Introduction: Navigating the Global Market for electric car trunck battery

The electric car trunk battery market is evolving rapidly, presenting both opportunities and challenges for international B2B buyers. One of the primary challenges faced by businesses is sourcing reliable and efficient battery solutions that meet their operational needs while adhering to regional regulations and market demands. This guide aims to equip buyers with essential insights into the various types of electric car trunk batteries, their applications across different vehicle models, and the critical factors to consider when selecting suppliers.

In this comprehensive resource, we will explore the latest trends in battery technology, including modular systems that enhance flexibility and scalability for diverse applications. We will also provide detailed guidance on supplier vetting processes to ensure that businesses partner with reputable manufacturers who can deliver quality products. Additionally, we will discuss cost considerations and potential financing options to facilitate informed purchasing decisions.

By focusing on the unique needs of international markets, particularly in Africa, South America, the Middle East, and Europe—regions that are increasingly investing in electric vehicle infrastructure—this guide empowers B2B buyers to navigate the complexities of sourcing electric car trunk batteries. With actionable insights and expert recommendations, businesses can confidently make strategic decisions that align with their growth objectives and sustainability goals.

Understanding electric car trunck battery Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Lithium-ion Battery | High energy density, lightweight, and long lifespan | Electric vehicles, renewable energy storage | Pros: High efficiency, rapid charging; Cons: Costly, sensitive to temperature. |

| Modular Battery Systems | Scalable design, customizable configurations | Commercial fleets, electric conversions | Pros: Flexibility in capacity, easy integration; Cons: Complexity in installation. |

| Solid-State Batteries | Enhanced safety, improved energy density | High-performance EVs, aerospace applications | Pros: Higher energy density, safer; Cons: Still in development, higher cost. |

| Battery Expansion Packs | Stackable design for increased capacity | DIY electric vehicle projects, retrofitting | Pros: Customizable capacity, easy to transport; Cons: May add weight, limited range. |

| Nickel-Metal Hydride (NiMH) | Established technology, reliable performance | Hybrid vehicles, lower-cost EVs | Pros: Cost-effective, robust; Cons: Lower energy density, heavier than lithium-ion. |

What Are the Characteristics and Suitability of Lithium-ion Batteries for B2B Buyers?

Lithium-ion batteries are the most prevalent type in electric vehicles due to their high energy density and lightweight design. Their long lifespan and efficiency make them suitable for various applications, including commercial electric vehicles and renewable energy storage systems. B2B buyers must consider the initial investment, as lithium-ion batteries can be costly. However, their rapid charging capabilities and decreasing prices over time make them a viable option for businesses looking to invest in electric fleets.

How Do Modular Battery Systems Benefit Businesses?

Modular battery systems offer a scalable solution for electric vehicles, allowing businesses to customize their energy storage based on specific needs. These systems can be easily integrated into various vehicle configurations, making them ideal for commercial fleets and electric vehicle conversions. When purchasing, businesses should evaluate the installation complexity and the need for specialized support, but the flexibility and adaptability of modular systems often justify these considerations.

What Advantages Do Solid-State Batteries Offer for High-Performance Applications?

Solid-state batteries represent the next generation of energy storage technology, characterized by their enhanced safety and higher energy density compared to traditional lithium-ion options. They are particularly suitable for high-performance electric vehicles and aerospace applications where weight and efficiency are paramount. However, buyers should be aware that solid-state technology is still emerging, which can result in higher costs and limited availability. Investing in this technology could yield significant long-term benefits as it matures.

How Can Battery Expansion Packs Enhance Electric Vehicle Customization?

Battery expansion packs are designed for modularity, allowing users to stack additional batteries to increase capacity as needed. This feature is particularly appealing for DIY electric vehicle projects and retrofitting existing vehicles. B2B buyers should consider the ease of transport and installation, as well as the potential for added weight affecting vehicle performance. The flexibility of battery expansion packs can provide businesses with tailored solutions for varying energy needs.

What Makes Nickel-Metal Hydride Batteries a Reliable Choice?

Nickel-metal hydride (NiMH) batteries have been a reliable choice for hybrid vehicles and lower-cost electric vehicles due to their established technology and robust performance. While they are generally less efficient than lithium-ion batteries, their lower cost can make them attractive for businesses with budget constraints. Buyers should weigh the trade-offs between energy density and cost-effectiveness, particularly if they are looking for a reliable yet economical solution for their electric vehicle needs.

Key Industrial Applications of electric car trunck battery

| Industry/Sector | Specific Application of electric car trunk battery | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Modular battery systems for electric vehicles | Enhanced vehicle performance and flexibility in design | Compatibility with existing vehicle models and scalability options |

| Renewable Energy | Mobile energy storage solutions | Provides backup power and supports renewable energy integration | Durability in various climates and ease of transportation |

| Logistics & Transportation | Auxiliary power units for electric delivery vehicles | Improved operational efficiency and reduced emissions | Weight distribution and integration with vehicle systems |

| Emergency Services | Emergency power supply for rescue vehicles | Reliable power for critical operations during emergencies | Rapid deployment capability and compliance with safety standards |

| Construction | Power supply for electric construction equipment | Reduces fuel costs and emissions, increasing sustainability | Robustness and performance in rugged environments |

How Is the Electric Car Trunk Battery Used in Automotive Manufacturing?

In the automotive manufacturing sector, electric car trunk batteries serve as modular battery systems for electric vehicles. These systems allow manufacturers to create vehicles with varying ranges and performance capabilities, catering to diverse market needs. The ability to customize battery configurations enhances the overall vehicle design and performance, which is crucial for gaining a competitive edge. For international buyers, understanding compatibility with existing vehicle models and the scalability of battery systems is essential for maximizing investment.

What Role Does the Electric Car Trunk Battery Play in Renewable Energy Solutions?

In renewable energy applications, electric car trunk batteries are utilized as mobile energy storage solutions. They provide backup power during outages and support the integration of renewable energy sources like solar and wind. This capability is particularly valuable in regions with unreliable power grids, such as parts of Africa and South America. Buyers must consider the battery’s durability in varying climates and its ease of transportation to ensure reliability in diverse operational environments.

How Can Logistics and Transportation Benefit from Electric Car Trunk Batteries?

Electric car trunk batteries are increasingly used as auxiliary power units in electric delivery vehicles within the logistics and transportation sector. These batteries improve operational efficiency by extending the range of electric vehicles and reducing reliance on fossil fuels, thus lowering emissions. For businesses in this sector, key sourcing considerations include weight distribution and integration with existing vehicle systems to ensure seamless operation and compliance with local regulations.

Why Are Electric Car Trunk Batteries Important for Emergency Services?

Emergency services utilize electric car trunk batteries as emergency power supplies for rescue vehicles. These batteries ensure reliable power for critical operations during emergencies, such as powering medical equipment or communication devices. The ability to deploy these batteries rapidly is vital in crisis situations. Buyers in this sector should prioritize compliance with safety standards and the battery’s capability for quick deployment to enhance operational readiness.

How Do Electric Car Trunk Batteries Contribute to Sustainable Construction Practices?

In the construction industry, electric car trunk batteries provide power supply for electric construction equipment, significantly reducing fuel costs and emissions. This transition to electric-powered machinery aligns with global sustainability goals and enhances the reputation of construction firms as environmentally responsible. Buyers must focus on the robustness and performance of these batteries in rugged environments to ensure they can withstand the demands of construction sites.

3 Common User Pain Points for ‘electric car trunck battery’ & Their Solutions

Scenario 1: Limited Battery Replacement Options for Fleet Vehicles

The Problem: B2B buyers managing fleets of electric vehicles often encounter challenges with battery replacement due to limited options available in their local markets. This issue is exacerbated in regions like Africa and South America, where access to reliable suppliers and advanced battery technologies may be constrained. Buyers may find themselves in a position where the only available replacement batteries are outdated, substandard, or incompatible with their fleet, leading to increased downtime and maintenance costs.

The Solution: To navigate this challenge, B2B buyers should prioritize establishing relationships with reputable suppliers who specialize in electric vehicle batteries, particularly those that offer modular solutions. By investing in modular battery systems, such as the HyperPack Energy, fleets can benefit from customizable configurations that adapt to various vehicle models. Buyers should conduct thorough market research to identify suppliers that provide comprehensive support, including diagnostics and installation services. Additionally, consider forming partnerships with local auto shops that have experience with electric vehicle battery replacements, ensuring that your fleet can access timely and professional service.

Scenario 2: Battery Degradation and Performance Monitoring Challenges

The Problem: Another common pain point for businesses utilizing electric vehicles is the gradual degradation of battery performance over time. As batteries age, they lose capacity, which can significantly affect the range and efficiency of the vehicles. This is particularly concerning for companies that rely on electric vehicles for logistics and transportation, as reduced range can lead to operational inefficiencies and increased costs.

The Solution: B2B buyers should implement a robust battery management system (BMS) that allows for real-time monitoring of battery health and performance. Investing in advanced diagnostic tools, such as those used by EV technicians, can enable businesses to track critical metrics like charge cycles, temperature, and remaining capacity. Regular diagnostics will help identify when a battery is nearing the end of its lifecycle, allowing for proactive replacements before performance drops significantly. Furthermore, consider establishing a battery maintenance schedule to ensure that all vehicles are routinely checked and serviced, extending the overall life of the batteries in use.

Scenario 3: Insufficient Storage Space for Battery Expansion

The Problem: Companies looking to enhance their electric vehicle capabilities may face challenges related to the physical storage of additional battery packs. In scenarios where businesses require increased range or backup power options, the need for extra battery capacity can lead to logistical issues, particularly if the vehicles do not have adequate trunk space or weight distribution capabilities for additional batteries.

The Solution: To address this issue, B2B buyers should explore innovative battery expansion solutions designed for easy integration and storage. Modular battery systems that allow for stacking or connecting additional packs can provide the flexibility needed without compromising vehicle performance. Buyers should look for battery solutions that are lightweight and designed with space efficiency in mind, such as those that can be integrated into the trunk without exceeding weight limits. Additionally, engaging with manufacturers that offer customizable battery configurations can help ensure that the chosen solution fits seamlessly with existing fleet operations while meeting capacity needs.

Strategic Material Selection Guide for electric car trunck battery

What Materials Are Commonly Used in Electric Car Trunk Batteries?

Electric car trunk batteries are integral to the performance and efficiency of electric vehicles (EVs). Selecting the right materials for these batteries is crucial for ensuring optimal performance, safety, and durability. Here, we analyze four common materials used in electric car trunk batteries: lithium-ion, nickel-metal hydride (NiMH), aluminum, and composite materials.

How Does Lithium-Ion Material Benefit Electric Car Trunk Batteries?

Lithium-ion batteries are the most prevalent type used in electric vehicles today due to their high energy density and lightweight characteristics. They typically operate effectively within a temperature range of -20°C to 60°C, making them suitable for diverse climates. Additionally, lithium-ion batteries exhibit excellent cycle stability and low self-discharge rates.

Pros: The primary advantages of lithium-ion batteries include their high energy capacity, lightweight nature, and relatively low maintenance requirements. They also have a longer lifespan compared to other battery types.

Cons: However, they can be sensitive to temperature extremes, requiring sophisticated thermal management systems. The initial manufacturing costs can also be high, and there are environmental concerns related to lithium extraction and disposal.

Impact on Application: Lithium-ion batteries are compatible with various electric vehicle designs, but their performance can be affected by extreme environmental conditions, necessitating careful design considerations.

Considerations for International Buyers: For buyers in regions like Africa and the Middle East, where extreme temperatures can be common, it’s essential to consider thermal management solutions. Compliance with international standards such as ISO 26262 for functional safety is also critical.

What Role Does Nickel-Metal Hydride (NiMH) Play in Electric Car Batteries?

Nickel-metal hydride batteries have been used in hybrid vehicles and some electric vehicles due to their robust performance and reliability. They can handle a temperature range of -20°C to 50°C, providing decent performance in moderate climates.

Pros: NiMH batteries are known for their durability and ability to withstand deep discharge cycles. They are also less sensitive to temperature fluctuations compared to lithium-ion batteries.

Cons: However, they have a lower energy density, making them heavier and less efficient for long-range applications. Additionally, they have a shorter lifespan than lithium-ion batteries.

Impact on Application: NiMH batteries are suitable for applications where weight is less of a concern, but they may not be ideal for high-performance electric vehicles that require lightweight solutions.

Considerations for International Buyers: Buyers should be aware of the varying regulations regarding battery recycling and disposal in different regions, particularly in Europe, where stringent environmental laws are in place.

How Does Aluminum Contribute to Battery Housing?

Aluminum is often used in the construction of battery enclosures due to its lightweight and corrosion-resistant properties. It can withstand a range of temperatures and offers good thermal conductivity.

Pros: The primary advantage of aluminum is its strength-to-weight ratio, which helps reduce the overall weight of the vehicle. It also provides excellent corrosion resistance, extending the lifespan of the battery housing.

Cons: The main disadvantage is that aluminum can be more expensive than other metals, and its manufacturing process can be complex, potentially increasing costs.

Impact on Application: Aluminum is particularly suitable for applications requiring lightweight structures without compromising durability, making it ideal for electric vehicle battery housings.

Considerations for International Buyers: Buyers should consider local sourcing options to mitigate costs and comply with international standards like ASTM for material specifications.

What Advantages Do Composite Materials Offer for Electric Car Batteries?

Composite materials, often a combination of polymers and fibers, are increasingly used in battery applications due to their lightweight and customizable properties. They can be engineered to meet specific temperature and pressure ratings.

Pros: Composites offer excellent weight savings and can be tailored for specific performance characteristics. They also provide good corrosion resistance and can be molded into complex shapes.

Cons: The main limitations include higher manufacturing costs and potential challenges in recycling. Additionally, the long-term durability of composites in battery applications is still under evaluation.

Impact on Application: Composites can be particularly beneficial in applications where weight is critical, but their long-term performance in battery systems needs further study.

Considerations for International Buyers: Buyers should assess the availability of composite materials in their region and ensure compliance with relevant standards, such as JIS for Japanese industrial standards.

Summary Table of Material Selection for Electric Car Trunk Batteries

| Material | Typical Use Case for electric car trunk battery | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Lithium-Ion | Main battery type for electric vehicles | High energy density | Sensitive to temperature extremes | High |

| Nickel-Metal Hydride | Hybrid vehicles and some EVs | Durable and robust | Lower energy density | Medium |

| Aluminum | Battery enclosures | Lightweight and corrosion-resistant | Higher manufacturing costs | Medium |

| Composite Materials | Lightweight battery housings | Customizable and lightweight | Higher costs and recycling issues | High |

This strategic material selection guide provides key insights for B2B buyers looking to optimize electric car trunk battery performance while considering the unique challenges and opportunities in various international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for electric car trunck battery

What Are the Main Stages in the Manufacturing Process of Electric Car Trunk Batteries?

The manufacturing process of electric car trunk batteries involves several critical stages, each contributing to the overall quality and performance of the final product. Understanding these stages can help B2B buyers ensure they are sourcing batteries that meet their operational needs.

1. Material Preparation: What Materials Are Essential for Battery Production?

The first step in manufacturing electric car batteries is material preparation. This involves sourcing high-quality raw materials such as lithium, cobalt, nickel, and graphite. These materials are essential for the production of lithium-ion batteries, which are commonly used in electric vehicles (EVs).

Suppliers often use advanced techniques to ensure the purity and quality of these materials. For instance, lithium is usually extracted from brine or hard rock sources and then processed to remove impurities. The quality of these raw materials significantly impacts the battery’s performance, lifecycle, and safety.

2. Forming: How Are Battery Cells Constructed?

Once the materials are prepared, the next stage is forming. This involves creating the individual battery cells, which are the building blocks of the battery pack. The process typically includes the following steps:

- Electrode Coating: A slurry containing active materials is coated onto thin metal foils, which will become the battery’s anode and cathode.

- Drying: The coated foils are then dried to remove any solvents, ensuring that the electrodes are ready for assembly.

- Cutting and Stacking: The dried electrodes are cut into precise shapes and stacked with separators to prevent short circuits.

Advanced techniques like roll-to-roll processing can enhance efficiency and reduce manufacturing costs.

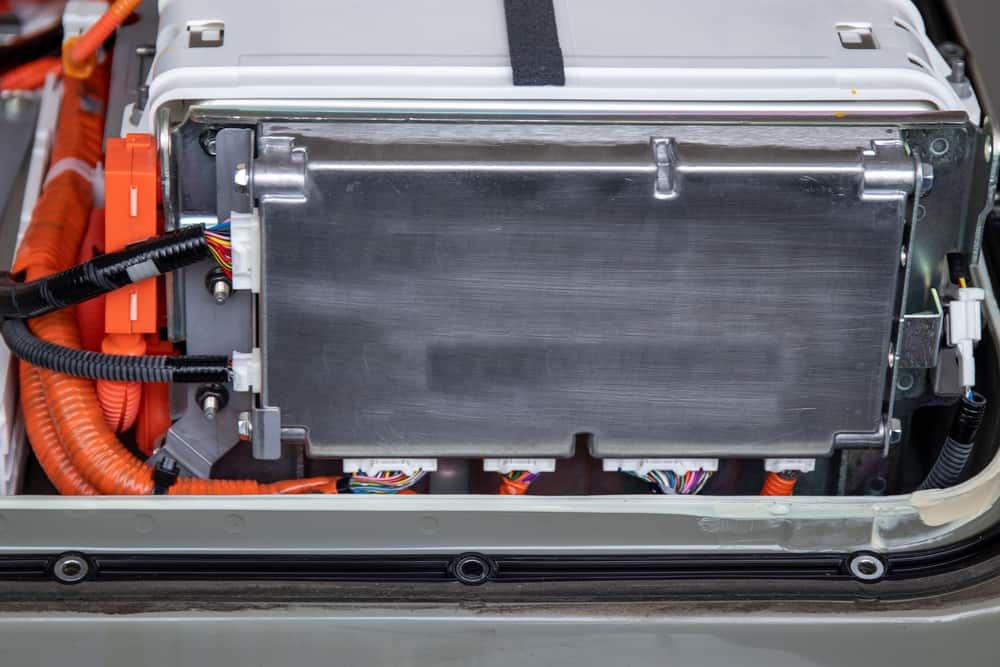

3. Assembly: How Are Battery Packs Made?

The assembly stage is where the individual cells are combined to form the complete battery pack. This process typically includes:

- Cell Connection: Cells are connected in series or parallel configurations depending on the desired voltage and capacity.

- Integration of Battery Management System (BMS): A BMS is integrated to monitor and manage the performance of the battery, ensuring safety and efficiency.

- Enclosure: The battery pack is enclosed in a robust housing to protect it from environmental factors and mechanical stress.

Automation plays a significant role in this stage, with robotic systems often used for precision and consistency.

4. Finishing: What Final Touches Ensure Quality?

The finishing stage involves several critical steps to ensure the battery meets industry standards:

- Sealing and Testing: Battery packs are sealed to prevent moisture ingress and subjected to rigorous testing to ensure they meet safety standards.

- Labeling and Packaging: Proper labeling is essential for compliance with international shipping regulations, especially for hazardous materials like lithium-ion batteries.

What Quality Assurance Standards Are Relevant for Electric Car Batteries?

Quality assurance is vital in the manufacturing of electric car batteries to ensure they meet international standards and regulations. B2B buyers should be familiar with several key quality standards and checkpoints.

International Standards: Which Certifications Should Buyers Look For?

One of the most recognized quality standards in manufacturing is ISO 9001, which outlines criteria for a quality management system. This certification ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

Additionally, industry-specific standards such as CE (Conformité Européenne) and API (American Petroleum Institute) certifications may apply, particularly for batteries intended for markets in Europe and North America.

Quality Control Checkpoints: What Are the Key Stages?

Quality control (QC) is generally divided into several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon receipt to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): During the manufacturing process, regular inspections and tests are performed to monitor quality and adherence to specifications.

- Final Quality Control (FQC): Once the battery packs are completed, a thorough examination is conducted to ensure they meet all safety and performance standards before shipping.

What Testing Methods Are Commonly Used for Electric Car Batteries?

Testing is a crucial aspect of quality assurance in battery manufacturing. B2B buyers should understand the various testing methods that manufacturers employ to guarantee the reliability and safety of electric car batteries.

- Electrical Testing: This includes capacity testing, voltage testing, and internal resistance measurements to ensure the battery performs as expected.

- Thermal Testing: Batteries are subjected to extreme temperatures to assess their thermal stability and safety under various conditions.

- Cycle Testing: This involves charging and discharging the battery multiple times to evaluate its lifecycle and performance degradation over time.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensuring product reliability and safety. Here are several methods buyers can use:

Audits: What Should Be Included in a Supplier Audit?

Conducting a supplier audit allows buyers to assess the manufacturer’s quality management systems and practices. Key areas to focus on during an audit include:

- Review of quality management certifications (e.g., ISO 9001).

- Examination of quality control checkpoints throughout the manufacturing process.

- Assessment of testing facilities and methodologies.

Reports: How Can Documentation Support Supplier Claims?

Buyers should request detailed quality assurance reports from suppliers, including:

- Results of IQC, IPQC, and FQC inspections.

- Data from testing methodologies, including electrical and thermal tests.

- Certifications and compliance documents relevant to international standards.

Third-Party Inspections: Why Are They Important?

Engaging a third-party inspection service can provide an unbiased evaluation of the manufacturer’s quality assurance processes. These inspections can include:

- Factory audits to assess compliance with quality standards.

- Random sampling of battery packs to evaluate performance and safety.

What Are the Quality Control Nuances for International Buyers?

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding regional regulations and standards is crucial. Compliance with local laws regarding hazardous materials, shipping regulations, and environmental standards may vary significantly.

Additionally, buyers should be aware of any potential tariffs or trade restrictions that could affect the import of electric car batteries. Establishing strong relationships with local regulatory bodies can facilitate smoother transactions and ensure compliance with all relevant laws.

In conclusion, the manufacturing processes and quality assurance practices for electric car trunk batteries are complex but essential. B2B buyers must navigate these processes carefully to ensure they procure high-quality batteries that meet their operational needs and comply with international standards. By focusing on material preparation, forming, assembly, finishing, and robust quality control, buyers can enhance their supply chain effectiveness and product reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric car trunck battery’

Introduction

This sourcing guide is designed for B2B buyers looking to procure electric car trunk batteries. It outlines essential steps to ensure you select the right products and suppliers, ultimately facilitating a smooth purchasing process. By following this checklist, buyers can make informed decisions that align with their technical requirements and business objectives.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. This includes determining the battery type, capacity (measured in kWh), voltage, and compatibility with your vehicle models. Defining these parameters ensures you select a product that meets your operational needs and performance expectations.

- Consider battery chemistry: Different chemistries (e.g., lithium-ion, nickel-metal hydride) have varying performance characteristics, affecting range and lifespan.

- Understand size and weight constraints: Ensure that the battery dimensions fit within the designated trunk space and do not exceed vehicle load limits.

Step 2: Research Market Trends and Innovations

Stay updated on the latest trends and innovations in electric vehicle battery technology. Understanding advancements can help you identify high-performance options that may provide a competitive edge in your market.

- Look for modular designs: Modular batteries can offer flexibility for scaling and easier upgrades in the future.

- Monitor thermal management solutions: Efficient thermal management can enhance battery life and performance, making it a critical factor in your selection process.

Step 3: Evaluate Potential Suppliers

Before making a purchase, thoroughly evaluate potential suppliers. This step is crucial to ensure reliability and quality in the products you source.

- Request company profiles: Look for information on their manufacturing processes, quality control measures, and experience in the industry.

- Seek references: Ask for case studies or testimonials from previous clients, particularly those in similar markets or applications.

Step 4: Verify Certifications and Compliance

Ensure that the batteries you are considering meet international safety and quality standards. This is vital for both performance and regulatory compliance, especially in diverse markets.

- Check for ISO certifications: An ISO-certified manufacturer is more likely to adhere to high-quality standards.

- Assess compliance with regional regulations: Different regions may have specific requirements, particularly in Africa, South America, the Middle East, and Europe.

Step 5: Request Samples and Conduct Testing

Before committing to a large order, request samples from your shortlisted suppliers. Conducting rigorous testing on these samples will help verify their performance and compatibility with your vehicles.

- Perform diagnostics: Use diagnostic tools to assess battery performance metrics, including capacity, charge cycles, and thermal stability.

- Evaluate real-world performance: If possible, install the samples in a vehicle and monitor performance under typical operating conditions.

Step 6: Negotiate Pricing and Terms

Once you have selected a supplier, engage in negotiations to secure favorable pricing and payment terms. Clear agreements can significantly impact your overall procurement costs.

- Consider volume discounts: Many suppliers offer reduced prices for bulk orders, which can enhance your profitability.

- Discuss warranty and service options: Ensure you understand the warranty terms and what support is available post-purchase.

Step 7: Finalize Logistics and Delivery Plans

Finally, coordinate logistics and delivery plans to ensure timely receipt of your batteries. This includes confirming shipping methods, lead times, and any potential import/export considerations.

- Establish a clear timeline: Having a defined schedule helps manage expectations and ensures that your supply chain remains uninterrupted.

- Prepare for customs clearance: Understand the regulations regarding the importation of batteries in your target markets to avoid delays.

By following these steps, B2B buyers can confidently navigate the procurement process for electric car trunk batteries, ensuring they choose the best solutions for their needs.

Comprehensive Cost and Pricing Analysis for electric car trunck battery Sourcing

What Are the Key Cost Components for Electric Car Trunk Batteries?

When sourcing electric car trunk batteries, understanding the cost structure is crucial for B2B buyers. The primary components influencing the total cost include:

-

Materials: The cost of raw materials such as lithium, cobalt, and nickel significantly impacts the overall price. These materials are subject to market fluctuations, and sourcing them sustainably can add to the cost.

-

Labor: Skilled labor is required for battery assembly, testing, and quality control. Labor costs can vary widely based on geographic location and the expertise of the workforce.

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, equipment maintenance, and facility management. Efficient manufacturing processes can help minimize these costs.

-

Tooling: Investment in specialized tooling for battery production is necessary for high-quality output. Custom tooling can increase initial costs but may lead to cost savings in the long run through improved efficiency.

-

Quality Control (QC): Ensuring the reliability and safety of battery packs requires rigorous quality control measures. This includes testing for performance, durability, and compliance with international safety standards.

-

Logistics: Transportation costs for shipping batteries from manufacturers to buyers are significant, especially for international transactions. Factors such as distance, mode of transport, and tariffs can influence these costs.

-

Margin: Suppliers typically build a profit margin into their pricing, which can vary depending on market demand, competition, and the perceived value of the product.

How Do Price Influencers Impact Battery Sourcing?

Several factors can influence the pricing of electric car trunk batteries, particularly for international buyers:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to discounts, making it essential for buyers to assess their needs and negotiate effectively to secure favorable pricing.

-

Specifications/Customization: Custom battery solutions that meet specific vehicle requirements can lead to higher costs. Buyers should consider whether the customization aligns with their business strategy and customer needs.

-

Materials and Quality Certifications: High-quality materials and certifications can drive up costs. However, investing in better quality can reduce long-term risks associated with battery performance and safety.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may command higher prices due to their track record of quality and service.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for pricing negotiations. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly affect total costs.

What Buyer Tips Can Help Optimize Battery Sourcing Costs?

To maximize cost-efficiency when sourcing electric car trunk batteries, buyers should consider the following strategies:

-

Negotiation: Engage in proactive negotiations with suppliers. Understanding the cost structure can provide leverage in discussions and help secure better pricing terms.

-

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the upfront costs. Consider factors like battery lifespan, warranty, and maintenance costs, which can significantly affect long-term expenses.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import duties, and regional market conditions that can impact pricing. Establishing long-term relationships with suppliers can also help mitigate risks associated with international sourcing.

-

Research Market Trends: Staying informed about market trends in battery technology and pricing can provide insights into potential price changes and help buyers make informed purchasing decisions.

Disclaimer on Indicative Prices

It’s important to note that prices for electric car trunk batteries can vary widely based on the factors discussed above. Buyers should conduct thorough market research and obtain quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing electric car trunck battery With Other Solutions

Introduction to Alternative Solutions for Electric Car Batteries

As the demand for electric vehicles (EVs) continues to grow, so does the need for efficient and reliable energy storage solutions. While the electric car trunk battery stands out as a prominent choice, it’s essential for B2B buyers to explore alternative technologies that may better fit their operational needs. This analysis compares electric car trunk batteries against modular battery systems and battery expansion packs, providing insight into their respective advantages and drawbacks.

Comparison Table

| Comparison Aspect | Electric Car Trunk Battery | Modular Battery System | Battery Expansion Packs |

|---|---|---|---|

| Performance | High energy density, tailored for specific vehicle designs | Scalable capacity, customizable for various needs | Limited capacity per pack; dependent on stacking |

| Cost | Moderate to high initial investment, potential for replacement costs | Variable pricing based on configuration; volume discounts available | Generally lower initial cost, but cumulative costs can add up |

| Ease of Implementation | Typically designed for specific models, may require professional installation | Requires technical expertise for installation and configuration | User-friendly design, easy stacking and removal |

| Maintenance | Moderate; battery life can vary, requiring eventual replacement | Low; designed for longevity with built-in management systems | Moderate; depends on usage and frequency of pack changes |

| Best Use Case | Ideal for OEMs and established vehicle platforms | Suitable for custom builds and off-road applications | Excellent for users needing flexibility in battery capacity |

Detailed Breakdown of Alternatives

Modular Battery Systems

Modular battery systems, like the HyperPack Energy, offer scalability and customization, making them suitable for various applications, from racing to heavy-duty vehicles. These systems can be connected to create higher capacity, allowing businesses to tailor energy storage according to specific requirements. However, they often require technical expertise for proper installation and integration, which could deter less experienced buyers. The initial investment can be higher, but the long-term benefits of flexibility and efficiency may outweigh the costs.

Battery Expansion Packs

Battery expansion packs present a unique solution for users looking to increase their vehicle’s capacity without committing to a full battery replacement. These packs can be stacked and removed easily, providing a modular approach to energy storage. This design is particularly beneficial for users needing temporary boosts in capacity for specific tasks. However, each pack may have limited energy output, and the cumulative costs can rise if multiple packs are needed. Additionally, while installation is relatively straightforward, managing multiple packs can introduce complexity regarding weight distribution and vehicle dynamics.

Conclusion: How to Choose the Right Battery Solution

For B2B buyers, selecting the appropriate battery solution hinges on understanding specific operational needs, budget constraints, and the desired performance characteristics. Electric car trunk batteries provide reliability for standard applications, while modular systems offer flexibility for custom projects. Battery expansion packs serve as a versatile option for temporary capacity boosts. Ultimately, the decision should align with the company’s long-term strategy, whether it aims for scalability, cost-effectiveness, or specialized performance. Conducting thorough research and considering future growth will ensure that buyers make informed choices that enhance their operational capabilities.

Essential Technical Properties and Trade Terminology for electric car trunck battery

What Are the Key Technical Properties of Electric Car Trunk Batteries?

When sourcing electric car trunk batteries, understanding their technical properties is vital for B2B buyers. Here are some critical specifications that can significantly impact battery performance and integration:

-

Energy Density (Wh/kg)

Energy density measures how much energy a battery can store relative to its weight. Higher energy density allows for lighter batteries, which can improve vehicle efficiency and performance. For B2B buyers, selecting batteries with optimal energy density is crucial for meeting performance standards without compromising vehicle design. -

Cycle Life

Cycle life refers to the number of complete charge and discharge cycles a battery can undergo before its capacity drops to a specified percentage of its original capacity. A longer cycle life translates to lower replacement frequency and costs. For international buyers, particularly in regions like Africa and South America where battery logistics can be challenging, investing in batteries with extended cycle life can offer significant long-term savings. -

Temperature Range

This specification indicates the operational temperature limits within which the battery can function effectively. Batteries that can operate in wider temperature ranges are more versatile and reliable, especially in diverse climates. Buyers should consider this property to ensure that batteries will perform consistently in the intended geographical markets. -

Battery Management System (BMS)

A BMS monitors the battery’s state, controls its charging and discharging, and ensures safety by preventing overcharging and overheating. A robust BMS is essential for maintaining battery health and performance. B2B buyers should prioritize batteries with advanced BMS features to minimize risks and enhance longevity. -

Form Factor

The physical dimensions and design of the battery are critical for integration into vehicle designs. Standardized dimensions can simplify installation and replacement processes. Buyers need to ensure that the battery’s form factor aligns with their vehicle models to avoid additional costs in modifications. -

Safety Ratings

Safety ratings assess the battery’s resistance to failure modes like thermal runaway or short circuits. High safety ratings are essential for compliance with industry regulations and consumer safety expectations. B2B buyers should verify safety certifications and consider them a priority to mitigate liability risks.

What Common Trade Terms Should B2B Buyers Understand in the Electric Car Battery Market?

Familiarity with industry jargon is crucial for effective communication and negotiation. Here are some common trade terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the electric vehicle sector, OEMs are often responsible for integrating batteries into their vehicles. Understanding OEM relationships can help buyers negotiate better pricing and warranty terms. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This is important for budgeting and inventory management. B2B buyers should clarify MOQs to ensure they can meet supplier requirements without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document that solicits price quotes from suppliers for specific products or services. Issuing RFQs can help buyers compare prices and terms from multiple suppliers, enabling better decision-making based on cost and quality. -

Incoterms (International Commercial Terms)

Incoterms are a set of pre-defined commercial terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help B2B buyers navigate shipping, insurance, and delivery responsibilities effectively. -

KWh (Kilowatt-hour)

A kilowatt-hour is a unit of energy that represents the amount of energy consumed if a device uses one kilowatt of power for one hour. Understanding KWh is essential for evaluating battery capacity and energy consumption in electric vehicles. -

Thermal Management

This term refers to systems and processes that regulate battery temperature to optimize performance and longevity. Effective thermal management is crucial for maintaining battery efficiency, especially in high-performance electric vehicles.

In conclusion, comprehending the essential technical properties and trade terminology associated with electric car trunk batteries is paramount for B2B buyers looking to make informed purchasing decisions. By focusing on these key aspects, buyers can align their procurement strategies with industry standards and market demands.

Navigating Market Dynamics and Sourcing Trends in the electric car trunck battery Sector

What are the Current Market Dynamics and Key Trends in the Electric Car Trunk Battery Sector?

The electric vehicle (EV) market is experiencing robust growth driven by increasing environmental regulations, consumer demand for sustainable transportation, and advances in battery technology. Notably, the global push towards net-zero emissions has accelerated the adoption of electric vehicles, particularly in regions like Africa, South America, the Middle East, and Europe. For B2B buyers in these markets, understanding the dynamics of electric car trunk batteries is crucial.

Emerging trends such as modular battery systems and enhanced battery management systems (BMS) are reshaping sourcing strategies. Modular batteries allow for flexible scaling, enabling manufacturers to customize energy solutions for different vehicle models, which is particularly beneficial in regions with varying infrastructure capabilities. Additionally, the trend of battery-as-a-service (BaaS) is gaining traction, allowing businesses to minimize upfront costs by leasing battery packs instead of purchasing them outright.

International buyers must also consider local sourcing partnerships. Collaborating with regional manufacturers not only mitigates supply chain disruptions but also aligns with local regulations and incentives aimed at promoting EV adoption. As the market matures, the focus will shift towards optimizing performance and reducing costs, making it essential for B2B buyers to stay informed about technological advancements and competitive pricing models.

How Does Sustainability and Ethical Sourcing Impact the Electric Car Trunk Battery Sector?

Sustainability is a pivotal concern in the electric car trunk battery sector. The environmental impact of battery production, particularly in terms of resource extraction and waste management, has prompted a shift towards more sustainable practices. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing and sustainable manufacturing processes.

The importance of ethical supply chains cannot be overstated. Buyers should seek partners that comply with international labor standards and employ sustainable practices in sourcing raw materials like lithium and cobalt. Certifications such as ISO 14001 (Environmental Management) and the Responsible Business Alliance (RBA) are indicators of a supplier’s commitment to sustainability.

Moreover, the adoption of ‘green’ materials and technologies is becoming a competitive advantage. For instance, companies that invest in recycling programs for battery materials can significantly reduce their environmental footprint. B2B buyers can leverage these sustainable practices not only to enhance their brand reputation but also to meet the increasing consumer demand for environmentally responsible products.

What is the Brief Evolution and History of Electric Car Trunk Batteries Relevant to B2B Buyers?

The evolution of electric car trunk batteries has been marked by significant technological advancements and market shifts. Initially, lead-acid batteries dominated the early EV market due to their affordability. However, as the demand for electric vehicles grew, manufacturers began transitioning to lithium-ion technology, which offers superior energy density and longevity.

The development of modular battery systems represents a key milestone in this evolution. These systems allow for easier upgrades and replacements, addressing concerns about battery lifespan and performance degradation. As manufacturers have shifted towards more sustainable practices, the integration of advanced BMS and thermal management systems has become standard, enhancing the reliability and efficiency of electric car batteries.

Understanding this historical context is essential for B2B buyers. It provides insights into the technological advancements that have shaped the current market landscape and informs future sourcing decisions. By recognizing the trajectory of electric car trunk batteries, buyers can better anticipate market trends and align their procurement strategies accordingly.

Frequently Asked Questions (FAQs) for B2B Buyers of electric car trunck battery

-

How do I solve issues related to battery replacement for electric vehicles?

To address battery replacement issues, first conduct comprehensive diagnostics to evaluate the battery’s health and performance using specialized tools. Engage with a certified technician who understands various electric vehicle (EV) models and their specific requirements. It’s crucial to maintain a stock of compatible batteries and establish relationships with reputable suppliers to ensure timely replacements. Additionally, keep abreast of warranty conditions and customer expectations to enhance service quality and build trust with your clients. -

What is the best battery type for electric vehicles in emerging markets?

Lithium-ion batteries are generally the best choice for electric vehicles in emerging markets due to their high energy density, lightweight, and declining costs. They offer a balance of performance and affordability, making them suitable for various EV applications. Consideration should also be given to local climate conditions, as some battery types perform better in specific environments. Collaborating with suppliers who can provide customizable solutions tailored to local market needs will further enhance your product offering. -

What are the minimum order quantities (MOQ) for electric car trunk batteries?

Minimum order quantities for electric car trunk batteries can vary significantly based on the supplier and specific battery model. Typically, MOQs range from 10 to 100 units, depending on the manufacturer’s production capabilities and market demand. It’s advisable to negotiate with suppliers, especially if you are looking to establish a long-term partnership. Ensure that your order aligns with your inventory management strategy to avoid overstocking or stockouts. -

How can I verify the credibility of a battery supplier for international trade?

To verify a supplier’s credibility, start by checking their business licenses, certifications, and industry reputation. Look for reviews and testimonials from previous clients and conduct background checks using platforms such as LinkedIn or trade associations. Request product samples and assess their quality and compliance with international standards. Additionally, consider visiting their manufacturing facilities or arranging for third-party inspections to ensure they meet your quality and safety requirements. -

What payment terms should I consider when sourcing batteries internationally?

When sourcing batteries internationally, aim for payment terms that minimize risk while ensuring cash flow. Common terms include Letter of Credit (LC) for larger orders, which provides security for both parties. For smaller orders, consider partial upfront payments with the remainder due upon delivery or after inspection. Establishing clear terms regarding currency exchange, potential tariffs, and payment timelines is crucial to avoid misunderstandings and protect your investment. -

What logistics considerations are essential for importing electric car batteries?

Logistics for importing electric car batteries require careful planning due to their hazardous nature. Ensure compliance with international shipping regulations, including the International Air Transport Association (IATA) guidelines for transporting lithium batteries. Partner with logistics providers experienced in handling hazardous materials to navigate customs regulations efficiently. Additionally, consider the costs associated with shipping, insurance, and potential tariffs to ensure a smooth import process. -

How can I customize battery solutions for my market needs?

Customization of battery solutions can be achieved through collaboration with manufacturers who offer flexible production capabilities. Discuss your specific requirements regarding capacity, size, and performance characteristics to develop tailored solutions. Additionally, consider local market conditions, such as temperature variations and charging infrastructure, to enhance compatibility. Regular communication with your supplier during the design and production phases is key to achieving the desired outcome. -

What quality assurance measures should I expect from battery suppliers?

Quality assurance measures from battery suppliers should include rigorous testing protocols throughout the production process. Expect certifications such as ISO 9001 and adherence to industry standards like IEC and UN38.3 for safety. Inquire about the supplier’s testing methods for capacity, cycle life, and performance under various conditions. Regular audits and feedback loops between you and the supplier can also help maintain product quality and address any issues promptly.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 3 Electric Car Trunck Battery Manufacturers & Suppliers List

1. Gruber Motors – Roadster 12 Volt Battery Relocation Kit

Domain: grubermotors.com

Registered: 2019 (6 years)

Introduction: Roadster – 12 Volt Battery to Trunk Relocation Kit

– Price: $924

– Purpose: Relocates the secondary 12 Volt battery from the passenger wheel well to the trunk for easier access and replacement.

– Battery Type: 8 AH AGM motorcycle battery replaced with a higher capacity 12 AH battery or a Lithium battery with a 4-year warranty.

– Components Included: Battery Enclosure with Meter, 12′ of heavy 30 AM…

2. Facebook – Frunk Trigger Solution

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Frunk Trigger Solution, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Toyota RAV4 Hybrid – Battery Location Insights

Domain: mechanics.stackexchange.com

Registered: 2009 (16 years)

Introduction: 2016 Toyota RAV4 hybrid; 12V battery located under the trunk; advantages include improved temperature management and potentially longer battery life; drawbacks include longer and thicker cables required, wasted storage space in the trunk, need for a jumper terminal under the hood, and difficulty in accessing the battery for maintenance.

Strategic Sourcing Conclusion and Outlook for electric car trunck battery

What Are the Key Takeaways for B2B Buyers in the Electric Car Battery Market?

In the rapidly evolving electric vehicle (EV) sector, strategic sourcing of trunk batteries presents significant opportunities for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. Understanding the nuances of battery replacement and the growing demand for modular battery solutions is crucial. As the market shifts towards sustainable practices, investing in high-quality, modular battery systems like the HyperPack Energy can streamline operations and reduce costs. Additionally, staying informed about the technological advancements in battery diagnostics and management systems can enhance service offerings and customer satisfaction.

How Can International Buyers Leverage Strategic Sourcing for Competitive Advantage?

B2B buyers should prioritize partnerships with manufacturers that offer comprehensive solutions, including battery management systems and thermal management features. By leveraging volume pricing and robust support, businesses can optimize their procurement strategies to meet the increasing demand for electric vehicles.

What Is the Future Outlook for Electric Car Trunk Batteries?

As the global transition to electric vehicles accelerates, the demand for reliable and efficient trunk batteries will continue to grow. International buyers are encouraged to act now—explore partnerships, invest in innovative battery technologies, and stay ahead of market trends. Embrace this pivotal moment to secure a competitive edge in the electric vehicle landscape.