being used in heavy-duty lifters due to their unique properties. They can be engineered to provide specific performance characteristics, such as high strength-to-weight ratios and excellent corrosion resistance.

Pros: Composites can be tailored for specific applications, offering versatility in design. They are lightweight, which improves handling and reduces the overall weight of lifting equipment.

Cons: The manufacturing process for composites can be complex and costly, which may deter some buyers. Additionally, composites may not be suitable for applications requiring high-temperature resistance.

Why Are Plastics Considered for Heavy Duty Lifters?

Plastics are less common in heavy-duty lifting applications but can be used in specific contexts, such as for components that require lightweight and corrosion-resistant properties. Certain high-performance plastics can withstand moderate loads and are resistant to chemicals.

Pros: Plastics are lightweight and resistant to corrosion, making them suitable for specific environments. They also offer lower manufacturing costs and can be produced in various shapes and sizes.

Cons: Plastics generally have lower load-bearing capabilities compared to metals, which limits their use in heavy-duty applications. They may also be susceptible to deformation under high loads or extreme temperatures.

Considerations for International B2B Buyers

When selecting materials for heavy-duty lifters, international buyers must consider compliance with local standards and regulations. For instance, buyers in Europe may need to adhere to DIN standards, while those in the United States may follow ASTM guidelines. Buyers from Africa and South America should also be aware of local manufacturing capabilities and material availability. Understanding these factors can help ensure that the selected material meets both performance requirements and regulatory compliance.

| Material | Typical Use Case for heavy Duty Lifter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Industrial lifting equipment | High strength and durability | Heavy and prone to corrosion | Medium |

| Aluminum | Mobile lifting devices | Lightweight and corrosion-resistant | Lower load capacity than steel | High |

| Composite | Specialized lifting applications | Customizable and lightweight | Complex manufacturing process | High |

| Plastic | Light-duty lifting components | Low cost and corrosion-resistant | Limited load capacity | Low |

This analysis provides a comprehensive overview of material options for heavy-duty lifters, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for heavy Duty Lifter

What Are the Main Stages in the Manufacturing Process of Heavy Duty Lifters?

The manufacturing process of heavy-duty lifters typically involves several key stages: material preparation, forming, assembly, and finishing.

Material Preparation: The initial stage focuses on selecting high-quality raw materials, often steel or aluminum, known for their strength and durability. Materials are cut to size using precision tools, ensuring they meet the specific dimensions required for the lifter design. This phase also includes quality checks to ensure that the materials are free from defects.

Forming: During this stage, the prepared materials undergo various forming techniques such as bending, stamping, or machining. Advanced technologies like CNC (Computer Numerical Control) machines are often employed to achieve precise shapes and tolerances. This precision is critical for ensuring the lifters can handle the heavy loads they are designed for.

Assembly: The assembly stage involves bringing together the various components of the lifter, including hydraulic systems, safety mechanisms, and structural elements. Skilled technicians typically oversee this process to ensure that each part fits together seamlessly. Attention to detail during assembly is crucial to maintain the structural integrity and functionality of the lifter.

Finishing: The final stage includes surface treatment processes such as painting, galvanizing, or powder coating. These treatments enhance corrosion resistance and improve the aesthetic appeal of the lifters. Additionally, final inspections and tests are conducted to ensure that the finished products meet all operational standards and customer specifications.

What Quality Control Measures Are Essential in Heavy Duty Lifter Manufacturing?

Quality assurance in heavy-duty lifter manufacturing is critical to ensure safety and reliability. Companies often adhere to international standards such as ISO 9001, which focuses on quality management systems, and industry-specific standards like CE marking for compliance in the European market and API standards for lifting equipment.

Quality Control Checkpoints: Several checkpoints are essential in the quality control process:

– Incoming Quality Control (IQC): This step involves inspecting raw materials and components as they arrive at the manufacturing facility. This initial check helps identify any defects before production begins.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process ensures that each stage meets quality standards. This includes real-time inspections and testing of critical dimensions and specifications.

– Final Quality Control (FQC): Before products leave the facility, final inspections are conducted. This includes functional testing of the lifters to ensure they can safely support the intended loads.

How Can B2B Buyers Verify Quality Control Standards and Practices of Suppliers?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is vital to ensure product reliability.

Supplier Audits: One effective method is to conduct supplier audits. This involves visiting the manufacturing facility to assess the quality management systems in place. Audits can reveal whether the supplier adheres to international standards and industry best practices.

Quality Reports and Certifications: Requesting detailed quality reports and certifications from suppliers is another important step. Documentation such as ISO certifications, CE marking, or API compliance can provide insights into the supplier’s commitment to quality. Buyers should look for regular updates and reports that document quality checks and any corrective actions taken.

Third-Party Inspections: Engaging third-party inspection services can add an additional layer of assurance. These independent entities can verify that the manufacturing process and final products meet the specified standards. This is particularly valuable for international transactions, where buyers may not be able to visit the supplier’s facility.

What Common Testing Methods Are Used in Quality Assurance for Heavy Duty Lifters?

Testing methods play a crucial role in ensuring that heavy-duty lifters are safe and effective. Common testing methods include:

Load Testing: This involves applying a load to the lifter to verify its lifting capacity. Load tests are often conducted at or above the rated capacity to ensure that the lifter can handle expected loads without failure.

Functional Testing: This type of testing checks the operational features of the lifter, including hydraulic systems, safety locks, and controls. Functional tests ensure that all systems work correctly and safely.

Durability Testing: Lifters may also undergo durability testing, simulating extended use to assess wear and tear. This is particularly important for B2B buyers who need assurance that their equipment will last under heavy use.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers should be aware of certain nuances in quality control when sourcing heavy-duty lifters.

Regulatory Compliance: Different regions have varying regulatory requirements. For instance, products sold in Europe must comply with CE marking, while in the United States, ANSI and OSHA standards may apply. Buyers must ensure that their suppliers are familiar with and compliant with the regulations applicable to their specific markets.

Cultural Differences in Quality Perception: Quality standards and expectations may vary across cultures. B2B buyers from Europe may have different expectations compared to those from Africa or South America. Understanding these differences can help buyers communicate their needs more effectively and select suppliers that align with their quality expectations.

Supply Chain Considerations: The global supply chain can impact quality assurance. Buyers should consider the entire supply chain, from material sourcing to final assembly, and ensure that each link in the chain adheres to the required quality standards. This holistic approach can help mitigate risks associated with quality issues.

By understanding the manufacturing processes and quality assurance measures for heavy-duty lifters, B2B buyers can make informed decisions when selecting suppliers. This knowledge not only enhances their purchasing strategy but also ensures that they receive reliable and safe lifting equipment tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘heavy Duty Lifter’

This guide serves as a practical resource for international B2B buyers seeking to procure heavy-duty lifters. Sourcing the right lifting equipment is crucial for ensuring operational efficiency, safety, and cost-effectiveness in various industries. Follow this checklist to make informed decisions throughout the procurement process.

Step 1: Define Your Technical Specifications

Before you begin sourcing, it’s essential to clearly define the technical specifications of the heavy-duty lifter you need. Consider the maximum load capacity, lifting height, and the type of materials the lifter will be used with. This clarity will help you streamline your search and ensure you acquire equipment that meets your operational requirements.

Step 2: Research Market Trends and Innovations

Stay informed about the latest trends and innovations in lifting equipment. This knowledge can help you identify products that enhance efficiency, such as those with hydraulic systems or advanced safety features. Understanding market dynamics also aids in predicting pricing fluctuations and availability, particularly in different regions like Africa and Europe.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request company profiles, product catalogs, and references from other businesses in similar industries. Look for suppliers with a proven track record of reliability and customer service, as well as those who adhere to international safety standards.

- Check for Certifications: Ensure that the supplier holds relevant industry certifications, which can indicate quality and compliance with safety regulations.

- Read Reviews: Look for customer testimonials or case studies that highlight the supplier’s performance and service reliability.

Step 4: Request Product Samples or Demonstrations

If feasible, request samples or demonstrations of the lifters you are considering. This step allows you to assess the quality, functionality, and ease of use of the equipment firsthand. Observing how the lifter operates in real-world conditions can provide invaluable insights into its suitability for your specific needs.

Step 5: Analyze Pricing and Total Cost of Ownership

When comparing different suppliers, focus not just on the initial purchase price but also on the total cost of ownership. This includes maintenance costs, warranty terms, and potential downtime costs associated with equipment failure. Understanding the long-term financial implications will help you make a more informed decision.

Step 6: Negotiate Terms and Conditions

Once you have identified a preferred supplier, negotiate the terms of your purchase. Discuss pricing, delivery timelines, payment terms, and warranties in detail. Clear communication at this stage can prevent misunderstandings later and ensure that both parties are aligned on expectations.

Step 7: Plan for Training and Implementation

After purchasing your heavy-duty lifter, plan for training sessions for your staff. Proper training ensures that operators understand how to use the equipment safely and efficiently. Additionally, consider establishing a maintenance schedule to prolong the equipment’s lifespan and optimize performance.

By following this checklist, you can enhance your procurement process for heavy-duty lifters and ensure that you select equipment that aligns with your operational goals and safety standards.

Comprehensive Cost and Pricing Analysis for heavy Duty Lifter Sourcing

What Are the Key Cost Components in Heavy Duty Lifter Pricing?

When sourcing heavy-duty lifters, understanding the cost structure is vital for making informed decisions. The primary cost components include:

-

Materials: The choice of materials significantly influences the price. Steel is commonly used for its strength and durability, but variations like aluminum or composite materials can alter costs based on specific requirements.

-

Labor: Labor costs encompass the workforce involved in production, assembly, and quality control. This can vary by region; for instance, labor costs in Europe may differ significantly from those in Africa or South America.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and equipment depreciation. These costs are often factored into the final pricing.

-

Tooling: Tooling costs relate to the equipment and molds needed for production. Custom tooling for specialized lifters may lead to higher upfront costs but can yield better efficiencies and lower long-term expenses.

-

Quality Control (QC): Ensuring that lifters meet safety and performance standards requires investment in quality assurance processes. Certifications may also add to the cost but are essential for international compliance.

-

Logistics: The cost of transporting lifters from the manufacturer to the buyer can vary widely based on distance, shipping methods, and import duties. Understanding local regulations is crucial for estimating these costs accurately.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and risks. This margin can vary based on the supplier’s reputation, the exclusivity of the product, and market demand.

What Factors Influence Heavy Duty Lifter Pricing?

Several factors can influence the pricing of heavy-duty lifters, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs due to economies of scale. Negotiating MOQ can lead to better pricing structures.

-

Specifications and Customization: Custom features or specifications can increase costs. Buyers should assess whether these features are essential for their operations to avoid unnecessary expenses.

-

Material Quality and Certifications: Higher-quality materials and recognized certifications can elevate costs but also ensure durability and safety. Buyers should weigh the benefits of these factors against their budget constraints.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can significantly affect pricing. Established suppliers may offer higher prices due to reliability and quality assurance.

-

Incoterms: Understanding Incoterms is crucial for international transactions, as they define the responsibilities of buyers and sellers regarding shipping and handling costs. Selecting the right Incoterm can lead to significant savings.

How Can Buyers Negotiate for Better Pricing on Heavy Duty Lifters?

Negotiation is a critical aspect of sourcing heavy-duty lifters. Here are some strategies:

-

Leverage Volume Discounts: Buyers should consider combining orders across multiple projects or collaborating with other companies to meet higher volume thresholds, which can unlock significant discounts.

-

Discuss Custom Specifications: If custom features are not essential, discussing standard options can result in lower prices. Suppliers may have existing stock of standard models that can be offered at reduced rates.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on upfront costs, buyers should consider TCO, which includes maintenance, operational costs, and potential downtime. This approach can justify higher initial investments for more reliable products.

-

Understand Regional Pricing Nuances: Pricing can vary significantly based on region due to local demand, labor costs, and material availability. Buyers from Africa, South America, the Middle East, and Europe should consider these factors when negotiating.

What Should International Buyers Consider Regarding Pricing Nuances?

International buyers face unique challenges that can impact pricing:

-

Currency Fluctuations: Exchange rates can affect the total cost of procurement. Buyers should monitor currency trends to make timely purchasing decisions.

-

Import Duties and Taxes: Understanding local customs regulations is essential to avoid unexpected costs. Buyers should factor these into their overall budget.

-

Shipping Times and Costs: International shipping can introduce delays and additional costs. Buyers should discuss these aspects with suppliers to establish realistic timelines and budgets.

Disclaimer on Pricing

Prices for heavy-duty lifters can vary based on multiple factors, including market conditions and supplier negotiations. The figures provided in various sources are indicative and should be verified with suppliers for accuracy. Buyers are encouraged to conduct thorough research and engage in discussions with multiple suppliers to achieve the best possible pricing.

Alternatives Analysis: Comparing heavy Duty Lifter With Other Solutions

Introduction: Understanding Alternatives to Heavy Duty Lifters

In the realm of material handling, heavy-duty lifters are indispensable for lifting, moving, and transporting large and heavy items. However, businesses often need to evaluate various alternatives to determine the most effective solution for their specific operational requirements. This analysis will compare heavy-duty lifters with other viable lifting solutions, including furniture lifters and hydraulic lift tables. By examining these alternatives, B2B buyers can make informed decisions that align with their operational needs and budget constraints.

Comparison Table

| Comparison Aspect | Heavy Duty Lifter | Furniture Lifter | Hydraulic Lift Table |

|---|---|---|---|

| Performance | High load capacity (up to 6,600 lbs) | Moderate load capacity (up to 800 lbs) | Variable load capacity (up to 2,200 lbs) |

| Cost | Higher initial investment | Lower initial investment | Moderate initial investment |

| Ease of Implementation | Requires space and setup | Simple to use, no setup required | Requires setup, but easy to operate |

| Maintenance | Moderate; regular checks needed | Low; minimal maintenance | Moderate; periodic hydraulic checks |

| Best Use Case | Industrial settings, heavy machinery lifting | Home and office moves | Warehousing, assembly lines |

Detailed Breakdown of Alternatives

Furniture Lifter

Furniture lifters are manual tools designed to assist in the movement of heavy furniture and appliances. They typically consist of a lever and a set of pads that help to lift items off the ground, making it easier for a small team to maneuver them.

Pros:

– Cost-Effective: Generally, furniture lifters are less expensive than heavy-duty lifters, making them accessible for small businesses or individual users.

– Ease of Use: They require no complex setup and can be operated by anyone, reducing training time.

Cons:

– Load Capacity Limitations: Most furniture lifters can only handle loads up to around 800 lbs, which may not suffice for heavier applications.

– Manual Operation: They require physical effort, which can lead to fatigue or injury if not used correctly.

Hydraulic Lift Table

Hydraulic lift tables utilize hydraulic mechanisms to raise and lower heavy items, making them an excellent option for warehouses and assembly lines. They provide a stable platform for lifting goods, enhancing ergonomics and safety.

Pros:

– Variable Load Capacity: Hydraulic lift tables can accommodate a range of weights, making them versatile for different lifting tasks.

– Improved Ergonomics: They can be adjusted to the desired height, reducing strain on workers when loading or unloading goods.

Cons:

– Moderate Cost: While they are cost-effective for large operations, the initial investment can be significant for smaller businesses.

– Setup Required: Hydraulic lift tables require space and some setup, which might not be feasible for all businesses.

Conclusion: Choosing the Right Lifting Solution

When selecting a lifting solution, B2B buyers must assess their specific needs, including load capacity, budget, and operational efficiency. Heavy-duty lifters excel in industrial environments where heavy machinery is frequently handled. In contrast, furniture lifters may serve well for smaller-scale operations, while hydraulic lift tables offer flexibility and ergonomic benefits in high-volume settings. Ultimately, the right choice will depend on the unique requirements of each business, including the types of loads to be moved, the working environment, and long-term operational goals. By carefully considering these factors, companies can invest in the most suitable lifting solution to enhance productivity and safety in their operations.

Essential Technical Properties and Trade Terminology for heavy Duty Lifter

What Are the Key Technical Properties of a Heavy Duty Lifter?

When selecting a heavy-duty lifter, several technical specifications are critical for ensuring optimal performance, durability, and safety. Here are some essential properties to consider:

-

Material Grade

The material used in the construction of a heavy-duty lifter significantly affects its strength and longevity. Common materials include high-tensile steel and aluminum alloys, which offer high load-bearing capacities and resistance to wear. For B2B buyers, understanding material grades helps ensure they are investing in equipment that meets their operational demands and can withstand the rigors of industrial environments. -

Load Capacity

This specification indicates the maximum weight the lifter can safely handle. Load capacities can range from a few hundred pounds to several tons, depending on the model. For businesses, accurately assessing load capacity is crucial to prevent equipment failure, accidents, and damage to goods, thereby protecting both personnel and investment. -

Adjustable Features

Many heavy-duty lifters come with adjustable components, such as height or width, to accommodate various loads and working conditions. Features like adjustable spring tension in mixer lifts or hand-crank bail adjustments in load lifters enhance versatility. For international buyers, this adaptability can lead to more efficient operations across diverse applications and environments. -

Safety Features

Incorporating safety mechanisms such as overload protection, emergency stop buttons, and soft-close systems is vital in preventing accidents. These features not only ensure compliance with safety regulations but also foster a culture of safety within organizations. B2B buyers should prioritize lifters with robust safety features to minimize risks associated with heavy lifting. -

Mobility and Stability

A lifter’s design should promote both ease of movement and stability during operation. Features like swivel casters, non-slip grips, and a wide base enhance mobility while ensuring the lifter remains stable under load. For businesses, mobility can improve workflow efficiency, while stability is crucial for safe operation in busy environments. -

Finish and Corrosion Resistance

The surface finish of a heavy-duty lifter, often painted or galvanized, plays a key role in preventing corrosion, especially in industries exposed to moisture or chemicals. A durable finish extends the equipment’s lifespan and reduces maintenance costs. For B2B buyers, selecting lifters with high-quality finishes can lead to lower total cost of ownership over time.

Which Common Trade Terms Should B2B Buyers Know?

Understanding industry jargon can streamline communications and negotiations. Here are some common terms relevant to heavy-duty lifters:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components that are sold under another company’s brand name. In the context of heavy-duty lifters, knowing the OEM can help buyers assess the quality and reliability of the product. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity a supplier is willing to sell. Understanding MOQ is essential for buyers to ensure they can meet their purchasing needs without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For buyers, issuing an RFQ is a critical step in the procurement process, enabling comparison across different suppliers. -

Incoterms

These are international commercial terms that define the responsibilities of buyers and sellers in global trade. Familiarity with Incoterms is crucial for B2B buyers to understand shipping costs, risks, and delivery obligations. -

Lead Time

This term refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times helps businesses plan their operations and inventory management more effectively. -

Certification Standards

Certifications, such as ISO or CE, indicate that a product meets specific safety and quality standards. For B2B buyers, prioritizing certified products ensures compliance with regulations and builds trust in the supplier’s commitment to quality.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when purchasing heavy-duty lifters, ensuring they meet both operational requirements and safety standards.

Navigating Market Dynamics and Sourcing Trends in the heavy Duty Lifter Sector

What Are the Current Market Dynamics and Key Trends in the Heavy Duty Lifter Sector?

The heavy-duty lifter market is experiencing significant growth, driven by an increase in industrial activities and infrastructure development globally. Key trends include the rise of automation and digitalization in manufacturing processes, which necessitate advanced lifting solutions. B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly looking for equipment that not only meets their operational needs but also enhances efficiency and safety. The demand for innovative lifting equipment, such as electric lifters and automated solutions, is on the rise as companies seek to reduce labor costs and improve productivity.

Moreover, the integration of IoT technology in lifting devices is transforming the sector. IoT-enabled lifters allow for real-time monitoring and data analytics, enabling businesses to optimize operations and reduce downtime. In addition, there is a growing emphasis on ergonomics and safety features, such as soft-close mechanisms and adjustable settings, to protect workers and enhance usability. As industries strive for greater efficiency, these emerging technologies will play a crucial role in shaping purchasing decisions for international buyers.

How Does Sustainability and Ethical Sourcing Impact the Heavy Duty Lifter Market?

In today’s B2B landscape, sustainability is more than just a buzzword; it is a critical factor influencing purchasing decisions. For heavy-duty lifters, the environmental impact of materials and production processes is under scrutiny. Buyers are increasingly favoring suppliers who prioritize eco-friendly practices, such as using recyclable materials and minimizing carbon footprints during manufacturing.

Ethical sourcing is also gaining traction, with a focus on ensuring fair labor practices throughout the supply chain. International buyers are looking for certifications that demonstrate a commitment to sustainability and ethical standards, such as ISO 14001 for environmental management and Fair Trade certifications. By choosing suppliers with these credentials, businesses not only fulfill their corporate social responsibilities but also align with the values of their customers, thereby enhancing their brand reputation.

What Is the Historical Context of the Heavy Duty Lifter Sector?

The heavy-duty lifter sector has evolved significantly over the past few decades. Initially, lifting equipment was primarily mechanical, relying on manual operation and simple lever systems. As industries grew and the demand for efficiency increased, the introduction of hydraulic and pneumatic lifters revolutionized the market, allowing for heavier loads and greater lifting heights.

In recent years, technological advancements have led to the development of electric and automated lifting devices. This evolution reflects broader trends in industrial automation and digitalization, which are reshaping operational paradigms across various sectors. As the market continues to innovate, international B2B buyers are presented with a range of options that cater to modern operational needs, emphasizing the importance of adaptability and technological integration in sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of heavy Duty Lifter

-

How do I choose the right heavy-duty lifter for my business needs?

Selecting the right heavy-duty lifter involves assessing your specific lifting requirements, such as load capacity, lifting height, and the type of materials you typically handle. Consider the weight of the heaviest item you’ll lift, as well as the dimensions and shape of your loads. Additionally, evaluate the workspace where the lifter will be used—tight spaces may require a more compact model. Engaging with manufacturers or suppliers for detailed specifications and recommendations can also help ensure you make an informed decision. -

What is the best lifting equipment for heavy machinery in industrial settings?

The best lifting equipment for heavy machinery typically includes hydraulic lifts, overhead cranes, and fork lifts, depending on the application. Hydraulic lifts are ideal for precise lifting and lowering, while overhead cranes are essential for moving heavy loads across a factory floor. Forklifts provide versatility in transporting items over short distances. It’s crucial to consider factors like load capacity, reach, and maneuverability to select the most suitable equipment for your industrial needs. -

What should I consider when vetting suppliers for heavy-duty lifters?

When vetting suppliers, assess their reputation, experience, and product quality. Look for suppliers with industry certifications and compliance with international safety standards. Request references from previous clients and evaluate customer feedback to gauge reliability. Additionally, inquire about their after-sales support, warranty policies, and availability of replacement parts. Establishing a relationship with a supplier who understands your regional market, particularly in areas like Africa or South America, can enhance service quality. -

What are typical payment terms when purchasing heavy-duty lifting equipment internationally?

Payment terms can vary widely among suppliers but generally include options like advance payment, letters of credit, or payment upon delivery. It’s common for international transactions to require a deposit (often 30-50%) before production, with the balance payable upon shipment or delivery. Ensure that the terms are clearly defined in the purchase agreement to avoid any misunderstandings. Discussing payment terms upfront can help establish trust and facilitate smoother transactions. -

What is the minimum order quantity (MOQ) for heavy-duty lifters?

The minimum order quantity for heavy-duty lifters varies by supplier and product type. Some manufacturers may offer MOQs as low as one unit, especially for standard models, while others may require larger orders for custom or specialized equipment. It’s advisable to communicate your requirements with potential suppliers early in the negotiation process to understand their policies and explore options for smaller orders if necessary. -

How do I ensure the quality of heavy-duty lifting equipment?

To ensure quality, request certifications and test reports from suppliers that demonstrate compliance with safety and performance standards. Conduct thorough inspections upon receipt of the equipment, checking for defects or damage. It may also be beneficial to inquire about the manufacturing processes and materials used. Establishing a quality assurance agreement with the supplier can provide additional peace of mind regarding the durability and reliability of the lifters. -

What logistics considerations should I keep in mind when importing lifting equipment?

When importing lifting equipment, consider factors such as shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder who understands international shipping requirements and can handle customs clearance efficiently. Additionally, factor in delivery timelines, especially for heavy equipment, as transport logistics can impact your operational schedule. Ensure all documentation, including invoices and certificates of origin, is correctly prepared to prevent delays at customs. -

Can heavy-duty lifters be customized to meet specific operational needs?

Yes, many manufacturers offer customization options for heavy-duty lifters to suit specific operational requirements. Customizations can include modifications to load capacity, dimensions, or additional features like remote controls or specialized attachments. Engaging in a detailed discussion with suppliers about your unique needs can lead to tailored solutions that enhance productivity and safety in your operations. Be prepared to provide specifications and any relevant operational challenges to facilitate the customization process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Heavy Duty Lifter Manufacturers & Suppliers List

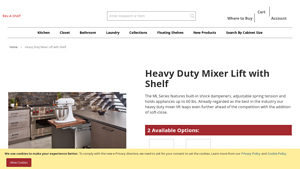

1. Rev-A-Shelf – Heavy Duty Mixer Lift

Domain: rev-a-shelf.com

Registered: 1995 (30 years)

Introduction: Heavy Duty Mixer Lift with Shelf from the ML Series features built-in shock dampeners, adjustable spring tension, and can hold appliances up to 60 lbs. It includes a soft-close mechanism and is regarded as the best in the industry. Available options: ML-MPHDSCCR-18 and ML-WNHDSCOG-18FL. The product is not yet available for purchase. Specifications include: ML-MPHDSCCR-18 with a minimum cabinet ope…

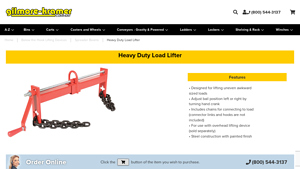

2. Gilmore Kramer – Heavy Duty Load Lifter

Domain: gilmorekramer.com

Registered: 2001 (24 years)

Introduction: {“product_name”: “Heavy Duty Load Lifter”, “model_number”: “HDLL-15”, “chain_length”: “42 inches”, “overall_size”: “25 1/2 inches x 12 1/2 inches x 7 9/16 inches”, “capacity”: “1500 lbs”, “weight”: “18 lbs”, “price”: “$116.07”, “features”: [“Designed for lifting uneven awkward sized loads”, “Adjust bail position left or right by turning hand crank”, “Includes chains for connecting to load (connect…

3. Heavy Duty Furniture Lifter – Moving Made Easy

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Heavy Duty Furniture Lifter, includes 4 sliders for moving, designed for easy and safe moving, supports up to 220 lbs, various listings available with prices ranging from $9.99 to $29.77, free delivery options, open box condition, multiple sellers with different offers.

4. Lifting Equipment Store – Portable Load Lifters

Domain: liftingequipmentstore.us

Registered: 2018 (7 years)

Introduction: Portable Load Lifters available from Lifting Equipment Store USA include various models such as Manual Portable Lifters, Battery-Powered Lifts, and Compact Machine Lifters. Key products include: 1. Vestil Manual & DC Work Positioners – From $897.34 2. Vestil Hydra Carts – From $979.21 3. Vestil Powered Quick Lifts – From $2,314.47 4. Vestil Heater Tank Lift Truck – $1,408.67 5. Vestil Portable Wor…

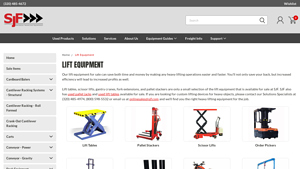

5. SJF – Lift Equipment for Sale

Domain: shop.sjf.com

Registered: 1996 (29 years)

Introduction: Lift Equipment for Sale includes various categories such as Lift Tables (Manual and Electric), Pallet Stackers, Scissor Lifts, Order Pickers, Lift Platforms, Forklift Forks & Extensions, Motorcycle Lifts, Gantry Cranes, Hoists & Trollies, and Jibs. The site also features a range of other equipment including Carts, Conveyors, Dock Equipment, Drum Handling tools, Forklift Accessories, Floor Cleaning…

6. Heavy Duty – Furniture Lifter with Sliders

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Heavy Duty Furniture Lifter with 4 Sliders for Easy Moving, Appliance Roller Suitable for Sofas, Couches and Refrigerators, Adjustable Height, Load Capacity: 660 lbs. Includes 4 lifting pads and an adjustable frame that fits under most furniture or appliances. Designed to prevent scuff marks on floors and reduce back pain from lifting heavy objects.

7. Stertil-Koni – Heavy Duty Vehicle Lifts

Domain: stertil-koni.com

Registered: 1997 (28 years)

Introduction: Stertil-Koni offers a broad range of heavy duty vehicle lifts including: mobile column lifts, inground piston lifts, scissor lifts, 2-post lifts, 4-post lifts, and platform lifts. They are recognized as the leader in advanced, safe, and dependable heavy duty vehicle lifting systems suitable for buses and trucks. Key features include award-winning designs, innovative solutions like the Compressed A…

Strategic Sourcing Conclusion and Outlook for heavy Duty Lifter

In the competitive landscape of heavy-duty lifting solutions, strategic sourcing emerges as a critical factor for international B2B buyers. By leveraging quality products from reputable manufacturers, businesses can ensure safety, efficiency, and durability in their operations. Key takeaways include the importance of understanding the specific lifting requirements, considering load capacities, and evaluating supplier reliability. The integration of advanced technologies, such as soft-close mechanisms and adjustable spring tensions, can significantly enhance operational efficiency and user satisfaction.

For buyers in regions like Africa, South America, the Middle East, and Europe, forming strategic partnerships with trusted suppliers not only mitigates risks but also fosters innovation in lifting solutions. As global supply chains evolve, staying informed about market trends and product advancements will be paramount.

Looking ahead, the demand for heavy-duty lifters is poised for growth, driven by industrial expansion and technological advancements. We encourage international buyers to explore the diverse offerings available and engage with suppliers who prioritize quality and service. Taking proactive steps today will position your business for success in tomorrow’s market.