Introduction: Navigating the Global Market for handicap cabin closed vehicles

Navigating the complexities of sourcing handicap cabin closed vehicles can be a daunting task for international B2B buyers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe. The challenge lies not only in identifying the right vehicle type that meets accessibility needs but also in ensuring compliance with local regulations, understanding market trends, and evaluating the reliability of suppliers. This guide is designed to empower you with the insights necessary to make informed purchasing decisions in this evolving market.

Within this comprehensive guide, we delve into various types of handicap cabin closed vehicles, including minivans and SUVs, and their specific applications tailored for different user needs. We will also provide strategic tips on supplier vetting processes, highlighting key factors to consider, such as product quality, service reliability, and after-sales support. Additionally, we will explore cost considerations and financing options to help you navigate budget constraints effectively.

By equipping you with actionable insights and industry knowledge, this guide aims to streamline your procurement process, ensuring that you can confidently select the best handicap cabin closed vehicles for your organization. Whether you are looking to enhance mobility solutions for your customers or seeking to expand your fleet, our guide will serve as a valuable resource in your decision-making journey.

Understanding handicap cabin closed vehicles Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Side-Entry Wheelchair Vans | Ramp deployment from the side; spacious interior; often features power in-floor ramps. | Transportation services, healthcare facilities | Pros: Easy access, spacious; Cons: Requires more parking space. |

| Rear-Entry Wheelchair Vans | Ramp deployment from the rear; typically more compact; manual or powered options available. | Shuttle services, personal use | Pros: More compact; Cons: Less interior space. |

| Wheelchair Accessible SUVs | Higher ground clearance; adaptable seating arrangements; often includes advanced safety features. | Family transport, tourism, emergency services | Pros: Versatile for various passengers; Cons: Generally more expensive. |

| Manual Wheelchair Accessible Vehicles | Manual ramps; often less costly; suitable for users with a companion. | Budget-conscious buyers, small transport firms | Pros: Cost-effective; Cons: Requires physical effort. |

| Luxury Wheelchair Accessible Vehicles | High-end finishes; advanced technology; customizable features. | Corporate transport, high-end mobility services | Pros: Premium comfort and style; Cons: Higher initial investment. |

What are Side-Entry Wheelchair Vans and Their B2B Benefits?

Side-entry wheelchair vans are designed for optimal accessibility, featuring ramps that deploy from the side of the vehicle. This design allows for a spacious interior that can accommodate larger wheelchairs and multiple passengers. They are particularly suitable for transportation services and healthcare facilities, where ease of access is critical. B2B buyers should consider factors such as ramp weight capacity and interior dimensions when selecting a side-entry van, as these features directly impact usability and comfort for clients.

How Do Rear-Entry Wheelchair Vans Differ in Functionality?

Rear-entry wheelchair vans offer a more compact solution, with ramps that deploy from the rear of the vehicle. These vehicles are ideal for shuttle services and personal use where space is limited. While they may not provide as much interior space as side-entry models, their compact size allows for easier maneuverability in urban environments. Buyers should evaluate the ramp deployment mechanism and overall vehicle length to ensure it meets their operational needs.

Why Choose Wheelchair Accessible SUVs for Diverse Applications?

Wheelchair accessible SUVs combine the ruggedness of traditional SUVs with features that facilitate wheelchair access. These vehicles often include removable front seats and spacious cargo areas, making them suitable for family transport, tourism, and emergency services. Their higher ground clearance can be a significant advantage in regions with uneven terrain. B2B buyers should consider the SUV’s engine power, safety features, and adaptability when making a purchasing decision, as these factors will affect operational efficiency.

What are the Advantages of Manual Wheelchair Accessible Vehicles?

Manual wheelchair accessible vehicles are designed with cost-effectiveness in mind, featuring manual ramps that are easy to deploy. These vehicles are suitable for budget-conscious buyers and small transport firms that may not require high-tech solutions. While they can be less convenient than powered options, they offer a reliable and straightforward solution for users who have companions. Buyers should assess the ease of ramp operation and the vehicle’s overall durability when considering a manual option.

How Do Luxury Wheelchair Accessible Vehicles Stand Out in the Market?

Luxury wheelchair accessible vehicles provide high-end finishes and advanced technology, catering to corporate transport and high-end mobility services. These vehicles offer customizable features that enhance the user experience, making them ideal for clients who prioritize comfort and style. However, the higher initial investment may be a consideration for B2B buyers. It is essential to weigh the benefits of premium features against budget constraints when evaluating these luxury options.

Key Industrial Applications of handicap cabin closed vehicles

| Industry/Sector | Specific Application of handicap cabin closed vehicles | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Patient transportation for hospitals and clinics | Enhances accessibility for patients with mobility challenges, improving service delivery and patient satisfaction. | Compliance with health regulations, vehicle customization options, and service support. |

| Public Transport | Accessible shuttle services for urban areas | Fulfills legal requirements for accessibility, broadening customer base and enhancing public service reputation. | Vehicle capacity, ramp design, and ease of maintenance. |

| Tourism and Hospitality | Accessible tours and excursions for travelers with disabilities | Expands market reach by catering to diverse customer needs, enhancing brand image and customer loyalty. | Comfort features, vehicle aesthetics, and adaptability for various terrains. |

| Education | Transport for special needs students | Ensures equal access to education, fostering inclusivity and compliance with educational regulations. | Safety features, seating arrangements, and reliability of service. |

| Corporate Services | Employee transportation for companies with diverse workforces | Promotes inclusivity and enhances company reputation, attracting a wider talent pool. | Customization options, fleet management solutions, and operational costs. |

How are Handicap Cabin Closed Vehicles Utilized in Healthcare?

In the healthcare sector, handicap cabin closed vehicles are primarily used for patient transportation to and from hospitals and clinics. These vehicles are designed to accommodate individuals with mobility challenges, ensuring they can access medical care without barriers. By providing reliable and accessible transport, healthcare providers can enhance patient satisfaction and service delivery. Buyers in this sector should consider compliance with health regulations, customization options for specific needs, and the availability of service support to maintain fleet efficiency.

What Role Do Handicap Cabin Closed Vehicles Play in Public Transport?

Public transport systems utilize handicap cabin closed vehicles to provide accessible shuttle services in urban areas. These vehicles are essential for meeting legal requirements regarding accessibility, thereby expanding the customer base and enhancing the public transport service’s reputation. By ensuring mobility for all, including those with disabilities, cities can foster inclusivity and improve overall community engagement. When sourcing these vehicles, considerations should include vehicle capacity, ramp design, and ease of maintenance to ensure consistent service delivery.

How Can the Tourism and Hospitality Industry Benefit from Accessible Vehicles?

In the tourism and hospitality industry, handicap cabin closed vehicles are crucial for offering accessible tours and excursions for travelers with disabilities. By incorporating these vehicles into their fleets, businesses can cater to a wider audience, thus enhancing their brand image and customer loyalty. This inclusivity not only meets customer demand but also complies with accessibility regulations. Buyers should focus on comfort features, vehicle aesthetics, and adaptability for various terrains to ensure a positive experience for all travelers.

Why Are Handicap Cabin Closed Vehicles Important for Education?

For the education sector, handicap cabin closed vehicles serve as vital transport solutions for special needs students. These vehicles ensure that all students have equal access to educational opportunities, promoting inclusivity and compliance with educational regulations. By providing safe and reliable transport, schools can foster a supportive learning environment. Buyers in this sector must prioritize safety features, seating arrangements, and the overall reliability of service to meet the unique needs of their student populations.

How Do Corporations Use Handicap Cabin Closed Vehicles for Employee Transportation?

Corporations increasingly recognize the importance of inclusivity and accessibility in their operations, leading to the use of handicap cabin closed vehicles for employee transportation. These vehicles help companies accommodate diverse workforces, enhancing their reputation and attracting a broader talent pool. When sourcing these vehicles, businesses should consider customization options, fleet management solutions, and operational costs to maximize efficiency and employee satisfaction.

3 Common User Pain Points for ‘handicap cabin closed vehicles’ & Their Solutions

Scenario 1: Difficulty in Customizing for Diverse Needs

The Problem: B2B buyers often encounter challenges when trying to procure handicap cabin closed vehicles that cater to a diverse range of user needs. For instance, a transportation service provider may require vehicles that accommodate both manual and power wheelchair users, as well as individuals who may not use wheelchairs but require extra space due to mobility aids. Without sufficient customization options, these buyers can struggle to find vehicles that meet all necessary specifications, leading to dissatisfaction among end-users and potential loss of business.

The Solution: To effectively address this issue, B2B buyers should prioritize manufacturers that offer a wide range of customization options. Engage with suppliers like BraunAbility, which provide various models with different ramp configurations, entry points, and interior layouts. Conduct a thorough needs assessment to identify specific requirements, such as ramp weight capacity and interior space. Additionally, consider arranging product demonstrations or trials to ensure the vehicles can accommodate multiple user types comfortably. Collaborating with a specialist in vehicle conversions can also help in selecting the right model that meets diverse user needs without sacrificing comfort or safety.

Scenario 2: Navigating Accessibility Compliance Regulations

The Problem: International B2B buyers frequently face the challenge of ensuring that their fleet of handicap cabin closed vehicles complies with varying local and international accessibility regulations. This is particularly pertinent in regions with stringent laws regarding disability access, such as the EU and certain countries in Africa and the Middle East. Non-compliance can lead to legal repercussions and damage to brand reputation, ultimately affecting the bottom line.

The Solution: Buyers should proactively familiarize themselves with the specific accessibility standards in their target markets, such as the Americans with Disabilities Act (ADA) in the U.S. or the European Accessibility Act. It’s advisable to partner with manufacturers that have a strong track record of compliance with these regulations. This may involve requesting detailed documentation of the vehicles’ compliance features and certifications. Furthermore, consider engaging legal experts or consultants who specialize in transportation accessibility laws to provide guidance and ensure all vehicles meet necessary requirements before purchase. This proactive approach will not only safeguard against compliance issues but also enhance the service offering to clients.

Scenario 3: Ensuring Safe and Comfortable Transportation

The Problem: Safety and comfort are paramount when providing transportation solutions for individuals with disabilities. B2B buyers often find that some handicap cabin closed vehicles do not adequately address these concerns, leading to a subpar experience for users. For instance, poorly designed ramps can create risks during entry and exit, while inadequate interior space can lead to discomfort during travel.

The Solution: To mitigate these issues, B2B buyers should prioritize vehicles that feature industry-leading safety and comfort specifications. Look for models with sturdy, wide ramps and a high weight capacity, such as those from BraunAbility, which offers ramps designed to support up to 1,000 lbs. Additionally, assess interior features such as adjustable seating, ample legroom, and climate control options. Conduct user feedback sessions to gather insights from current users about their experiences and comfort levels, and use this information to guide vehicle selection. Investing in vehicles that prioritize user comfort and safety will result in higher satisfaction rates and foster long-term loyalty among clients.

Strategic Material Selection Guide for handicap cabin closed vehicles

What Are the Key Materials Used in Handicap Cabin Closed Vehicles?

When selecting materials for handicap cabin closed vehicles, it is crucial to consider their properties, advantages, disadvantages, and compliance with international standards. Below, we analyze four common materials used in the construction and conversion of these vehicles: aluminum, steel, composite materials, and high-density polyethylene (HDPE).

How Does Aluminum Benefit Handicap Cabin Closed Vehicles?

Aluminum is a popular choice for handicap vehicles due to its lightweight nature and excellent corrosion resistance. With a temperature rating that can withstand extreme conditions, aluminum is suitable for various climates.

Pros: Aluminum’s lightweight property enhances fuel efficiency and ease of maneuverability, making it ideal for conversion vehicles. It is also resistant to rust, which is beneficial in humid or coastal regions.

Cons: The primary downside is its relatively high cost compared to steel, along with lower tensile strength. This may necessitate additional reinforcements, increasing manufacturing complexity.

Impact on Application: Aluminum’s compatibility with various media, including saltwater, makes it suitable for diverse geographical locations, including coastal areas in Africa and South America.

International Considerations: Buyers in regions like Europe and the Middle East should ensure compliance with standards such as EN 573 for aluminum alloys.

What Advantages Does Steel Offer for Vehicle Conversions?

Steel is widely used in the automotive industry for its strength and durability. It can withstand high pressure and impacts, making it a reliable choice for structural components in handicap vehicles.

Pros: Steel’s high strength-to-weight ratio allows for robust construction, ensuring passenger safety. It is also cost-effective, making it a budget-friendly option for manufacturers.

Cons: Steel is prone to corrosion if not properly treated, which can lead to maintenance issues over time. Its heavier weight can negatively impact fuel efficiency.

Impact on Application: Steel’s durability makes it suitable for regions with rough terrains, such as parts of South America and Africa, where vehicles may face challenging driving conditions.

International Considerations: Buyers should be aware of compliance with standards like ASTM A36 for structural steel and consider additional coatings for corrosion resistance, especially in humid climates.

Why Are Composite Materials Gaining Popularity in Vehicle Manufacturing?

Composite materials, such as fiberglass and carbon fiber, are increasingly being used in handicap cabin vehicles due to their lightweight and high-strength properties.

Pros: Composites offer excellent corrosion resistance and can be molded into complex shapes, providing design flexibility. They are also lightweight, which can improve fuel efficiency.

Cons: The primary limitation is the higher cost of composite materials, which can significantly increase the overall vehicle price. Additionally, manufacturing processes for composites can be more complex and time-consuming.

Impact on Application: Composites are particularly advantageous in regions with high humidity or coastal environments due to their resistance to moisture and corrosion.

International Considerations: Compliance with standards such as ISO 527 for tensile properties is essential for manufacturers targeting international markets.

What Role Does High-Density Polyethylene (HDPE) Play in Vehicle Interiors?

HDPE is commonly used for interior components in handicap vehicles, such as flooring and storage compartments, due to its durability and ease of maintenance.

Pros: HDPE is highly resistant to impact and chemicals, making it suitable for various applications. It is also lightweight and cost-effective, which is appealing for manufacturers.

Cons: While HDPE is durable, it may not withstand extreme temperatures as well as metals, which could limit its application in certain climates.

Impact on Application: HDPE’s compatibility with various media makes it suitable for diverse environments, including the hot climates of the Middle East and Africa.

International Considerations: Buyers should ensure compliance with standards such as ASTM D638 for tensile properties, particularly when sourcing materials from different regions.

Summary Table of Material Selection for Handicap Cabin Closed Vehicles

| Material | Typical Use Case for handicap cabin closed vehicles | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Structural components, ramps, and body panels | Lightweight and corrosion-resistant | Higher cost and lower tensile strength | High |

| Steel | Chassis and structural reinforcements | High strength and cost-effective | Prone to corrosion if untreated | Medium |

| Composite Materials | Body panels and interior components | Excellent corrosion resistance and design flexibility | Higher cost and complex manufacturing processes | High |

| High-Density Polyethylene (HDPE) | Interior flooring and storage solutions | Impact-resistant and lightweight | Limited temperature resistance | Low |

This strategic material selection guide provides valuable insights for B2B buyers in the handicap vehicle market, helping them make informed decisions based on performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for handicap cabin closed vehicles

What Are the Main Stages of Manufacturing Handicap Cabin Closed Vehicles?

The manufacturing process for handicap cabin closed vehicles involves several critical stages that ensure the final product meets safety, accessibility, and quality standards. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The journey begins with the selection of high-quality materials, including lightweight yet durable metals, reinforced composites, and specialized fabrics. Manufacturers often source materials that comply with international safety standards, ensuring they can withstand the demands of daily use while remaining accessible.

-

Forming: This stage involves shaping the materials into the necessary components, such as chassis, ramps, and interior fittings. Advanced technologies like CNC machining and robotic welding are commonly employed to achieve precision and consistency. Manufacturers may also utilize hydroforming techniques for creating complex shapes, enhancing both strength and aesthetics.

-

Assembly: The assembly phase brings together all individual components. Skilled technicians work with automated systems to integrate electrical systems, ramps, and safety features. Attention to detail is paramount, particularly in the installation of wheelchair securement systems, which must meet rigorous safety standards.

-

Finishing: The final stage includes painting, upholstery, and the application of protective coatings. This not only improves the vehicle’s aesthetic appeal but also enhances durability against environmental factors. Quality control checks are integral at this stage to ensure that all features function correctly and meet specified standards.

Which Key Techniques Are Used in the Manufacturing of Handicap Cabin Closed Vehicles?

Manufacturers employ a variety of techniques to enhance the functionality and safety of handicap cabin closed vehicles. These techniques include:

-

Robotic Automation: Automated processes increase efficiency and precision in tasks such as welding, painting, and assembly, reducing human error and improving overall quality.

-

Modular Design: This approach allows for easier customization and assembly, facilitating a range of conversion options tailored to specific user needs, such as different ramp types and seating configurations.

-

Advanced Quality Control Technologies: Technologies like laser scanning and 3D modeling are used to ensure that parts fit together seamlessly, which is critical for maintaining structural integrity and user safety.

What International Standards and Quality Assurance Practices Are Relevant for B2B Buyers?

B2B buyers should be aware of the various international and industry-specific standards that guide the manufacturing and quality assurance processes for handicap cabin closed vehicles. Key standards include:

-

ISO 9001: This international standard outlines the requirements for a quality management system (QMS). Compliance indicates that the manufacturer has established processes to ensure consistent product quality and customer satisfaction.

-

CE Marking: Particularly relevant in Europe, CE marking indicates compliance with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA).

-

API Standards: For manufacturers involved in the production of components that may encounter high stress or require additional durability, adhering to American Petroleum Institute (API) standards can be crucial.

What Are the Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is vital throughout the manufacturing process, with several checkpoints designed to catch potential issues early. Common QC checkpoints include:

-

Incoming Quality Control (IQC): At this stage, raw materials and components are inspected upon arrival to ensure they meet specified quality criteria. This prevents defective materials from entering the production line.

-

In-Process Quality Control (IPQC): This involves monitoring the manufacturing process at various stages. Regular inspections and tests are conducted to ensure that production techniques are being followed and that components meet quality standards.

-

Final Quality Control (FQC): Once assembly is complete, a comprehensive inspection is performed. This includes functional testing of all systems, visual inspections for defects, and verification of compliance with safety standards.

What Common Testing Methods Are Used to Ensure Quality in Handicap Cabin Closed Vehicles?

Testing methods play a crucial role in validating the safety and performance of handicap cabin closed vehicles. Common testing methods include:

-

Load Testing: Ramps and securement systems are subjected to load tests to ensure they can support the weight of users and their wheelchairs safely.

-

Functional Testing: All electrical systems, including lighting, ramp operations, and securement features, undergo functional testing to ensure they operate correctly under various conditions.

-

Crash Testing: Compliance with safety regulations often necessitates crash testing to evaluate how the vehicle would perform in an accident. This testing helps ensure that all safety features, such as seat belts and securement systems, function as intended.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to ensure that their suppliers maintain high-quality standards. These include:

-

Conducting Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality assurance practices. Buyers should look for adherence to recognized standards such as ISO 9001.

-

Requesting Quality Reports: Suppliers should provide detailed quality reports, including inspection results and compliance documentation, to verify their commitment to quality.

-

Engaging Third-Party Inspectors: Employing independent third-party inspectors can offer an unbiased evaluation of the manufacturing process and product quality. This is especially important for international transactions where standards may vary.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control and certification is crucial. Different regions may have varying regulatory requirements, necessitating thorough research before engaging with suppliers.

-

Regional Standards: Buyers should familiarize themselves with the specific standards applicable in their target markets. For instance, while ISO certification is recognized globally, CE marking is essential for products sold in Europe.

-

Documentation Requirements: International transactions often require extensive documentation to prove compliance with local regulations. Buyers must ensure that suppliers can provide the necessary certifications and test results.

-

Cultural Considerations: Understanding the cultural context of suppliers in regions such as Africa or the Middle East can aid in establishing effective communication and ensuring adherence to quality expectations.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing handicap cabin closed vehicles, ensuring they select suppliers who prioritize safety, quality, and compliance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘handicap cabin closed vehicles’

Introduction

Procuring handicap cabin closed vehicles is a critical process for businesses looking to enhance mobility solutions for individuals with disabilities. This guide provides a practical checklist to streamline your sourcing process, ensuring you make informed decisions that meet your organization’s needs and comply with relevant regulations.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical specifications of the vehicles you need. This includes the type of accessibility features required, such as ramp types (infloor or foldout), door configurations (side or rear entry), and passenger capacity.

– Consider user demographics: Assess the specific needs of your target users, including wheelchair dimensions and user mobility requirements.

– Set performance standards: Determine necessary vehicle attributes like engine capacity, fuel efficiency, and safety features that align with your operational goals.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify suppliers that specialize in handicap cabin closed vehicles. Look for manufacturers with a proven track record in producing high-quality mobility solutions.

– Utilize industry resources: Leverage trade shows, industry directories, and online platforms to compile a list of reputable suppliers.

– Check for innovation: Focus on suppliers that offer customizable options and the latest technology in accessibility features to ensure you get the best value.

Step 3: Evaluate Supplier Certifications and Compliance

Ensure that potential suppliers adhere to local and international standards for accessibility and safety. Verify their certifications to mitigate risks related to quality and compliance.

– Request documentation: Ask for certifications such as ISO, ADA compliance, or other relevant industry standards.

– Understand warranty policies: Assess the warranty and service agreements to ensure long-term support for your investment.

Step 4: Assess Vehicle Customization Options

Customization is vital in meeting the specific needs of your users. Evaluate the range of options available from each supplier to find a vehicle that best fits your requirements.

– Explore modification capabilities: Look for suppliers that offer various modifications, including seating configurations, ramp types, and additional safety features.

– Consider future needs: Think ahead to potential changes in user requirements and choose a supplier that can accommodate those adjustments.

Step 5: Request and Analyze Quotes

After narrowing down your supplier options, request detailed quotes that outline pricing, delivery timelines, and any additional costs. This step is crucial for budgeting and financial planning.

– Compare apples to apples: Ensure that quotes include similar specifications and features for an accurate comparison.

– Negotiate terms: Don’t hesitate to negotiate pricing and terms based on your budget constraints and the volume of your order.

Step 6: Conduct Site Visits and Product Demonstrations

Whenever possible, arrange site visits or product demonstrations to evaluate the vehicles firsthand. This step allows you to assess build quality and accessibility features in real-world scenarios.

– Engage with users: If feasible, involve potential users in the evaluation process to gather feedback on their experiences and preferences.

– Inspect maintenance requirements: Look for ease of maintenance and serviceability, as these factors will impact your total cost of ownership.

Step 7: Finalize Contracts and Logistics

Once you’ve selected a supplier, finalize the contract with clear terms regarding delivery, payment schedules, and service agreements. Pay close attention to logistics to ensure smooth delivery.

– Outline service expectations: Clearly define maintenance and support terms in the contract to avoid misunderstandings later.

– Plan for training: Consider including training for staff on vehicle operation and maintenance to enhance user experience and safety.

By following this checklist, B2B buyers can navigate the complexities of sourcing handicap cabin closed vehicles effectively, ensuring they meet both business and user needs.

Comprehensive Cost and Pricing Analysis for handicap cabin closed vehicles Sourcing

What Are the Key Cost Components of Handicap Cabin Closed Vehicles?

When sourcing handicap cabin closed vehicles, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The cost of raw materials such as steel, aluminum, and specialized components for ramps and securement systems forms a significant portion of the total cost. High-quality materials ensure durability and safety, which are critical for wheelchair accessible vehicles.

-

Labor: Labor costs encompass skilled craftsmanship needed for vehicle modifications, including welding, assembly, and installation of accessibility features. The complexity of the modifications can influence labor costs significantly.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses associated with the production facility. Efficient manufacturing processes can help keep these costs down.

-

Tooling: Investment in specialized tools and machinery for custom modifications adds to the cost. Advanced tooling can improve precision and reduce production time, ultimately affecting the pricing.

-

Quality Control (QC): Ensuring vehicles meet safety and accessibility standards requires rigorous testing and quality assurance processes, which can increase costs but are essential for compliance and customer satisfaction.

-

Logistics: Shipping and handling costs vary based on the destination and volume of vehicles being transported. International shipping often incurs additional fees, making logistics a critical factor in overall pricing.

-

Margin: Manufacturers typically add a profit margin to cover costs and generate revenue. This margin can vary significantly based on brand reputation, market competition, and demand.

How Do Price Influencers Affect Handicap Cabin Closed Vehicle Costs?

Several factors can influence the pricing of handicap cabin closed vehicles:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often lead to discounted prices. Buyers should negotiate MOQs that align with their needs to benefit from economies of scale.

-

Specifications and Customization: Customized features, such as ramp types or interior layouts, can significantly increase costs. Buyers should clearly define their specifications to avoid unexpected expenses.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (e.g., ISO standards) can affect both the price and perceived value. Higher-quality vehicles may command premium pricing but offer better longevity and reliability.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established brands may charge more due to their market position and trustworthiness.

-

Incoterms: Understanding shipping terms (Incoterms) is crucial, as they dictate the responsibilities of buyers and sellers regarding shipping costs and risks. This can affect the total landed cost of the vehicles.

What Buyer Tips Can Help Achieve Cost-Efficiency in Sourcing?

To ensure cost-efficiency when sourcing handicap cabin closed vehicles, buyers should consider the following strategies:

-

Negotiate Pricing: Engage in discussions with suppliers to secure better pricing, especially for larger orders. Highlighting long-term partnership potential can also incentivize suppliers to offer competitive rates.

-

Evaluate Total Cost of Ownership (TCO): Beyond the purchase price, consider maintenance, fuel efficiency, and resale value. A slightly higher initial investment in a durable vehicle can lead to lower overall costs.

-

Understand Pricing Nuances for International Buyers: Different regions may have varying pricing structures due to local regulations, taxes, and import duties. Buyers should conduct thorough market research to understand these factors before committing to a purchase.

-

Leverage Local Partnerships: Establishing relationships with local dealers or distributors can provide insights into the best value options and streamline the logistics process, reducing costs associated with shipping and customs.

-

Stay Informed About Market Trends: Keeping abreast of industry trends, such as advancements in vehicle technology or shifts in consumer preferences, can help buyers make informed decisions and identify cost-saving opportunities.

Conclusion

Understanding the cost structure and pricing dynamics of handicap cabin closed vehicles is essential for international B2B buyers. By analyzing cost components, recognizing price influencers, and implementing strategic sourcing tips, buyers can enhance their purchasing decisions and achieve optimal value. Always remember that prices can fluctuate based on market conditions, so it’s advisable to seek quotes and conduct comprehensive comparisons before making a commitment.

Alternatives Analysis: Comparing handicap cabin closed vehicles With Other Solutions

Understanding Alternatives in Mobility Solutions

In the realm of accessible transportation, ‘handicap cabin closed vehicles’ represent a significant advancement in mobility for individuals with disabilities. However, several alternative solutions also cater to similar needs, each offering unique advantages and limitations. This analysis will explore how these alternatives compare in terms of performance, cost, ease of implementation, maintenance, and best use cases.

Comparison of Handicap Cabin Closed Vehicles with Alternatives

| Comparison Aspect | Handicap Cabin Closed Vehicles | Alternative 1: Wheelchair Accessible Vans | Alternative 2: Modified SUVs |

|---|---|---|---|

| Performance | High; designed for ease of entry/exit and mobility | High; spacious interiors with various ramp options | High; rugged performance and off-road capability |

| Cost | Typically starts at $64,381 USD | Generally lower; starting around $50,000 USD | Mid-range; starting around $70,000 USD |

| Ease of Implementation | Requires specialized conversion | Easier to convert existing vans | Requires significant modifications |

| Maintenance | Moderate; specialized service needed | Generally lower; standard vehicle maintenance | Higher; may require custom parts and service |

| Best Use Case | Ideal for frequent transport of wheelchair users | Best for families needing spacious seating | Suitable for adventurous users needing all-terrain capability |

In-Depth Analysis of Alternatives

Alternative 1: Wheelchair Accessible Vans

Wheelchair accessible vans, such as the Chrysler Pacifica and BraunAbility models, offer a robust solution tailored for individuals requiring frequent mobility assistance. These vehicles typically come equipped with features like power ramps and spacious interiors, allowing for easy access and comfortable travel. The cost is generally lower than that of specialized handicap cabin closed vehicles, making them an attractive option for families or organizations with budget constraints. However, while maintenance is more straightforward than specialized models, they still require periodic checks to ensure ramp functionality and general vehicle upkeep.

Alternative 2: Modified SUVs

Modified SUVs, like the Chevrolet Traverse, provide a versatile option for users seeking both accessibility and adventure. These vehicles often feature higher ground clearance and off-road capabilities, making them ideal for users who may need to navigate uneven terrains. With ample space for passengers and cargo, they are perfect for active families. However, the cost can be higher than standard vans, and modifications can complicate maintenance, as custom parts may not be readily available. Additionally, while they perform well in various conditions, their specific design might not be as tailored for wheelchair users as traditional vans.

Conclusion: Making the Right Choice for Mobility Solutions

When selecting the appropriate mobility solution, B2B buyers should carefully consider the specific needs of their user base. Handicap cabin closed vehicles offer specialized features tailored for wheelchair users, ensuring maximum comfort and accessibility. Conversely, wheelchair accessible vans and modified SUVs provide flexibility and a range of functionalities that may better suit families or organizations with diverse transportation needs. Evaluating factors such as performance requirements, budget constraints, and the intended use case will guide buyers in making informed decisions that best meet the mobility needs of their clients or community.

Essential Technical Properties and Trade Terminology for handicap cabin closed vehicles

What Are the Critical Technical Properties of Handicap Cabin Closed Vehicles?

When considering the procurement of handicap cabin closed vehicles, understanding specific technical properties is essential for making informed decisions. Here are some critical specifications:

-

Ramp Capacity

This refers to the maximum weight that the ramp can support when being used. Most wheelchair-accessible vehicles feature ramps with a capacity of at least 1,000 lbs. This specification is crucial as it ensures that the ramp can accommodate various wheelchair types and sizes, providing safety and reliability for users. -

Door Opening Dimensions

The usable width and height of the vehicle’s door openings are vital for accessibility. Wider and taller door openings facilitate easier entry and exit for wheelchair users. B2B buyers should prioritize vehicles with generous dimensions to ensure that they can accommodate different user needs and types of mobility devices. -

Interior Height and Space

This specification measures the vertical space available inside the vehicle, which is significant for user comfort. A higher interior height allows users to sit comfortably without feeling cramped. In B2B contexts, ensuring that the vehicle meets various user requirements can enhance satisfaction and usability. -

Ramp Angle

This refers to the incline of the ramp when deployed. A lower ramp angle (typically around 8-10 degrees) is preferred as it allows for easier access, especially for users with limited mobility. This property is particularly important in regions where uneven terrain may be encountered. -

Material Specifications

The materials used in the construction of the ramp and vehicle body affect durability and maintenance. High-grade aluminum or steel is often used for ramps to ensure they are lightweight yet sturdy. Understanding material specifications can help buyers assess long-term value and potential maintenance costs.

What Are Common Trade Terms Relevant to the Acquisition of Handicap Cabin Closed Vehicles?

Familiarity with industry jargon can simplify the procurement process and enhance communication between buyers and suppliers. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture vehicles or components that are sold under another brand. For buyers, working with OEMs ensures that they receive high-quality products that meet industry standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is crucial for B2B buyers as it impacts inventory levels and overall procurement costs. Buyers should negotiate MOQs to align with their purchasing strategies. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to suppliers requesting price quotes for specific products or services. This process is essential for comparing options and ensuring competitive pricing in B2B transactions. -

Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce that outline the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, insurance, and liability during transit. -

Lead Time

This term refers to the time taken from placing an order to delivery. For B2B buyers, understanding lead times is critical for planning and inventory management, especially in sectors requiring timely access to vehicles.

By grasping these technical properties and trade terms, international B2B buyers can navigate the complexities of acquiring handicap cabin closed vehicles more effectively, ultimately leading to better purchasing decisions and enhanced operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the handicap cabin closed vehicles Sector

What Are the Key Trends Impacting the Handicap Cabin Closed Vehicles Market?

The global market for handicap cabin closed vehicles is experiencing significant growth, driven by increasing demand for mobility solutions that cater to individuals with disabilities. This demand is influenced by a rising awareness of inclusivity and accessibility in transportation across various regions, particularly in Africa, South America, the Middle East, and Europe. Technological advancements, such as the integration of smart mobility features and enhanced safety systems, are transforming vehicle designs. International B2B buyers are also increasingly focused on customization options, as the needs of users can vary widely. For instance, options for side-entry or rear-entry ramps, as well as in-floor or fold-out ramps, allow buyers to cater to diverse customer preferences and regional requirements.

Emerging trends in sourcing are also notable. There is a growing emphasis on direct partnerships with manufacturers to ensure quality and reliability, as well as to navigate the complexities of import regulations. Buyers are leveraging digital platforms for sourcing, which streamline the procurement process and facilitate better communication with suppliers. Additionally, as electric and hybrid vehicles gain traction, manufacturers are exploring eco-friendly options for wheelchair-accessible vehicles, aligning with global sustainability goals.

How Is Sustainability and Ethical Sourcing Reshaping the Handicap Cabin Closed Vehicles Market?

Sustainability is becoming increasingly vital in the sourcing of handicap cabin closed vehicles. The environmental impact of manufacturing processes, from raw material extraction to vehicle production, is under scrutiny. B2B buyers are now prioritizing suppliers that demonstrate a commitment to reducing their carbon footprint. This includes the use of recycled materials and low-emission manufacturing practices.

Ethical sourcing is equally important. Buyers are seeking suppliers who uphold fair labor practices and maintain transparency in their supply chains. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as indicators of a supplier’s commitment to sustainable and ethical practices. Furthermore, the demand for ‘green’ vehicles is on the rise, with buyers looking for options that include energy-efficient technologies and sustainable materials. This focus not only meets the expectations of environmentally conscious consumers but also positions companies favorably in a competitive market.

How Has the Handicap Cabin Closed Vehicles Market Evolved Over Time?

The handicap cabin closed vehicles market has evolved significantly over the decades, transitioning from rudimentary adaptations to sophisticated, purpose-built vehicles. Early models primarily focused on basic accessibility features, often compromising on comfort and design. However, advancements in technology have led to the development of vehicles that not only meet accessibility needs but also prioritize user experience.

In recent years, the integration of smart technology has further enhanced these vehicles, offering features such as automated ramps, advanced safety systems, and customizable interiors. As a result, B2B buyers are now presented with a diverse range of options that cater to various mobility challenges, ensuring that every user can find a suitable solution that aligns with their lifestyle and needs. This evolution reflects a broader societal shift towards inclusivity, making it essential for international buyers to stay informed about the latest innovations and trends in the market.

Frequently Asked Questions (FAQs) for B2B Buyers of handicap cabin closed vehicles

-

How do I solve the challenge of sourcing handicap cabin closed vehicles internationally?

To effectively source handicap cabin closed vehicles internationally, start by identifying reliable manufacturers and suppliers with a proven track record in mobility solutions. Utilize online platforms and industry networks to gather information on potential vendors. Conduct thorough due diligence, including reviewing certifications, customer testimonials, and product quality standards. Establish communication to discuss your specific needs, and request samples or demonstrations to evaluate the product firsthand. Engaging with local representatives or trade shows can also provide valuable insights into the market dynamics and regulatory requirements in your target regions. -

What is the best type of handicap cabin closed vehicle for different market needs?

The best type of handicap cabin closed vehicle varies based on specific market needs and user requirements. For urban environments with limited space, compact wheelchair-accessible vans with side-entry ramps may be ideal. In contrast, larger SUVs or minivans with spacious interiors are better suited for families or organizations transporting multiple passengers. Additionally, consider the vehicle’s ramp system, weight capacity, and interior accessibility features. Assess local regulations and preferences in your target market to ensure the chosen vehicle aligns with user expectations and compliance standards. -

How can I customize handicap cabin closed vehicles for my target market?

Customization options for handicap cabin closed vehicles can include modifications to seating arrangements, ramp types (infloor vs. foldout), and interior features like lighting and storage solutions. Engage with manufacturers to understand their capabilities for bespoke designs that cater to your target audience’s needs. Consider incorporating local preferences, such as climate control systems or specific safety features. Collaboration with occupational therapists or end-users during the design phase can enhance usability and comfort, ensuring that the final product meets market demands. -

What are the minimum order quantities (MOQ) for handicap cabin closed vehicles?

Minimum order quantities (MOQ) for handicap cabin closed vehicles can vary significantly based on the manufacturer and the type of vehicle. Generally, larger manufacturers may have higher MOQs due to production efficiencies, while smaller companies might be more flexible. It’s essential to negotiate terms that align with your business needs, especially if you are entering a new market. Be clear about your budget and expected volume to foster a mutually beneficial relationship with the supplier, and inquire about tiered pricing based on larger orders. -

What payment terms should I expect when sourcing handicap cabin closed vehicles?

Payment terms for sourcing handicap cabin closed vehicles typically involve a combination of upfront deposits and payment upon delivery. Expect to encounter terms such as 30% deposit upon order confirmation, with the remaining balance due before shipment. Some suppliers may offer financing options or extended payment plans, particularly for bulk orders. Always clarify terms in advance and consider using a letter of credit for larger transactions to mitigate risks. Ensure that the payment methods are secure and acceptable for both parties involved. -

How do I ensure quality assurance (QA) for handicap cabin closed vehicles?

To ensure quality assurance for handicap cabin closed vehicles, establish clear specifications and standards with your supplier before production begins. Request to review certifications and compliance with international safety and accessibility standards. Implement a systematic QA process that includes inspections at various production stages and final product evaluations. Consider utilizing third-party inspection services to provide an unbiased assessment of the vehicles. Regular communication with the manufacturer throughout the production process will also help address any potential issues proactively. -

What logistics considerations should I keep in mind when importing handicap cabin closed vehicles?

When importing handicap cabin closed vehicles, consider logistics aspects such as shipping methods, customs regulations, and potential tariffs. Evaluate whether to use container shipping or roll-on/roll-off (RoRo) services based on cost and vehicle protection needs. Research the specific import regulations in your target country, including any required certifications for accessibility vehicles. Partnering with a logistics provider experienced in handling automotive imports can streamline the process and ensure compliance with all necessary documentation and procedures. -

How can I effectively vet suppliers of handicap cabin closed vehicles?

To effectively vet suppliers of handicap cabin closed vehicles, begin by reviewing their business history, industry reputation, and customer feedback. Request references from previous clients to gauge their satisfaction with product quality and service. Conduct site visits if possible to assess manufacturing capabilities and quality control processes firsthand. Additionally, verify certifications that demonstrate compliance with safety and accessibility standards. Establishing a trial order can also provide insight into their operational efficiency and product reliability before committing to larger purchases.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Handicap Cabin Closed Vehicles Manufacturers & Suppliers List

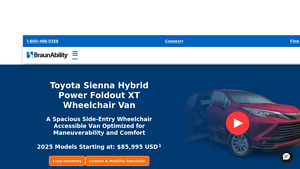

1. BraunAbility – Toyota Sienna Power Foldout XT Wheelchair Van

Domain: braunability.com

Registered: 2006 (19 years)

Introduction: Toyota Sienna Power Foldout XT Wheelchair Van

– Starting Price: $85,995 USD

– Engineered for independence and freedom for individuals with mobility challenges.

– Accommodates a variety of wheelchair users, including taller users.

– Features:

– SmartSuite+ Advanced Technology for diagnostics and service.

– Superior maneuverability with wider doorway and additional space.

– First-ever BraunAbi…

2. Ford – Accessible Vehicles

Domain: ford.com

Registered: 1988 (37 years)

Introduction: Ford offers a range of accessible vehicles including cars, trucks, and SUVs that provide comfort, style, and sophistication. These vehicles are suitable for adaptive equipment and modification upgrades, featuring ample interior space, versatility, and hauling capabilities. Key adaptations include various steering devices such as modified steering wheels and columns for those with limited mobility,…

3. Freedom Motors – Wheelchair-Accessible Chrysler Pacifica

Domain: freedommotors.com

Registered: 1997 (28 years)

Introduction: Wheelchair-accessible Chrysler Pacifica offers spacious dimensions with luxury appointments. Key specifications include: Door Height: 53.5″, Ramp Width: 37.5″, Ramp Length: 56.3″, Interior Height: 54.5″, Interior Length: 101″, Ground Clearance: 6″. Features include a 38″ rear entry ramp (manual or automatic), plush cloth carpet or commercial-grade non-slip flooring, power transfer seat, hand contr…

4. Ideal Auto Sales – Wheelchair Accessible Vehicles

Domain: idealautosalesrosemead.com

Registered: 2023 (2 years)

Introduction: Ideal Auto Sales in Rosemead, CA offers a wide selection of wheelchair accessible vehicles, including mobility minivans, rear-entry handicap-accessible SUVs, and ADA-compliant conversion vans. The inventory features both new and pre-owned wheelchair vans that meet high standards for quality, safety, and ADA compliance. Customers can choose between side-entry and rear-entry options, and vehicles co…

5. Pohanka Mobility – Wheelchair Vans & Mobility Vehicles

Domain: pohankamobility.com

Registered: 2023 (2 years)

Introduction: Wheelchair Vans and Mobility Vehicles available for sale in Chantilly, VA. Key offerings include: ADA Compliant Mobility Vans, Toyota Mobility Vehicles, Chrysler Mobility Vehicles, Toyota Sienna Mobility Van, Chrysler Pacifica Mobility Van. Locations served include Fairfax, Manassas, Woodbridge, Alexandria, Washington, DC, and Marshall, VA. Services offered include vehicle sales, trade-ins, financ…

6. United Access – Wheelchair Accessible Vehicles

Domain: unitedaccess.com

Registered: 2001 (24 years)

Introduction: United Access offers a variety of wheelchair accessible vehicles including new and used vans and SUVs. Key product details include:

1. **Vehicle Types**:

– Wheelchair Accessible Vans

– Wheelchair Accessible SUVs

– Wheelchair Accessible Trucks

– Wheelchair Accessible Full-Size Vans

2. **Brands Offered**:

– Chrysler (Pacifica, Voyager)

– Dodge (Grand Caravan)

– Honda (Odyssey)…

7. AMS Vans – Wheelchair Vehicles

Domain: amsvans.com

Registered: 2002 (23 years)

Introduction: AMS Vans offers various wheelchair vehicles, including wheelchair minivans, mobility cars, full-size handicap vans, wheelchair conversion vans with kneeling systems, disability accessible trucks, SUVs, MV-1, and wheelchair motorcycles.

1. **Wheelchair Minivans**:

– **Pros**: Ample interior space, great gas mileage, ease of parking, extended 4″ ramp, easy transfer for drivers, indoor wheelcha…

8. Disabled Cruise Club – Accessible Cabins

Domain: disabledcruiseclub.com

Registered: 2012 (13 years)

Introduction: Disabled cabins on Carnival cruise ships include two classifications: 1. Modified Cabins – designed for guests using wheelchairs or similar devices, featuring grab bars and shower seats. 2. Accessible Cabins – designed for guests with highly limited or no mobility, including turning space, accessible routes, and bathrooms. Staterooms are assigned on a first come, first serve basis. Mobility scoote…

Strategic Sourcing Conclusion and Outlook for handicap cabin closed vehicles

In the evolving landscape of handicap cabin closed vehicles, strategic sourcing is crucial for B2B buyers aiming to enhance mobility solutions. As demonstrated by leading manufacturers like BraunAbility, options such as the Chrysler Pacifica and Chevy Traverse offer unparalleled versatility, spaciousness, and innovative design features tailored for diverse needs. By focusing on quality, durability, and user-friendly functionalities, these vehicles not only meet regulatory standards but also enhance the overall experience for end-users.

For international buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding the nuances of these products can significantly influence purchasing decisions. Sourcing from reputable manufacturers ensures access to advanced technology and reliable support services, fostering long-term partnerships that benefit both suppliers and customers.

As we look to the future, it is imperative for B2B buyers to stay informed about emerging trends and innovations in mobility solutions. Engaging with industry experts and attending relevant trade shows can provide valuable insights. By prioritizing strategic sourcing, companies can position themselves at the forefront of this dynamic market, ultimately contributing to a more inclusive world for individuals with mobility challenges.