Introduction: Navigating the Global Market for electric vehicle chassis

Navigating the global market for electric vehicle chassis presents a unique set of challenges for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. As the demand for sustainable transportation solutions surges, sourcing the right electric vehicle chassis becomes crucial for ensuring efficiency, safety, and adaptability in diverse applications. This guide aims to demystify the complexities of selecting electric vehicle chassis by providing a comprehensive overview of various types, applications, and innovative technologies available in the market.

Buyers will gain insights into the latest modular and skateboard chassis designs, such as REEcorner® technology, which offers unparalleled customization and efficiency. Additionally, the guide delves into essential aspects like supplier vetting processes, cost considerations, and the implications of rapidly evolving electric vehicle standards. By equipping B2B buyers with actionable knowledge, this resource empowers them to make informed purchasing decisions that align with their operational needs and market demands. Whether you are a fleet operator in Nigeria seeking energy-efficient solutions or a manufacturer in Germany looking to innovate your product lineup, this guide serves as your roadmap to success in the electric vehicle chassis market.

Understanding electric vehicle chassis Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Modular Platforms | Customizable, mission-specific designs; integrates critical components into compact modules. | Commercial vehicles, delivery vans, and specialized applications. | Pros: High adaptability, reduced TCO; Cons: Initial complexity in design. |

| Skateboard Platforms | Flat chassis design with all components integrated; flexible for various body types. | Passenger vehicles, pick-up trucks, and light commercial vehicles. | Pros: Cost-effective, versatile; Cons: Limited load capacity compared to traditional designs. |

| Chassis with X-by-Wire Technology | Advanced control systems for steering, braking, and driving; enhances safety and performance. | Autonomous vehicles, high-performance electric cars, and specialized transport. | Pros: Improved safety, precision control; Cons: Higher development costs. |

| Integrated Battery Chassis | Battery placement within the chassis for better weight distribution and space efficiency. | Urban delivery vehicles, cargo transport, and public transit. | Pros: Optimized space and weight; Cons: Limited customization for battery types. |

| Lightweight Composite Chassis | Use of composite materials to reduce weight while maintaining strength; enhances energy efficiency. | High-performance sports cars and electric motorcycles. | Pros: Enhanced performance and range; Cons: Higher material costs and potential durability concerns. |

What Are the Characteristics of Modular Platforms?

Modular platforms, such as those developed by REE Automotive, allow for a high degree of customization tailored to specific missions. They integrate essential vehicle components into compact modules, providing flexibility for fleet operators and OEMs. This design approach facilitates the creation of vehicles that meet precise operational needs while significantly reducing the total cost of ownership (TCO). Buyers should consider the initial complexity of design and integration, but the long-term operational efficiencies can justify the investment.

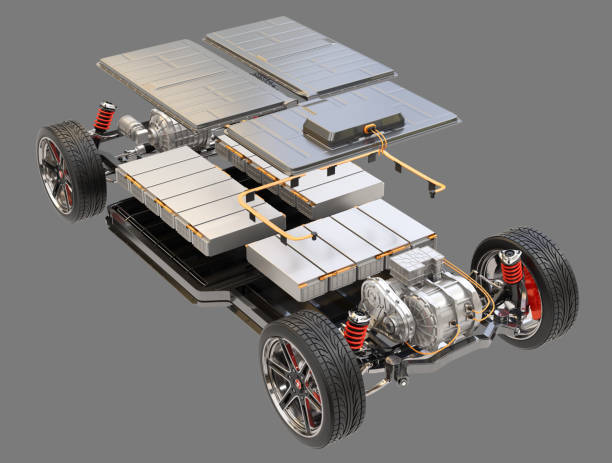

How Do Skateboard Platforms Benefit B2B Buyers?

Skateboard platforms represent a revolutionary approach to electric vehicle design, allowing manufacturers to build various vehicle types on a single chassis. This design includes all critical components, enabling quick adaptations for different applications, from passenger cars to delivery trucks. For B2B buyers, the cost-effectiveness and versatility of skateboard platforms are significant advantages. However, they may not support the same load capacities as traditional vehicle designs, which can be a consideration for heavy-duty applications.

What Advantages Does X-by-Wire Technology Offer?

X-by-wire technology enhances vehicle control by replacing traditional mechanical systems with electronic controls for steering, braking, and driving. This innovation not only improves safety through better stability and responsiveness but also prepares vehicles for autonomous driving capabilities. B2B buyers interested in cutting-edge technology and high-performance vehicles should weigh the benefits of enhanced safety and precision against the potentially higher development costs associated with these advanced systems.

Why Choose Integrated Battery Chassis for Urban Applications?

Chassis designed with integrated battery systems optimize space and weight distribution, making them ideal for urban delivery vehicles and public transport. This design ensures that batteries are securely housed within the chassis, improving efficiency and range. B2B buyers focusing on urban logistics and environmentally friendly transportation solutions will find integrated battery chassis beneficial, although customization options for battery types may be limited.

What Are the Benefits of Lightweight Composite Chassis?

Lightweight composite chassis offer significant advantages in performance and energy efficiency due to reduced weight without compromising strength. This is particularly advantageous for high-performance electric sports cars and motorcycles. B2B buyers looking to enhance vehicle performance and range should consider these chassis. However, the higher costs associated with composite materials and potential concerns regarding long-term durability are factors that must be evaluated in the purchasing decision.

Key Industrial Applications of electric vehicle chassis

| Industry/Sector | Specific Application of Electric Vehicle Chassis | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics & Delivery | Electric delivery vans and trucks | Enhanced operational efficiency and reduced TCO | Consider modularity for various cargo needs and local regulations. |

| Public Transportation | Electric buses and shuttles | Improved passenger comfort and lower emissions | Focus on chassis size, weight capacity, and battery integration. |

| Construction & Mining | Electric utility vehicles | Lower operational costs and reduced environmental impact | Evaluate chassis durability and load capacity for rugged terrains. |

| Agriculture | Electric tractors and farm vehicles | Increased efficiency and sustainability in farming | Assess compatibility with existing equipment and battery range. |

| Emergency Services | Electric ambulances and fire trucks | Faster response times and reduced operational costs | Ensure chassis adaptability for specialized equipment and safety features. |

How Can Electric Vehicle Chassis Transform the Logistics and Delivery Sector?

In the logistics and delivery industry, electric vehicle chassis are pivotal for the development of electric delivery vans and trucks. These vehicles are designed to optimize cargo space while minimizing weight, thereby enhancing operational efficiency. By leveraging modular designs, businesses can customize vehicles to meet specific delivery requirements, significantly reducing the total cost of ownership (TCO). For international buyers, especially in regions like Nigeria and Brazil, it is essential to consider local regulations and infrastructure compatibility when sourcing chassis.

What Advantages Do Electric Vehicle Chassis Offer Public Transportation Systems?

Electric buses and shuttles built on electric vehicle chassis offer public transportation systems improved passenger comfort and lower emissions. With a fully flat chassis design, these vehicles can provide more interior space, making them more appealing to passengers. Additionally, the integration of advanced technologies ensures better energy efficiency and operational reliability. For European buyers, ensuring compliance with stringent emissions regulations and focusing on battery range are critical factors in the sourcing process.

How Can Electric Vehicle Chassis Enhance Efficiency in Construction and Mining?

The construction and mining sectors benefit from electric utility vehicles that utilize robust electric vehicle chassis. These chassis are engineered to withstand harsh environments while providing lower operational costs through reduced fuel consumption and maintenance needs. Durability and load capacity are vital considerations for international buyers in these industries, particularly in regions with challenging terrains. Companies must assess the chassis’s ability to support heavy machinery and equipment to ensure operational efficiency.

What Role Do Electric Vehicle Chassis Play in Modern Agriculture?

Electric tractors and farm vehicles powered by electric vehicle chassis are revolutionizing agriculture by increasing efficiency and promoting sustainability. These vehicles can be tailored to specific farming tasks, reducing operational costs and environmental impact. For agricultural businesses in South America and Africa, sourcing chassis that can integrate with existing equipment while offering sufficient battery range is essential for maximizing productivity.

How Do Electric Vehicle Chassis Improve Emergency Services Operations?

Electric ambulances and fire trucks built on electric vehicle chassis are transforming emergency services by providing faster response times and lower operational costs. The adaptability of these chassis allows for the integration of specialized equipment, enhancing the effectiveness of emergency responses. Buyers in the Middle East and Europe should focus on sourcing chassis that meet safety standards and offer the necessary load capacity for emergency equipment, ensuring reliability in critical situations.

3 Common User Pain Points for ‘electric vehicle chassis’ & Their Solutions

Scenario 1: Difficulty in Customizing Chassis for Specific Applications

The Problem:

Many B2B buyers, particularly fleet operators and manufacturers, face challenges when trying to customize electric vehicle (EV) chassis for specific operational needs. Traditional chassis designs often come with fixed configurations that do not easily accommodate varied applications, such as delivery trucks, passenger shuttles, or specialized service vehicles. This lack of flexibility can lead to increased development costs, longer lead times, and a mismatch between the vehicle capabilities and the buyer’s operational requirements.

The Solution:

Investing in modular and scalable electric vehicle chassis systems, such as those offered by REE Automotive, can significantly alleviate these challenges. Modular platforms like the REEcorner® technology integrate all critical vehicle components into a compact design, enabling buyers to customize chassis configurations efficiently. B2B buyers should thoroughly evaluate their specific application needs and select chassis systems that offer design freedom. Engaging with manufacturers that provide flexible chassis solutions will allow for the rapid adaptation of the vehicle’s layout, ensuring that the final product meets precise operational requirements. Additionally, leveraging partnerships with body builders familiar with modular chassis can streamline the process, resulting in lower costs and faster time to market.

Scenario 2: Concerns Over Safety and Reliability

The Problem:

Safety and reliability are paramount for B2B buyers in industries such as logistics and public transport, where the stakes involve not just financial investments but also the safety of drivers and passengers. Traditional chassis often have complex mechanical systems that can be prone to failures, leading to costly downtimes and potential safety hazards. This concern becomes more pronounced in regions where the infrastructure may not support conventional vehicle performance.

The Solution:

To address safety concerns, buyers should consider electric vehicle chassis equipped with advanced safety technologies like x-by-wire systems, which eliminate mechanical components between the chassis and wheels. This technology enhances electronic stability control and allows for redundant fail-operational designs, ensuring that the vehicle can maintain safe operation even in the event of a failure. Buyers should specifically look for chassis systems compliant with international safety standards, such as ISO 262626, which ensures that the design has been rigorously tested. Collaborating with manufacturers that prioritize safety through innovative technology can mitigate risks and provide peace of mind for fleet operators.

Scenario 3: High Total Cost of Ownership (TCO)

The Problem:

A significant pain point for B2B buyers is the high total cost of ownership associated with electric vehicle chassis, which includes upfront costs, maintenance, and operational expenses. Many buyers are deterred by the perception that electric vehicles, while environmentally friendly, come with hidden costs that can erode profit margins. This concern is especially relevant in emerging markets where budget constraints are critical.

The Solution:

To reduce the total cost of ownership, buyers should seek out electric vehicle chassis that emphasize operational efficiencies and lower maintenance needs. Platforms that feature easy-to-replace components, such as the REEcorner® systems, enable quick servicing that minimizes downtime. Additionally, selecting chassis that are designed for energy efficiency—such as those with optimized aerodynamics—can lead to significant savings in energy consumption. Buyers are encouraged to conduct a comprehensive cost-benefit analysis, considering both initial investments and long-term savings, to identify chassis solutions that provide the best financial outcome. Engaging in discussions with manufacturers about lifecycle costs and warranties can also provide insights into potential savings and ensure that investments align with financial objectives.

Strategic Material Selection Guide for electric vehicle chassis

What Are the Key Properties of Common Materials for Electric Vehicle Chassis?

When selecting materials for electric vehicle (EV) chassis, several factors must be considered, including weight, strength, cost, and manufacturing complexity. Here, we analyze four common materials: aluminum, steel, carbon fiber, and composite materials.

Aluminum: A Lightweight Option with Strong Performance

Aluminum is widely used in the automotive industry due to its excellent strength-to-weight ratio, corrosion resistance, and thermal conductivity. It typically has a temperature rating of up to 600°F and exhibits good performance under pressure.

Pros: Aluminum is lightweight, which enhances vehicle efficiency and range. Its corrosion resistance reduces maintenance costs over time, making it a durable choice for various climates, especially in regions with high humidity or coastal areas.

Cons: The primary drawbacks include higher costs compared to steel and increased manufacturing complexity, particularly in welding and joining processes.

Impact on Application: Aluminum is compatible with various media, making it suitable for battery enclosures and structural components.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and DIN for aluminum grades. Countries like Germany have specific regulations regarding aluminum recycling, which may affect sourcing decisions.

Steel: The Traditional Heavyweight

Steel remains a popular choice for EV chassis due to its high strength, durability, and cost-effectiveness. It can withstand high temperatures and pressures, making it suitable for structural applications.

Pros: Steel is relatively inexpensive and widely available, making it an economical option for manufacturers. Its strength provides excellent crashworthiness, which is crucial for safety.

Cons: The main limitation of steel is its weight, which can negatively impact the vehicle’s range and efficiency. Additionally, it is prone to corrosion, requiring protective coatings.

Impact on Application: Steel’s compatibility with various media makes it versatile, but it may require additional treatment for battery applications to prevent corrosion.

Considerations for International Buyers: Buyers in regions like Africa and South America should be aware of local steel production standards and the availability of high-strength steel grades that comply with international standards.

Carbon Fiber: The High-Performance Choice

Carbon fiber is increasingly being considered for high-performance electric vehicles due to its exceptional strength and lightweight properties. It can withstand temperatures up to 300°F and offers excellent fatigue resistance.

Pros: The key advantage of carbon fiber is its weight reduction, which significantly enhances vehicle performance and energy efficiency. It also offers superior rigidity, which can improve handling.

Cons: The primary drawback is the high cost and complexity of manufacturing, which can limit its use to premium vehicles. Additionally, carbon fiber can be less effective in energy absorption during crashes compared to metals.

Impact on Application: Carbon fiber is particularly suitable for high-performance chassis and body panels, but its compatibility with other materials must be considered during assembly.

Considerations for International Buyers: Buyers should ensure compliance with specific manufacturing standards, as carbon fiber production often requires specialized processes. Regions like Europe may have stricter regulations regarding composite materials.

Composite Materials: Versatile and Innovative

Composite materials, often a combination of plastics and fibers, offer a unique blend of properties suitable for electric vehicle chassis. They can withstand various temperature ranges and are generally resistant to corrosion.

Pros: Composites are lightweight and can be engineered for specific performance characteristics, making them highly versatile. They also offer good impact resistance and can be molded into complex shapes.

Cons: The main limitations include higher costs and challenges in recycling, which may concern environmentally conscious buyers. Manufacturing processes can also be complex.

Impact on Application: Composites can be tailored for specific applications, such as battery housings or structural components, providing flexibility in design.

Considerations for International Buyers: Buyers should be aware of the varying regulations regarding composite materials across regions, especially in Europe and the Middle East, where environmental standards are stringent.

Summary Table of Material Selection for Electric Vehicle Chassis

| Material | Typical Use Case for electric vehicle chassis | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Structural components, battery enclosures | Lightweight and corrosion-resistant | Higher cost and manufacturing complexity | Medium |

| Steel | Main chassis structure | Cost-effective and durable | Heavier and prone to corrosion | Low |

| Carbon Fiber | High-performance chassis and body panels | Exceptional strength-to-weight ratio | High cost and complex manufacturing | High |

| Composite Materials | Battery housings, structural components | Lightweight and customizable | Higher costs and recycling challenges | Medium |

This analysis provides a comprehensive overview of material options for electric vehicle chassis, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for electric vehicle chassis

What Are the Key Stages in the Manufacturing Process of Electric Vehicle Chassis?

The manufacturing process of electric vehicle (EV) chassis involves several critical stages that ensure the final product meets the stringent requirements of performance, safety, and efficiency. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: What Materials Are Used for EV Chassis?

The first step in the manufacturing process is material preparation, which involves selecting high-strength materials such as aluminum, steel, and composites. These materials are chosen for their durability, lightweight properties, and ability to withstand the rigors of electric vehicle operation. Advanced materials like carbon fiber composites are increasingly being used to reduce weight and enhance performance.

Once the materials are selected, they undergo processes such as cutting, shearing, and machining to achieve the necessary dimensions and specifications. This stage is crucial for ensuring that the components fit together seamlessly during assembly, thereby enhancing the structural integrity of the chassis.

What Forming Techniques Are Employed in EV Chassis Production?

After material preparation, the next stage is forming, where the processed materials are shaped into components. Common techniques include stamping, extrusion, and forging.

-

Stamping: This technique is often used to create flat panels that will form the chassis structure. Large presses are utilized to shape metal sheets into specific forms.

-

Extrusion: This is particularly useful for producing long, continuous shapes such as beams or rails that form the chassis frame. It allows for complex cross-sections that improve the strength-to-weight ratio.

-

Forging: Used for high-stress components, forging enhances the mechanical properties of the material, making it more resilient.

These forming techniques not only shape the chassis components but also contribute to their overall performance and safety.

How is the Assembly of Electric Vehicle Chassis Conducted?

The assembly stage is where all formed components are put together. This process typically involves welding, bolting, and using adhesives to ensure a robust structure. Advanced robotic systems are increasingly being employed for welding and assembly tasks, which improves precision and reduces human error.

During assembly, it is essential to maintain tight tolerances to ensure that all components fit correctly. This precision is crucial for the performance of systems like the suspension and powertrain, which rely on a well-structured chassis.

What Finishing Processes Are Applied to Electric Vehicle Chassis?

Once assembled, the chassis undergoes various finishing processes to enhance durability and aesthetic appeal. These processes may include surface treatment, painting, and coating.

-

Surface Treatment: Techniques such as anodizing or galvanizing can be applied to improve corrosion resistance, which is vital for the longevity of the chassis.

-

Painting and Coating: These not only provide an aesthetic finish but also add a layer of protection against environmental factors.

Finishing processes play a significant role in ensuring that the chassis can withstand the rigors of diverse operating conditions, especially in markets with varying climates, such as those found in Africa, South America, and the Middle East.

How is Quality Assurance Integrated Throughout the Manufacturing Process?

Quality assurance (QA) is an integral part of the manufacturing process for electric vehicle chassis, ensuring that the final product meets international standards and customer expectations.

What International Standards Should Buyers Be Aware Of?

B2B buyers should be familiar with several international standards that govern quality management systems, such as ISO 9001. This standard focuses on meeting customer and regulatory requirements and enhancing customer satisfaction. Additionally, specific industry standards like CE certification for safety and performance in Europe, and API standards for components, are essential for ensuring compliance in various markets.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are established at various stages of the manufacturing process to ensure compliance with quality standards. Common checkpoints include:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specifications before production begins.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, ongoing inspections are conducted to monitor production quality. This helps identify and rectify issues early on.

-

Final Quality Control (FQC): Once the chassis is fully assembled, a comprehensive inspection is performed to ensure that all components function as intended and meet safety standards.

What Testing Methods Are Commonly Used in Quality Assurance?

Common testing methods include:

-

Functional Testing: Ensures that all systems, such as braking and steering, are operational.

-

Stress Testing: Evaluates the chassis’s performance under load conditions to ensure it can handle operational stresses.

-

Environmental Testing: Assesses the chassis’s resilience to various environmental factors, such as temperature fluctuations and humidity.

These testing methods are critical for validating the performance and safety of the chassis.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers should take proactive steps to verify the quality control measures of potential suppliers. This can be achieved through:

-

Audits: Conducting regular audits of suppliers’ facilities to evaluate their adherence to quality standards.

-

Reports: Requesting detailed quality control reports that outline testing results and compliance with international standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality assurance processes.

What Are the Nuances of Quality Control for International B2B Buyers?

For international B2B buyers, particularly those from regions like Africa, South America, and the Middle East, understanding the nuances of quality control is crucial. This includes being aware of regional standards and compliance requirements, which may differ from those in Europe or North America.

Additionally, buyers should consider the logistical aspects of quality assurance, such as transportation and handling, which can impact the condition of the chassis during delivery. Establishing clear communication with suppliers regarding quality expectations and requirements is essential for ensuring a successful partnership.

In conclusion, the manufacturing processes and quality assurance measures for electric vehicle chassis are complex and multifaceted. By understanding these elements, B2B buyers can make informed decisions that align with their operational needs and market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric vehicle chassis’

Introduction

This guide provides a practical checklist for B2B buyers seeking to procure electric vehicle (EV) chassis. As the demand for electric vehicles rises globally, especially in regions such as Africa, South America, the Middle East, and Europe, it is essential to navigate the sourcing process effectively. This checklist will help you make informed decisions and ensure that the chassis you select meets your operational requirements.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the EV chassis based on your intended applications. Consider factors such as payload capacity, dimensions, and compatibility with various powertrains (battery electric vehicles or fuel cell electric vehicles).

– Key Considerations:

– Assess the types of vehicles you plan to develop (e.g., commercial, passenger).

– Determine the necessary performance attributes, such as range and speed.

Step 2: Research Available Chassis Options

Explore the market for different EV chassis offerings, focusing on modular and skateboard platforms that provide flexibility for various applications. These platforms often allow for easy customization, reducing development time and costs.

– Look for:

– Platforms with integrated technologies like drive-by-wire and x-by-wire systems that enhance maneuverability and safety.

– Chassis designed to accommodate different battery configurations for scalability.

Step 3: Evaluate Potential Suppliers

Before making a commitment, conduct thorough due diligence on potential suppliers. Request company profiles, past project case studies, and references from clients in similar sectors.

– Important Actions:

– Verify the supplier’s experience in producing electric vehicle components and their capacity for large-scale production.

– Check for industry certifications and compliance with relevant safety standards, such as ISO 262626.

Step 4: Assess Customization Capabilities

Ensure that the supplier can accommodate specific customization needs for your chassis. This includes the ability to modify design elements to suit various vehicle types and operational requirements.

– Consider:

– Whether the supplier offers flexible design options that allow for different cabin configurations and interior layouts.

– The potential for rapid prototyping and iterative design processes to expedite development.

Step 5: Review Cost and Total Cost of Ownership (TCO)

Analyze the pricing structures and evaluate the total cost of ownership for the chassis, including maintenance and operational costs over time. Understanding TCO is critical in determining the long-term financial viability of your investment.

– Key Factors:

– Inquire about warranties, service agreements, and any additional costs associated with the chassis.

– Compare the TCO of various suppliers to ensure you are making a cost-effective decision.

Step 6: Request Prototypes or Samples

Whenever possible, request prototypes or samples of the chassis to evaluate their build quality and performance. This hands-on assessment can provide invaluable insights into how well the chassis meets your operational needs.

– Action Steps:

– Conduct field tests to assess performance in real-world conditions.

– Evaluate the ease of integration with other vehicle systems during the testing phase.

Step 7: Finalize Agreements and Terms

Once you have selected a supplier, negotiate the terms of the agreement, ensuring clarity on delivery timelines, payment terms, and after-sales support. A well-defined contract helps mitigate risks and aligns expectations.

– Key Points to Address:

– Establish clear communication channels for project updates.

– Define the scope of after-sales support, including maintenance and parts replacement.

By following this checklist, B2B buyers can systematically approach the sourcing of electric vehicle chassis, ensuring they select the right partner and product for their needs.

Comprehensive Cost and Pricing Analysis for electric vehicle chassis Sourcing

What Are the Key Cost Components in Electric Vehicle Chassis Sourcing?

When sourcing electric vehicle (EV) chassis, it is essential to understand the various cost components that contribute to the overall pricing structure. These components typically include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials directly impacts cost. Lightweight materials like aluminum and composites are preferred for their strength-to-weight ratio but often come at a higher price than traditional steel. The need for specialized materials that meet safety and performance standards can further increase costs.

-

Labor: Skilled labor is required for the assembly and integration of advanced technologies such as x-by-wire systems and modular designs. Labor costs vary significantly by region, with countries in Europe generally facing higher wages compared to those in Africa or South America.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and equipment maintenance. High-tech manufacturing processes for EV chassis often require significant investment in specialized equipment, contributing to overhead costs.

-

Tooling: The cost of tooling can be substantial, particularly for custom chassis designs. This includes molds, dies, and fixtures necessary for production, which can be amortized over larger production volumes.

-

Quality Control (QC): Ensuring compliance with international safety and performance standards necessitates rigorous QC processes. This involves testing and certification, which adds to the overall cost but is crucial for maintaining product reliability and customer satisfaction.

-

Logistics: Transportation costs for raw materials and finished products must be factored in, especially for international buyers. The complexity of global supply chains can lead to variable logistics costs, influenced by shipping distances and customs regulations.

-

Margin: Finally, manufacturers typically include a profit margin that reflects their business strategy, market conditions, and competitive landscape. This margin can vary widely based on the supplier’s positioning and the specific features of the chassis.

What Factors Influence Pricing for Electric Vehicle Chassis?

Several key factors can influence the pricing of electric vehicle chassis, making it essential for buyers to consider these when negotiating:

-

Volume/MOQ: Minimum Order Quantities (MOQ) and volume purchases can significantly affect pricing. Higher volumes often lead to reduced per-unit costs, making it advantageous for large-scale buyers.

-

Specifications and Customization: Customized chassis that meet specific operational requirements can incur additional costs. Buyers should balance their need for customization with the associated cost implications.

-

Materials: The type and quality of materials used can affect both performance and price. Buyers should assess their needs carefully, considering factors like durability, weight, and cost.

-

Quality Certifications: Compliance with industry standards and certifications can influence the price. Suppliers that offer certified products may charge a premium but provide assurance of quality and safety.

-

Supplier Factors: The reputation and reliability of the supplier can also impact pricing. Established suppliers with proven track records may command higher prices, but they often provide better support and product reliability.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international transactions. These terms define the responsibilities of buyers and sellers, impacting overall logistics costs and risk management.

What Are the Best Practices for Negotiating Electric Vehicle Chassis Pricing?

B2B buyers, particularly those from diverse markets such as Africa, South America, the Middle East, and Europe, should adopt strategic approaches for negotiating chassis pricing:

-

Research and Benchmarking: Conduct thorough market research to understand prevailing prices and practices. Benchmarking against competitors can provide leverage during negotiations.

-

Total Cost of Ownership (TCO): Focus on TCO rather than just initial pricing. Evaluate factors such as maintenance, operational efficiency, and longevity, which can provide significant savings over time.

-

Leverage Volume Discounts: When possible, consolidate orders to meet MOQ requirements and negotiate better pricing based on volume.

-

Explore Multiple Suppliers: Engaging with multiple suppliers can create competitive pressure, leading to more favorable terms.

-

Negotiate Terms and Conditions: Discuss payment terms, delivery schedules, and warranties to ensure they align with business needs. Favorable terms can enhance cash flow and operational efficiency.

Conclusion

In conclusion, understanding the cost components and pricing influencers in electric vehicle chassis sourcing is crucial for international B2B buyers. By leveraging strategic negotiation techniques and considering the total cost of ownership, buyers can make informed decisions that align with their operational needs and budget constraints. Always remember that prices can vary widely based on numerous factors, so it is essential to approach each sourcing decision with careful analysis and consideration.

Alternatives Analysis: Comparing electric vehicle chassis With Other Solutions

Introduction: Exploring Alternatives to Electric Vehicle Chassis

In the evolving landscape of electric mobility, the search for efficient vehicle solutions has led to the emergence of various chassis technologies. While electric vehicle (EV) chassis have gained traction for their modular design and operational efficiencies, it is essential for B2B buyers to consider alternative options that may better suit their operational needs and budget. This analysis compares electric vehicle chassis with two viable alternatives: skateboard platforms and traditional internal combustion engine (ICE) vehicle platforms.

Comparison Table

| Comparison Aspect | Electric Vehicle Chassis | Skateboard Platform | Traditional ICE Vehicle Platform |

|---|---|---|---|

| Performance | High efficiency, customizable for specific needs | Versatile, adaptable to various applications | Established performance metrics, but less efficient |

| Cost | Higher initial investment, lower TCO over time | Moderate initial costs, scalable design | Lower upfront costs, higher long-term fuel expenses |

| Ease of Implementation | Complex integration of components | Simplified assembly with modular design | Well-understood design and manufacturing processes |

| Maintenance | Advanced AI for predictive maintenance | Relatively low maintenance requirements | Regular maintenance needed for engine and transmission |

| Best Use Case | Urban delivery, specialized commercial vehicles | Diverse applications from consumer cars to commercial trucks | General consumer use and fleet operations |

Detailed Breakdown of Alternatives

Skateboard Platforms

Skateboard platforms represent a flexible alternative to traditional vehicle designs, allowing for a wide range of applications from passenger vehicles to commercial trucks. These platforms streamline the vehicle design process by centralizing all critical components, including motors and batteries, into a flat chassis. The primary advantage of skateboard platforms lies in their adaptability; manufacturers can easily adjust dimensions to meet specific requirements without extensive redesign. However, while they offer considerable design freedom and lower development costs, skateboard platforms may not always match the performance efficiency of dedicated electric vehicle chassis, particularly in specialized applications.

Traditional Internal Combustion Engine (ICE) Vehicle Platforms

Traditional ICE platforms have been the backbone of the automotive industry for decades. These platforms are well understood, with established manufacturing processes and supply chains. The initial cost of ICE platforms is generally lower compared to electric vehicle chassis, making them accessible for budget-conscious buyers. However, the long-term total cost of ownership tends to be higher due to fuel expenses and more frequent maintenance requirements. Additionally, as global markets shift towards sustainability, the demand for ICE platforms is decreasing, which could lead to obsolescence issues in the near future.

Conclusion: Choosing the Right Chassis Solution for Your Business

Selecting the appropriate vehicle chassis technology requires a careful assessment of your business’s specific needs, operational environment, and long-term objectives. Electric vehicle chassis offer advanced features and operational efficiencies, making them ideal for urban logistics and specialized commercial applications. In contrast, skateboard platforms provide versatility across various vehicle types, while traditional ICE platforms may serve well for conventional applications but face a declining market. By evaluating performance, cost, and implementation ease, B2B buyers can make informed decisions that align with their strategic goals in the evolving electric mobility landscape.

Essential Technical Properties and Trade Terminology for electric vehicle chassis

What Are the Key Technical Properties of Electric Vehicle Chassis?

Understanding the essential technical properties of electric vehicle (EV) chassis is crucial for B2B buyers, particularly those involved in manufacturing, fleet operations, or vehicle design. Here are some critical specifications that play a significant role in the performance and adaptability of electric vehicle chassis:

-

Material Grade

The choice of materials for chassis construction, such as high-strength steel, aluminum, or composite materials, directly impacts weight, durability, and cost. High-strength materials enhance structural integrity while reducing overall vehicle weight, which is crucial for maximizing battery efficiency and range. Buyers should consider the trade-off between material costs and performance benefits when sourcing chassis components. -

Tolerance Levels

Tolerances refer to the permissible limits of variation in physical dimensions and are critical for ensuring proper fit and function of chassis components. Tight tolerances are essential in maintaining alignment and performance, especially in complex systems like drive-by-wire technologies. For B2B buyers, understanding tolerance specifications can influence manufacturing processes and quality control measures. -

Modular Design Capability

A modular chassis design allows for customization based on specific operational needs, such as varying body styles or configurations for different vehicle types (e.g., delivery trucks vs. passenger vehicles). This flexibility reduces development time and costs, making it easier for manufacturers to adapt to market demands. B2B buyers should look for chassis systems that offer modularity to enhance their competitive edge. -

Weight Distribution and Load Capacity

The ability to manage weight distribution and load capacity is vital for vehicle stability, handling, and performance. Manufacturers should ensure that the chassis design accommodates the intended payload while maintaining optimal balance. This is particularly important for commercial vehicles that may have varying cargo loads. Understanding load ratings can help buyers select the right chassis for their operational needs. -

Aerodynamic Efficiency

Aerodynamic properties significantly influence energy consumption and vehicle range. Chassis designs that minimize drag can lead to improved fuel efficiency and extended battery life. B2B buyers should prioritize chassis with optimized aerodynamic profiles, especially for commercial applications where operational costs are a primary concern. -

Safety Features

Advanced safety features, such as redundant systems and electronic stability control, are essential in modern electric vehicle chassis. These features ensure that the vehicle can operate safely even in the event of a system failure. Buyers must assess safety specifications to align with regulatory requirements and enhance user confidence in the vehicles they procure.

What Are Common Trade Terms in the Electric Vehicle Chassis Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B landscape. Here are several common terms that buyers should understand:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the EV chassis context, OEMs design and manufacture chassis components that meet specific industry standards. Buyers should engage with reputable OEMs to ensure quality and compliance. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B transactions as it affects inventory management and cost structure. Buyers should negotiate MOQs that align with their production needs and financial capabilities. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotations from potential suppliers for specific products or services. It is a key step in the procurement process, allowing buyers to compare offers and negotiate terms. Crafting a precise RFQ can streamline supplier selection. -

Incoterms (International Commercial Terms)

Incoterms are a set of standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify issues such as shipping costs, insurance, and risk transfer. Understanding Incoterms is essential for B2B buyers engaged in cross-border transactions to mitigate risks and ensure compliance. -

DaaS (Data as a Service)

In the context of electric vehicles, DaaS refers to the provision of data-driven services, such as real-time monitoring and analytics. This can enhance vehicle performance and maintenance. Buyers should consider the value of DaaS in improving operational efficiency and reducing downtime. -

X-by-Wire Technology

This term describes systems in which traditional mechanical controls (like steering and braking) are replaced by electronic controls. X-by-wire systems enhance precision and responsiveness, making them critical for modern electric vehicle chassis. Buyers should assess x-by-wire capabilities when evaluating chassis options for performance and safety.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing electric vehicle chassis, ultimately leading to better performance and cost-efficiency in their fleets.

Navigating Market Dynamics and Sourcing Trends in the electric vehicle chassis Sector

What Are the Global Drivers and Key Trends Impacting the Electric Vehicle Chassis Market?

The electric vehicle (EV) chassis market is experiencing unprecedented growth driven by several global factors. Increasing governmental regulations aimed at reducing carbon emissions, along with a global shift toward sustainable transportation, are key motivators for the adoption of electric vehicles. International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are keenly observing these dynamics as they navigate the transition to electric mobility.

One notable trend is the rise of modular and skateboard platforms that offer enhanced flexibility and reduced costs for vehicle design and manufacturing. Companies such as REE Automotive are pioneering technology that integrates critical components within compact modules, allowing for diverse applications—from commercial trucks to passenger vehicles—without the need for extensive redesigns. This adaptability is vital for OEMs and fleet operators looking to customize vehicles according to specific operational needs, thereby reducing total cost of ownership (TCO).

Emerging technologies such as ‘x-by-wire’ systems are revolutionizing chassis designs by replacing mechanical linkages with electronic controls, enhancing safety and performance. As these technologies become more prevalent, B2B buyers must stay informed about the technological capabilities of suppliers to ensure they are making informed sourcing decisions. Furthermore, the demand for electric vehicles is expected to rise significantly, particularly in urban areas where regulations favor low-emission transportation solutions, creating new opportunities for international buyers.

How Can Sustainability and Ethical Sourcing Shape B2B Strategies in the Electric Vehicle Chassis Sector?

Sustainability is no longer just a trend; it has become a core business imperative for B2B buyers in the electric vehicle chassis sector. The environmental impact of vehicle production and the sourcing of materials is under scrutiny, pushing companies to prioritize ethical supply chains. Buyers are increasingly looking for suppliers who can demonstrate transparency in their sourcing practices and provide ‘green’ certifications for materials used in chassis production.

The adoption of recycled materials and sustainable practices is becoming a competitive differentiator. As B2B buyers seek to align with sustainability goals, they must evaluate the lifecycle of chassis components, focusing on materials that minimize environmental impact and reduce waste. Certifications such as ISO 14001 for environmental management systems can serve as benchmarks for assessing potential suppliers.

Additionally, the move towards electric mobility inherently emphasizes the importance of sustainable sourcing. Buyers should prioritize partnerships with manufacturers who are committed to reducing their carbon footprint and who utilize renewable energy sources in their production processes. This not only enhances brand reputation but also appeals to increasingly eco-conscious consumers and stakeholders.

How Has the Electric Vehicle Chassis Market Evolved Over Time?

The evolution of the electric vehicle chassis market is marked by significant technological advancements and shifts in consumer demand. Initially, chassis designs were heavily influenced by traditional internal combustion engine (ICE) vehicles, leading to rigid and often inefficient architectures. However, the rise of electric mobility has catalyzed a transformation in chassis design paradigms.

The introduction of modular platforms and skateboard chassis has enabled manufacturers to streamline production processes and reduce costs. These innovations allow for greater customization and flexibility, accommodating various vehicle types and applications without necessitating extensive redesigns. As a result, companies can respond more rapidly to market demands and emerging trends, thereby gaining a competitive edge.

Moreover, the convergence of digital technologies, such as AI and IoT, is reshaping the landscape of chassis production and maintenance. With capabilities for real-time monitoring and predictive maintenance, manufacturers can enhance vehicle performance and safety while minimizing downtime. This evolution not only signifies a shift in engineering practices but also underscores the importance of technological adaptability for B2B buyers navigating this dynamic market.

Frequently Asked Questions (FAQs) for B2B Buyers of electric vehicle chassis

-

How do I determine the right electric vehicle chassis for my business needs?

To select the appropriate electric vehicle chassis, assess your operational requirements, including vehicle type, load capacity, and intended use (e.g., passenger transport, delivery, or specialized applications). Evaluate different chassis configurations, such as modular or skateboard platforms, which provide design flexibility and can adapt to various body styles. Additionally, consider factors like energy efficiency, maintenance requirements, and total cost of ownership (TCO). Engage with suppliers to understand customization options and ensure the chassis aligns with your fleet’s specific operational goals. -

What customization options are available for electric vehicle chassis?

Electric vehicle chassis often come with a range of customization options, including size, weight capacity, and component configurations. Many suppliers offer modular designs that allow for tailored solutions to meet specific industry demands, such as delivery vans or specialized service vehicles. Features such as battery placement, wheel configurations, and drive systems (like all-wheel or front-wheel drive) can also be adjusted. Collaborate closely with your supplier to outline your requirements and explore how their chassis can be optimized for your unique applications. -

What are the minimum order quantities (MOQ) for electric vehicle chassis?

Minimum order quantities for electric vehicle chassis can vary significantly based on the manufacturer, the complexity of the design, and the level of customization required. Generally, established suppliers may have higher MOQs due to production efficiencies, while smaller manufacturers might accommodate lower quantities. It’s advisable to discuss your purchasing plans upfront to find a supplier willing to work within your order size and budget constraints, ensuring a balance between cost-effectiveness and meeting your operational needs. -

What payment terms should I expect when purchasing electric vehicle chassis?

Payment terms for electric vehicle chassis can vary widely among suppliers. Common arrangements include upfront payments, deposits with balance due upon delivery, or installment payments based on production milestones. International buyers should also consider currency fluctuations and potential import duties when negotiating terms. Clarifying payment terms early in discussions can help prevent misunderstandings and ensure a smooth transaction process. -

How can I vet suppliers of electric vehicle chassis for reliability and quality?

To vet suppliers, start by researching their industry reputation through reviews, testimonials, and case studies. Request references from other businesses that have purchased chassis to gain insights into their experiences. Evaluate the supplier’s manufacturing capabilities, certifications (such as ISO compliance), and quality assurance processes. It’s also beneficial to visit their facilities if possible or engage in virtual tours to assess their operations. Ensuring that the supplier has a track record of delivering on time and meeting specifications is crucial for a successful partnership. -

What quality assurance measures should be in place for electric vehicle chassis?

Quality assurance for electric vehicle chassis should encompass a comprehensive testing and inspection process. Look for suppliers who implement rigorous QA protocols at each production stage, including material selection, assembly, and final inspections. Certifications such as ISO 9001 can indicate a commitment to quality standards. Additionally, inquire about warranty terms and post-sale support to ensure you have recourse in case of defects or issues. Robust QA measures will enhance the reliability and performance of the chassis in your fleet. -

What logistics considerations should I keep in mind when sourcing electric vehicle chassis internationally?

When sourcing electric vehicle chassis internationally, consider shipping options, lead times, and customs regulations in both your country and the supplier’s. Assess the supplier’s experience with international shipping to ensure they can handle documentation and compliance requirements effectively. It’s also wise to factor in logistics costs, including freight, insurance, and potential tariffs. Establish clear communication with your supplier regarding shipping schedules and any possible delays to ensure your operations remain uninterrupted. -

How do I ensure compliance with international regulations for electric vehicle chassis?

To ensure compliance with international regulations, familiarize yourself with the specific standards applicable in your target markets, including safety, emissions, and manufacturing practices. Engage with suppliers who have experience exporting to your region and understand local regulations. Additionally, request documentation proving compliance with relevant certifications, such as ISO or CE marking, which can facilitate smoother customs processes. Keeping abreast of regulatory changes and maintaining open communication with your supplier will help ensure ongoing compliance as regulations evolve.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Electric Vehicle Chassis Manufacturers & Suppliers List

1. REE.auto – Modular Electric Vehicle Platform

Domain: ree.auto

Registered: 2019 (6 years)

Introduction: REEcorner technology is a fully modular software-defined electric vehicle platform designed for commercial vehicles. Key features include:

– Modular and customizable design for mission-specific applications.

– Best-in-class function with optimal volumetric efficiency, maneuverability, serviceability, and safety.

– 36% more load capacity for a given footprint with more space for batteries.

– Power …

2. eMobility Engineering – Skateboard Platforms for EVs

Domain: emobility-engineering.com

Registered: 2018 (7 years)

Introduction: Skateboard platforms for EVs allow for flexible vehicle design across various applications, including passenger cars, delivery trucks, and off-road vehicles. Key features include:

– Available in a range of sizes

– Simplified body construction on top of a chassis resembling a skateboard

– Easy variation of chassis size and shape to meet different requirements

– Modular design allows for quick r…

3. Harbinger Motors – Electric & Hybrid Chassis

Domain: harbingermotors.com

Registered: 2018 (7 years)

Introduction: Harbinger Motors offers a range of electric and plug-in hybrid chassis designed for commercial and specialty vehicles. Key features include:

– Extended Range: Up to 500 miles with the plug-in hybrid chassis.

– Industry-Leading Warranty: Up to 10 years of coverage for major systems.

– Versatile Chassis Solutions: Stripped chassis that integrate with popular medium-duty body types.

– Engineered …

4. Nature – EV Chassis Performance Analysis

Domain: nature.com

Registered: 1994 (31 years)

Introduction: The study evaluates the structural performance of electric vehicle (EV) chassis under static and dynamic loads. Key findings include:

– Maximum stress during dynamic analysis: 288 MPa with a safety factor of 1.12.

– Maximum stress during static analysis: 64 MPa with a safety factor of 5.69.

– Load factor between static and dynamic loads: 4.44.

– The chassis is designed to withstand complex loa…

5. Fuel2Electric – EV Skateboard Chassis

Domain: fuel2electric.com

Registered: 2021 (4 years)

Introduction: EV skateboard chassis is a modular platform designed for electric vehicles, featuring a flat, rectangular base that houses the battery pack, electric motors, suspension, and wheels. Key features include: 1. Flat Design: Low center of gravity for better stability. 2. Modular EV Design: Adaptable to various body styles (SUVs, sedans, trucks). 3. Efficiency and Space: Maximizes cabin space, lighter a…

6. Eluminator – EV Rolling Chassis Packages

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The discussion revolves around the interest in EV rolling chassis, specifically looking for companies that sell bare bones rolling chassis type EV packages. The user mentions the ‘Eluminator crate motor’ and expresses a desire for a pre-sorted setup that includes battery, speed controllers, and weight distribution, allowing them to focus on building a driver and passenger space. There are mentions…

7. Zero Labs Automotive – Electric Classic Vehicles

Domain: zerolabs.com

Registered: 2002 (23 years)

Introduction: Zero Labs Automotive is an integrated design, engineering, and manufacturing company based in Los Angeles, California, specializing in electric vehicle technology. They offer fully carbon, classic, collectable electric vehicles, including the reengineered Land Rover Series 109 and Defender 110. The company has been shipping electrified classic cars since 2021 and provides electrification solutions…

8. Everything PE – EV Chassis

Domain: everythingpe.com

Registered: 2020 (5 years)

Introduction: The EV chassis is the structural framework of an electric vehicle, integrating and supporting critical components such as the battery pack, electric motors, drivetrain, suspension, and electronic systems. Key features include:

– **Structural Frame**: Provides skeletal support, often using a skateboard design for a flat base to house the battery pack, maximizing interior space and lowering the cent…

Strategic Sourcing Conclusion and Outlook for electric vehicle chassis

The future of electric vehicle chassis presents an array of strategic sourcing opportunities for international buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. By investing in modular and scalable chassis solutions, businesses can achieve significant operational efficiencies and cost reductions. The integration of advanced technologies, such as x-by-wire systems and customizable platforms, allows for tailored designs that meet specific commercial needs while enhancing performance and safety.

Strategic sourcing is paramount in leveraging these innovations to stay competitive. Buyers must prioritize partnerships with manufacturers who offer flexibility in design and rapid development cycles, ensuring they can adapt to market demands swiftly. The shift towards sustainable and efficient transportation solutions is not just a trend but a necessity, and sourcing the right chassis can position businesses at the forefront of this transformation.

As the electric vehicle market continues to evolve, now is the time for international buyers to explore collaborations that align with their strategic goals. By embracing cutting-edge chassis technology, businesses can not only enhance their operational capabilities but also contribute to a more sustainable future in transportation. Engage with industry leaders today to secure a competitive edge in the electric vehicle revolution.