Introduction: Navigating the Global Market for cargo tricycle

In today’s fast-paced global market, sourcing reliable cargo tricycles presents both opportunities and challenges for international B2B buyers. As businesses across Africa, South America, the Middle East, and Europe seek sustainable and efficient transportation solutions, understanding the diverse offerings and applications of cargo tricycles becomes paramount. This guide delves into the world of cargo tricycles, providing insights on different types, their practical applications, and essential considerations for supplier vetting.

From heavy-duty models designed for industrial use to versatile options suitable for urban delivery, cargo tricycles are an eco-friendly alternative that can reduce operational costs and enhance delivery efficiency. Furthermore, we will explore the various features that set apart high-quality cargo tricycles, including load capacity, stability, and innovative technologies such as e-drives and tilting systems.

By equipping B2B buyers with actionable insights into pricing, performance, and application suitability, this comprehensive guide empowers stakeholders to make informed purchasing decisions. Whether you are a distributor in Brazil or a logistics manager in Vietnam, understanding the nuances of cargo tricycles will enable you to select the right solutions that align with your operational needs and sustainability goals.

Understanding cargo tricycle Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Front-Loading Cargo Trike | Large cargo area at the front, enhanced stability | Delivery services, urban transport | Pros: Easy to steer, good visibility. Cons: Limited cargo height. |

| Rear-Loading Cargo Trike | Cargo compartment at the back, high loading capacity | Heavy-duty transport, construction sites | Pros: High load capacity, stable for heavy loads. Cons: Less maneuverable. |

| Electric Cargo Trike | Integrated e-motor for assisted pedaling | Logistics, last-mile delivery | Pros: Reduces physical strain, suitable for longer distances. Cons: Higher upfront cost, maintenance of electric components. |

| Adaptable Cargo Trike | Versatile design for various cargo sizes | Retail, food delivery | Pros: Customizable, can handle different loads. Cons: Potentially less robust than specialized models. |

| Tilting Cargo Trike | Allows for dynamic maneuvering, similar to a bicycle | Recreational use, urban commuting | Pros: Sporty ride, better handling in corners. Cons: More complex design may require maintenance. |

What are the Key Features of Front-Loading Cargo Trikes?

Front-loading cargo trikes are characterized by their large cargo area positioned ahead of the rider. This design enhances stability and allows for better visibility while navigating urban environments. They are particularly well-suited for delivery services and urban transport applications, where ease of steering and quick access to cargo is essential. B2B buyers should consider the trike’s maneuverability in crowded spaces and the limitations on cargo height, which may restrict certain types of loads.

How Do Rear-Loading Cargo Trikes Support Heavy-Duty Transport?

Rear-loading cargo trikes feature a robust cargo compartment located behind the rider, making them ideal for transporting heavy and bulky items. This design allows for a high loading capacity, making them a popular choice in construction and logistics sectors. Buyers should evaluate the trike’s weight distribution and stability, especially when carrying heavy loads, to ensure safe operation in various conditions. While they are stable, their maneuverability can be limited compared to front-loading models.

Why Choose Electric Cargo Trikes for Logistics?

Electric cargo trikes are equipped with an integrated e-motor that assists with pedaling, making them an excellent choice for logistics and last-mile delivery. This feature significantly reduces the physical strain on the rider, allowing for longer distances to be covered with ease. B2B buyers should weigh the benefits of reduced rider fatigue against the higher initial investment and ongoing maintenance costs associated with electric components. These trikes are particularly advantageous in urban areas with steep terrain.

What Makes Adaptable Cargo Trikes Versatile for Various Applications?

Adaptable cargo trikes offer a flexible design that can accommodate different cargo sizes and types, making them suitable for various applications such as retail and food delivery. Their customizable features allow businesses to tailor the trike to their specific needs, enhancing operational efficiency. When purchasing, businesses should consider the balance between versatility and the potential trade-offs in durability compared to models designed for specific heavy-duty tasks.

How Do Tilting Cargo Trikes Enhance the Riding Experience?

Tilting cargo trikes incorporate technology that allows the rider to lean into turns, similar to traditional bicycles. This design improves maneuverability and handling, making them suitable for recreational use and urban commuting. They offer a sporty riding experience, which can be appealing for businesses looking to provide a unique transport option. However, buyers should be aware that the more complex design may necessitate additional maintenance, which could impact long-term operational costs.

Key Industrial Applications of cargo tricycle

| Industry/Sector | Specific Application of Cargo Tricycle | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & E-commerce | Last-mile delivery of goods | Reduces carbon footprint and operational costs while enhancing delivery speed. | Look for durable models with large cargo capacity and weather-resistant features. |

| Food & Beverage | Mobile food vendors | Provides a flexible and eco-friendly solution for food delivery, enhancing customer reach. | Ensure compliance with local health regulations and consider models with refrigeration options. |

| Logistics & Warehousing | Transporting tools and materials | Improves efficiency in moving goods within facilities, reducing reliance on motorized vehicles. | Prioritize tricycles with high load capacity and ease of maneuverability in tight spaces. |

| Tourism & Recreation | Guided tours and passenger transport | Offers a unique, sustainable experience for tourists, increasing engagement and satisfaction. | Consider models with comfortable seating and safety features for passenger transport. |

| Healthcare | Mobile health clinics | Facilitates access to healthcare services in remote areas, improving community health outcomes. | Focus on tricycles that can accommodate medical equipment and provide stability on various terrains. |

How Are Cargo Tricycles Used in Retail & E-commerce?

In the retail and e-commerce sector, cargo tricycles are increasingly used for last-mile delivery solutions. They enable businesses to transport goods directly to customers in urban areas, reducing the reliance on motor vehicles, which can be costly and environmentally harmful. Cargo tricycles can navigate congested streets and tight spaces more easily than vans, leading to quicker deliveries. For international buyers, it’s essential to select models that offer ample cargo space and durability to handle frequent use, particularly in diverse weather conditions.

What Role Do Cargo Tricycles Play in Food & Beverage Industries?

Cargo tricycles serve as mobile food vendors, allowing businesses to reach customers in various locations without the need for a traditional storefront. They are particularly effective at markets and events, where quick service and mobility are crucial. The sustainability factor attracts environmentally conscious consumers, enhancing brand image. Buyers in this sector should consider tricycles equipped with features such as refrigeration or heating elements to meet food safety standards, as well as easy access for serving customers.

How Do Cargo Tricycles Enhance Logistics & Warehousing Operations?

In logistics and warehousing, cargo tricycles streamline the transport of tools, materials, and products within facilities. They provide an efficient, eco-friendly alternative to motorized vehicles, reducing operational costs while increasing mobility. Cargo tricycles can easily navigate narrow aisles and tight corners, making them ideal for warehouses. Businesses should prioritize sourcing tricycles with a high load capacity and robust construction to withstand the demands of heavy-duty use.

In What Ways Are Cargo Tricycles Beneficial for Tourism & Recreation?

In the tourism sector, cargo tricycles are utilized for guided tours and transporting passengers. They offer an eco-friendly and engaging way for tourists to explore urban areas, enhancing the overall experience. Their stability and spacious design allow for comfortable rides, making them suitable for families and groups. Buyers in this industry should focus on tricycles that provide safety features, comfortable seating, and the ability to carry additional gear or supplies for tours.

How Are Cargo Tricycles Transforming Healthcare Access?

Cargo tricycles are playing a vital role in healthcare, particularly in underserved or remote areas. They can be equipped as mobile health clinics, providing essential services and medications directly to communities. This increases access to healthcare and promotes better health outcomes. When sourcing cargo tricycles for this application, it’s important to choose models that can accommodate medical equipment and ensure stability on varied terrains, especially in regions where road conditions may be poor.

3 Common User Pain Points for ‘cargo tricycle’ & Their Solutions

Scenario 1: Navigating the Challenges of Heavy Loads

The Problem: B2B buyers often face the daunting task of transporting heavy and bulky items, such as construction materials or large deliveries, using cargo tricycles. The inherent design of many tricycles may not be suited for handling excessive weight, leading to concerns about stability, safety, and potential damage to both the cargo and the vehicle. For instance, a logistics company may find that their standard cargo tricycle struggles to maintain balance when loaded to capacity, resulting in inefficient delivery processes and increased costs due to potential damages.

The Solution: To effectively address this challenge, buyers should focus on selecting heavy-duty cargo tricycles specifically designed for transporting substantial loads. When sourcing these tricycles, it’s crucial to review weight capacity ratings and choose models that feature reinforced frames and robust suspension systems. A prime example is the Worksman Mover Series, known for its exceptional load-bearing capabilities. Additionally, buyers should consider investing in accessories like secure cargo nets or straps to stabilize the load during transit. Proper training for operators on loading techniques can also mitigate risks and enhance safety, ensuring that deliveries are completed without incident.

Scenario 2: Ensuring User Comfort and Accessibility

The Problem: Many businesses operate in environments where employees or customers may have physical disabilities, making it challenging to find suitable transportation solutions. Standard cargo tricycles may not provide the necessary comfort or accessibility features, limiting their usability. For example, a community organization that aims to transport people with disabilities may struggle to find a cargo tricycle that accommodates various mobility needs, resulting in missed opportunities for inclusivity.

The Solution: To remedy this situation, B2B buyers should prioritize cargo tricycles that come equipped with features designed for comfort and accessibility. Look for models that offer adjustable seating, easy access ramps, and safety harnesses to accommodate users of different abilities. Cargo tricycles with e-drives can also make riding easier for individuals with limited mobility, allowing for a smoother experience. Brands like Mäx & Mäleon provide customizable options that can be tailored to meet specific needs. Engaging with manufacturers to discuss custom configurations can lead to solutions that enhance user experience and broaden the scope of operations for businesses focused on inclusive mobility.

Scenario 3: Overcoming Limited Maneuverability in Urban Settings

The Problem: Urban environments often present unique challenges for transportation, including narrow streets, crowded sidewalks, and heavy traffic. B2B buyers may find that standard cargo tricycles lack the maneuverability needed to navigate these settings efficiently. For instance, a delivery service operating in a bustling city might encounter difficulties when trying to make quick stops or turn sharply, ultimately leading to delays and customer dissatisfaction.

The Solution: To enhance maneuverability in urban settings, buyers should seek cargo tricycles that incorporate tilting technology or advanced steering systems. Models with Ackermann steering allow for tighter turns, making them ideal for navigating congested areas. Additionally, investing in cargo tricycles with a compact design can significantly improve handling in tight spaces. It’s also beneficial to conduct a thorough analysis of the routes used for deliveries and identify areas where a more agile vehicle can be utilized. Training delivery personnel on effective navigation techniques can further optimize the use of these vehicles, ensuring that they can meet the demands of fast-paced urban environments without sacrificing service quality.

Strategic Material Selection Guide for cargo tricycle

What Are the Key Materials Used in Cargo Tricycle Manufacturing?

When selecting materials for cargo tricycles, several factors come into play, including performance, durability, cost, and compliance with international standards. Below, we analyze four common materials used in cargo tricycle construction: steel, aluminum, composite materials, and plastic. Each material has unique properties and implications for B2B buyers, especially in diverse markets like Africa, South America, the Middle East, and Europe.

How Does Steel Perform in Cargo Tricycle Applications?

Key Properties: Steel is known for its high tensile strength and durability, making it suitable for heavy-duty applications. It generally has excellent corrosion resistance when treated with coatings or galvanization.

Pros & Cons: The primary advantage of steel is its strength, which allows for the construction of robust frames that can handle heavy loads. However, steel is heavier than other materials, which can affect maneuverability and energy efficiency. Manufacturing complexity can increase if advanced welding techniques are required, potentially raising costs.

Impact on Application: Steel’s strength makes it ideal for transporting heavy goods, but it may require additional treatments to ensure longevity in humid or coastal environments, which is a consideration for buyers in regions like Brazil or Vietnam.

What Advantages Does Aluminum Offer for Cargo Tricycles?

Key Properties: Aluminum is lightweight yet strong, with good corrosion resistance, especially when anodized. It also has a high strength-to-weight ratio, making it an attractive option for cargo tricycles.

Pros & Cons: The main advantage of aluminum is its weight, which enhances maneuverability and reduces energy consumption. However, aluminum can be more expensive than steel, and its manufacturing process may require specialized equipment, increasing complexity.

Impact on Application: Aluminum’s corrosion resistance makes it suitable for environments with high humidity or salt exposure, such as coastal areas in Africa or South America. Buyers should ensure compliance with relevant standards, such as ASTM for aluminum alloys.

How Do Composite Materials Enhance Cargo Tricycle Design?

Key Properties: Composites, such as fiberglass and carbon fiber, offer high strength with significantly reduced weight. They also provide excellent resistance to corrosion and environmental degradation.

Pros & Cons: Composites can be molded into complex shapes, allowing for innovative designs. However, they are typically more expensive and may require specialized manufacturing techniques, which can limit their use in cost-sensitive markets.

Impact on Application: The lightweight nature of composites enhances performance, particularly in urban settings where agility is essential. International buyers should consider the availability of materials and manufacturing capabilities in their regions to avoid delays.

What Role Does Plastic Play in Cargo Tricycle Construction?

Key Properties: Plastics, particularly high-density polyethylene (HDPE) and polypropylene, are lightweight, resistant to moisture, and can be molded into various shapes.

Pros & Cons: Plastics are generally low-cost and easy to manufacture, making them suitable for various components like storage boxes or fenders. However, they may not provide the same structural integrity as metals, which could limit their use in load-bearing applications.

Impact on Application: Plastic components are ideal for regions with high humidity or rain, as they resist moisture damage. Buyers should verify compliance with local regulations regarding plastic use and recycling, especially in Europe, where environmental standards are stringent.

Summary of Material Selection for Cargo Tricycles

| Material | Typical Use Case for cargo tricycle | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Frame construction | High strength and durability | Heavier, can affect maneuverability | Medium |

| Aluminum | Frame and components | Lightweight, good corrosion resistance | More expensive, complex manufacturing | High |

| Composite | Specialized components | High strength-to-weight ratio | Expensive, requires specialized equipment | High |

| Plastic | Non-structural components | Low cost, moisture resistant | Limited structural integrity | Low |

This material selection guide provides international B2B buyers with insights into the properties, advantages, and limitations of various materials used in cargo tricycle manufacturing. Understanding these factors will aid in making informed purchasing decisions tailored to specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for cargo tricycle

What Are the Key Stages in the Manufacturing Process of Cargo Tricycles?

The manufacturing of cargo tricycles involves several well-defined stages, each crucial for ensuring the final product meets quality standards and customer expectations. These stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation

The manufacturing process begins with the selection of high-quality materials, primarily steel or aluminum for the frame, and durable plastics or composites for components like the cargo box. Materials are sourced based on strength, weight, and corrosion resistance to ensure longevity and performance under various conditions. Suppliers often conduct initial quality checks, and materials are classified according to their specifications before moving to the next stage. -

Forming

Once the materials are prepared, they undergo forming processes, such as cutting, bending, and welding. Advanced techniques like CNC machining and laser cutting may be employed to achieve precise dimensions and complex shapes. For instance, the frame of the cargo tricycle is typically welded together using robotic welding systems that provide consistency and strength. This stage is critical, as the structural integrity of the tricycle depends on accurate forming. -

Assembly

After forming, the components are assembled. This stage involves the integration of various parts, including the frame, wheels, cargo area, and any additional features like electric motors or tilting mechanisms. Assembly lines are often set up to streamline the process, with workers or robots systematically assembling the tricycles. Quality control checks are frequently performed at this stage to ensure that all components fit correctly and function as intended. -

Finishing

The finishing stage includes surface treatments such as painting, powder coating, or galvanizing, which protect the cargo tricycle from corrosion and wear. The choice of finishing technique can affect both aesthetics and durability. Quality checks are performed after finishing to ensure that the surface treatment meets industry standards, and any defects are addressed before the products are packaged for shipment.

How Is Quality Assurance Implemented in Cargo Tricycle Manufacturing?

Quality assurance is a fundamental aspect of cargo tricycle manufacturing, ensuring that each product not only meets customer expectations but also complies with international standards. Various international standards, such as ISO 9001, along with industry-specific certifications like CE and API, guide the quality assurance process.

-

What International Standards Are Relevant?

ISO 9001 establishes criteria for a quality management system and is applicable to various industries, including manufacturing. Compliance with this standard ensures that manufacturers maintain consistent quality throughout their processes. The CE marking indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area. For manufacturers exporting to regions like Africa or South America, understanding and complying with local regulations is essential. -

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are strategically placed throughout the manufacturing process to monitor and verify product quality. Key checkpoints include:

– Incoming Quality Control (IQC): This occurs at the material preparation stage, where incoming materials are inspected for quality and compliance with specifications.

– In-Process Quality Control (IPQC): During the forming and assembly stages, regular inspections are conducted to ensure that processes are being followed correctly and that any defects are caught early.

– Final Quality Control (FQC): After finishing, a comprehensive inspection assesses the final product against quality standards and specifications. -

What Common Testing Methods Are Used?

Various testing methods are employed to validate the quality and performance of cargo tricycles. These may include:

– Load Testing: Assessing the tricycle’s ability to carry specified weights without structural failure.

– Stability Testing: Evaluating the tricycle’s handling and stability under different conditions, particularly important for models designed for heavy loads.

– Durability Testing: Subjecting the tricycle to environmental conditions (like rain, humidity, and temperature extremes) to ensure it withstands wear over time.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for ensuring product reliability and performance.

-

What Audit Processes Should Be Followed?

Conducting regular audits of suppliers can provide insights into their quality control practices. Buyers should request access to audit reports and certifications to confirm compliance with international standards. Third-party audits can also be beneficial, as they provide an unbiased assessment of the supplier’s processes. -

How to Request Quality Reports?

Buyers should proactively request quality assurance documentation from suppliers, including:

– ISO Certifications: Proof of compliance with international quality standards.

– Quality Control Reports: Documentation of quality checks performed throughout the manufacturing process.

– Testing Certifications: Results from any performance testing conducted on the cargo tricycles. -

What Role Do Third-Party Inspections Play?

Third-party inspections can provide an additional layer of verification for buyers. Engaging independent inspection agencies to evaluate the manufacturing facility and the products can help ensure that the cargo tricycles meet the required quality standards before shipment.

What Are the Nuances of Quality Control for International B2B Buyers?

Understanding the nuances of quality control is particularly important for international B2B buyers. Different regions may have varying regulatory requirements and quality expectations.

-

What Are the Regional Regulations?

Buyers should familiarize themselves with the specific regulations that apply to their regions. For instance, Europe has strict environmental and safety standards that cargo tricycles must meet, while regulations in Africa and South America may differ significantly. Understanding these differences can help buyers select suppliers that are compliant with local laws. -

How to Navigate Certification Challenges?

Certain certifications may be more challenging to obtain in some regions. Buyers should verify that suppliers have the necessary certifications to sell in their target markets. This includes understanding the implications of certifications like CE in Europe or local certifications in African and South American countries. -

What Strategies Can Be Used to Ensure Consistent Quality?

Establishing long-term relationships with suppliers and engaging in regular communication can help ensure consistent quality. Buyers should work closely with suppliers to understand their quality control processes and provide feedback to drive improvements.

By understanding the manufacturing processes and quality assurance practices associated with cargo tricycles, B2B buyers can make informed decisions when selecting suppliers, ensuring they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cargo tricycle’

In the quest to procure cargo tricycles for your business needs, it’s essential to approach the sourcing process methodically. This guide will help you navigate through the critical steps necessary to make an informed purchase that aligns with your operational requirements.

Step 1: Define Your Technical Specifications

Before beginning your search, outline the specific requirements for your cargo tricycles. Consider factors such as load capacity, dimensions, and intended use (e.g., transporting goods, children, or heavy materials). This clarity will streamline your supplier search and ensure you select a model that meets your operational needs.

Step 2: Research the Market and Trends

Investigate the current market landscape for cargo tricycles. Look into emerging trends, such as electric-assisted models or innovative designs with tilting technology. Understanding these trends will help you identify features that can enhance efficiency and sustainability in your operations.

Step 3: Evaluate Potential Suppliers

It’s crucial to vet suppliers thoroughly before making a commitment. Request detailed company profiles, product catalogs, and references from buyers in similar industries. Focus on suppliers who demonstrate a robust track record and positive customer feedback to ensure reliability.

- Check their product range: Ensure they offer a variety of models suitable for your specifications.

- Assess their experience: Favor suppliers with extensive industry experience, as they are likely to understand the nuances of cargo tricycle manufacturing.

Step 4: Verify Certifications and Compliance

Ensure that the cargo tricycles meet relevant industry standards and regulations. This may include certifications related to safety, emissions, and quality control. Compliance not only ensures the safety of your operations but also mitigates risks associated with non-compliant products.

Step 5: Request Samples or Demonstrations

Before finalizing your order, request samples or arrange for a demonstration of the cargo tricycles. This hands-on experience will allow you to assess the build quality, maneuverability, and overall performance. Pay attention to the ease of use, especially if your team will be operating the tricycles frequently.

Step 6: Negotiate Terms and Pricing

Once you have selected potential suppliers, engage in negotiations regarding pricing, delivery times, and payment terms. Ensure that you understand all associated costs, including shipping and potential import duties, especially when dealing with international suppliers. A clear agreement will help avoid unexpected expenses later.

Step 7: Plan for After-Sales Support and Maintenance

Finally, evaluate the after-sales support provided by the supplier. Ensure they offer accessible customer service and maintenance options. This is particularly important for long-term operational efficiency and can significantly affect the lifespan and performance of your cargo tricycles.

By following this structured checklist, you can confidently navigate the sourcing process for cargo tricycles, ensuring that you make a well-informed decision that supports your business objectives.

Comprehensive Cost and Pricing Analysis for cargo tricycle Sourcing

What Are the Key Cost Components in Sourcing Cargo Tricycles?

When sourcing cargo tricycles, understanding the cost structure is critical for B2B buyers to make informed decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of materials directly impacts both the quality and cost of the cargo tricycles. High-strength steel or aluminum frames are often preferred for their durability, but they also carry a higher price tag. Additional components like wheels, brakes, and cargo areas contribute to the overall material costs.

-

Labor: Labor costs can vary significantly based on the region of manufacturing. Countries with higher labor costs may offer better-skilled workers, while lower-cost regions may compromise on craftsmanship. Understanding local labor markets can help in negotiating better pricing.

-

Manufacturing Overhead: This includes utilities, rent, and other operational expenses associated with the production facility. Efficient factories with lower overhead can pass on cost savings to buyers.

-

Tooling: Initial tooling costs for specialized parts can be substantial, especially for custom designs. Buyers should consider these costs when evaluating quotes from suppliers.

-

Quality Control (QC): Investing in robust QC processes ensures the cargo tricycles meet safety and performance standards. This is particularly important for international buyers who may face stringent compliance regulations.

-

Logistics: Shipping costs can fluctuate based on the shipping method, distance, and any tariffs applicable to the destination country. It’s essential to incorporate these logistics costs into the total pricing analysis.

-

Margin: Supplier profit margins can vary widely. Understanding industry standards for margins can help buyers negotiate more effectively.

How Do Price Influencers Affect Cargo Tricycle Sourcing?

Several factors influence pricing, including volume, specifications, materials, quality certifications, supplier factors, and Incoterms.

-

Volume/MOQ: Larger orders often qualify for bulk pricing discounts. Buyers should assess their needs to determine optimal order sizes that balance cost and inventory management.

-

Specifications/Customization: Custom features, such as electric motors or specialized cargo areas, can significantly increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials: The choice between standard and premium materials can impact pricing. High-quality materials may offer better durability and lower long-term maintenance costs.

-

Quality/Certifications: Compliance with international safety and environmental standards can affect costs. Products with necessary certifications may come at a premium but can reduce liability risks.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with a track record of quality may charge more but offer peace of mind regarding product reliability.

-

Incoterms: Understanding the terms of shipping and delivery can impact the total cost. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) dictate who bears shipping costs and risks, affecting overall pricing.

What Buyer Tips Can Enhance Cost-Efficiency in Cargo Tricycle Sourcing?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, implementing strategic sourcing practices can yield significant cost benefits.

-

Negotiation: Leverage multiple supplier quotes to negotiate better terms. Building long-term relationships with suppliers can also lead to favorable pricing and terms.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which encompasses not just the purchase price but also maintenance, operational costs, and resale value. This holistic view ensures better investment decisions.

-

Pricing Nuances: Be aware of regional pricing trends and economic conditions. Currency fluctuations and local market demands can affect costs and should be factored into budgeting.

-

Consider Local Suppliers: Sourcing from local manufacturers can reduce logistics costs and lead times. This is particularly advantageous for buyers in emerging markets where access to international shipping may be limited.

Disclaimer on Indicative Prices

While indicative prices for cargo tricycles range from approximately $500 to $2,000 based on specifications and features, it is crucial for buyers to conduct thorough market research and obtain multiple quotes to ensure accurate pricing aligned with their specific needs. Prices can vary widely based on the factors discussed, and this analysis should serve as a guide rather than a definitive pricing structure.

Alternatives Analysis: Comparing cargo tricycle With Other Solutions

Exploring Alternatives to Cargo Tricycles for Cargo Transport

In the quest for efficient cargo transport solutions, businesses often find themselves weighing various options. Cargo tricycles offer unique advantages, but alternatives such as cargo bicycles, electric vans, and traditional trucks also merit consideration. Each option has its strengths and weaknesses, which can significantly impact operational efficiency, cost, and suitability for specific use cases.

Comparison Table

| Comparison Aspect | Cargo Tricycle | Cargo Bicycle | Electric Van |

|---|---|---|---|

| Performance | High stability, good for heavy loads | Moderate capacity, agile | High capacity, fast |

| Cost | Moderate initial investment | Lower initial cost | Higher purchase and operating costs |

| Ease of Implementation | Simple to deploy in urban areas | Easy to maneuver in tight spaces | Requires infrastructure (charging) |

| Maintenance | Low maintenance needs | Low maintenance | Higher maintenance and servicing |

| Best Use Case | Urban deliveries, transporting bulky items | Grocery deliveries, small loads | Long-distance transportation, larger cargo |

Detailed Breakdown of Alternatives

Cargo Bicycle

Cargo bicycles are a popular alternative for transporting goods. With their two-wheel design, they offer agility and ease of maneuverability in urban settings. They are generally more affordable than cargo tricycles and are easy to maintain. However, they have a lower load capacity and stability, making them less suitable for heavier or bulkier items. This makes them ideal for small-scale deliveries, such as groceries or light equipment, but may not meet the demands of businesses needing to transport heavier loads.

Electric Van

Electric vans represent a modern solution for businesses requiring greater transport capacity. They can carry substantial loads over longer distances and are equipped with advanced technologies for navigation and safety. However, the initial investment and ongoing operational costs (such as charging infrastructure) can be significant. While electric vans are excellent for long-distance transport and larger cargo, they may not be as environmentally friendly in urban areas due to traffic congestion and parking challenges. They are best suited for businesses that require regular transport of large quantities of goods across varying distances.

Conclusion: How to Choose the Right Cargo Transport Solution

When selecting the right cargo transport solution, B2B buyers should consider their specific operational needs, budget constraints, and the nature of the goods being transported. Cargo tricycles stand out for their stability, environmental benefits, and versatility in urban settings, making them ideal for local deliveries and transporting bulky items. In contrast, cargo bicycles are more suited for lighter loads, while electric vans are best for larger volumes over longer distances. Ultimately, the choice should align with the operational goals, financial considerations, and environmental commitments of the business.

Essential Technical Properties and Trade Terminology for cargo tricycle

What Are the Key Technical Properties of a Cargo Tricycle?

1. Load Capacity

Load capacity refers to the maximum weight a cargo tricycle can safely carry. This specification is crucial for B2B buyers as it directly impacts operational efficiency and safety. Depending on the model, load capacities can range from 150 kg to over 400 kg, making it essential for businesses to select a tricycle that meets their specific transportation needs.

2. Frame Material

Cargo tricycles are typically constructed from materials like steel, aluminum, or high-strength alloys. Steel offers durability and resistance to wear, while aluminum is lightweight and rust-resistant, making it easier to maneuver. Understanding the frame material is vital for B2B buyers, as it affects longevity, maintenance costs, and overall performance in varying environmental conditions.

3. Wheel Size and Type

The size of the wheels (usually between 20 to 26 inches) and their type (solid or pneumatic) play a significant role in the tricycle’s stability and comfort. Larger wheels can navigate rough terrains more effectively, which is especially important in regions with poor infrastructure. Buyers should consider their typical operating environment when evaluating wheel specifications.

4. Braking System

Cargo tricycles may feature various braking systems, including coaster brakes, disc brakes, or drum brakes. A reliable braking system is essential for safety, particularly when transporting heavy loads. B2B buyers should assess the braking technology used, as it can influence the vehicle’s stopping power and maintenance requirements.

5. Steering Mechanism

The steering mechanism, whether it be traditional or tilting technology, affects maneuverability and ease of handling. A tilting mechanism allows for more dynamic riding, especially in urban environments. Buyers should consider how the steering system aligns with their operational needs, such as navigating tight spaces or handling heavy cargo.

What Are Common Trade Terms Related to Cargo Tricycles?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand name. In the context of cargo tricycles, B2B buyers may work with OEMs to customize specifications or features tailored to their needs. Understanding OEM relationships can help businesses secure better pricing and quality assurance.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is particularly relevant for B2B buyers looking to purchase cargo tricycles in bulk. Knowing the MOQ can help businesses plan their inventory and budget more effectively, especially if they anticipate a steady demand for the vehicles.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific products or services. For cargo tricycles, submitting an RFQ allows buyers to compare multiple suppliers, negotiate terms, and ensure they are getting the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping and delivery responsibilities. Familiarity with Incoterms is crucial for B2B buyers engaged in cross-border transactions, as they clarify costs, risks, and logistics involved in importing cargo tricycles.

5. Warranty and After-Sales Support

Understanding warranty terms and after-sales support is essential for B2B buyers. This includes the duration of the warranty, what it covers, and the availability of maintenance services. Effective after-sales support can significantly reduce downtime and operational disruptions, making it a key consideration in purchasing decisions.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the cargo tricycle Sector

What Are the Current Market Dynamics and Key Trends Influencing the Cargo Tricycle Sector?

The cargo tricycle market is experiencing significant growth driven by a combination of urbanization, rising e-commerce, and a shift toward sustainable transportation solutions. In regions like Africa, South America, the Middle East, and Europe, the demand for efficient and eco-friendly logistics alternatives is surging. Cargo tricycles offer a versatile solution for last-mile delivery, catering to the needs of businesses that require transportation of goods in crowded urban environments.

Emerging technologies, such as electric assist systems and smart tracking capabilities, are enhancing the functionality of cargo tricycles, making them attractive to international B2B buyers. These innovations not only increase operational efficiency but also improve rider comfort and safety. Additionally, the trend toward local sourcing and production is reshaping supply chains. Buyers are increasingly looking for manufacturers who can offer quick turnaround times and responsive service, particularly in regions where logistics can be challenging.

Market dynamics are also being influenced by government policies promoting green transportation initiatives. Incentives for using low-emission vehicles and stricter regulations on urban congestion are encouraging businesses to adopt cargo tricycles as part of their logistics strategy. This shift presents a lucrative opportunity for B2B buyers to invest in cargo tricycles that align with sustainability goals while meeting operational needs.

How Can Sustainability and Ethical Sourcing Practices Enhance Cargo Tricycle Supply Chains?

Sustainability is becoming a non-negotiable criterion for B2B buyers in the cargo tricycle sector. The environmental impact of transportation is under scrutiny, and businesses are increasingly held accountable for their carbon footprint. Cargo tricycles offer a sustainable alternative to traditional vehicles, as they emit zero CO2 emissions during operation. This eco-friendly profile makes them appealing to companies aiming to enhance their sustainability credentials.

When sourcing cargo tricycles, buyers should prioritize manufacturers that adhere to ethical sourcing practices. This includes ensuring that materials are sourced responsibly and that labor practices throughout the supply chain meet international standards. Certifications such as ISO 14001 for environmental management and Fair Trade can provide assurance of a manufacturer’s commitment to sustainability and ethical practices.

Additionally, the use of sustainable materials, such as recycled metals and eco-friendly coatings, is gaining traction in the cargo tricycle manufacturing process. By choosing suppliers who prioritize these materials, B2B buyers can contribute to a circular economy and reduce waste, further enhancing their corporate social responsibility (CSR) initiatives.

What Is the Historical Context of Cargo Tricycles and Their Relevance Today?

Cargo tricycles have a rich history, initially gaining popularity in urban environments as practical solutions for transporting goods. Their design has evolved significantly, adapting to meet the demands of modern logistics while maintaining their core advantage of stability and load capacity. Historically, cargo tricycles were primarily used for local deliveries, but today they are being embraced by a wide range of industries, from e-commerce to food delivery services.

The evolution of cargo tricycles has been marked by technological advancements, such as the introduction of electric motors and smart technology. These innovations have expanded their functionality, allowing them to handle heavier loads and operate over longer distances. As cities grow and the demand for sustainable transport solutions increases, cargo tricycles are well-positioned to play a critical role in the future of urban logistics.

In summary, understanding the market dynamics, emphasizing sustainability, and recognizing the historical context of cargo tricycles can provide valuable insights for B2B buyers looking to invest in this sector. By aligning sourcing strategies with current trends and ethical practices, businesses can enhance their operations while contributing to a more sustainable future.

Frequently Asked Questions (FAQs) for B2B Buyers of cargo tricycle

-

How do I select the right cargo tricycle for my business needs?

Choosing the right cargo tricycle involves evaluating your specific transportation requirements. Consider factors such as the weight capacity, size of the loading area, and the terrain where the tricycle will be used. For instance, if you need to transport heavy items over rough surfaces, opt for a heavy-duty model with a robust frame and larger wheels. Additionally, assess whether a front or rear loading area suits your operational needs better, as this will impact maneuverability and ease of loading. -

What are the advantages of using cargo tricycles in urban logistics?

Cargo tricycles offer numerous advantages for urban logistics, including reduced emissions and improved maneuverability in congested areas. They provide a stable platform for transporting goods and can often navigate areas where larger vehicles cannot. Additionally, their design allows for easy loading and unloading, which can enhance delivery efficiency. By utilizing cargo tricycles, businesses can contribute to sustainable transport solutions while potentially reducing operational costs associated with fuel and maintenance. -

What customization options are available for cargo tricycles?

Many manufacturers offer customization options for cargo tricycles to meet specific business needs. Customizations may include variations in the loading area size, types of braking systems, and additional features like electric motors for enhanced performance. Businesses can also request branding options or specialized compartments for specific goods. When sourcing from suppliers, inquire about the extent of customization available and any associated costs or lead times. -

What is the typical minimum order quantity (MOQ) for cargo tricycles?

The minimum order quantity (MOQ) for cargo tricycles can vary significantly by supplier and model. Generally, MOQs can range from as few as five units for smaller manufacturers to 50 or more for larger companies. When sourcing, it’s important to communicate your volume needs upfront to negotiate favorable terms. Additionally, consider the potential for bulk discounts, which can significantly reduce your overall costs. -

What payment terms should I expect when sourcing cargo tricycles internationally?

Payment terms for international orders of cargo tricycles typically involve an upfront deposit, often around 30% of the total order value, with the balance due upon shipment or delivery. However, terms can vary based on the supplier’s policies and your relationship with them. Always clarify payment methods accepted (e.g., bank transfer, letter of credit) and ensure that terms are documented in your contract to avoid misunderstandings. -

How can I vet suppliers when sourcing cargo tricycles?

Vetting suppliers is crucial to ensure you partner with reputable manufacturers. Start by researching potential suppliers online, checking reviews, and requesting references from other businesses. It’s also advisable to verify their certifications and compliance with international quality standards. If possible, arrange a visit to their facility or request a video tour. Engaging in direct communication to discuss your needs and assess their responsiveness can also provide insights into their reliability. -

What quality assurance measures should be in place when purchasing cargo tricycles?

Quality assurance is essential when purchasing cargo tricycles to ensure they meet your operational requirements. Suppliers should provide detailed specifications and quality certifications for their products. It’s beneficial to request samples or conduct inspections before finalizing large orders. Additionally, inquire about the supplier’s warranty policies and after-sales support, as these can significantly impact your satisfaction and the longevity of your investment. -

What logistics considerations should I keep in mind when importing cargo tricycles?

When importing cargo tricycles, consider logistics factors such as shipping methods, customs duties, and delivery timelines. Choose a reliable freight forwarder familiar with your destination country’s regulations. It’s essential to understand the import duties and taxes that may apply to your shipment to avoid unexpected costs. Additionally, ensure that you have the necessary documentation, such as bills of lading and commercial invoices, to facilitate smooth customs clearance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Cargo Tricycle Manufacturers & Suppliers List

1. Worksman – Heavy Duty Industrial Trikes

Domain: worksmancycles.com

Registered: 1997 (28 years)

Introduction: Worksman Mover(TM) Industrial Tricycle M2626-3CB: Global standard in heavy duty industrial trikes, 26 inch wheels, THREE SPEED coaster brake, optional cargo basket and rear fenders, price: $1,159.00. Worksman Front Loader – Super Delivery Trike – Model SUD: Industrial Front Load Tricycle with 42″ x 23″ x 24″ front cabinet, super heavy duty, price: $1,899.00. Worksman Adaptable Industrial Tricycle …

2. Reddit – 3-Wheeled Cargo Bikes

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 3-wheeled cargo bikes provide balance and stability, making it easier to stop without tilting. They offer a secure spot for children to sit and store items, such as groceries or personal belongings. These bikes are suitable for families, especially those with young children, as they allow kids to get in and out easily and provide rain cover options. However, some users report that riding enjoyment…

3. Max and Maeleon – Cargo Tricycle

Domain: maxandmaeleon.com

Registered: 2021 (4 years)

Introduction: The Cargo Tricycle is a three-wheeled bicycle designed for transporting loads or people. It features a large or small loading area located at the front or rear, making it a stable and environmentally friendly alternative to cars and vans. Key features include:

– Front loading area for stable steering and easy communication with passengers, ideal for transporting children.

– Rear loading area for…

4. Amsterdam Bicycle – E-Cargo Trike Classic

Domain: amsterdam-bicycle.com

Registered: 2015 (10 years)

Introduction: Product Name: E-Cargo Trike Classic – Wide

Main Features:

– Full size cargo box with capacity for four kids (two benches, four double seat belts)

– Classic design with black saddle and grips, black Schwalbe Marathon tires, and a rear rack

– Reliable electric system by Shimano with a maximum pedal assist speed of 18kph

– Long range of 35 – 75 miles (can increase range by 20% with battery upgrade)

-…

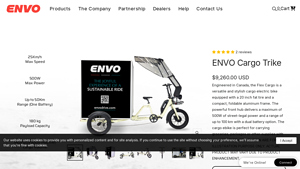

5. ENVO – Cargo Trike

Domain: envodrive.com

Registered: 2019 (6 years)

Introduction: ENVO Cargo Trike

– Sale Price: $9,260.00 USD

– Engineered in Canada

– Versatile and stylish cargo electric bike

– Equipped with 20 inch fat tire

– Compact, foldable aluminum frame

– Maximum Power: 500W

– Maximum Speed: 25Km/h (15.5mph)

– Maximum Range: Up to 50Km (30 miles) with single battery; up to 100 km (62 miles) with dual batteries

– Payload Capacity: 180 kg (400 lb)

– Dimensions: 140x120x90…

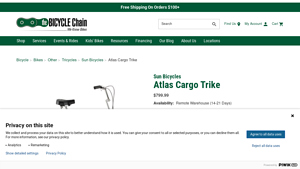

6. Sun Bicycles – Atlas Cargo Trike

Domain: thebicyclechain.com

Registered: 2005 (20 years)

Introduction: {“name”: “Sun Bicycles Atlas Cargo Trike”, “price”: “$799.99”, “availability”: “Unavailable”, “description”: “Originally designed for industrial complexes and farms, Sun’s Atlas Cargo Trike is just as much at home hauling the groceries. Its heavy-duty frame, wheels and tires are built for easy riding and long life. Plus, this sweet trike has an amazing 500-pound carrying capacity (rider and cargo)…

Strategic Sourcing Conclusion and Outlook for cargo tricycle

As the demand for sustainable and efficient transportation solutions grows globally, cargo tricycles emerge as a pivotal asset for businesses. Their versatility allows for the transportation of goods, children, and even pets, making them an ideal choice for various sectors, from logistics to retail. Strategic sourcing of cargo tricycles can significantly enhance operational efficiency, reduce carbon footprints, and provide a competitive edge in increasingly eco-conscious markets.

Investing in high-quality cargo tricycles not only addresses immediate logistical needs but also promotes a greener business model. With features such as robust load capacities, stability, and optional electric assistance, these vehicles are tailored to meet diverse needs across different regions.

International buyers, particularly from Africa, South America, the Middle East, and Europe, should consider the unique advantages of cargo tricycles. The time to act is now—explore partnerships with reputable manufacturers to leverage this sustainable transportation solution. By integrating cargo tricycles into your supply chain, you will not only enhance operational efficiency but also contribute to a more sustainable future. Embrace this opportunity to innovate your logistics and mobility strategies today!